A processing method for adaptive milling of the outer surface of the casing

It is a technology for opening casings and processing methods, which is applied in metal processing, metal processing equipment, metal processing machinery parts, etc. It can solve the problems of unguaranteed surface quality of parts, low processing efficiency, and complex external surface, etc., and achieve the goal of processing Stable quality, improved processing efficiency, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The invention provides a processing method for adaptive milling of the outer profile of the opening case, which is characterized in that: the processing method for the adaptive milling of the external profile of the opening case determines the adaptive milling of the external profile of the opening case Trajectory planning, determine the online measurement trajectory planning of the outer surface of the opening box, and generate a processing program with adaptive milling compensation variables through the software post-processing method.

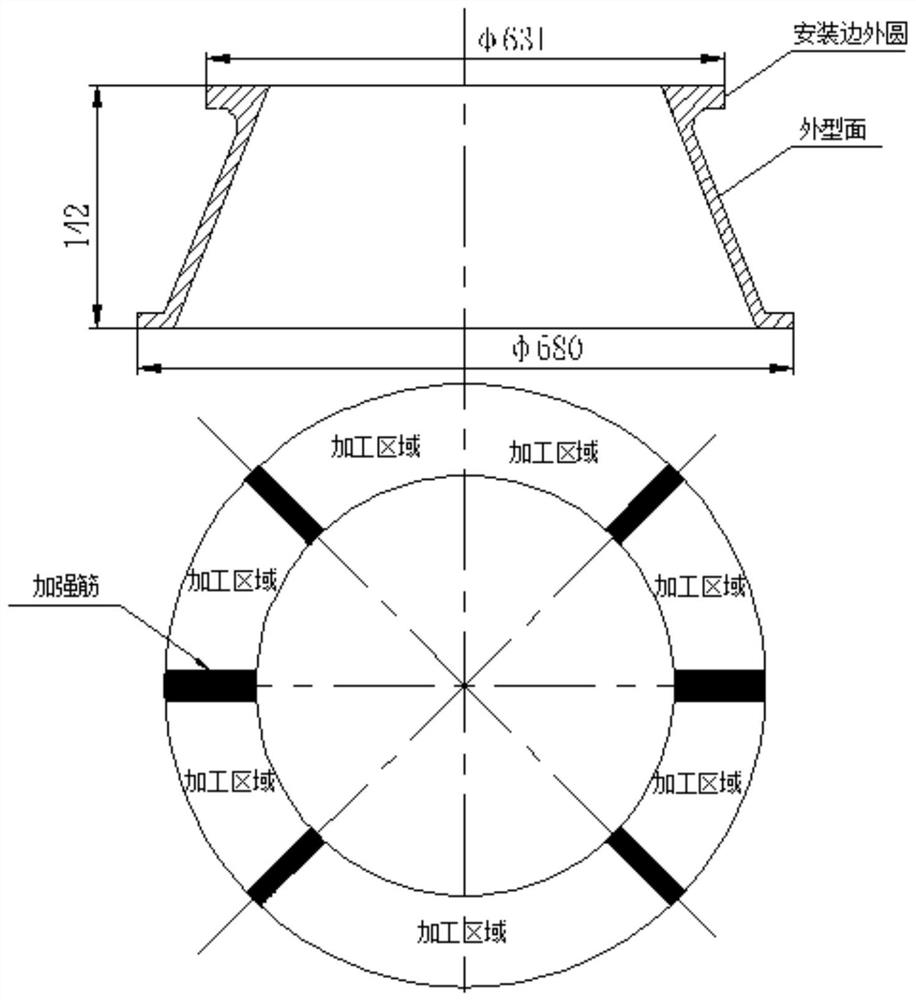

[0023] Milling the outer surface of an extended casing. The material of the casing is superalloy, the outer diameter of the casing is Φ680mm, the outer diameter of the outer circle of the casing installation side is Φ631mm, and the height is 142mm. area, see figure 1 shown.

