Patents

Literature

256 results about "Material Stretched" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

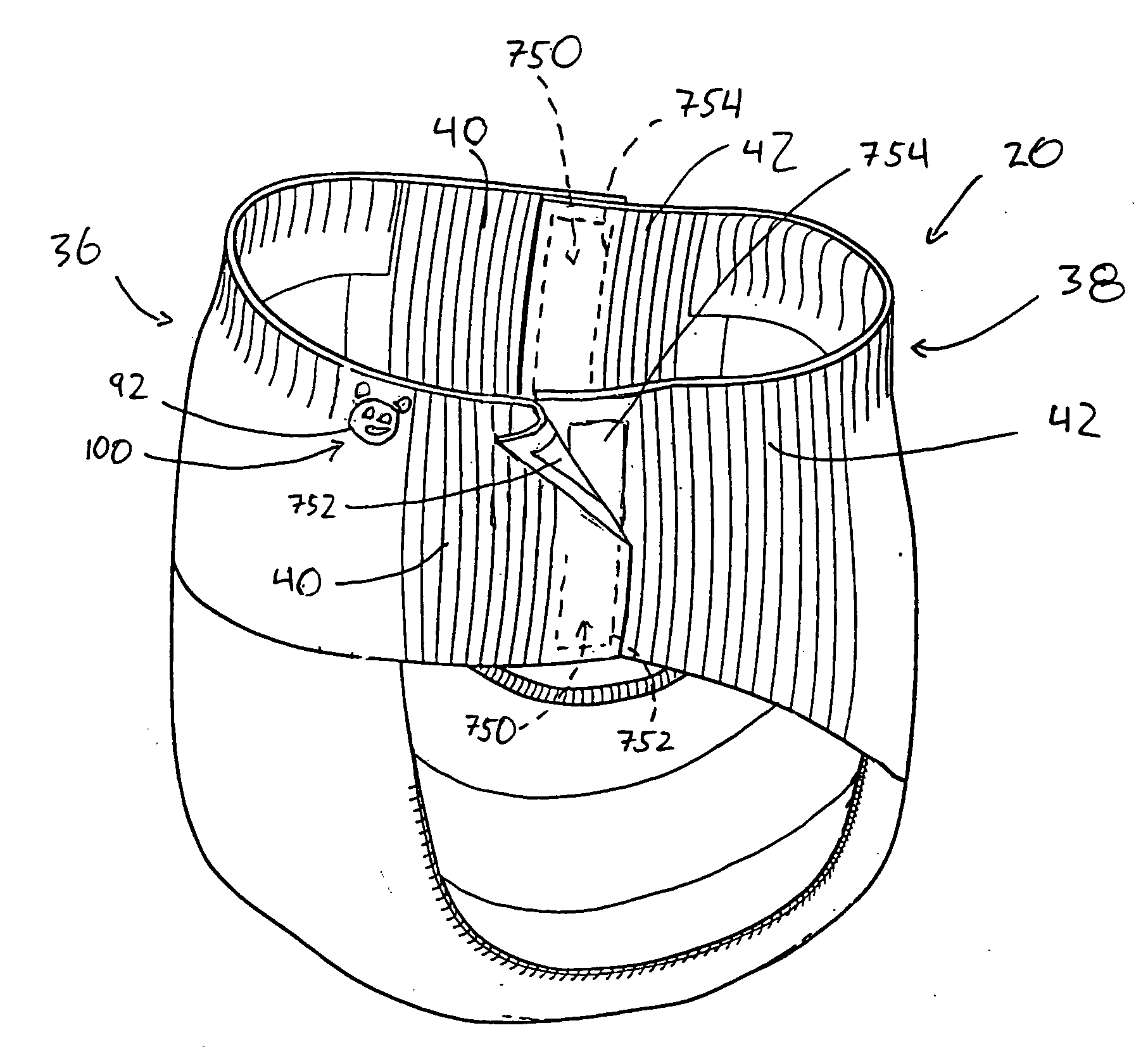

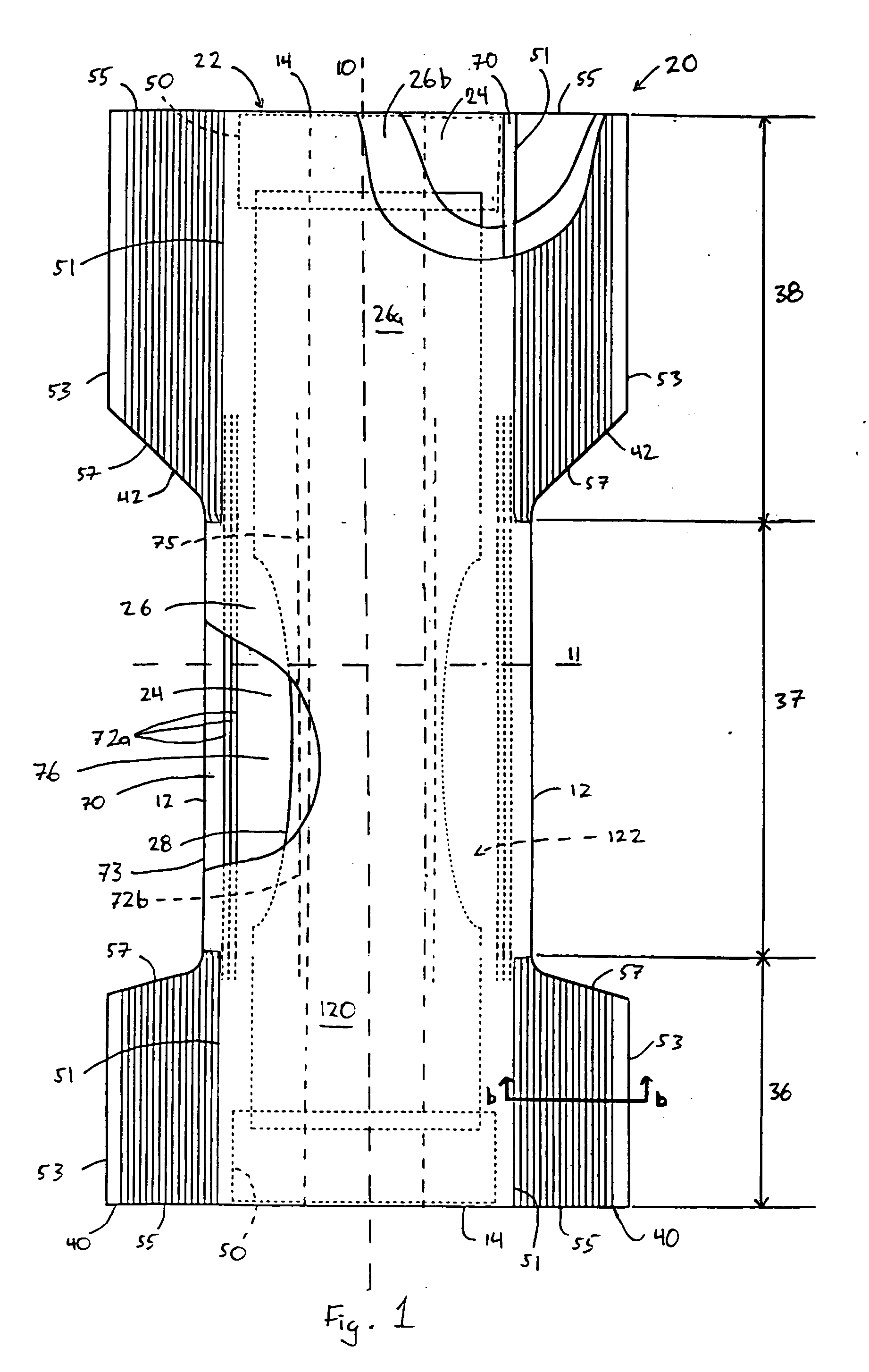

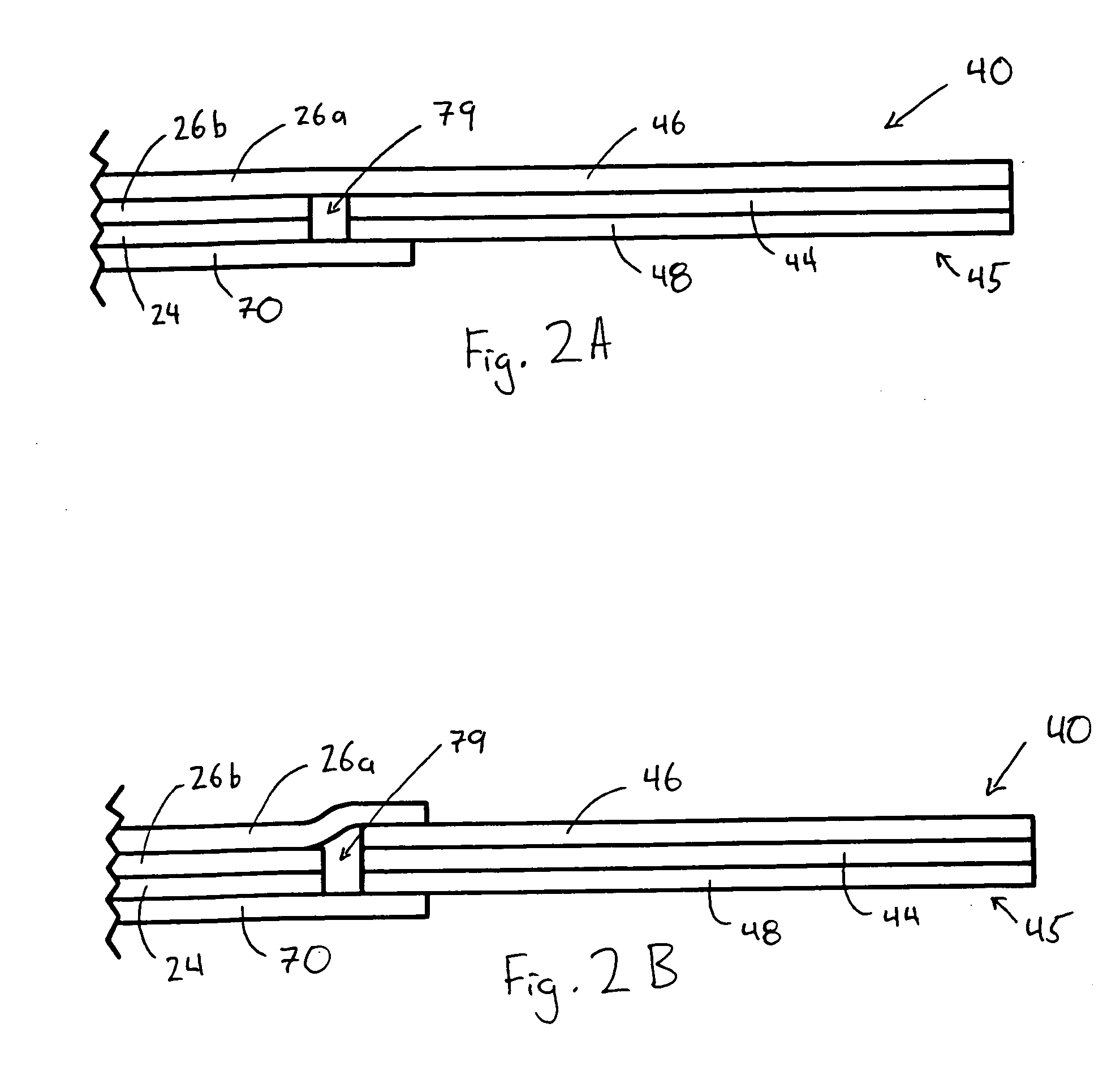

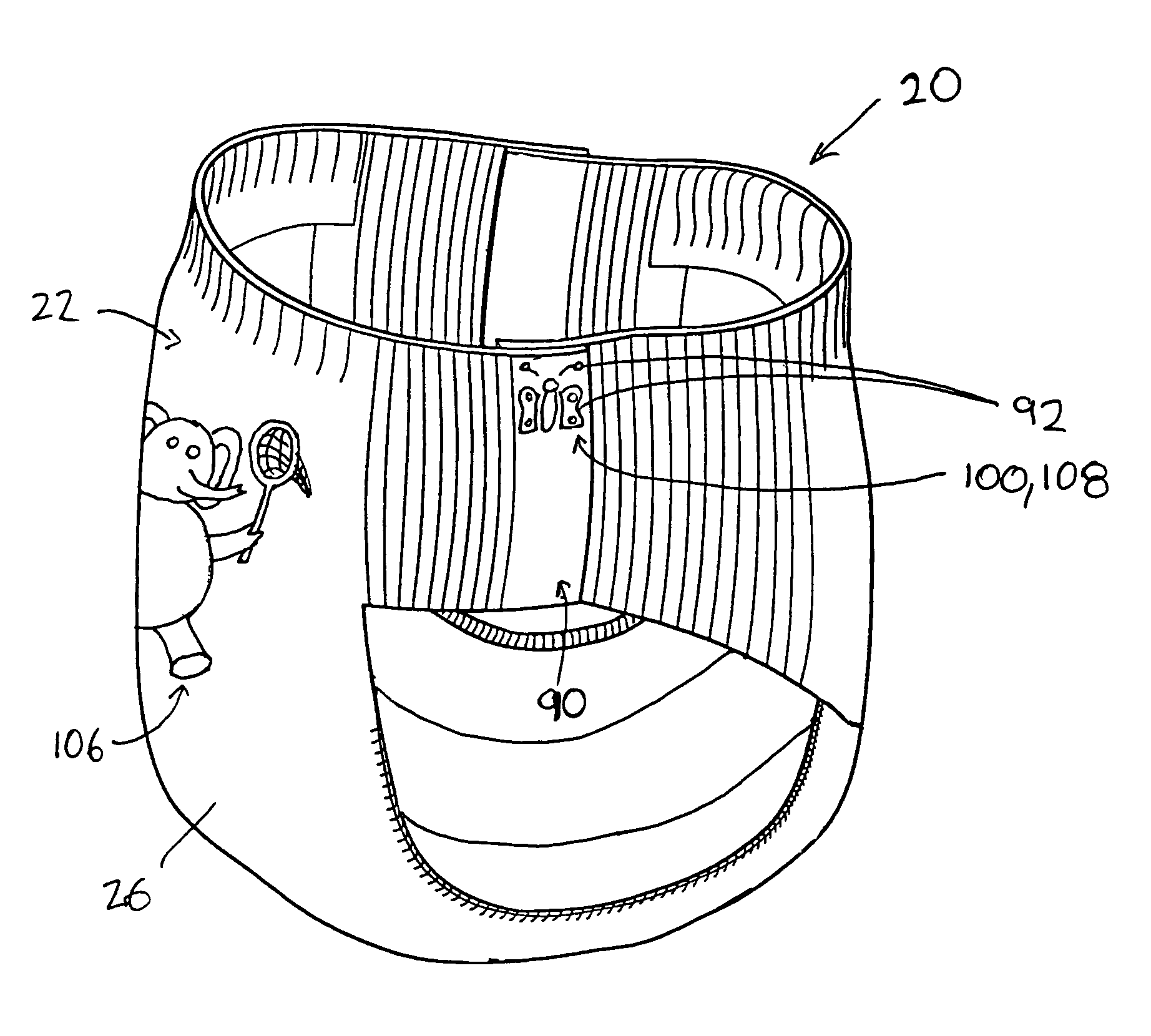

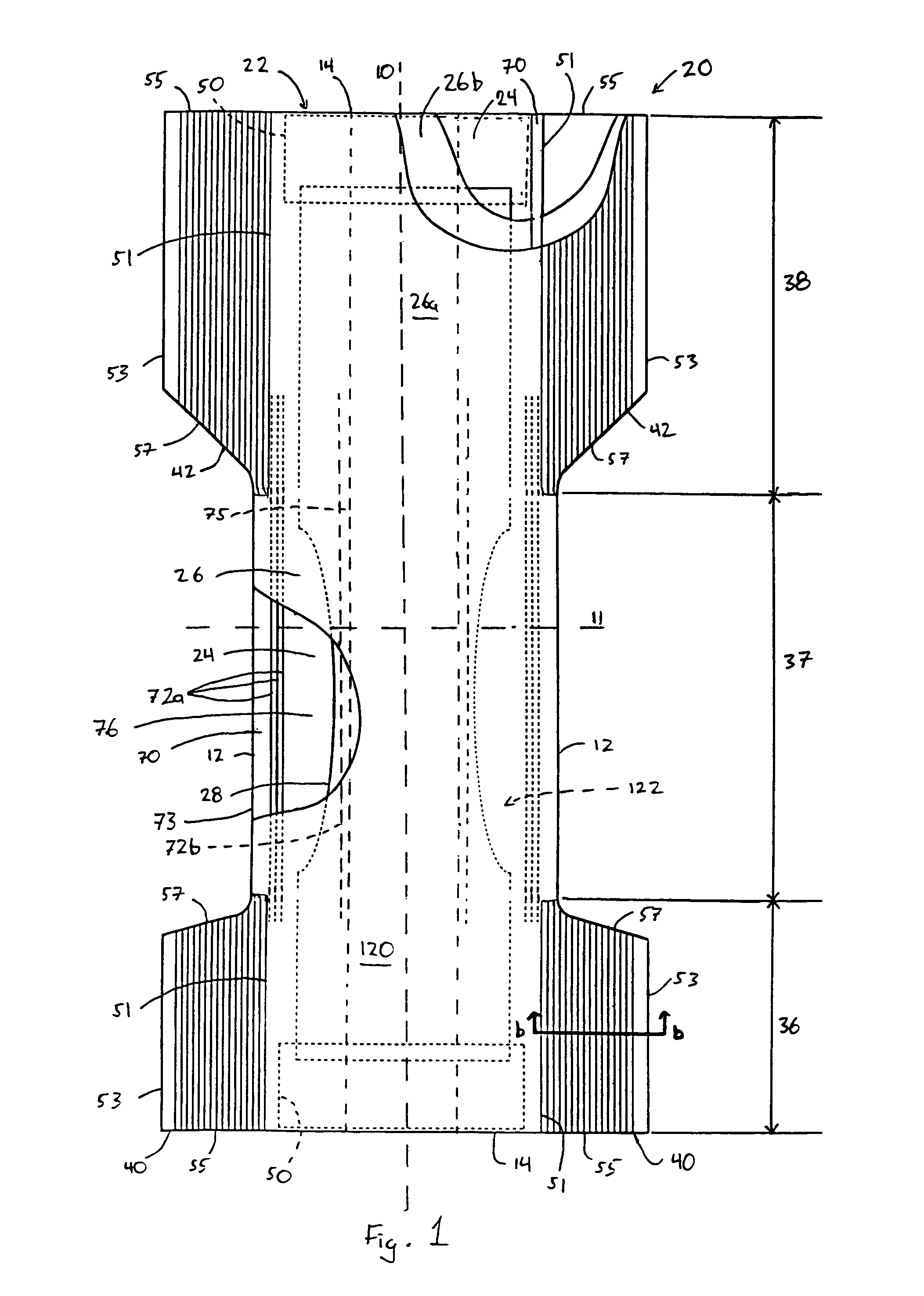

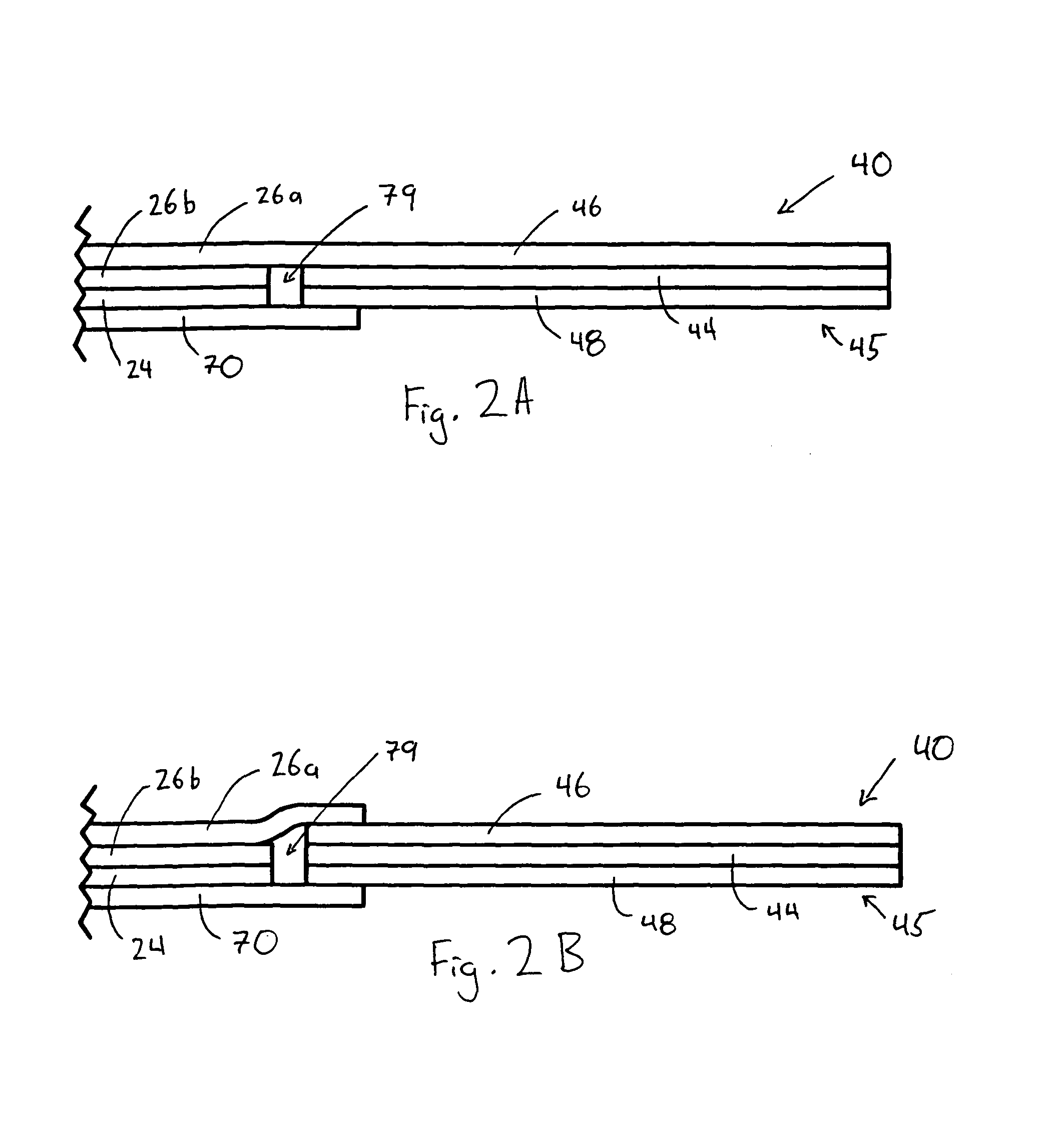

Absorbent article with a multifunctional side panel

An absorbent article may comprise a chassis having a front waist region, a rear waist region, a crotch region between the front waist region and the rear waist region, a pair of longitudinal edges, and a pair of side panels extending between and connecting the front waist region and the rear waist region to form a leg opening. Each side panel may comprise a uniformly colored stretch laminate. The stretch laminate may comprise a colored elastomeric member and a first substrate joined to the elastomeric material. The side panels may be joined by a mechanical bond which may form an informational indicia.

