Line windproof low-temperature-resistant telescopic spring, power transmission line and method

A technology of telescopic springs and transmission lines, which is applied in the direction of overhead lines/cable equipment, springs, springs/shock absorbers, etc. It can solve the problems of line shrinkage in winter, increase the cost of line reconstruction, and discharge of wire crossarms. Achieve the effects of shortening the line reconstruction time, avoiding sudden breakage and reducing the cost of line reconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

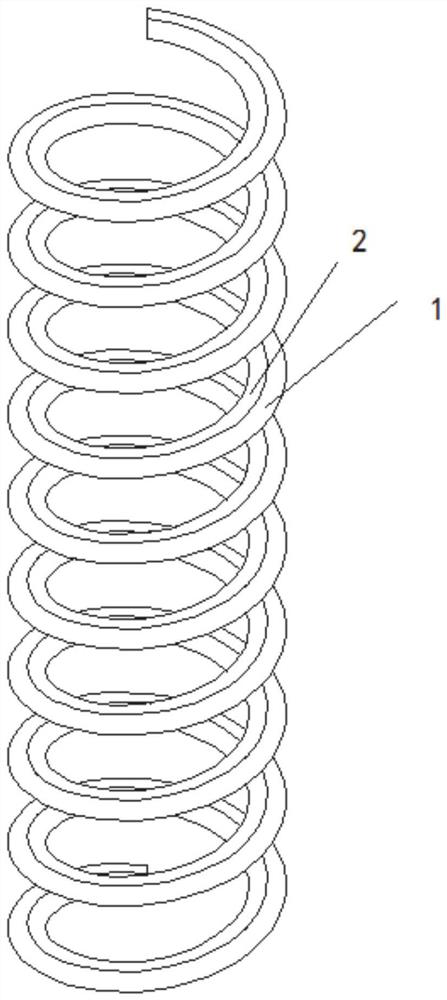

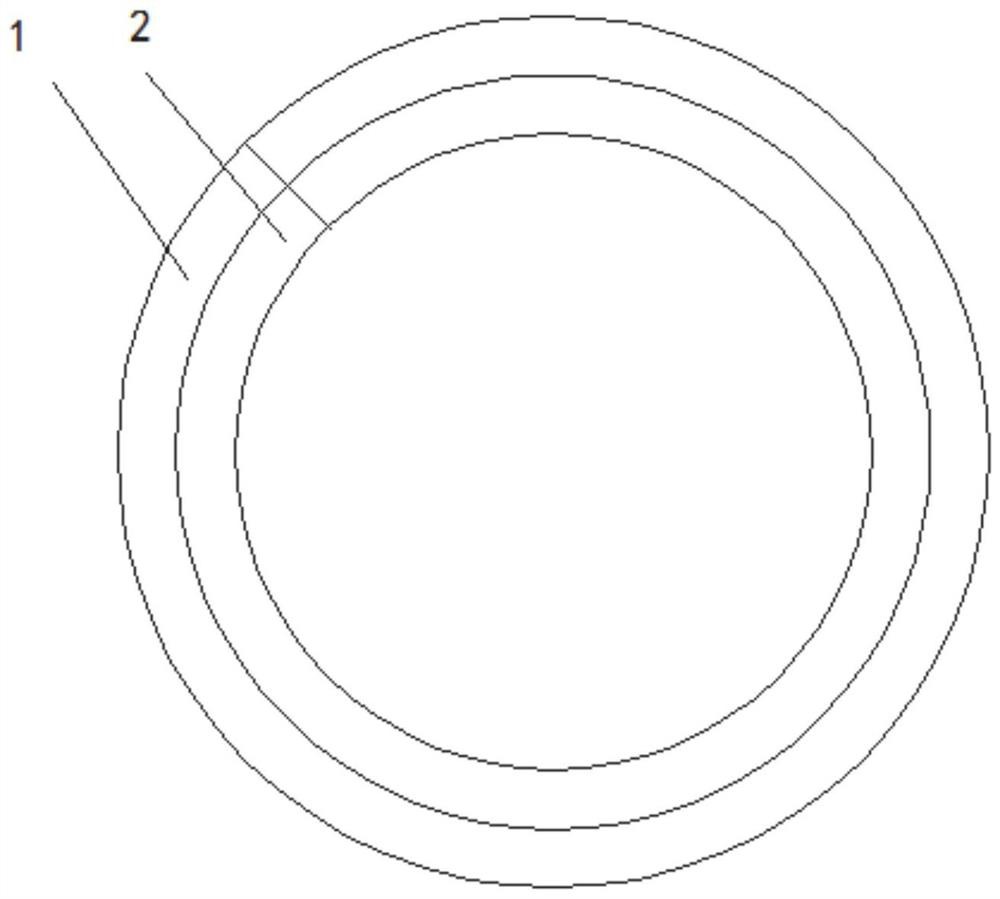

[0036] Such as figure 1 As shown, this embodiment provides a line windproof and low temperature resistant telescopic spring, including: a first layer of elastic body and a second layer of elastic body, the first layer of elastic body is connected with the second layer of elastic body, the first layer of elastic body The coefficient of thermal expansion of the elastic body of the layer is higher than that of the elastic body of the second layer.

