A Machining Method for Offset Milling of Conical Outer Surface of Case

A processing method and external surface technology, applied in metal processing equipment, milling machine equipment, manufacturing tools, etc., can solve problems such as tool wear and low processing efficiency, and achieve the effects of reducing development costs, improving efficiency, and cutting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

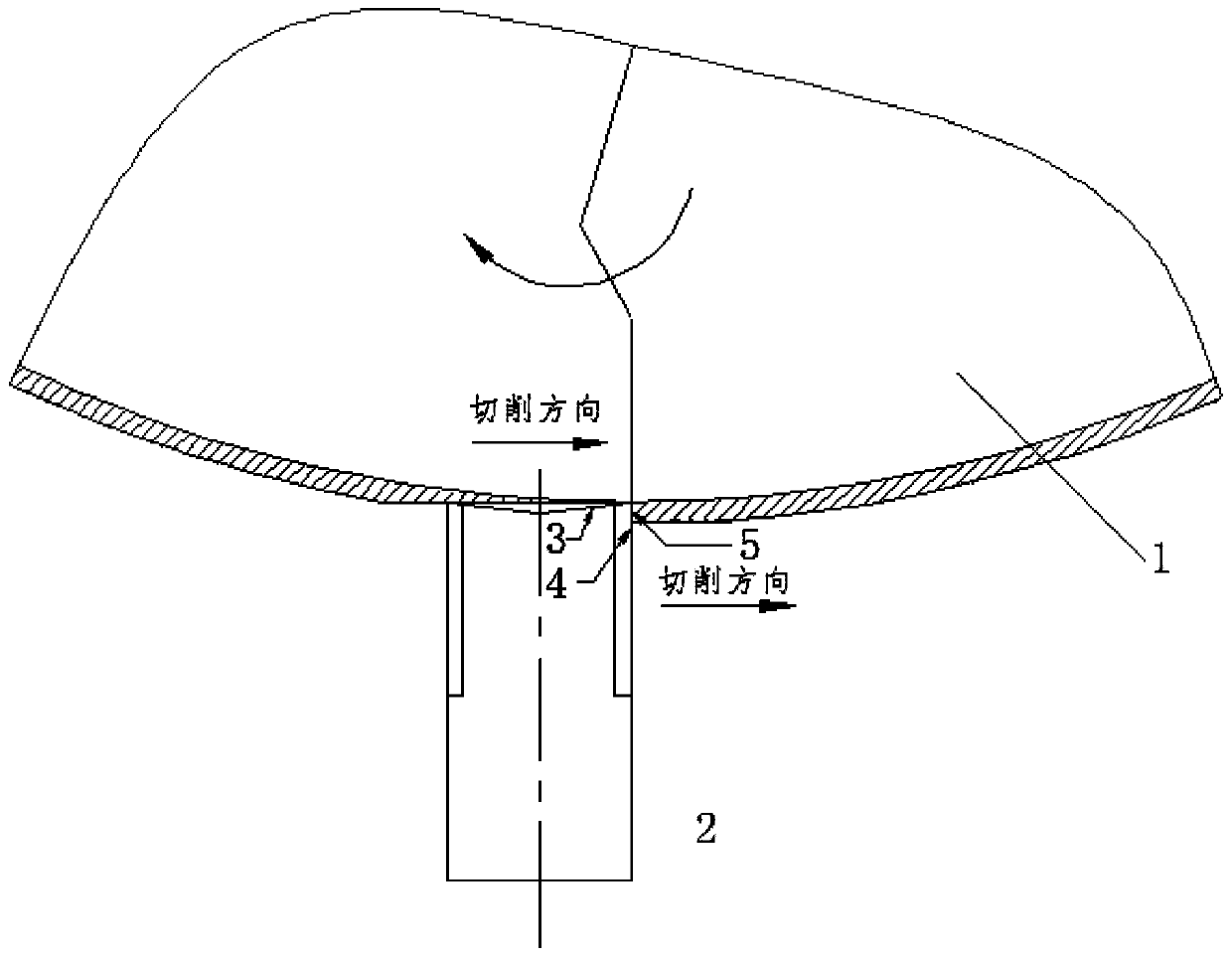

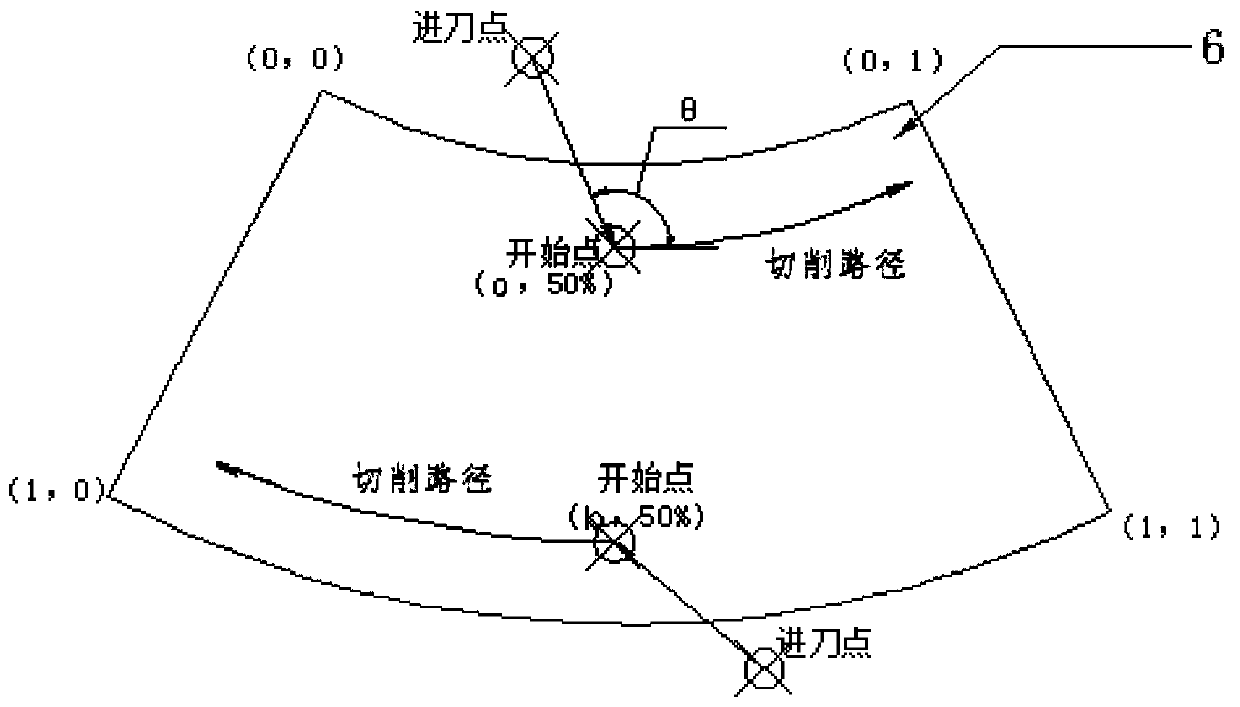

[0031] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

[0032] The processing method of the present invention for offset milling of the tapered outer surface of the casing comprises the following steps:

