Method for water control and oil production increasing acidification of oil well at water content increasing stage of low-pressure heterogeneous reservoir

A heterogeneous reservoir and stage technology, applied in the direction of earthwork drilling, wellbore/well components, production fluid, etc., can solve problems such as inability to increase oil production, increase water production, and scrap oil wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

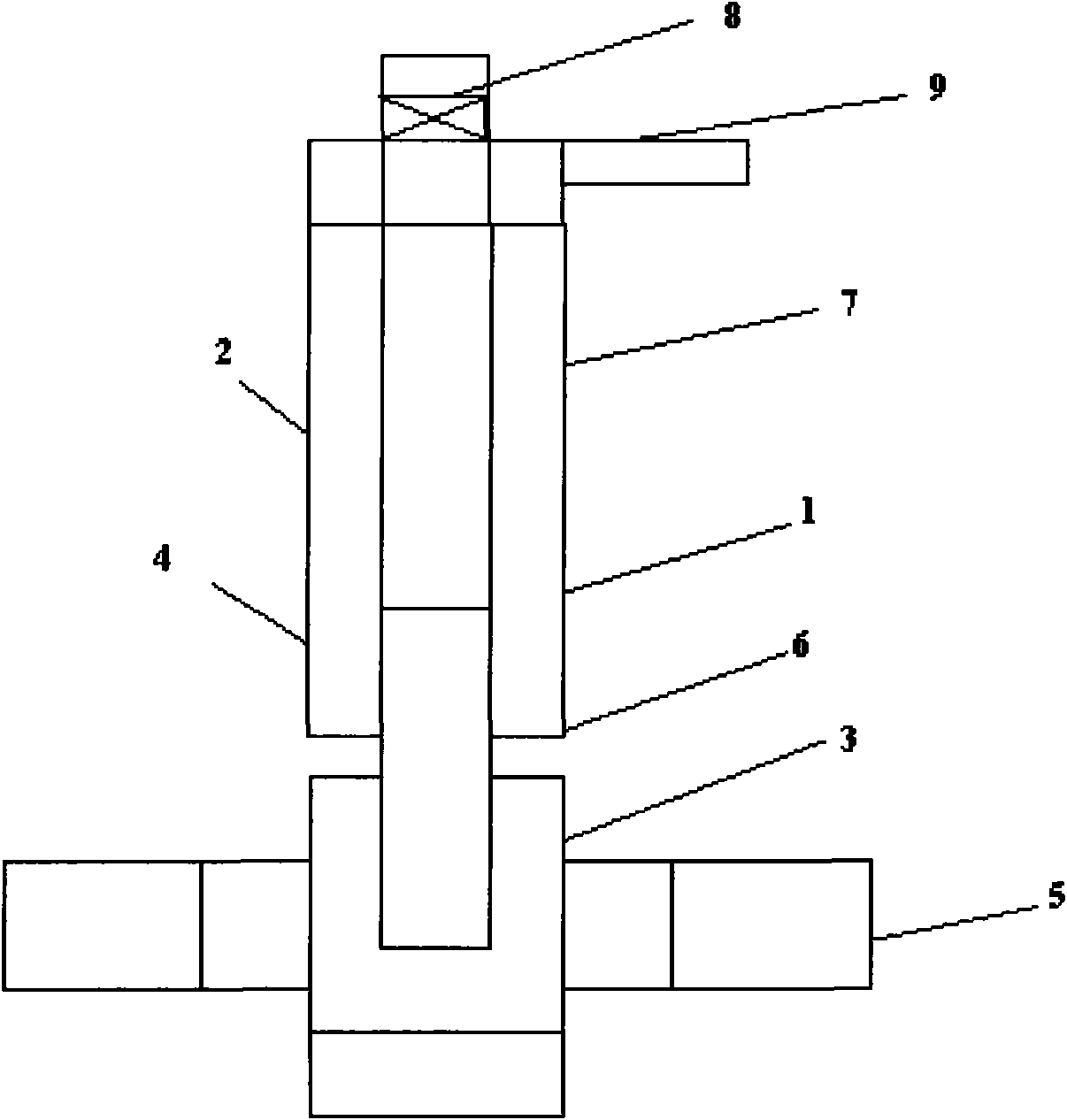

[0009] Firstly, use the well flushing fluid (0.5% clay stabilizer + 0.3% 8608 active agent) 1 to circulate and wash the wellbore, and fill the casing 2; , acetic acid 6-10%, corrosion inhibitor 0.5%-1%, iron ion stabilizer 1%-2%, surfactant 0.3-0.5%) 3 replace the flushing fluid in the oil pipe 4 to the middle part of the oil layer 5; sit well Packer 6, use high-viscosity displacement fluid (xanthan gum heated to 90°C to dissolve at 0.5%) 7 to displace the acidizing fluid in the tubing into the oil layer, close the tubing gate 8 and casing gate 9 respectively after reacting for a certain period of time, Suction the flowback with a tubing aspirator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com