Mounting positioning device for automobile tail door hinge

A technology for installation and positioning and hinges, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems affecting the quality of body-in-white assembly and production tempo, gap gaps, and difficult assembly, so as to reduce inaccurate positioning, The effect of reliable positioning and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

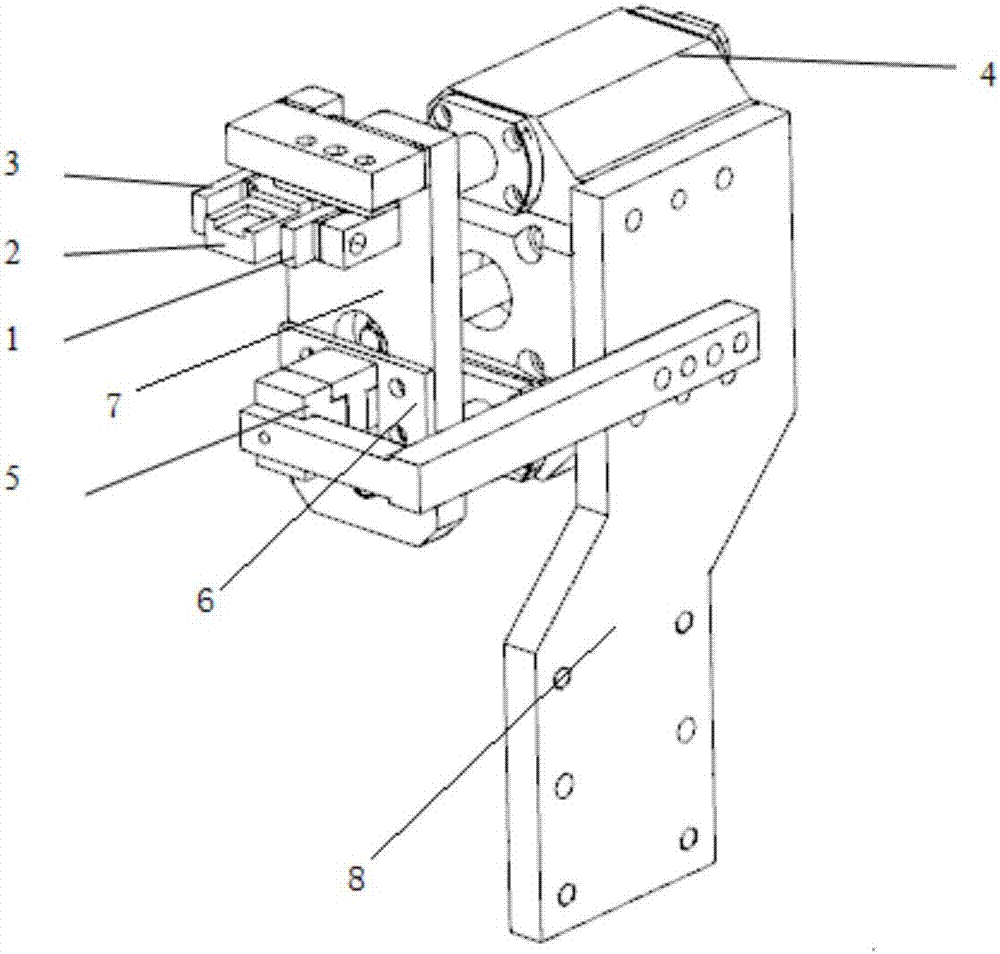

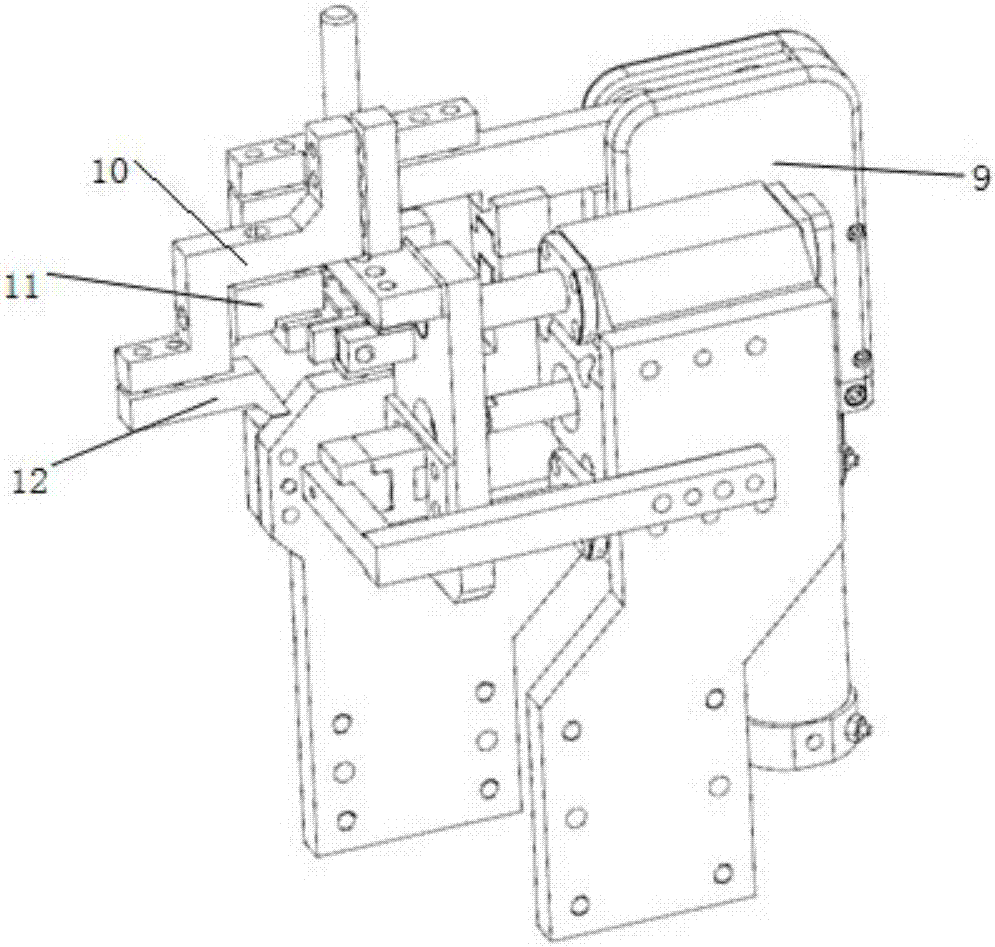

Image

Examples

Embodiment Construction

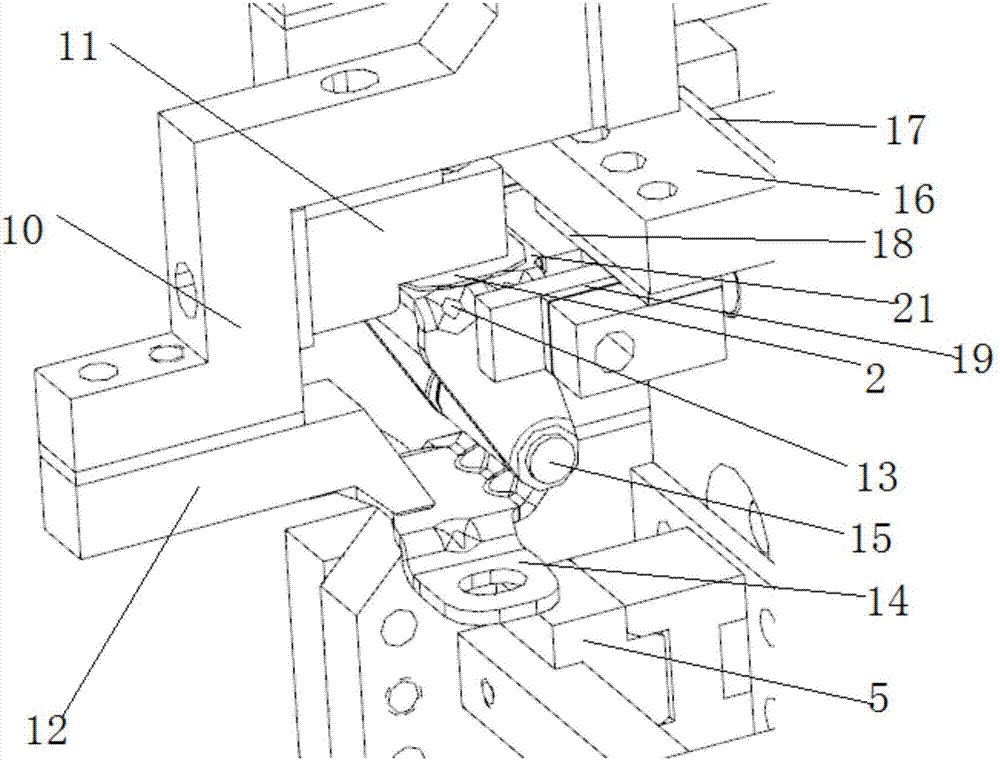

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0019] Such as image 3 As shown, the tailgate hinge of this example includes a hinge 13, a rotating shaft 15 and a mounting plate 14, wherein the tailgate hinge passes through the mounting plate 14 and is connected to the side of the door by two M8 screw rods, and the hinge 13 is connected to the side of the door through an M8 The screw rod is connected with the vehicle body, and the hinge 13 can rotate around the middle rotating shaft 15 to a certain extent. In the present invention, by analyzing the processing technology of the tailgate hinge, knowing the control size of the hinge, and combining the positioning requirements, the positioning strategy of the hinge is determined. The present invention is different from the processing method in the prior art. The present invention first installs the tailgate hinge on the car door through the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com