Owner:THE PROCTER & GAMBLE COMPANY

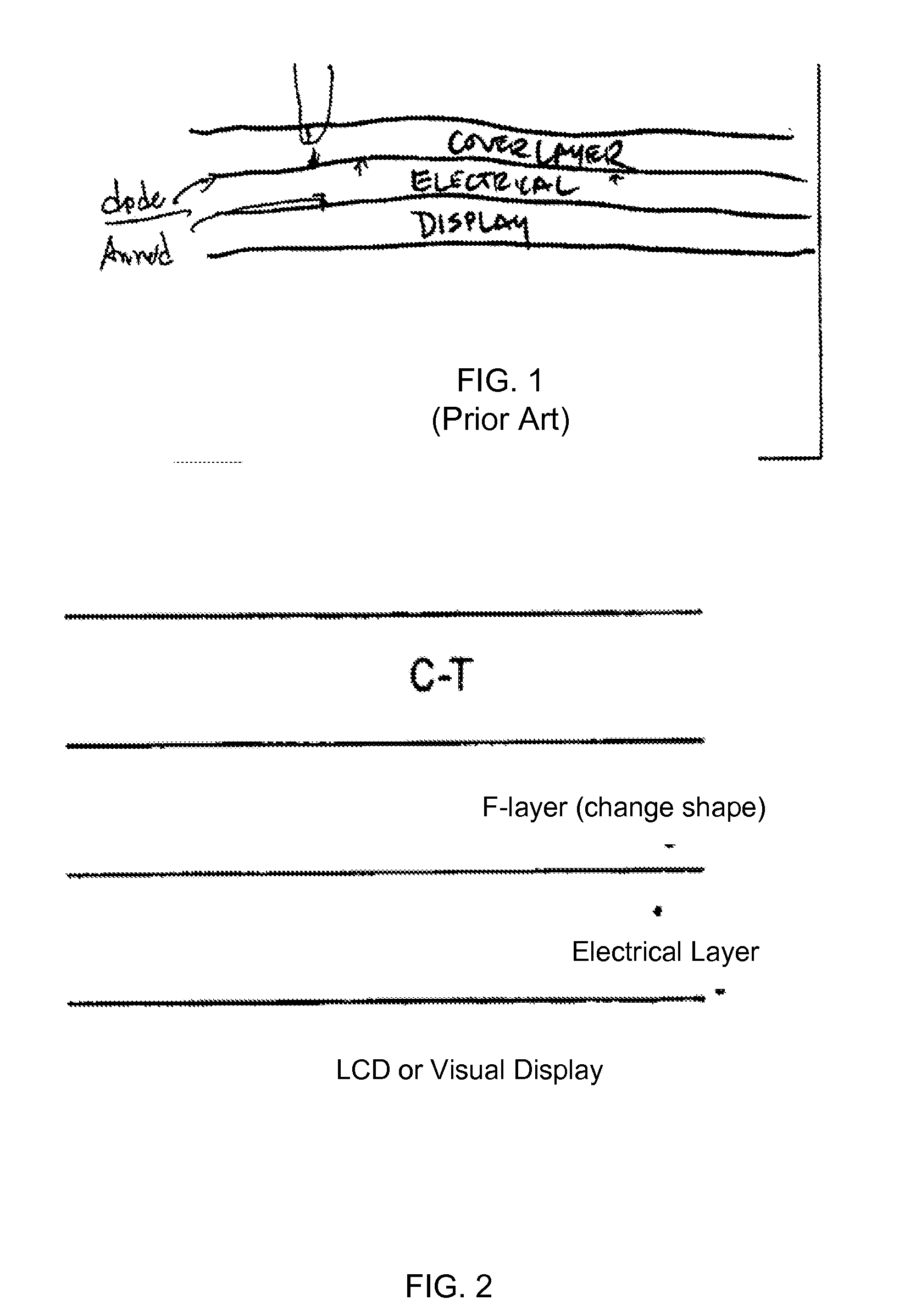

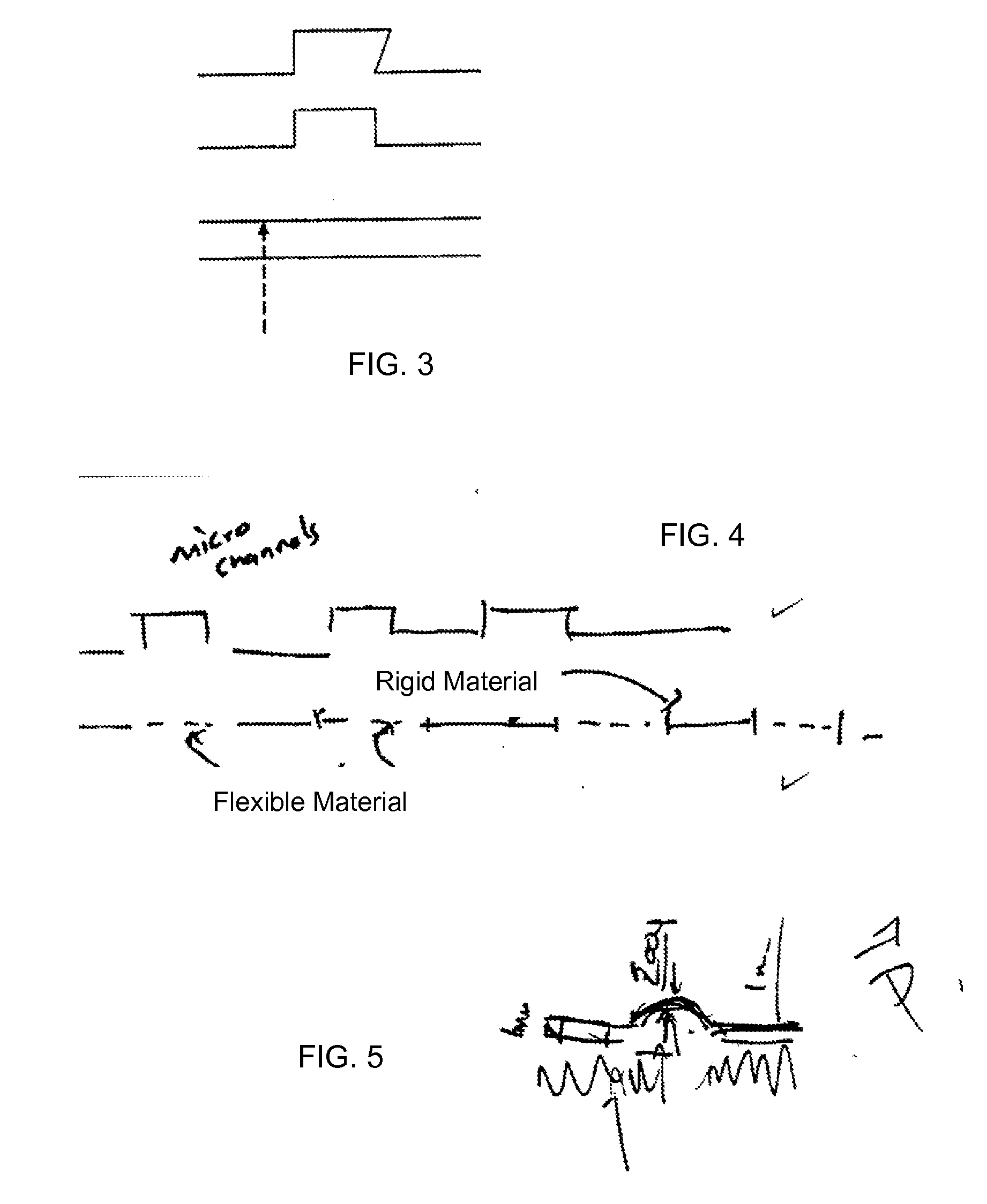

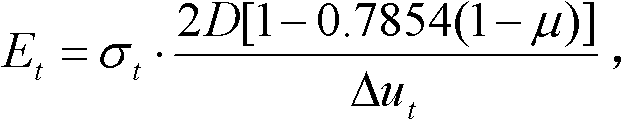

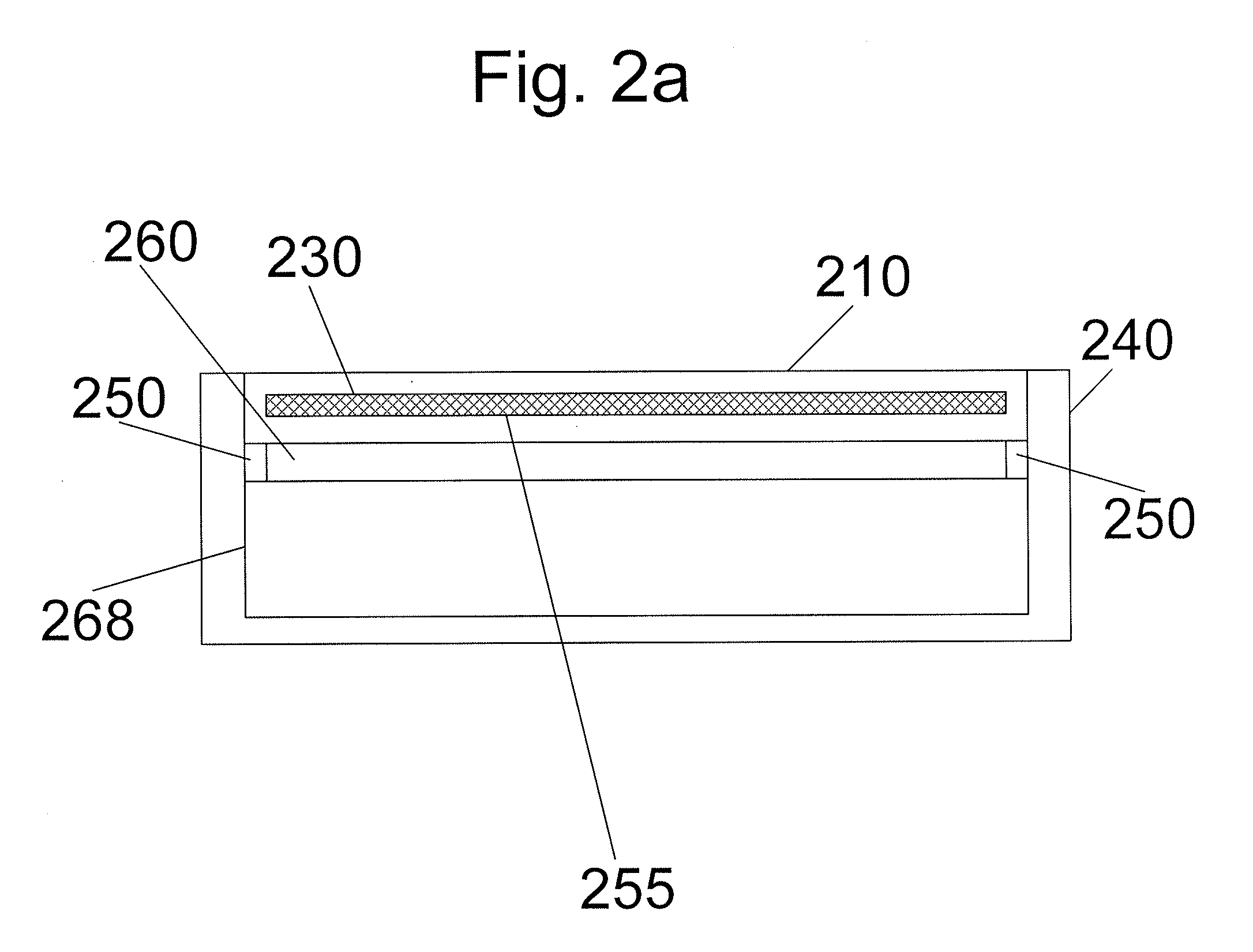

Reconfigurable tactile-enhanced display including "tap-and-drop" computing system for vision impaired users

InactiveUS20070229233A1Enhance tactile-based accuracyQuick filterRepeater circuitsTactile signalling systemsOptical propertyThin layer

The invention has an active touch-sensitive transparent layer over a display screen (LCD) in which an electrically responsive material, such as silicon oil or the above-described material is trapped in a very thin layer with a diode at the top part of the layer and an anode at the bottom. The electrically responsive material changes form by expanding when a current passes through the material from the anode part of the layer to the diode. The expanded material stretches part the top layer to create raised portions of the display screen. The raised portions can be used in the following capacities: to assist a vision impaired viewer, enhance night viewing, allowing for reduced attention or resources to touch-screen manipulation, or change the optical properties of the display by creating a three-dimensional optical property in the surface of the flexible material covering the expanding layer.

