Machining Method of Additive and Subtractive Material Composite Manufacture of Turbine Blades

A technology of turbine blades and processing methods, which is applied in the manufacturing of turbine blades, and in the field of composite processing of turbine blades manufactured by adding and subtracting materials, can solve the problems of increasing research and development costs, precise control, affecting blade flow, etc., and saves the cost of modifying molds Time, eliminate the error of repeated positioning, and improve the effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

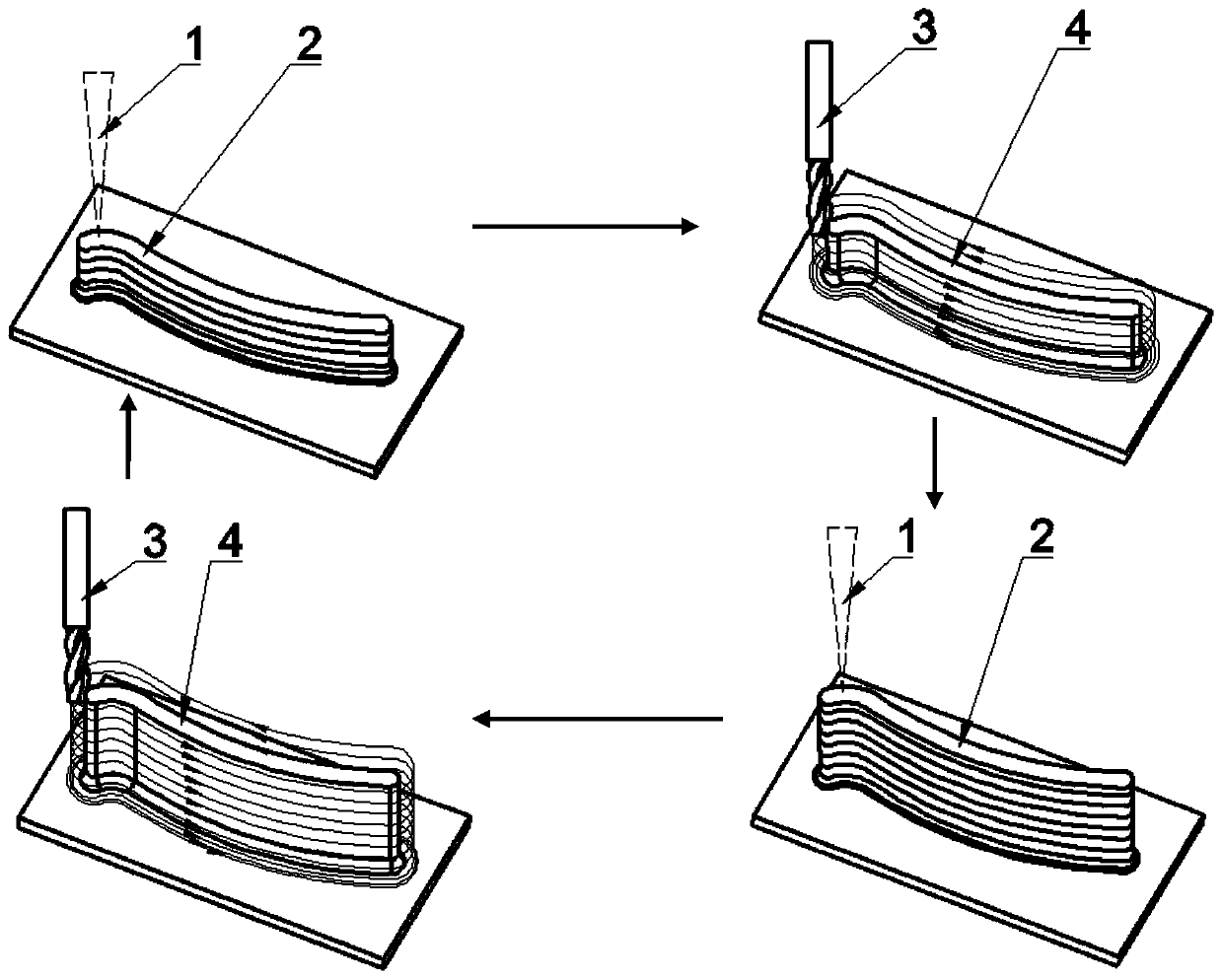

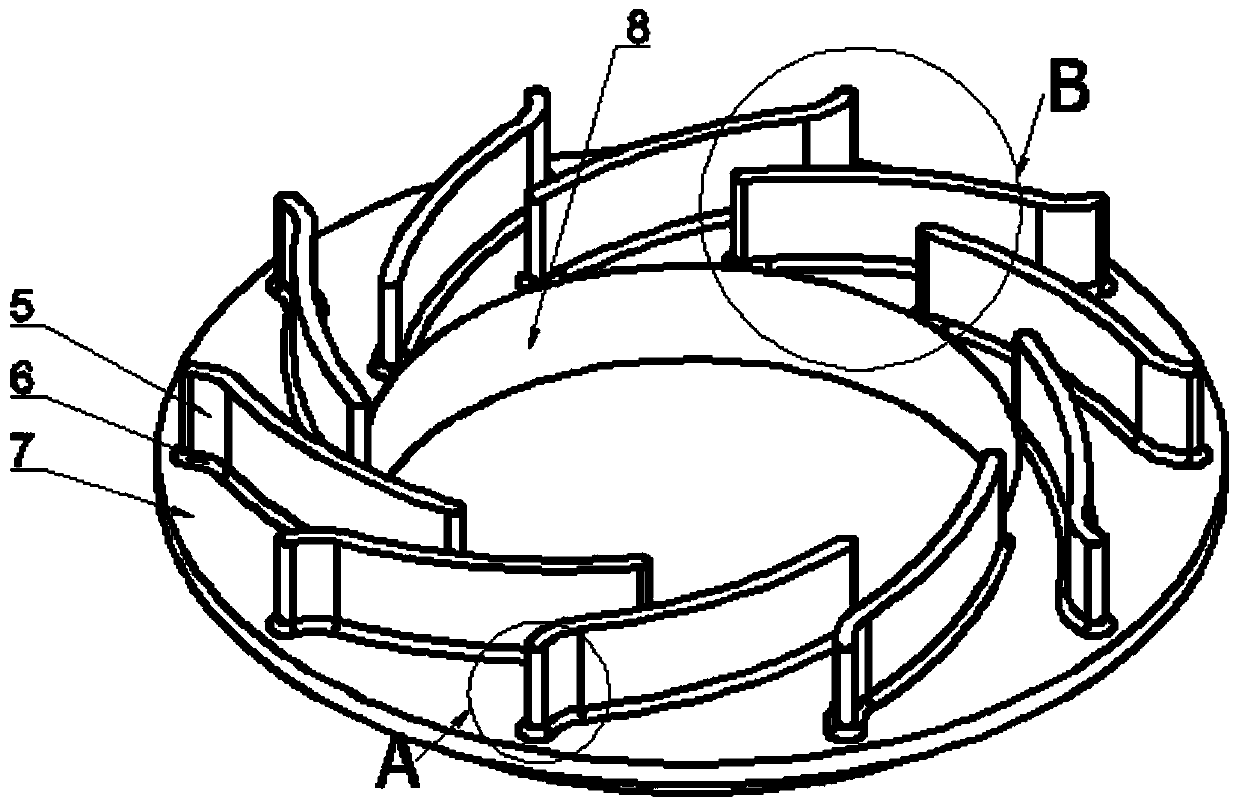

[0044] The specific embodiment of the present invention is shown in the accompanying drawings. The processing method for manufacturing turbine blades with additive and subtractive materials includes: additive forming and subtractive machining; additive forming and subtractive machining are carried out alternately;

