Rapid plugging method used for oil pocket for lubricating crown gear transmission shaft in high-speed rotating state

A technology of lubricating oil bag and plugging method, which is applied in the field of rapid plugging, metallurgical machinery/cold rolling machinery, and can solve the problems of consuming oil bag spare parts, affecting the normal operation of the unit, and long downtime.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

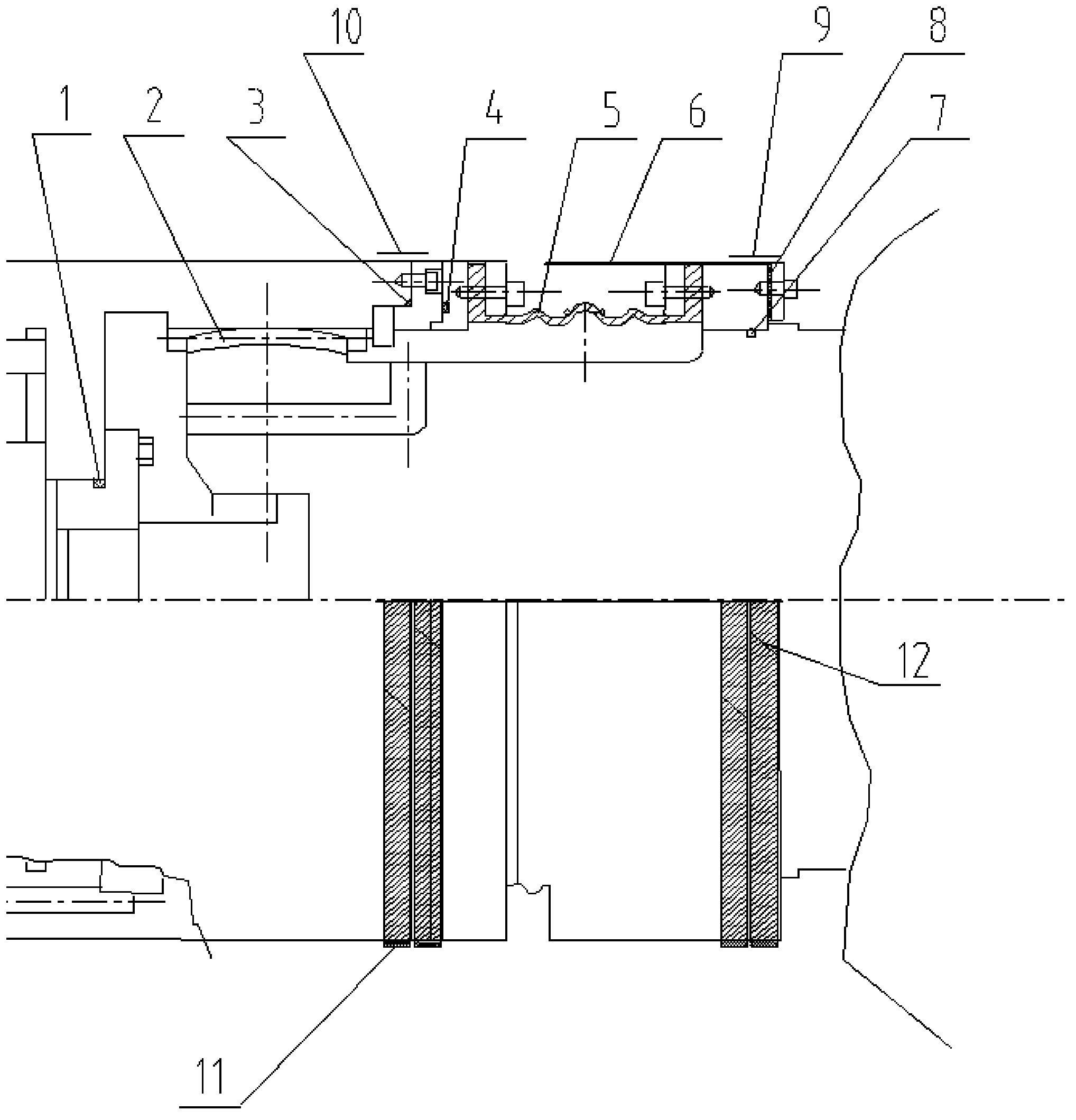

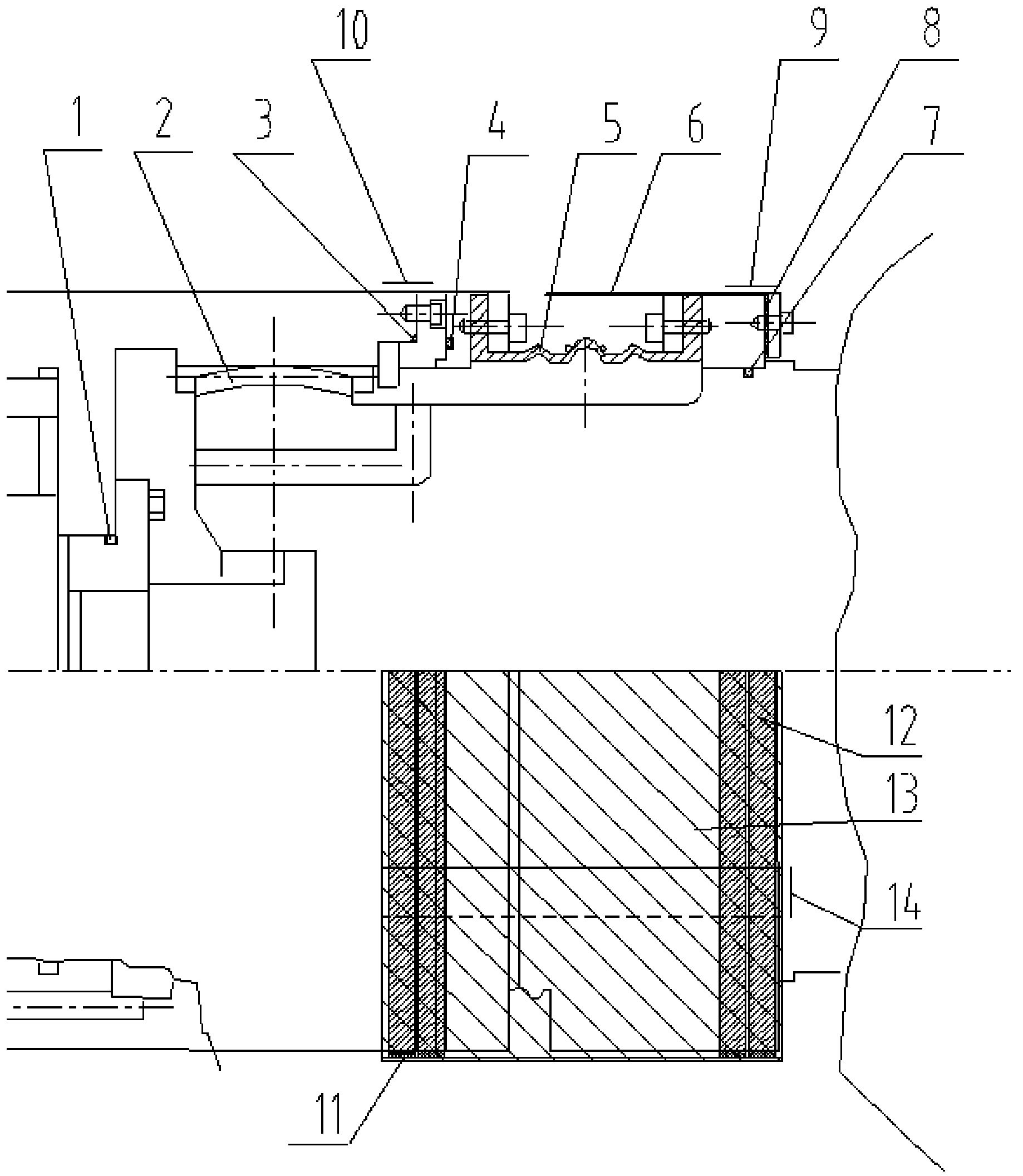