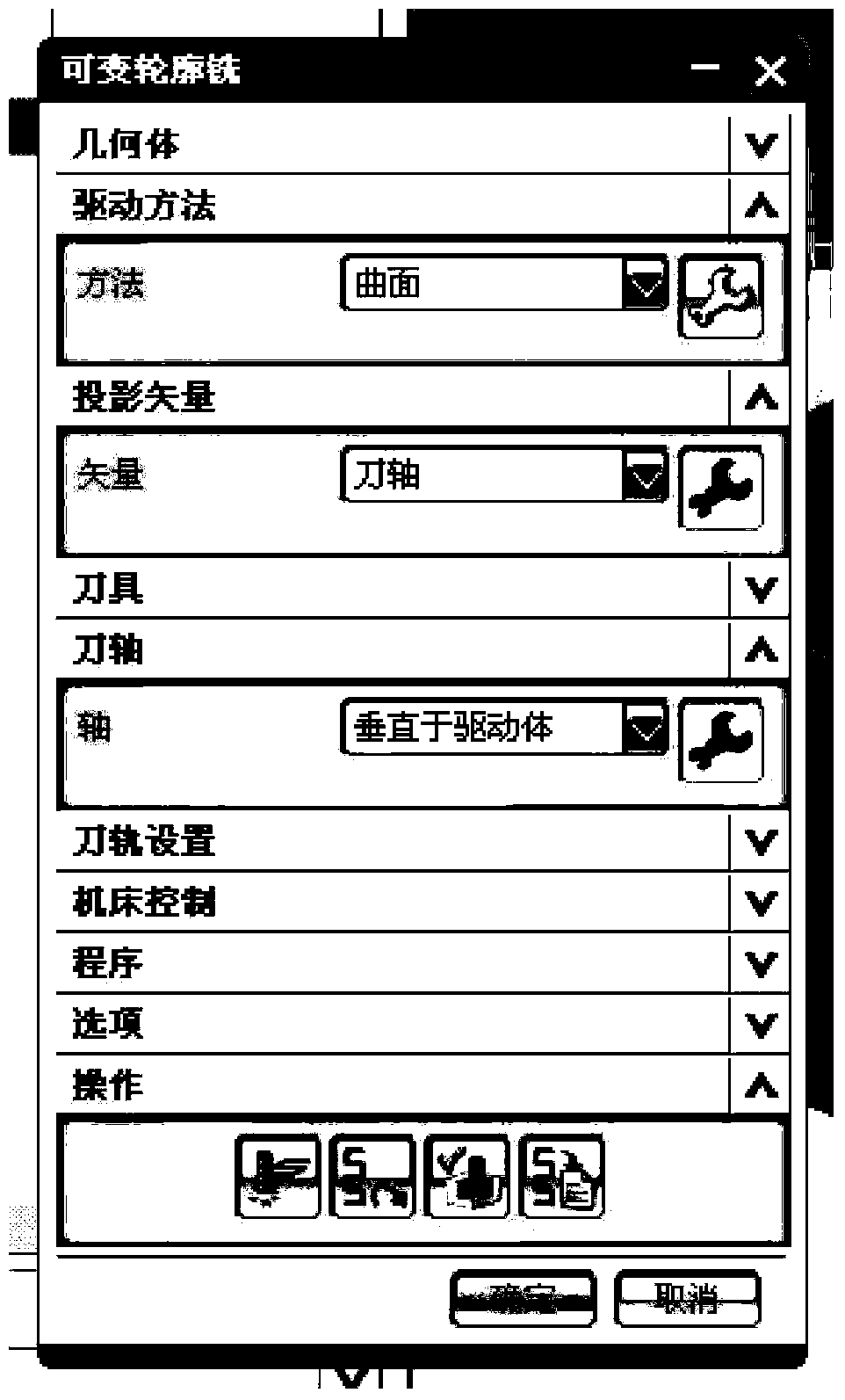

[0033] Step 1, use UG software to carry out the milling operation of the outer surface of the tapered casing;

[0034] Step 2, plan the milling sequence and tool trajectory of the tapered outer surface of the casing;

[0035] Step 3, customizing the special post-processing program for UG software;

[0036] Step 4, use a special post-processing program to create a G code program for machine tool recognition.

[0037] In step 1, UG software is used to establish the milling tool track for the cone-shaped outer surface of the casing, and generate variable contour milling operations. The main parameters are set as follows: select the surface for the driving method, select the tool axis for the projection v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com