Owner:DORT DAVID BOGART

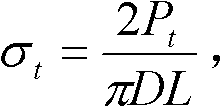

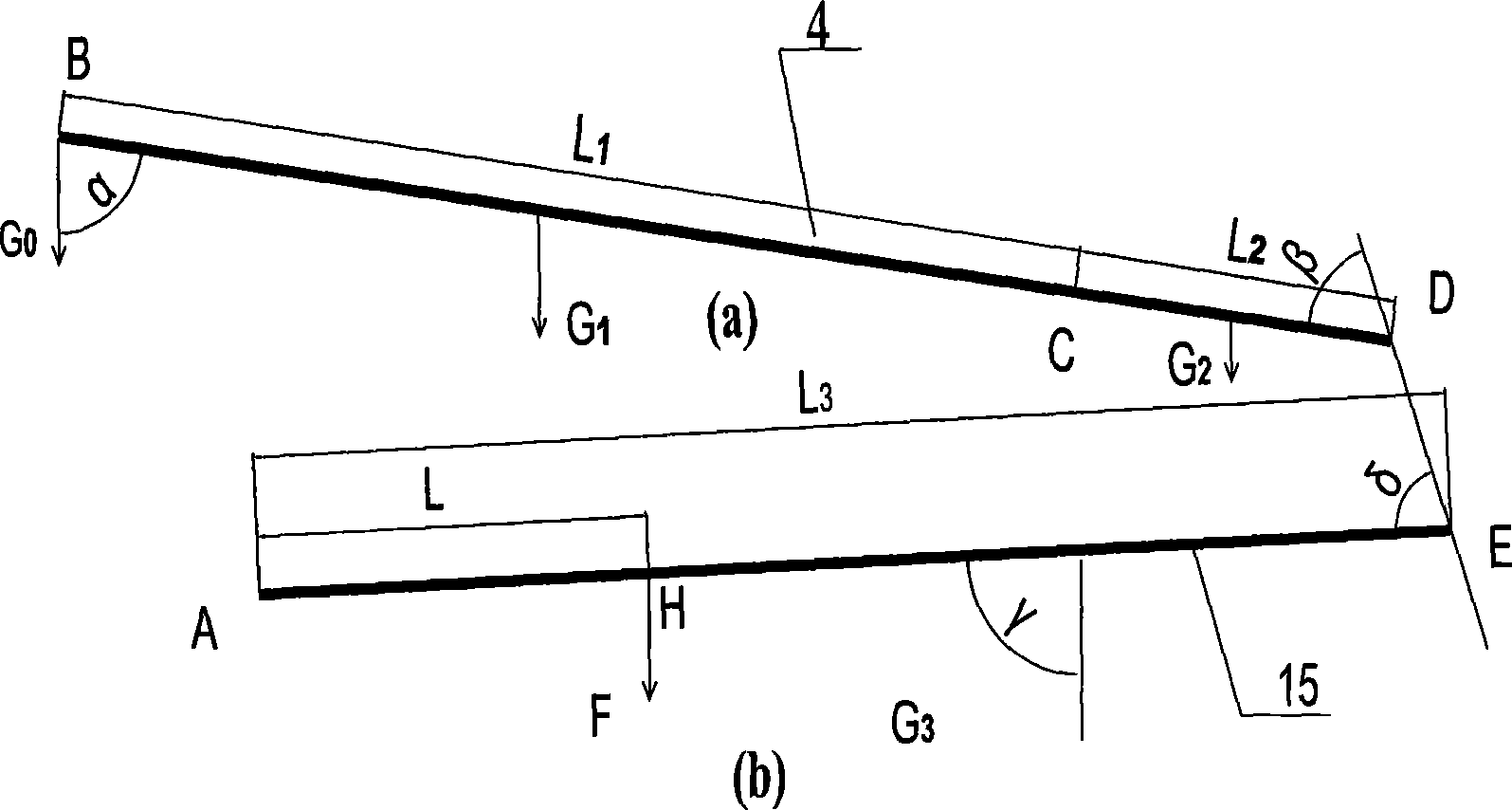

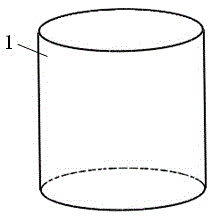

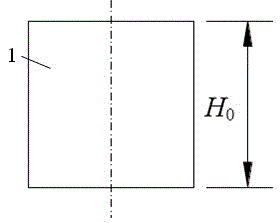

Method for testing tensile modulus of brittle material

InactiveCN101819111AEasy to controlEasy to operateMaterial strength using tensile/compressive forcesTest sampleMaterial Stretched

The invention discloses a method for testing tensile modulus of a brittle material, which is characterized by comprising the following steps of: arranging a test sample on a Brazilian split tester; symmetrically applying line load to the test sample in the radial direction of the test sample; measuring the total displacement of center of the test sample in the diameter direction, wherein the direction of the total displacement is vertical to the load applying direction of the test sample; calculating to obtain the tensile modulus Et of the material according to the following formula, wherein Et is the tensile modulus, sigma t is the Brazilian split tensile strength; Pt is the line load, L is the length of the test sample, D is the diameter of the test sample, Mu is the Poisson's ratio, and Delta ut is the total displacement of the center of the test sample in the diameter direction. The method for testing the tensile modulus of the brittle material can guarantee more accurate test result.

