Manufacturing method for chemical mechanical polishing pad as well as product thereof and mould

A chemical machinery and manufacturing method technology, applied in manufacturing tools, grinding/polishing equipment, grinding tools, etc., can solve the problem of poor bonding reliability between the window and the polishing layer body, poor overall process and quality stability of the polishing layer, and polishing layer body. Problems such as poor internal structure uniformity, to achieve the effect of firm and reliable window fitting, improved uniform stability and yield, and excellent uniform stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

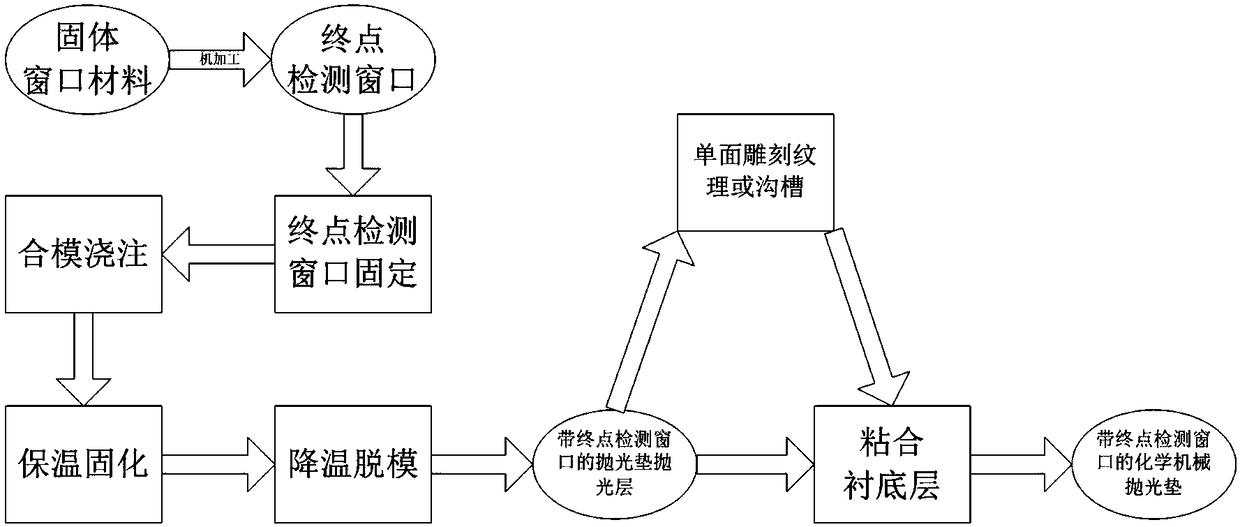

[0041] A manufacturing method of a chemical mechanical polishing pad, which is a one-time integrated casting molding process comprising the following steps:

[0042] The end point detection window is obtained by machining the casting temperature resistant, optically transparent solid material and the solid window material according to the shape and size;