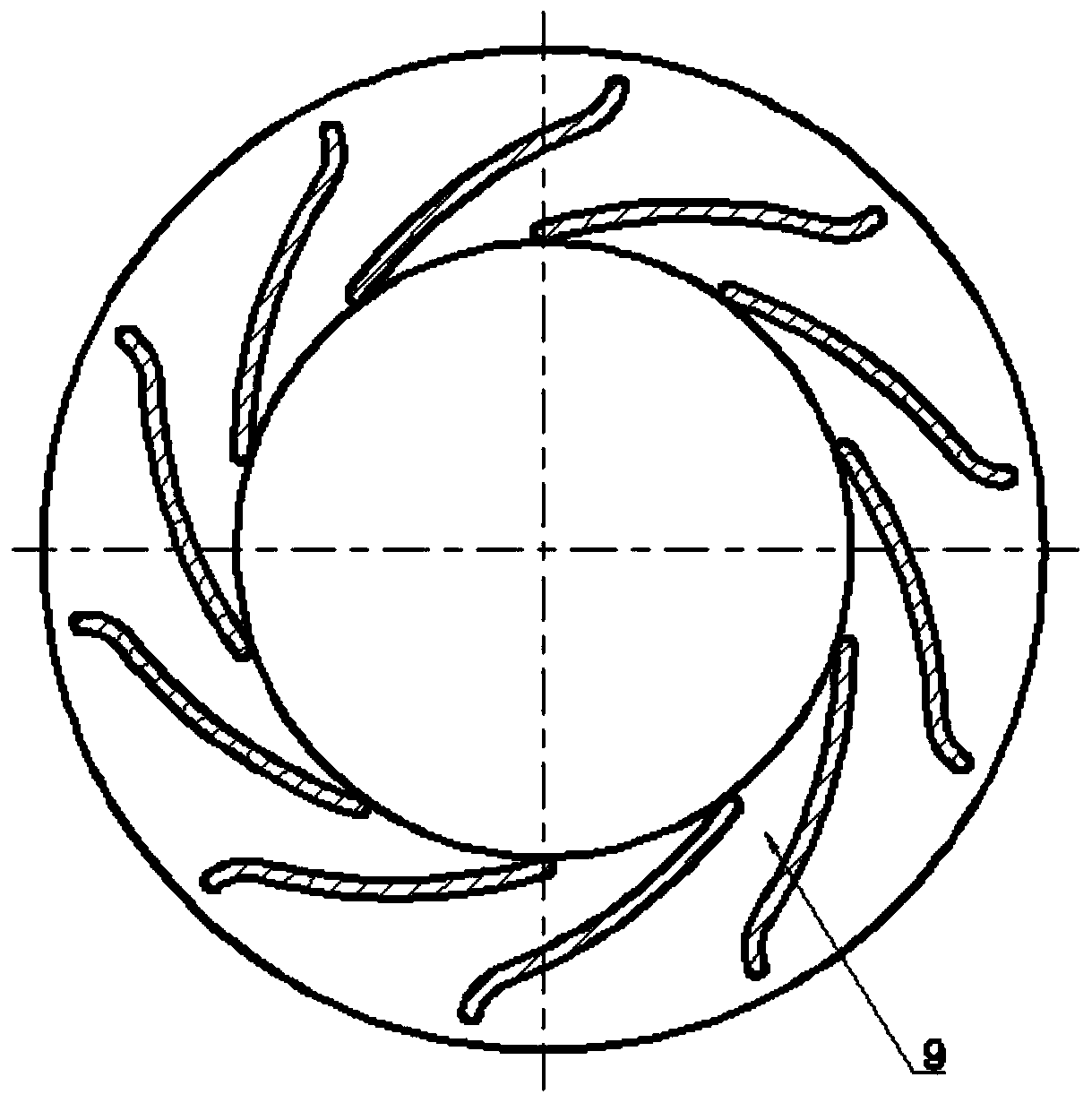

[0045] Additive molding: Use 3D modeling software to draw the turbine blade model to be prepared, use slicing software to slice and layer the 3D model, and in view of the small size of the turbine blade fillet, thin the layer at the turbine blade angle 6 (fillet) The thickness of the layer makes the feature size obtained by adding materials closer to the design size, which can reduce the removal amount of subtractive processing and plan the laser scanning path of additive materials; high-energy beam 1 melts / solidifies a certain number of layers according to the planned high-energy beam scanning path metal material, to obtain the additive processing layer 2, the turb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com