Owner:CENT SOUTH UNIV

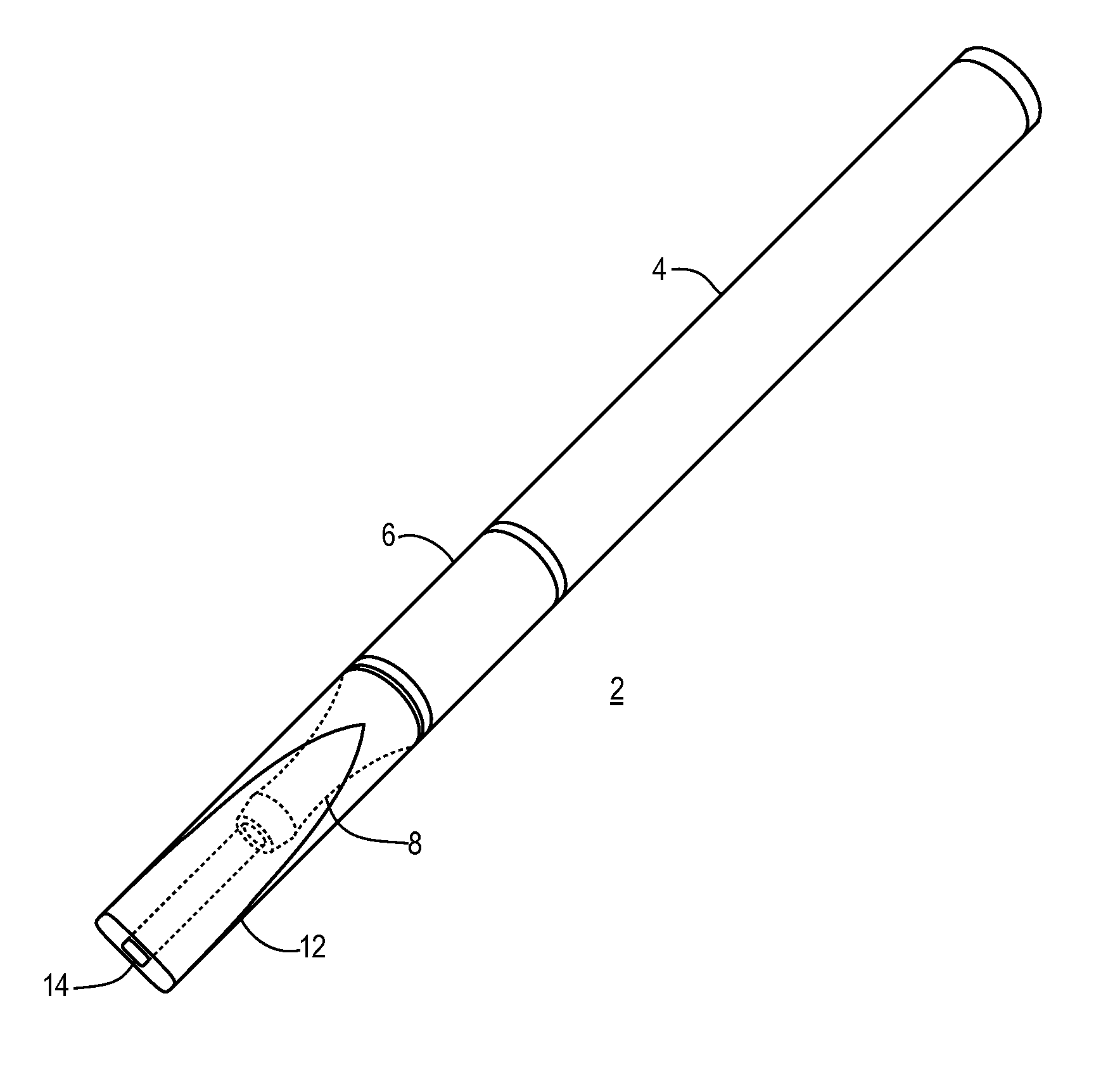

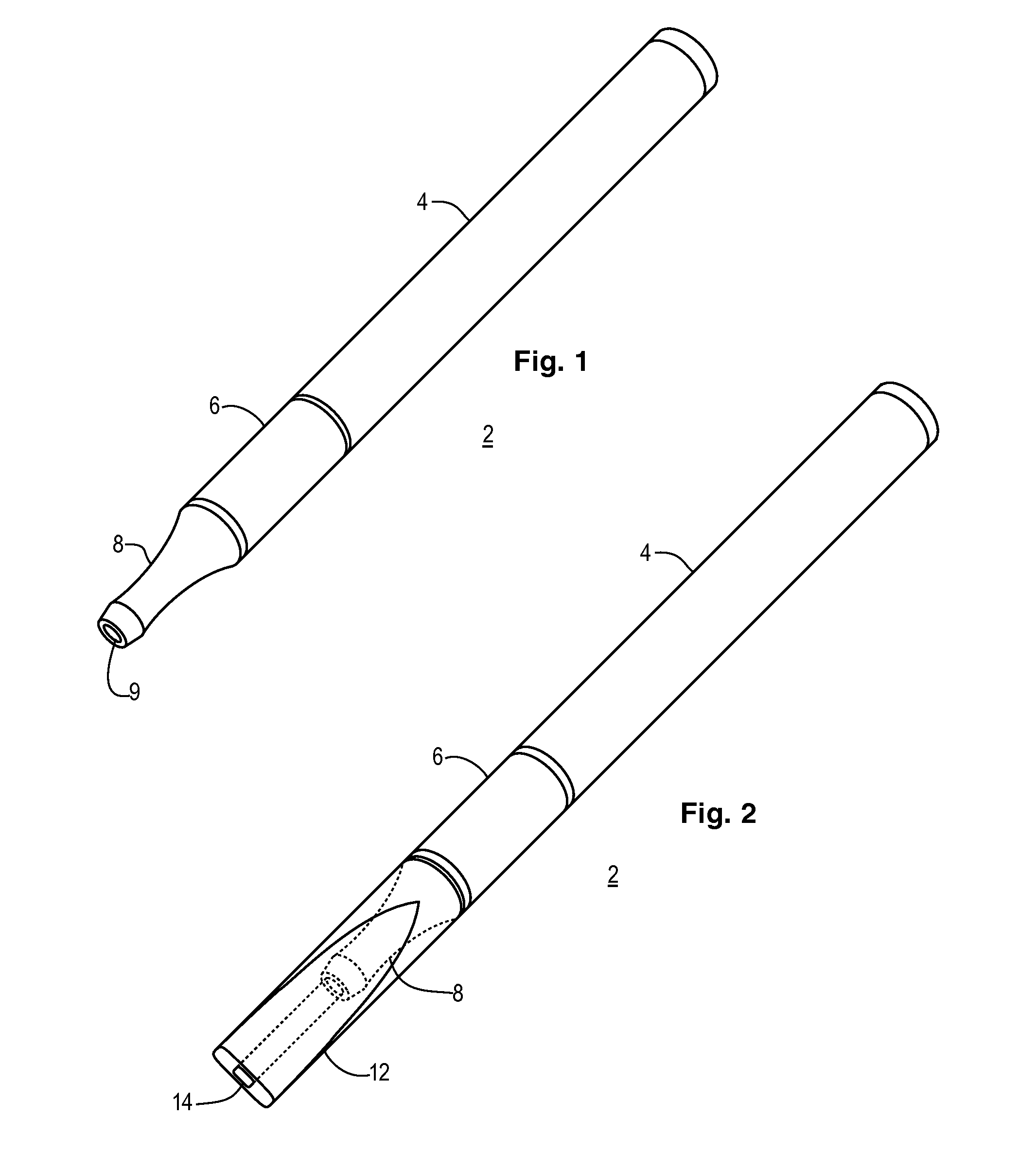

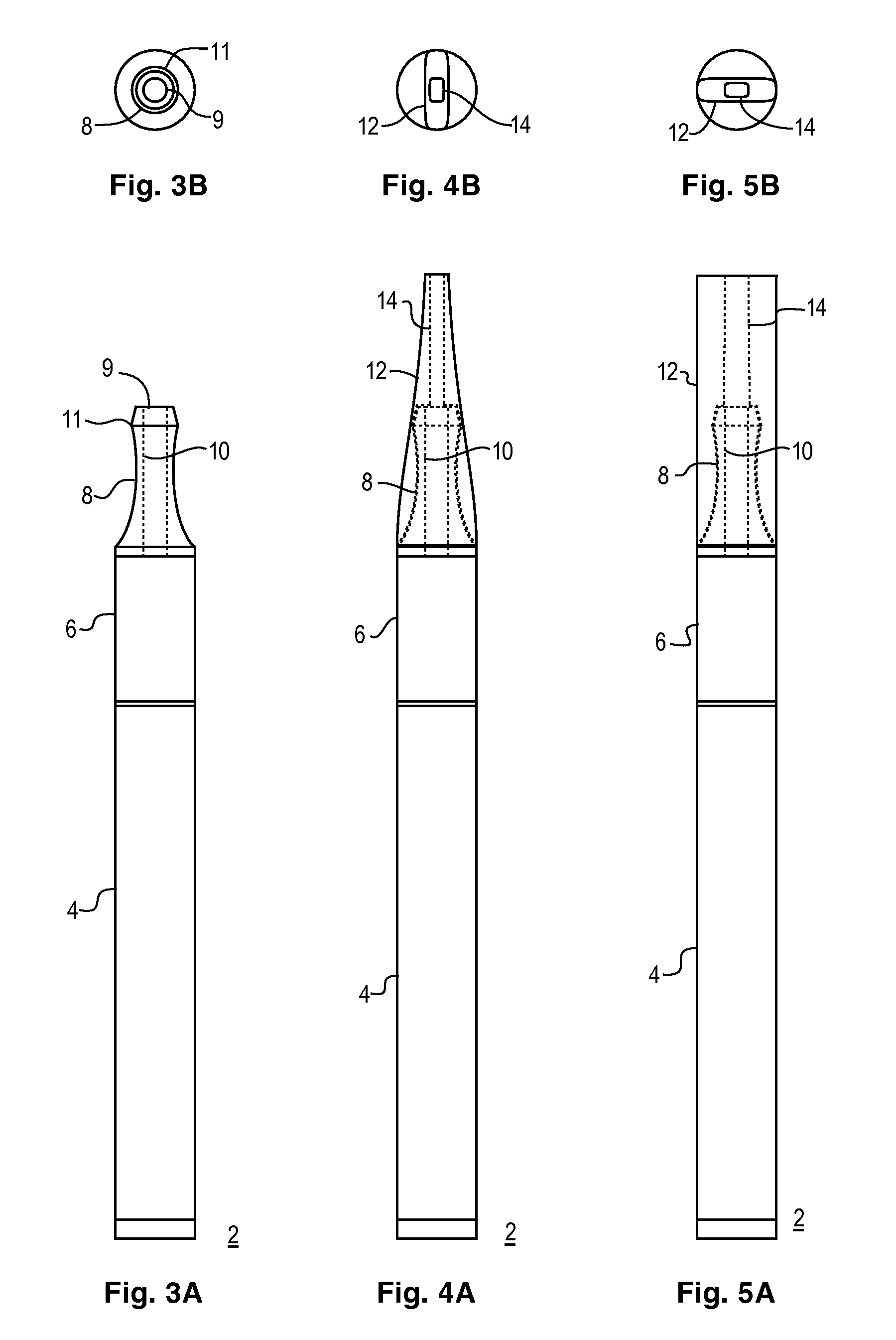

Electronic Cigarette with Replaceable Soft Tip Mouthpiece

An electronic cigarette with a selectively replaceable mouthpiece. This includes a vapor generating electronic cigarette with a rigid mouthpiece that has a vapor opening at its distal end. The rigid mouthpiece is configured with a first circumference located about its longitudinal axis, and a second circumference, which is larger than the first circumference, located distal from the first circumference. A mouthpiece cover is formed from a pliable polymeric material, and has an internal cavity that generally conform with the shape of rigid mouthpiece. The mouthpiece cover also has a vapor passage extending from the internal cavity to an outlet end, which defines a continuous passage for vapor to pass from the vapor generating electronic cigarette to the outlet end. In addition, the pliable polymeric material stretches to enable removal and replacement of the mouthpiece cover to and from the rigid mouthpiece of the electronic cigarette.

