PCD forming milling cutter for machining automobile inlay

A technology of forming milling cutters and inlays, which is applied in the direction of cutting tools for lathes, metal processing equipment, workpieces, etc., can solve problems such as the inability to form and process automotive steering gear parts at one time, achieve excellent use effects, eliminate repeated positioning errors, The effect of precise cooling and lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

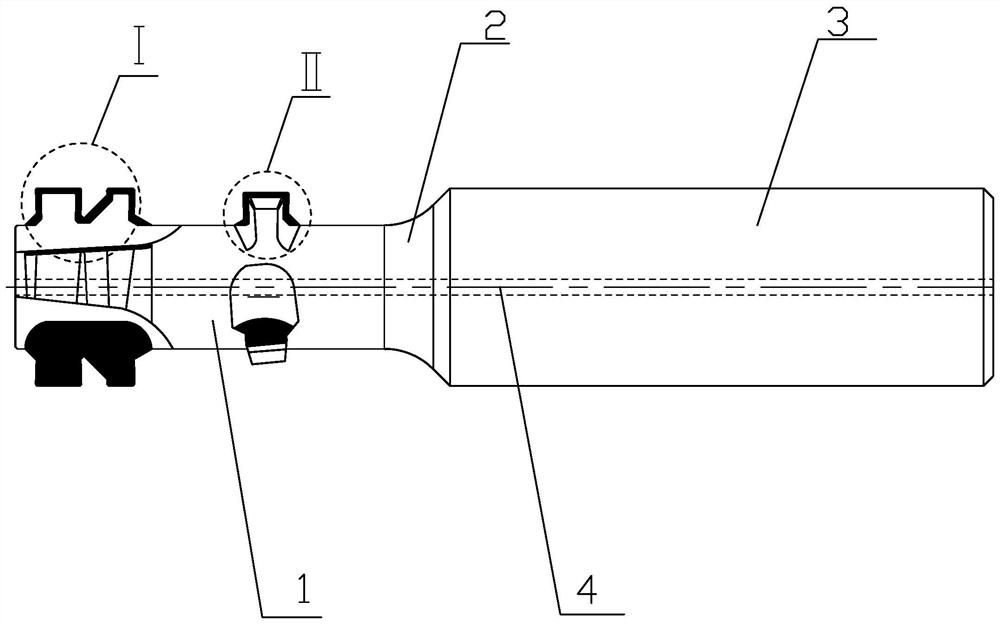

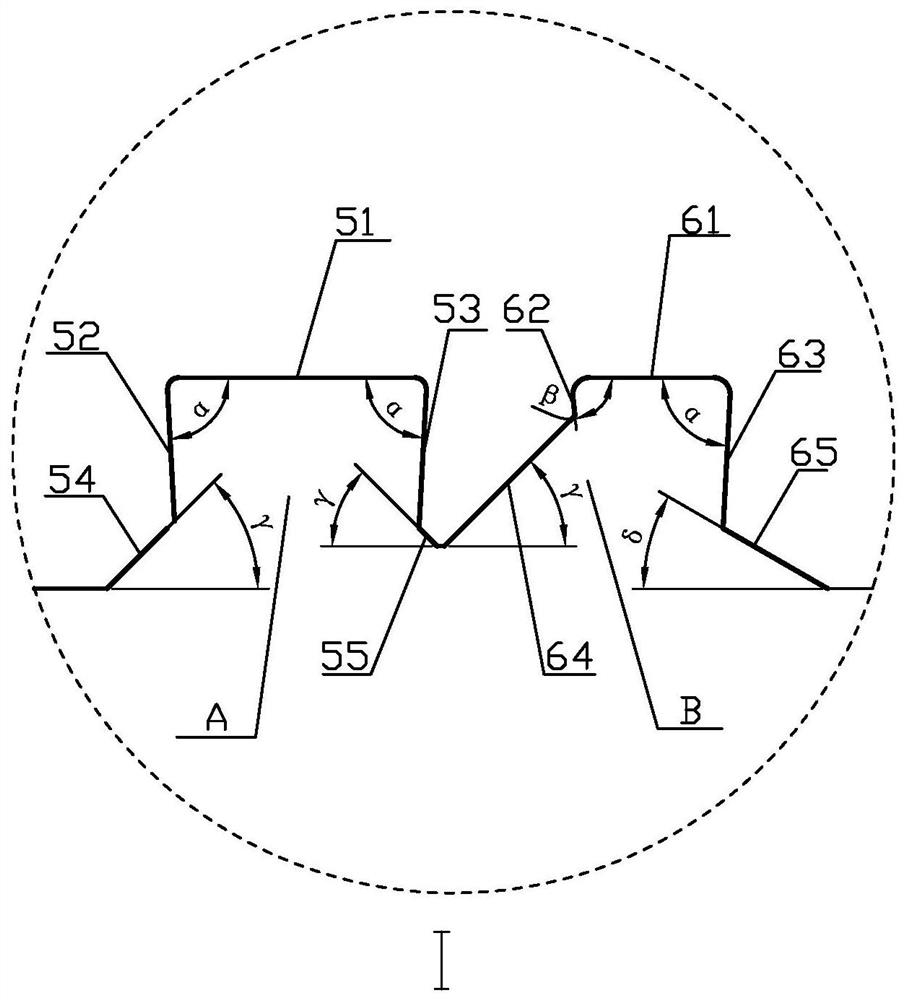

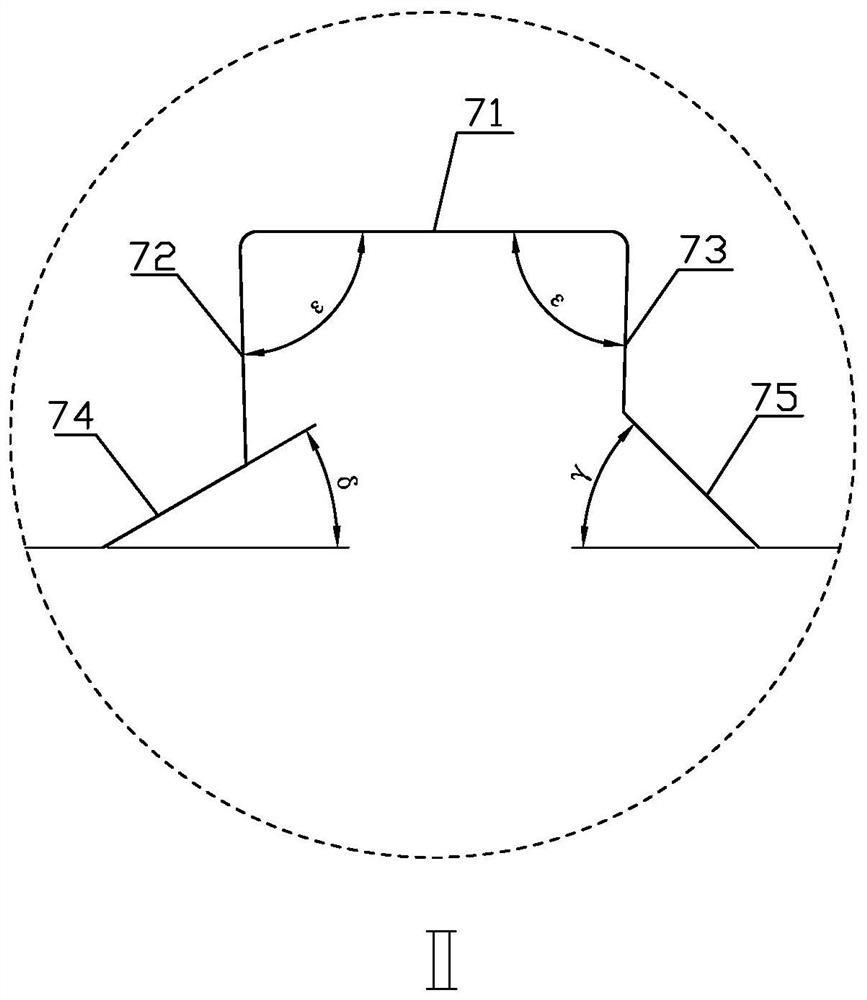

[0021] The PCD composite tool used for processing automobile steering gear includes a cutter body 5 and a handle 6, the cutter body 5 is arranged at the left end of the handle 6, and the cutter body 5 is provided with four cutting parts in sequence from the left end to the right, and the four cutting parts The parts are connected in a ladder shape, all of which are cylinders, and the diameters increase sequentially, and each cutting part is provided with no less than 2 cutting blades along the circumference;

[0022] The first cutting part 1 is arranged at the front end of the cutter body 5, and the first blade 11 extends from the left end surface of the first cutting part 1 to its second half, and is shaped as the same and continuous wave sawtooth, with peaks and troughs between two adjacent sawtooths The angles are all 60°, the sharp corner of the outer ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com