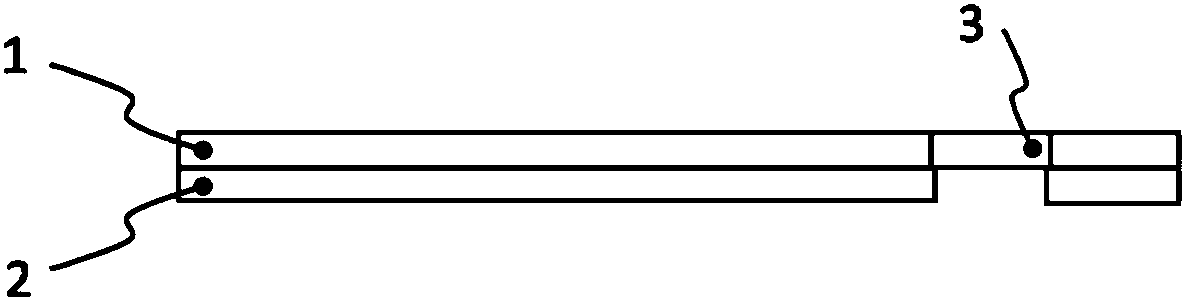

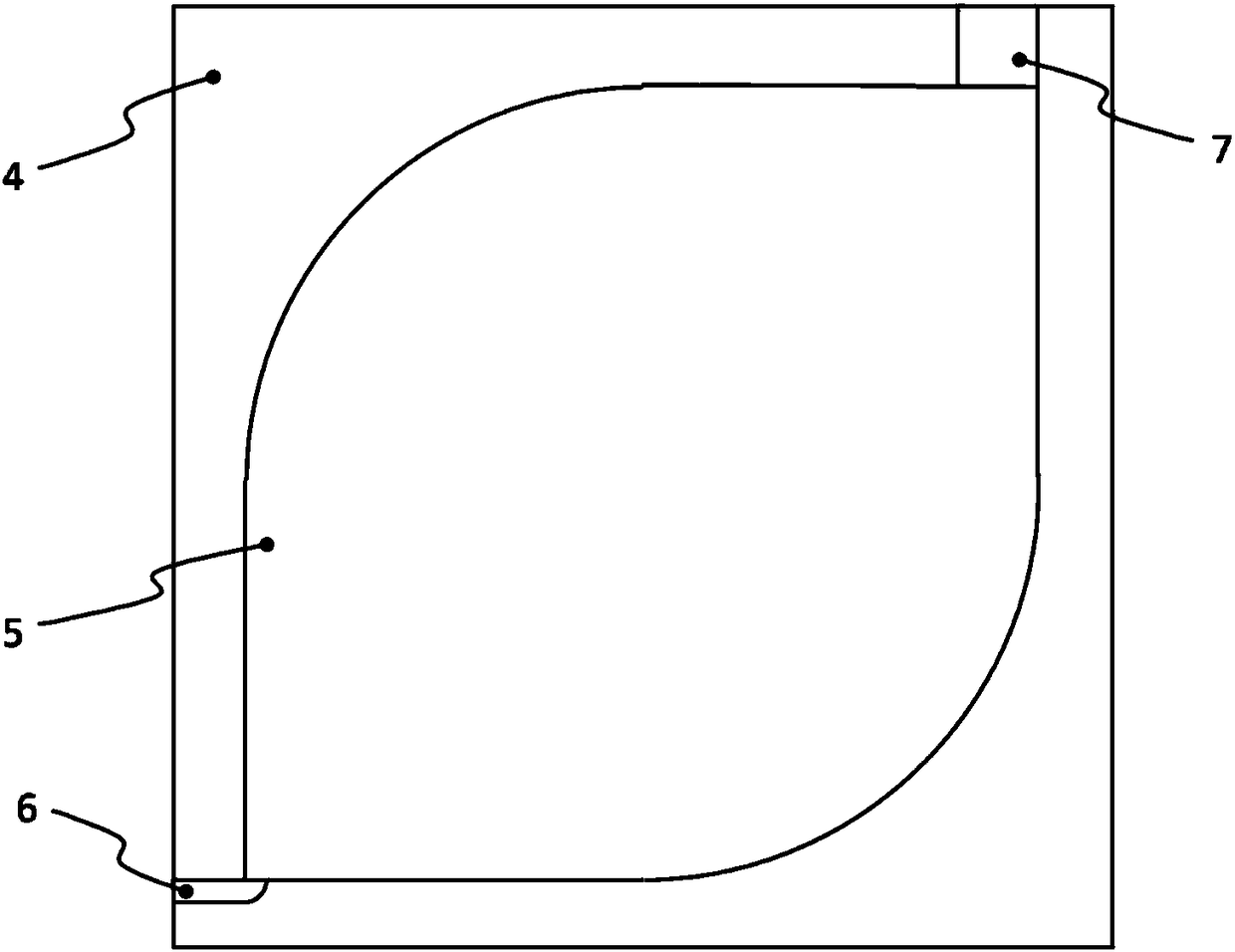

[0043] The obtained end point detection window is press-fitted and fixed at the designed fixed position in the cavity of the casting mold for the polishing layer of the polishing pad through the pressure generated by the size difference;

[0044] After the mold is closed, pour the polishing layer castable into the mold cavity, and keep it for a period of time under a certain curing temperature;

[0045] Cooling and demoulding to obtain a polishing pad polishing layer inlaid and bonded with an end point detection window;

[0046] The obtained polishing layer and the substrate layer with through holes opened according to the ...

Embodiment 2

[0048] A manufacturing method of a chemical mechanical polishing pad, which is a one-time integrated casting molding process, comprising the following steps:

[0049] The end point detection window is obtained by machining the casting temperature resistant, optically transparent solid material and the solid window material according to the shape and size;

[0050] The obtained end point detection window is fixed at the designed fixed position in the cavity of the casting mold of the polishing pad polishing layer through the double-sided tape of the casting temperature;

[0051] After the mold is closed, pour the polishing layer castable into the mold cavity, and keep it for a period of time under a certain curing temperature;

[0052] Cooling and demoulding to obtain a polishing pad polishing layer inlaid and bonded with an end point detection window;

[0053] The obtained polishing layer and the substrate layer with through holes opened according to the design requirements o...

Embodiment 3

[0055] A manufacturing method of a chemical mechanical polishing pad, which is a one-time integrated casting molding process, comprising the following steps:

[0056] The end point detection window is obtained by machining the casting temperature resistant, optically transparent solid material and the solid window material according to the shape and size;

[0057] installing the obtained end point detection window into the pre-opened grooves on the cavity wall of the polishing layer casting mold of the polishing pad with matching dimensions;

[0058] After the mold is closed, pour the polishing layer castable into the mold cavity, and keep it for a period of time under a certain curing temperature;

[0059] Cooling and demoulding to obtain a polishing pad polishing layer inlaid and bonded with an end point detection window;

[0060] The obtained polishing layer and the substrate layer with through holes opened according to the design requirements of the polishing pad are bond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com