Two-face machining method for blank

A double-sided processing and blank technology, which is applied in the field of double-sided processing of blanks, can solve problems such as workpiece modeling defects, achieve the effects of reducing positioning deviation, accurate positioning, and improving modeling defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

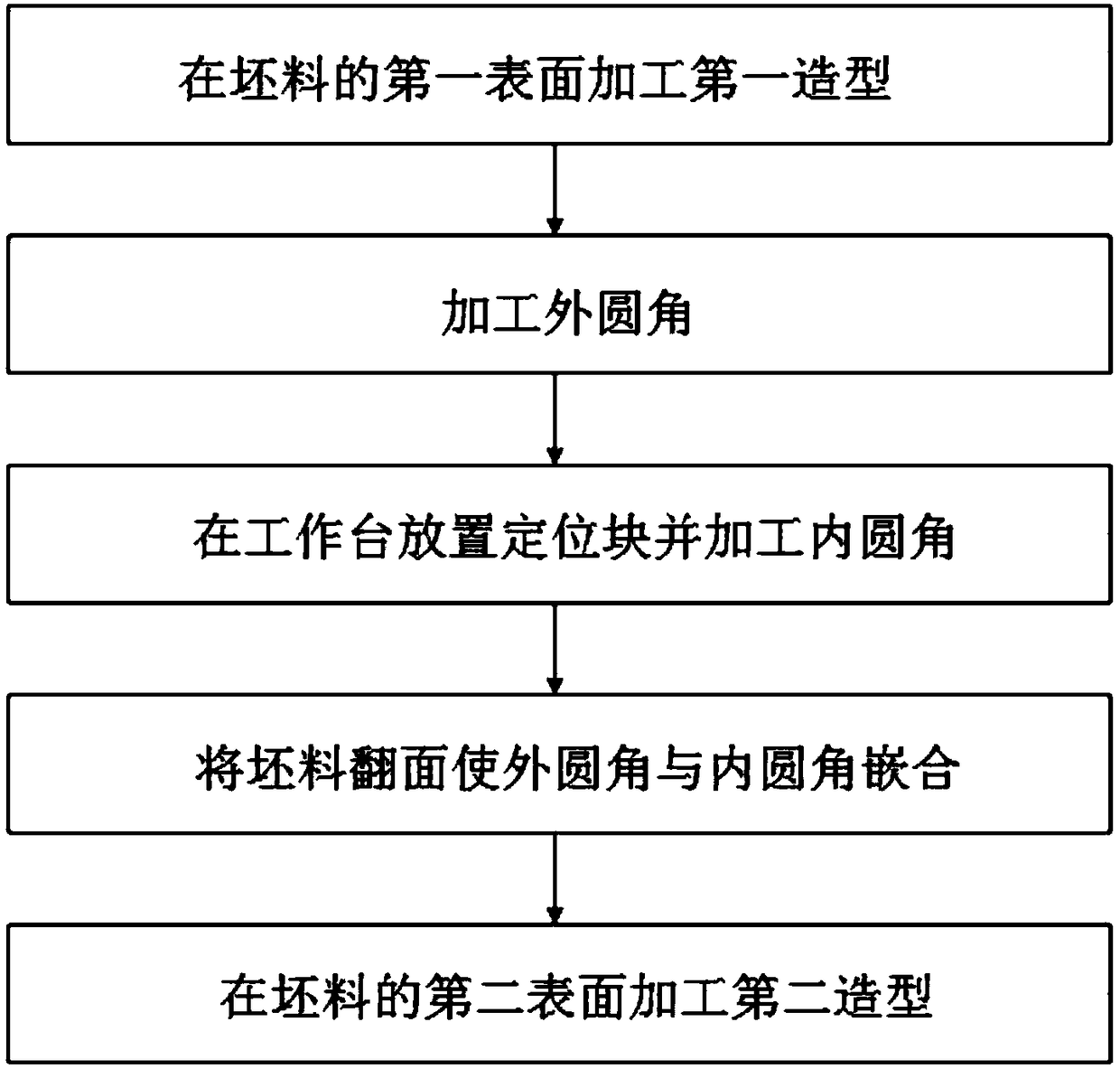

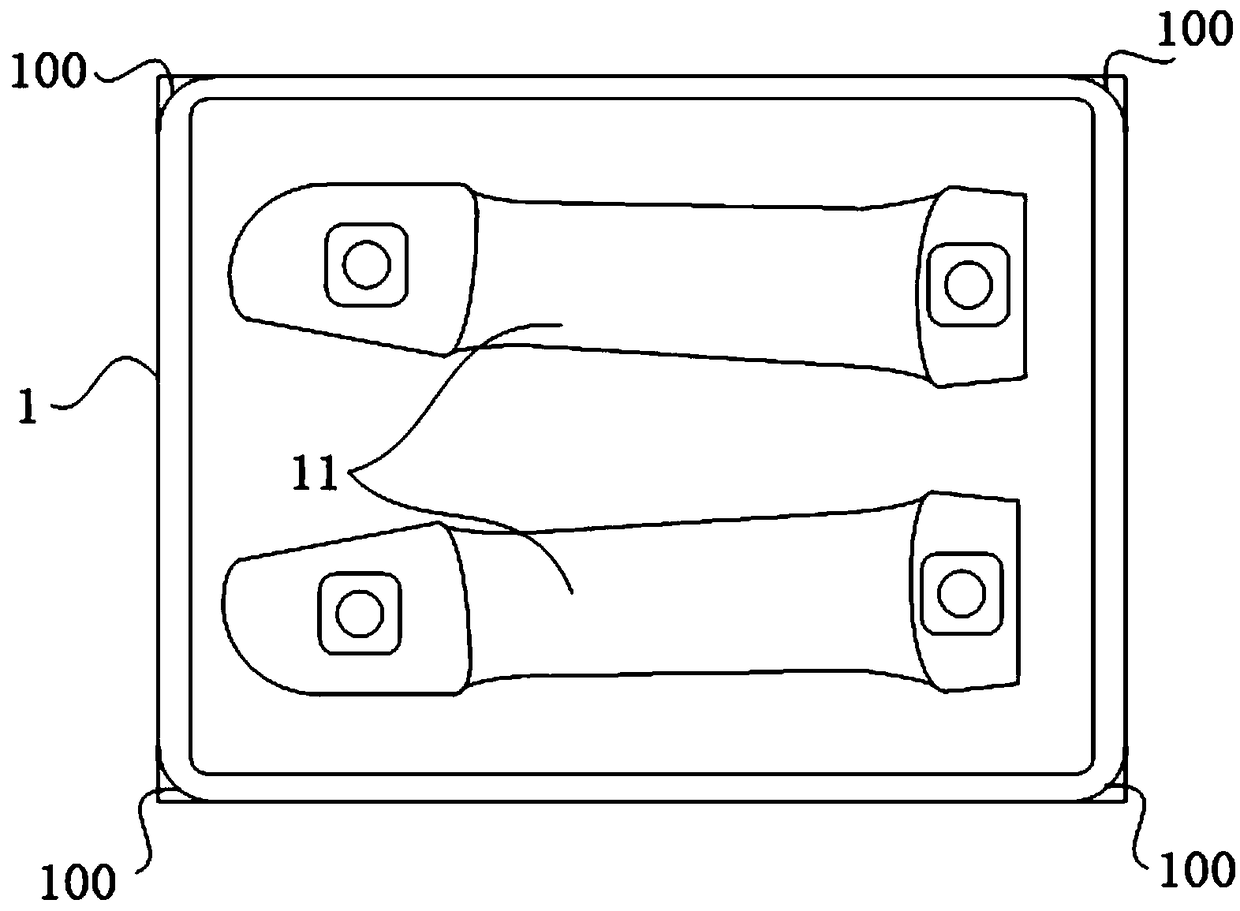

[0059] Such as Figure 2a As shown, in this embodiment, the blank 1 is first placed on the workbench, with the first surface of the blank 1 facing up and the second surface facing down, and the first surface of the blank 1 is processed by cutting the shape of one side of the workpiece - the first molding 11, and then cutting the four outer corners of the first surface of the blank 1 to form a bullnose 100, the radiuses of the four bullnose are the same.