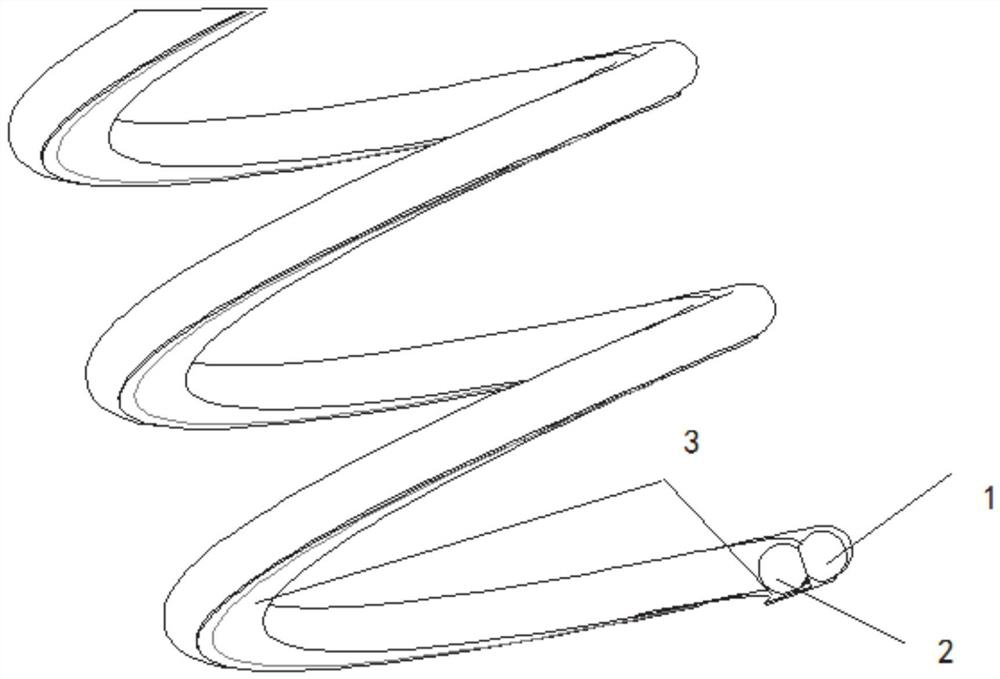

[0037] The first layer of elastic body is an outer layer elastic body, and the second layer of elastic body is an inner layer elastic body; as an embodiment, the outer layer elastic body is a spiral structure with a circular cross section, located in the spiral structure The inner side of the body has an outer installation plane, and the inner elastic body is also a spiral structure with a circular cross section. The outer side of the spiral structure has an inner installation plane, and the outer installation plane is connected with ...

Embodiment approach

[0046] As another implementation, the anti-breakage installation structure includes a first installation ring, a second installation ring and a plurality of line windproof and low-temperature telescopic springs, the first installation ring and the second installation ring are installed on the transmission line, and the first There is a set distance between the installation ring and the second installation ring, and a plurality of line windproof and low temperature resistant telescopic springs are installed between the first installation ring and the second installation ring, and the multiple line windproof and low temperature resistant telescopic springs are respectively arranged around the transmission line circumference One end of multiple lines of windproof and low-temperature telescopic springs is connected to the first installation ring, and the other end is connected to the second installation ring. When one of the lines of windproof and low-temperature telescopic springs ...

Embodiment 2

[0064] This embodiment also provides a power transmission line, including several line windproof and low temperature resistant telescopic springs as described in the first embodiment above. Line coaxial layout.

[0065] The line windproof and low temperature resistant telescopic spring is arranged on the outer surface of the transmission line or inside the transmission line. The length of the line windproof and low temperature resistant telescopic spring can be adjusted according to the line length configuration. The use of anti-typhoon and anti-cold wave telescopic springs on the line can make use of existing towers and existing lines, greatly reducing the cost of line transformation and shortening the time for line transformation.

[0066] As an implementation mode, there are multiple windproof and low temperature resistant telescopic springs for the line, and the size can be adjusted. The structural stability of the line windproof and low temperature telescopic spring, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com