Method of mounting felling traction rope

An installation method and the technology of the traction rope, which are applied in the field of logging traction rope installation, can solve the problems of safety hazards in climbing operations at high places, the inability to effectively control the falling of trees, and the inconvenience of carrying bamboo ladders, etc., achieving remarkable on-site use effects and convenient carrying , high safety and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

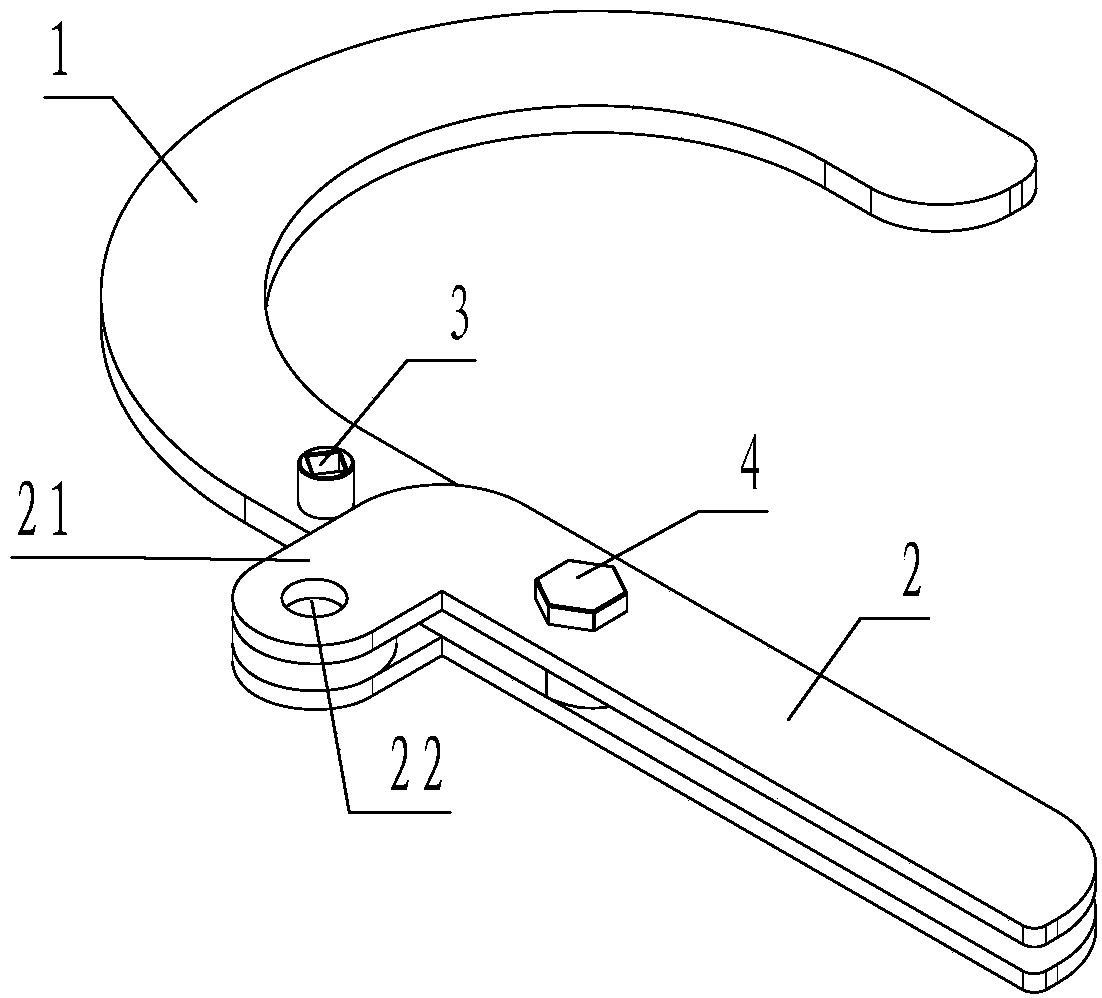

[0018] A method for installing a logging traction rope, providing a hoop for a logging traction rope, including an arc-shaped hoop body 1, and an "L"-shaped self-sealing tab 2, the "L"-shaped self-sealing tab The long side is hinged with the hoop body, the hinge point on the hoop body is located at one end of the hoop body, and the hinge point 4 of the "L"-shaped self-sealing tab is located on the long side near the short side 21, "L" The short side of the self-sealing tab is located outside the arc groove of the hoop body, and the opening of the "L"-shaped self-sealing tab forms an embrace with the arc-shaped groove of the hoop body when the "L"-shaped self-sealing tab is in the closed state. state, the short side end of the "L" type self-sealing tab is provided with a fixed hole 22 for the traction rope, and a fixed joint is provided at the center of gravity of the hoop of the logging traction rope. The fixed joint 3 is arranged on the hoop On the body, when installing the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com