A Calculation Method of Correction of Center of Integral Impeller

A technology of integral impeller and calculation method, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problems of scrap blank, large consumption of raw materials, complicated forging process, etc., and achieve stable quality and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

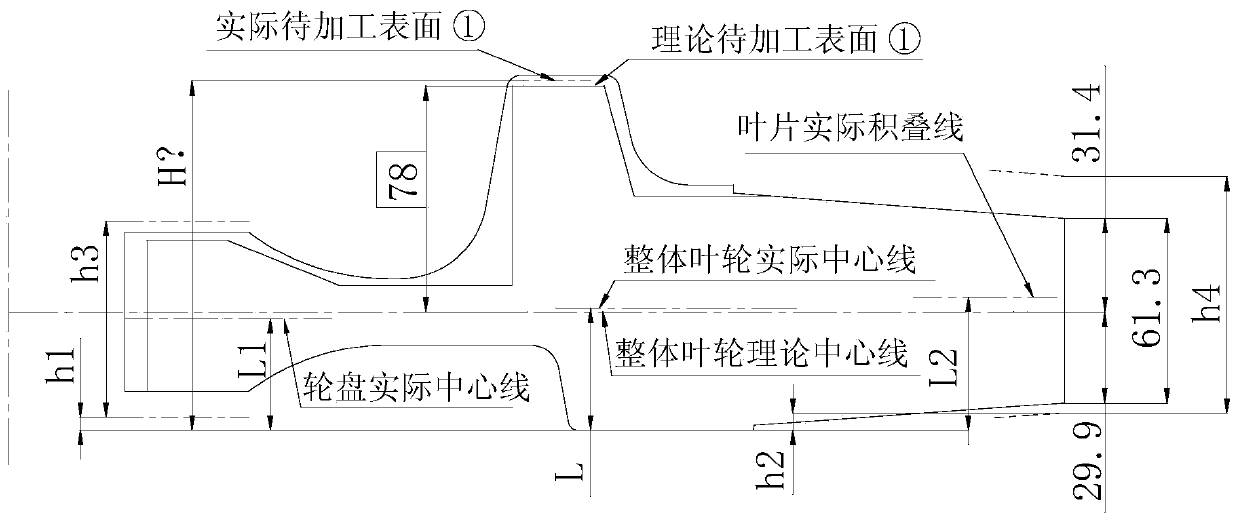

[0036] This embodiment provides an overall impeller center deviation calculation method, which is characterized in that: the overall impeller center deviation calculation method,

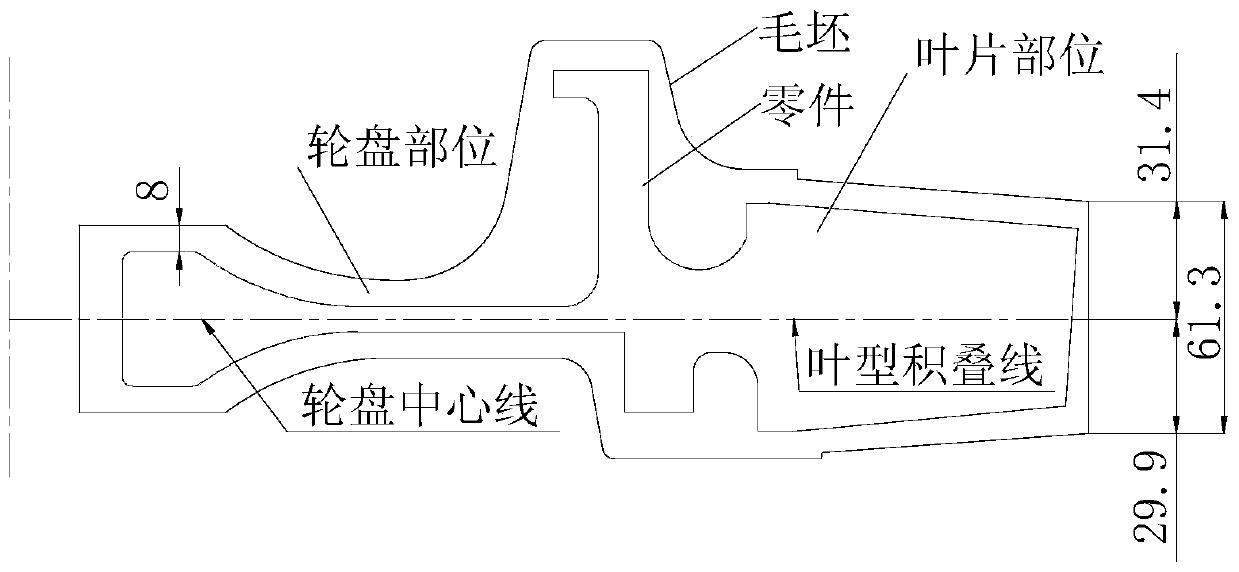

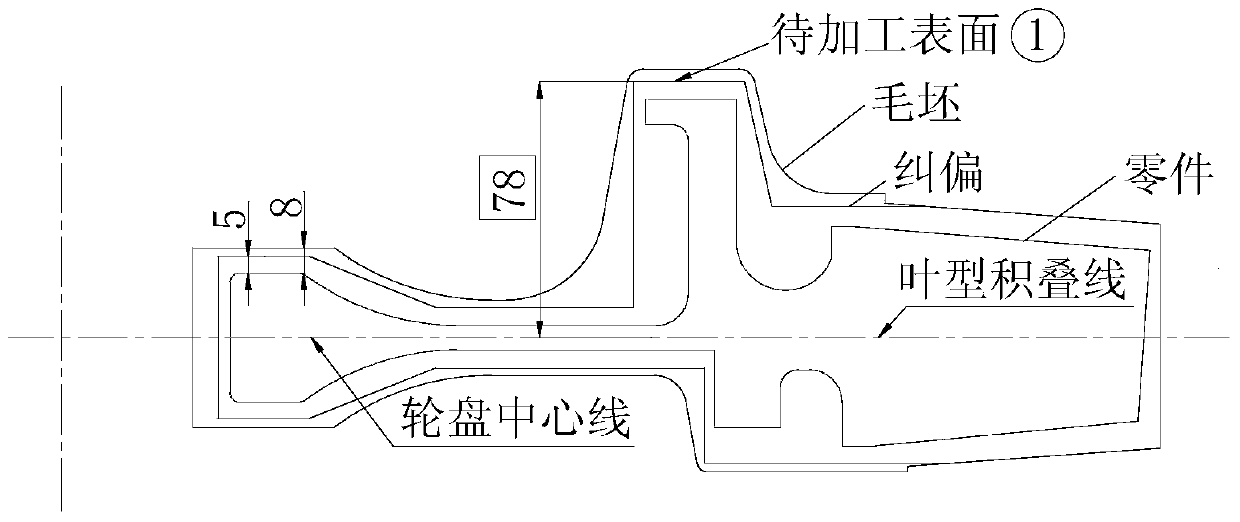

[0037] Algorithm for correcting the blank of large W-shaped integral impeller: the diameter of the impeller is about 870mm, the number of blades in the blade part is 43 pieces, the angle between the blades is 8.37°, the twist angle of the blades is about 14°, the length of the blades is about 130mm, the width is about 75mm, the disc The thickness of the disc center hole in the body part is 32mm, and the center line of the disc coincides with the stacking line of the airfoil. The determination and application process of the deviation correction algorithm are as follows:

[0038] a) Determine and calculate the center line of the disc body

[0039] b) Determine and calculate the centerline of the blade part through UG modeling software

[0040] c) Determine the centerline of the overall impeller to en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com