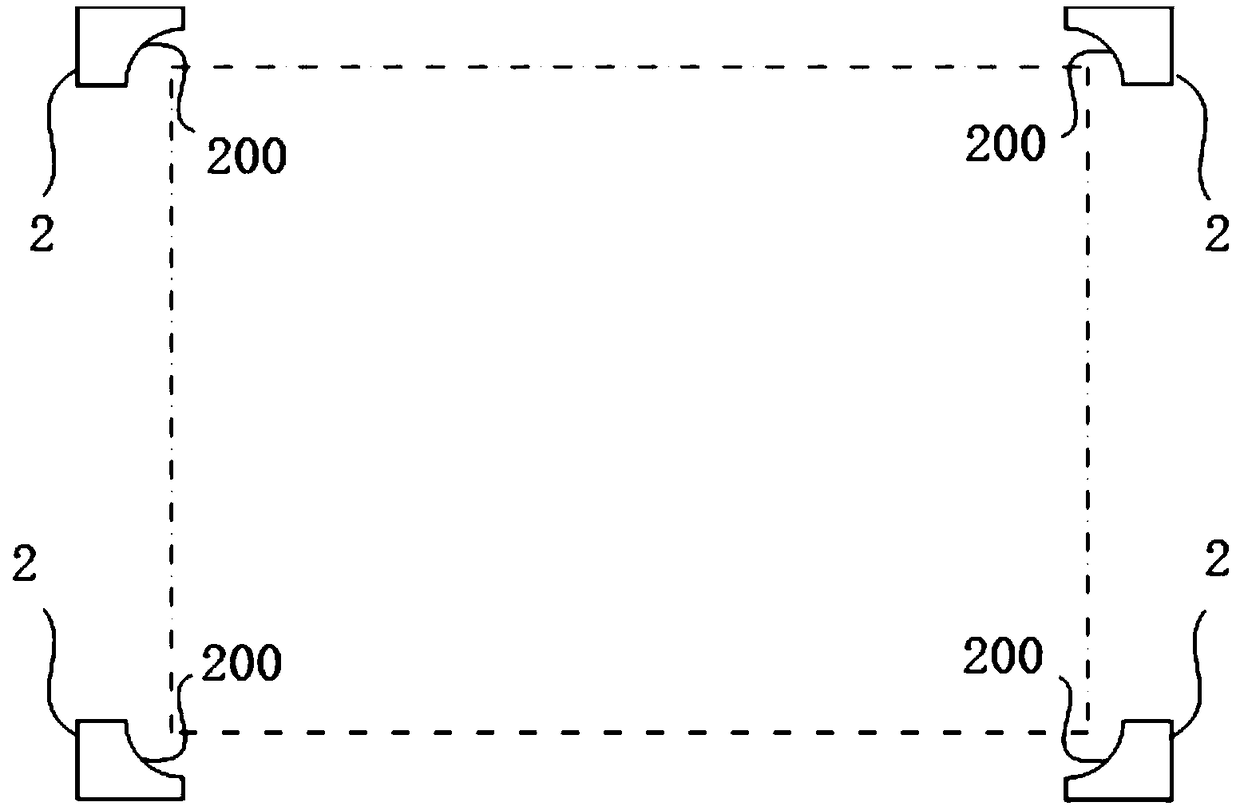

[0060] Such as Figure 2b As shown, after removing the blank from the workbench, place four corresponding positioning blocks 2 on the workbench with reference to the mirror image position of the outer fillet, and then cut and process the mirror image of the corresponding outer fillet on each positioning block 2 Fillet 200. Since the radii of the four outer fillets in this embodiment are the same, there is no need to specifically select whether the mirroring mode is up-down mirroring or left-right mirroring.

[0061] Such a...

Embodiment 2

[0065] The difference between this embodiment and Embodiment 1 lies in that the diameters of the four outer fillets of the first surface are different. In this case, the mirroring direction needs to be determined in advance. The mirroring direction in this embodiment is up-and-down mirroring.

[0066] Such as Figure 3a As shown, in this embodiment, the blank 1 is first placed on the workbench, with the first surface of the blank 1 facing up and the second surface facing down, and the first surface of the blank 1 is processed by cutting the shape of one side of the workpiece 11. Then cut the two outer corners on the left side of the first surface of the blank 1 to form two outer corners with the same radius size, and cut the two outer corners on the right side to form two outer corners with the same radius size. For purposes of distinction, the bullnose on the left is marked as left bullnose 100a, the bullnose on the right is marked as right bullnose 100b, and the radius of ...

Embodiment 3

[0072] This embodiment is a simplified form, and the difference from the above embodiment is that only the two outer corners on the left side of the first surface of the blank 1 are cut into bull fillets, and correspondingly, only the corresponding positioning block. Such a setting can also realize the positioning after turning over and avoid the wrong direction of turning over.

[0073] See the specific process Figure 4a-Figure 4d , first place the blank 1 on the workbench, make the first surface of the blank 1 face up and the second surface face down, and process the first shape 11 of the workpiece on the first surface of the blank 1 by cutting, and then place the blank 1 The two outer corners on the left side of the first surface of the first surface are cut to form two outer corners with the same radius size 100; then after the blank is removed from the table, place the corresponding two outer corners on the left side of the table with reference to the mirror image posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com