Flexible assembly welding device for thin-wall parts

A thin-walled and flexible technology, applied in the field of machinery, can solve the problems of complex structure, bulky transfer, inability to flexible production, etc., and achieve the effects of light structure, reduced positioning deviation, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

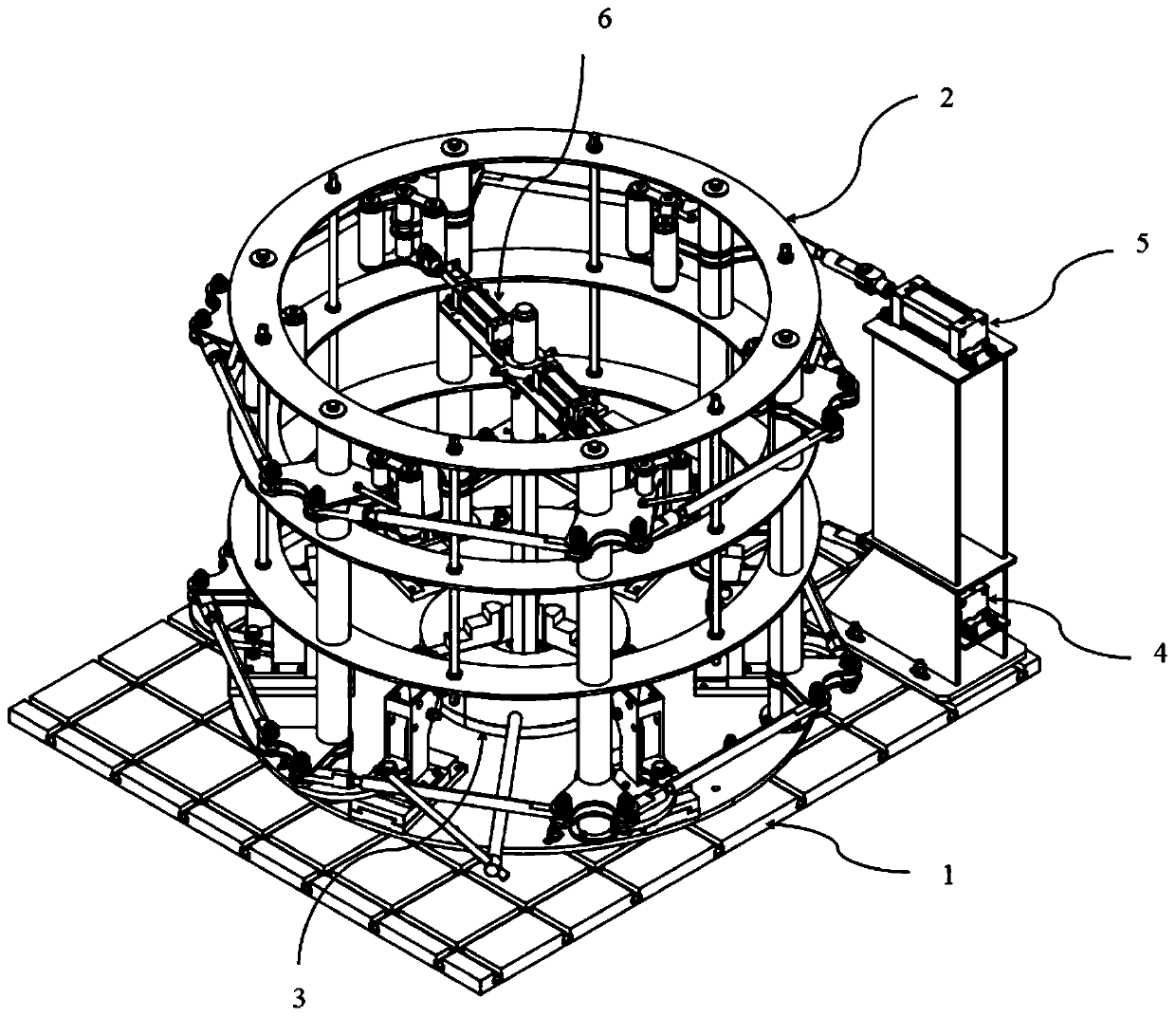

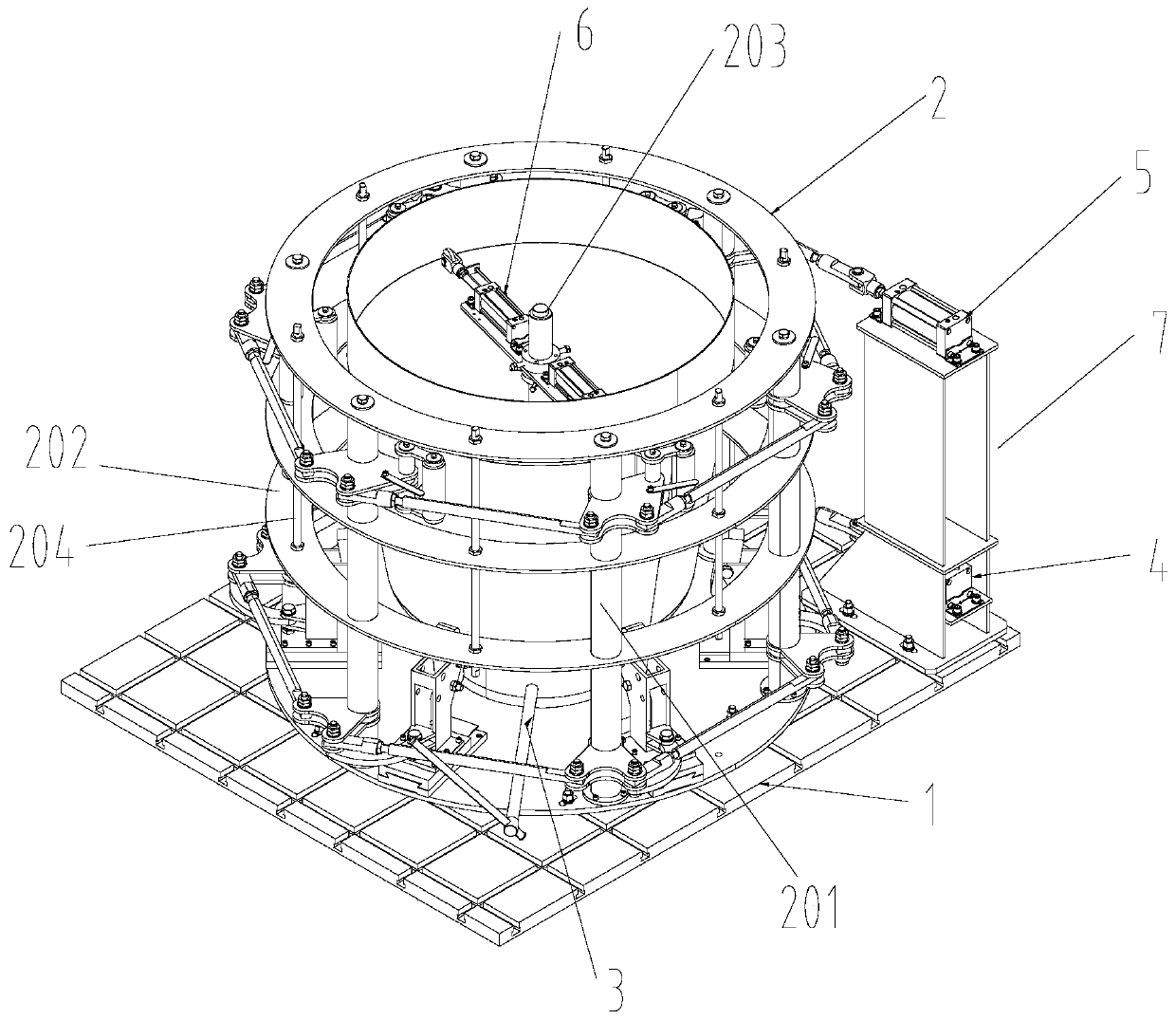

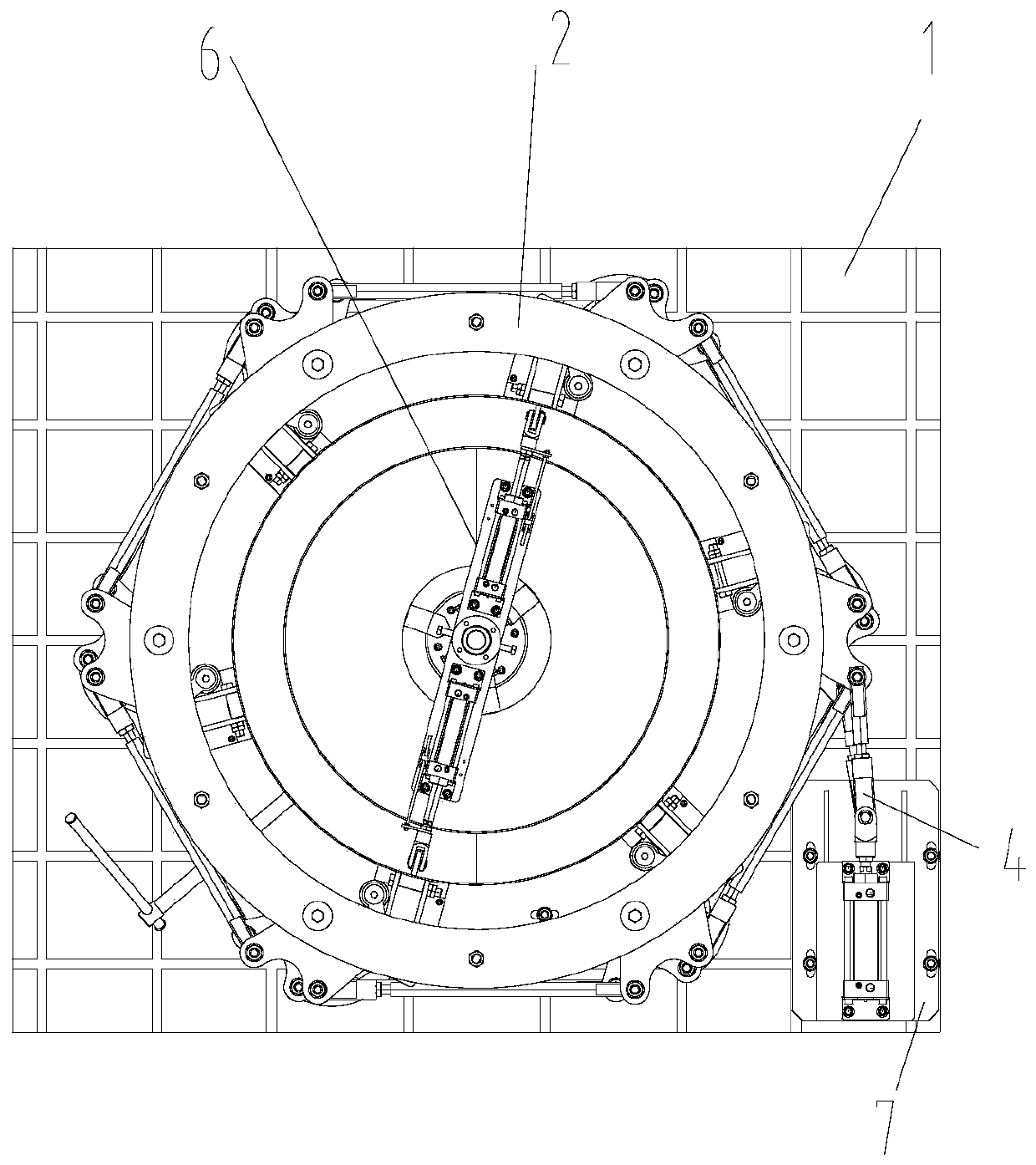

[0053] Reference attached figure 1 to attach image 3 As shown, the flexible assembly welding device for thin-walled parts in this embodiment includes a frame 2, a three-jaw chuck mechanism 3, a linkage clamping mechanism, and an inner wall pressing mechanism 6. A vertical bar 201, a beam 202 connecting multiple vertical bars 201 together, and a column 203 between the multiple vertical bars 201, the three-jaw chuck mechanism 3 is arranged on the bottom side of the frame 2 for tensioning For the thin-walled parts placed inside the frame 2, the horizontally arranged linkage clamping mechanism is connected to the vertical rod 201, and the linkage clamping mechanism is used to clamp the thin-walled parts inside the frame 2 from the outside, and the horizontally arranged inner wall is pressed The mechanism 6 is connected with the column 203 and is used for compressing the thin-walled parts placed inside the frame 2 . When the flexible welding device of this scheme is used for wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com