Owner:VAPETECH

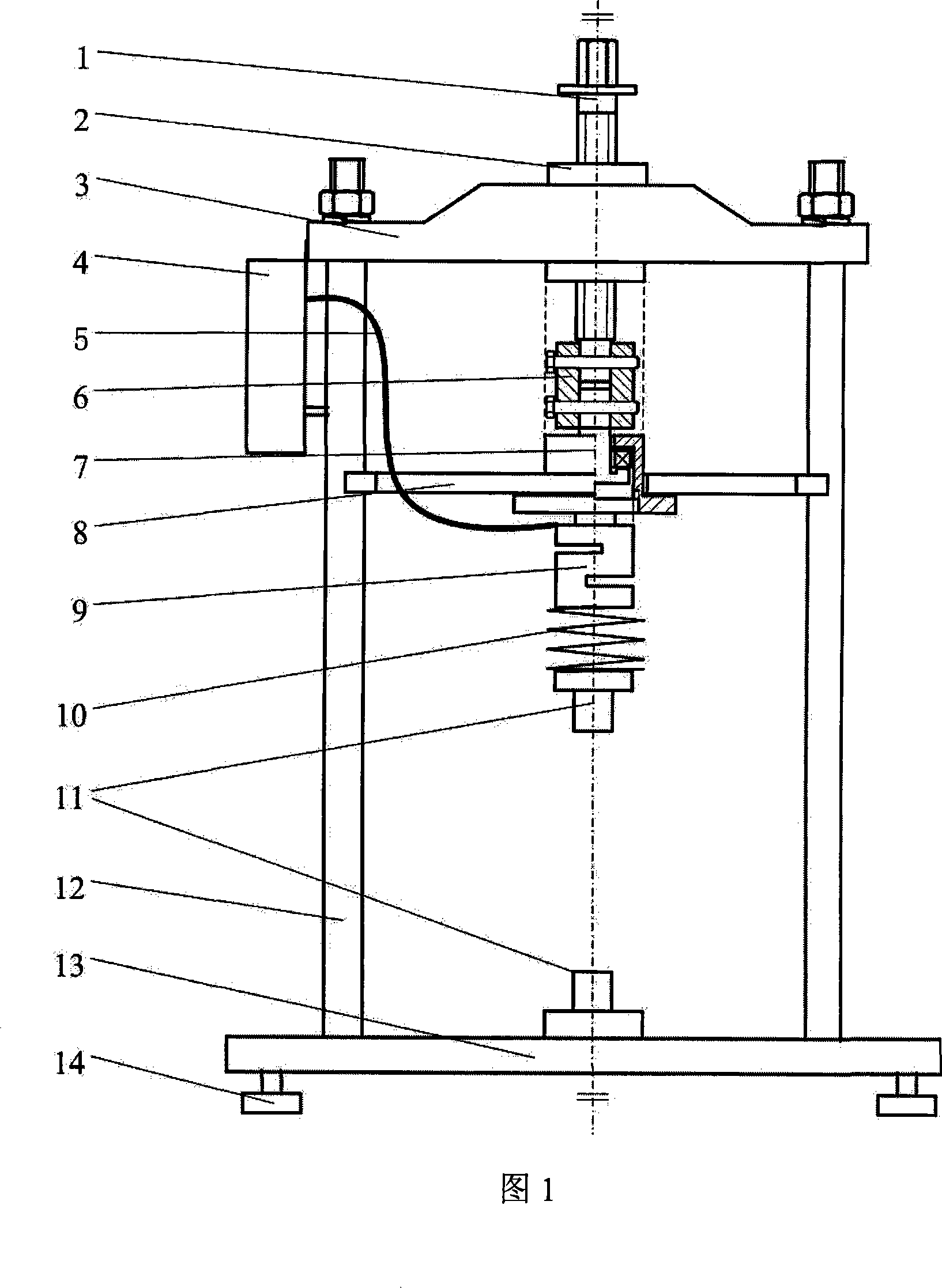

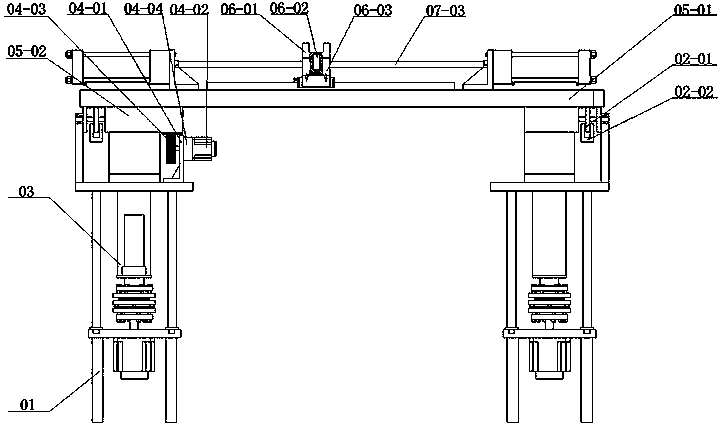

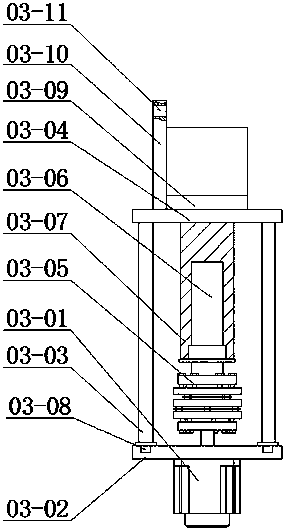

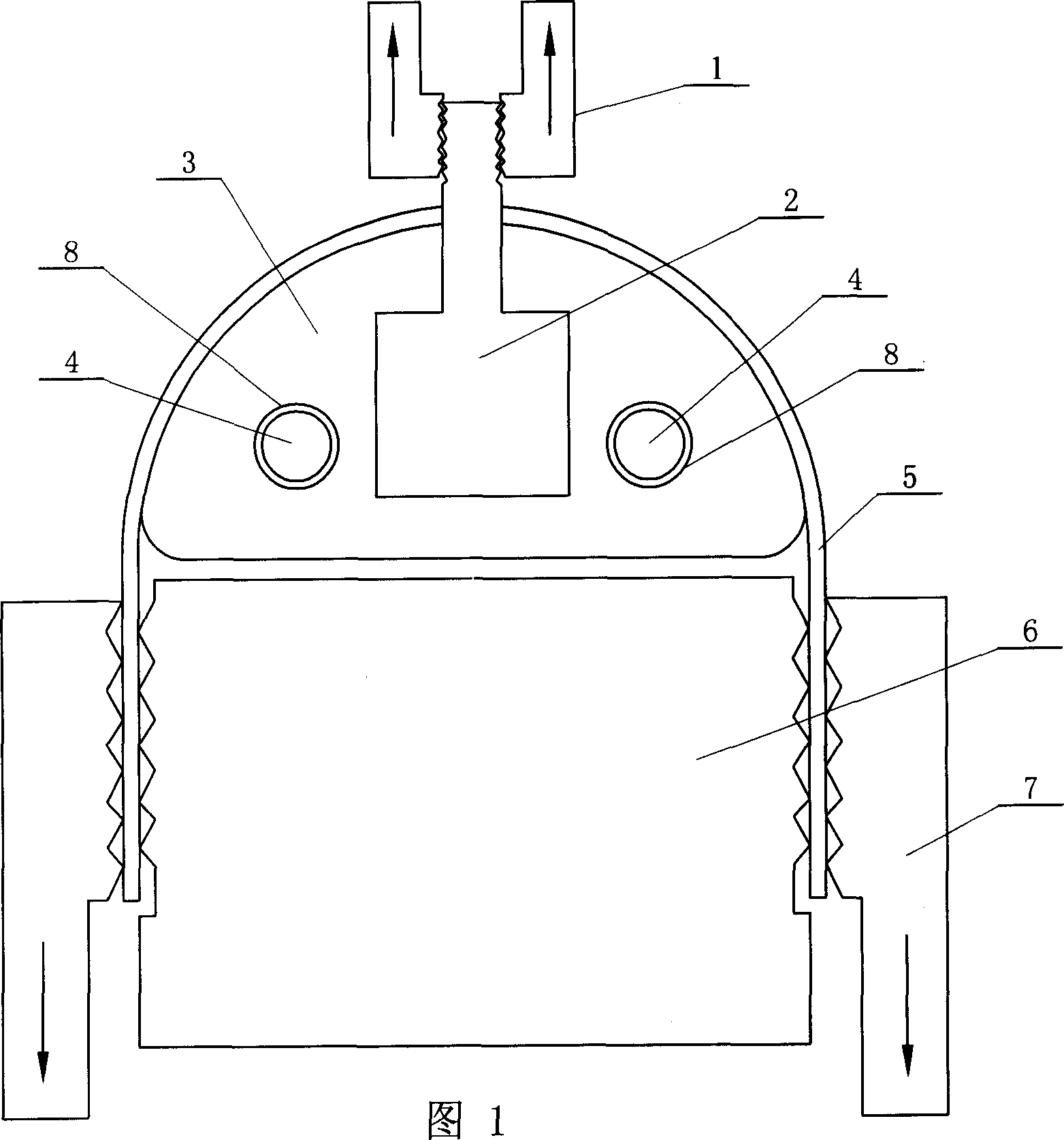

Constant Loading tension-compression test machine

InactiveCN101042322ALarge rangeSimple structureMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesTension compressionMetallic materials

This invention relates to one constant pushing test machine in metal materials stretching test technique field, which comprises machine rack, drive part and force test part, wherein, the rack is composed of socket, stand column, level beam and rack leg; the stand column is fixed onto socket with top end connected to beam to form one frame to fix drive and test parts; the drive part passes level beam fixed onto rack beam through drive screw or drive screw bar; the force test part is fixed on down end of drive part to realize puling and compressing data test.