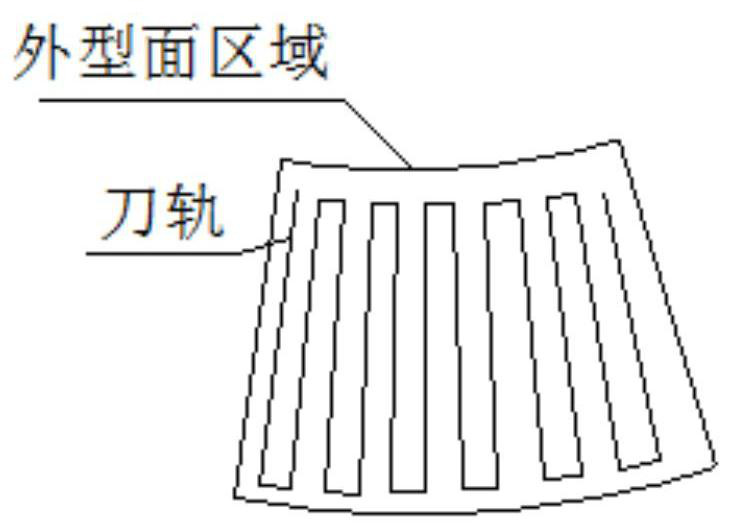

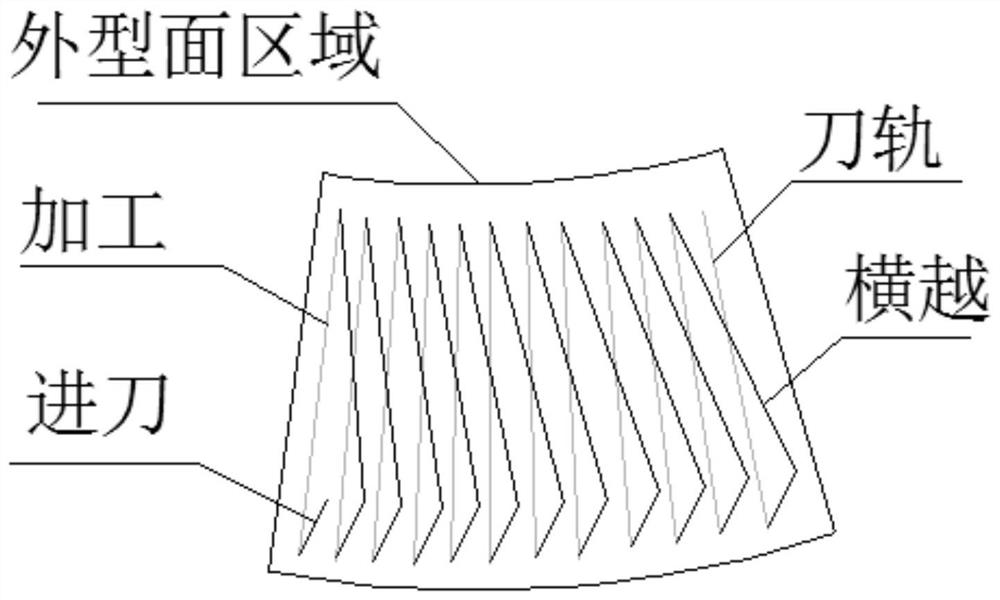

[0024] In the original plan, each area uses a 20R6.5 milling cutter and adopts a longitudinal reciprocating processing method, see figure 2 As shown, since th...

Embodiment 2

[0032] The invention provides a processing method for adaptive milling of the outer profile of the opening case, which is characterized in that: the processing method for the adaptive milling of the external profile of the opening case determines the adaptive milling of the external profile of the opening case Trajectory planning, determine the online measurement trajectory planning of the outer surface of the opening box, and generate a processing program with adaptive milling compensation variables through the software post-processing method.

[0033] Milling the outer surface of an extended casing. The material of the casing is superalloy, the outer diameter of the casing is Φ680mm, the outer diameter of the outer circle of the casing installation side is Φ631mm, and the height is 142mm. area, see figure 1 shown.

[0034] In the original plan, each area uses a 20R6.5 milling cutter and adopts a longitudinal reciprocating processing method, see figure 2 As shown, since ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com