Milling method for honeycomb parts

A technology of honeycomb parts and milling, which is applied in the direction of milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve the problems of unfavorable environmental protection and operator health, cutting chips and dust, honeycomb materials are not easy to hold, and parts are milled incorrectly. Effects of environmental protection, dust reduction, and cutting resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

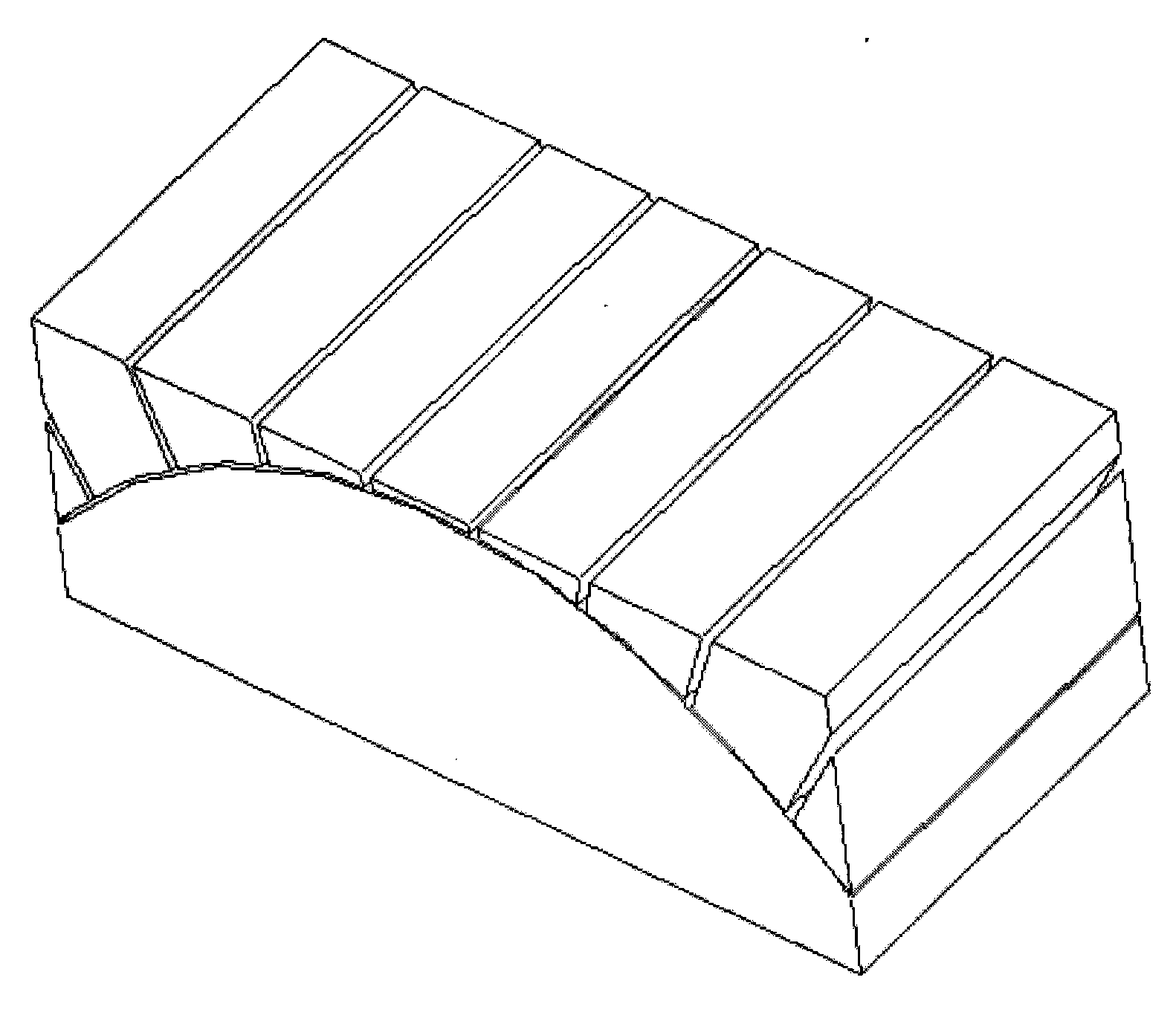

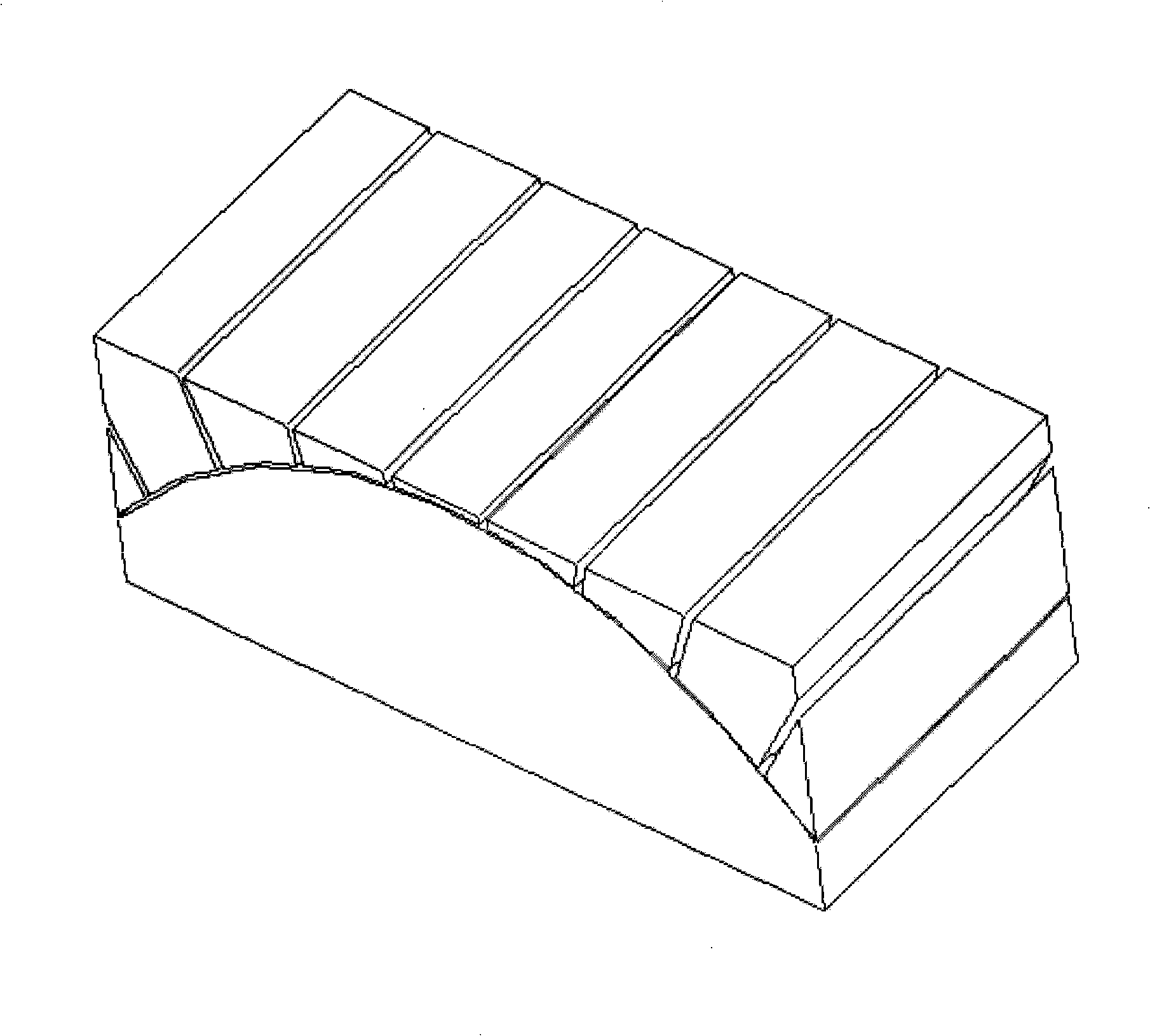

[0011] According to the shape of the part, choose a reasonable size sheet milling cutter and small cylindrical milling cutter. The diameter of the small cylindrical milling cutter should be slightly larger than the diameter of the cutter bar of the chip milling cutter, so as to ensure that the cutter bar will not interfere with the material during the processing of the chip milling cutter. First, according to the slope of the curved surface shape to be milled for the honeycomb part material workpiece to be structured, a small cylindrical milling cutter is used to mill out several vertically arranged small grooves with different heights above the curve, as shown in Figure 1. The groove of a typical honeycomb material. When using a small cylindrical milling cutter to open several small grooves, the distance between the small grooves should be smaller than the radius of the piece milling cutter, so as to ensure that the piece milling cutter can cut off the remaining material smoot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com