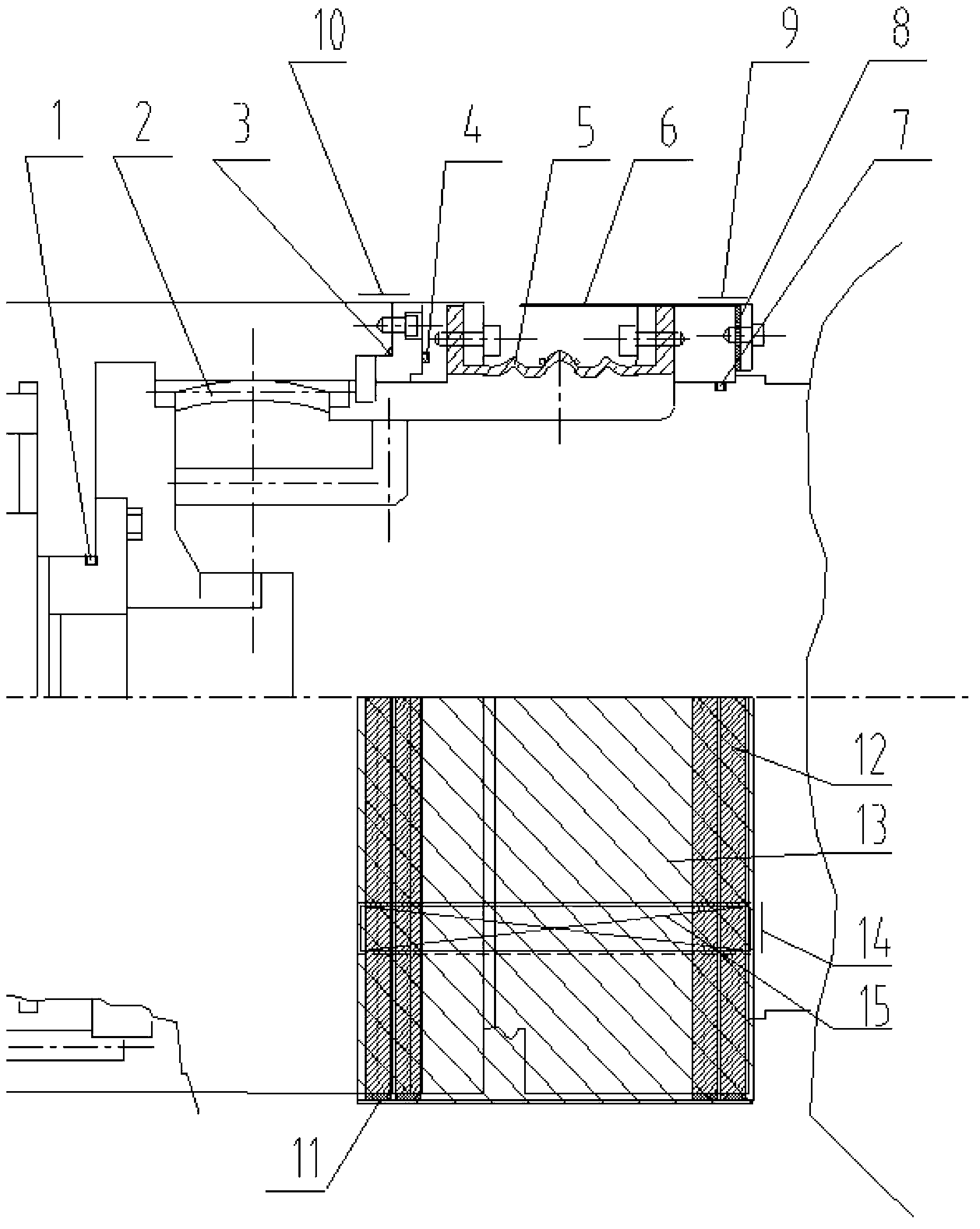

[0034] The technology of the present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

[0035] 1) The first step is to make the rubber gasket (on figure 1 8) It is installed at a circle of fastening bolts on the side of the oil bag protective cover 6 to prevent the lubricating oil from leaking out from here after the follow-up sealing is completed;

[0036] 2) The second step, on figure 1 Use cleaning agent to clean the circumference of the transmission shaft at positions 9 and 10 in the figure;

[0037] 3) In the third step, wrap and fix the shaft in the circumferential direction with a sticky PTFE sealing tape 11 (width: 5mm; thickness: 1mm) at the positions 9 and 10 shown in the figure above, and wrap 2 on each side. Circle, and ensure that the interface 12 intersects (60° cut at the interface), a closed circle of circumferential size and shape can be formed. The 2-turn PTFE sealing tape interfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com