Owner:UNIV OF SCI & TECH BEIJING

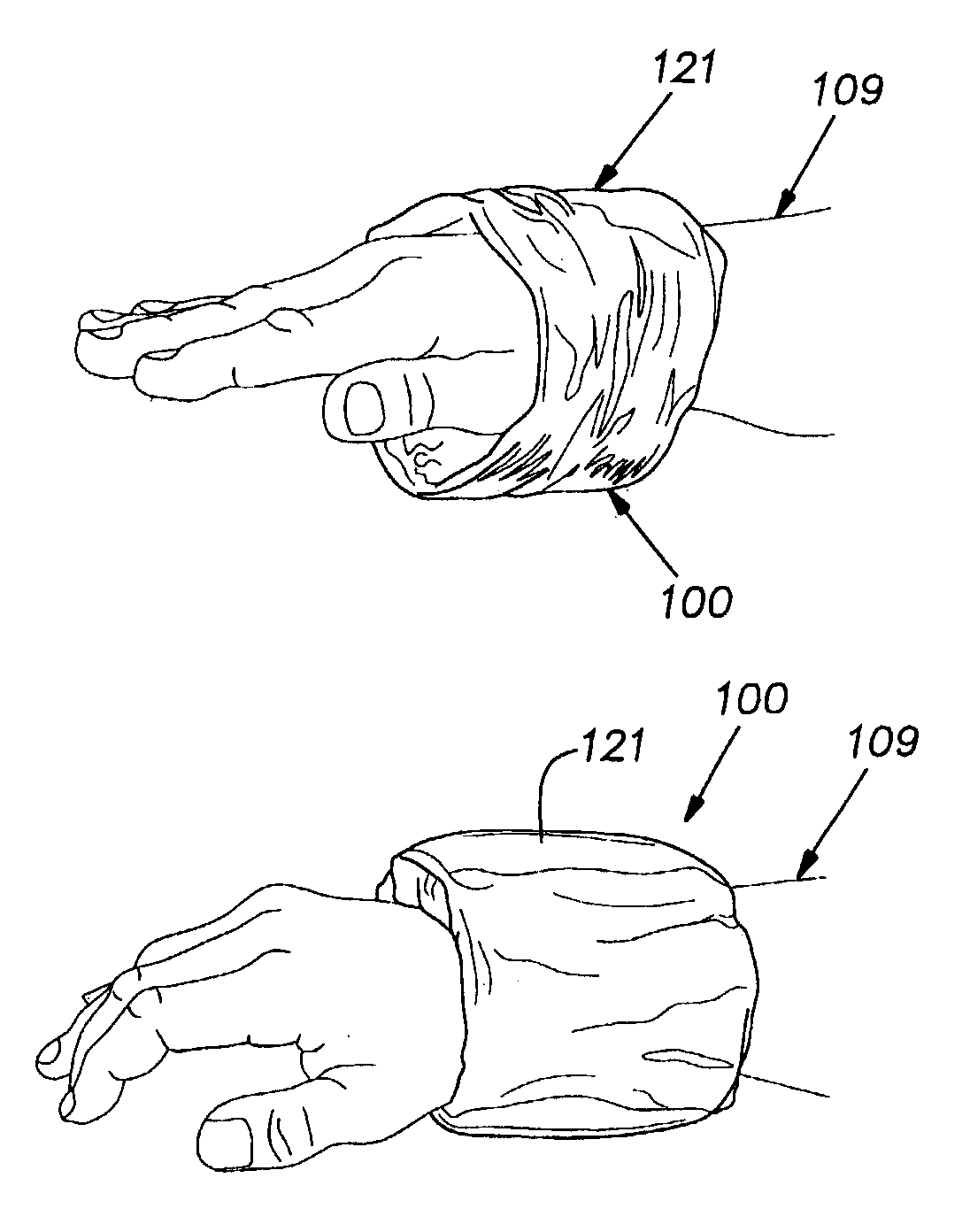

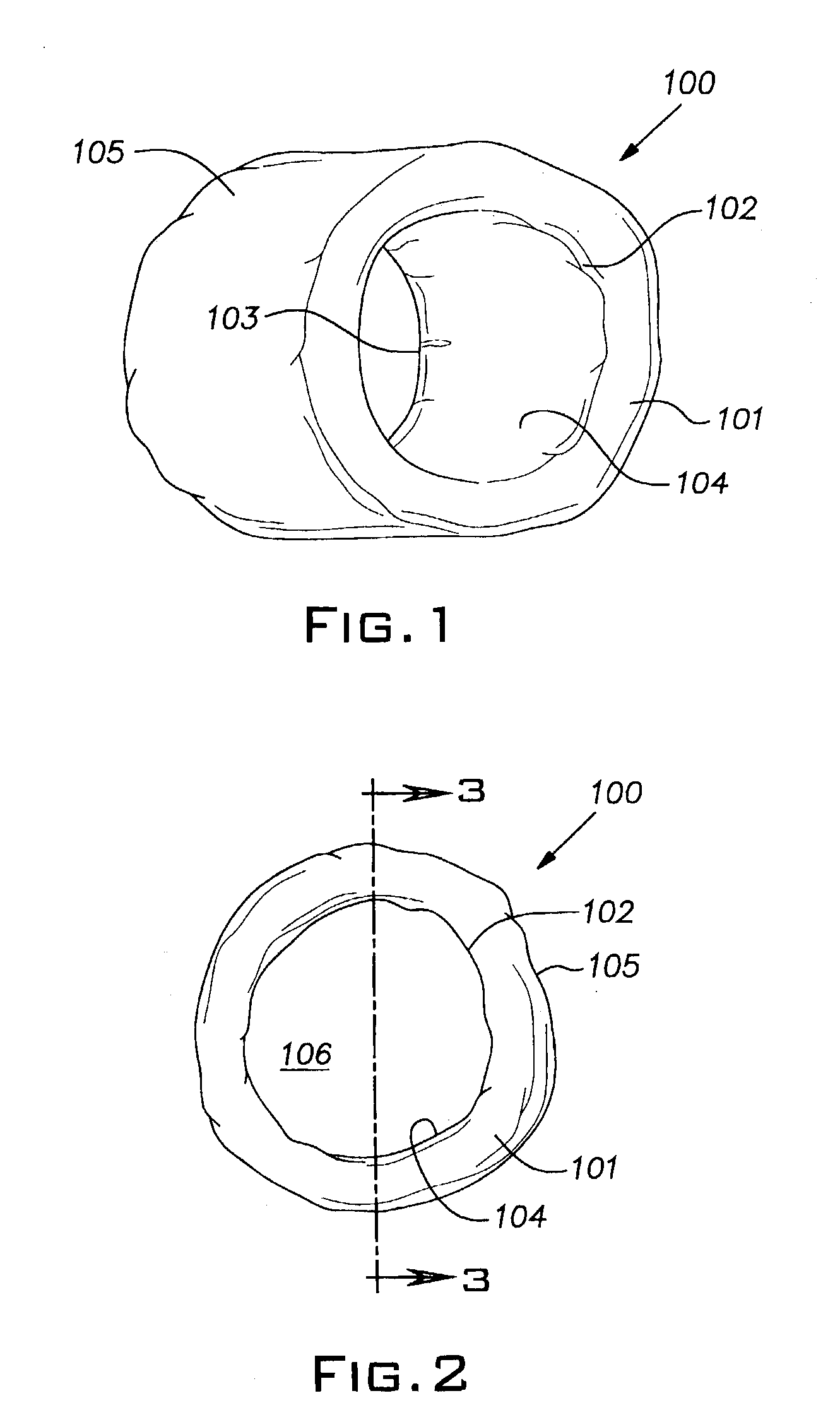

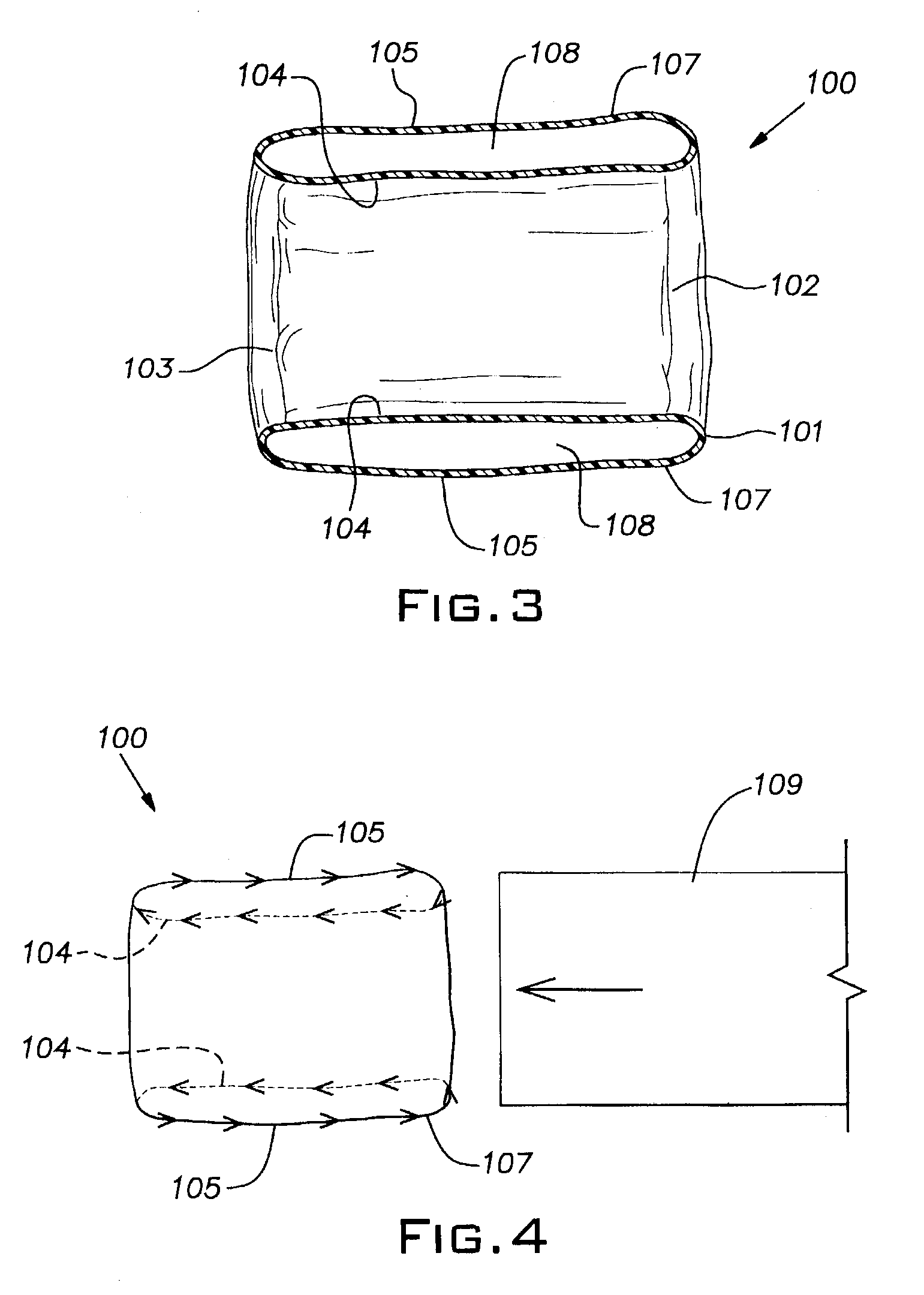

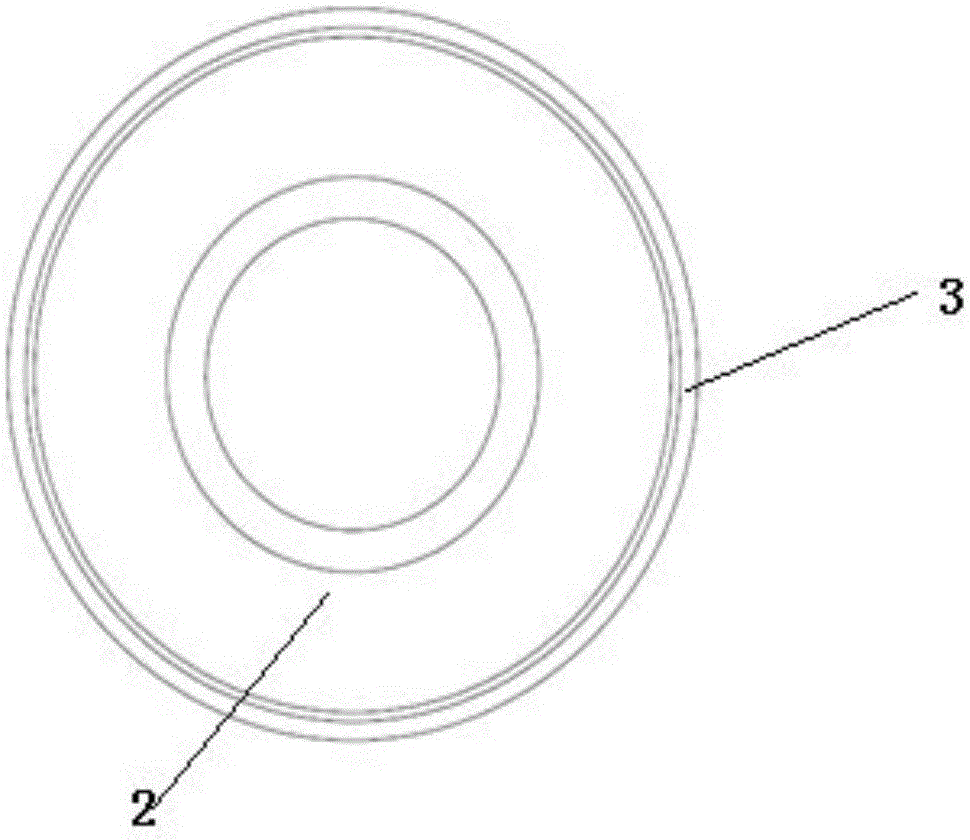

Thermal treatment pack

ActiveUS7060086B2The process is convenient and fastFeet bandagesTherapeutic coolingPolyesterWater based

The present invention provides a thermal treatment pack that includes a tubular body having a first opening, a second opening, an inner surface and an outer surface. The first opening, the inner surface and the second opening cooperate to define a passage through the tubular body for the limb. The inner surface and the outer surface of the tubular body are defined by a continuous film of flexible material such as a copolymer of polyester and polyurethane. A temperature-retaining fluid such as a water-based gel is received between the inner surface and the outer surface. Optionally, a thermal pack according to the invention can be covered with a fabric layer to provide insulation between the continuous film of flexible material and a user's skin. The diameter of the passage through the thermal treatment pack is preferably smaller than or equal to the diameter of the injured limb, which causes the inner surface of the thermal treatment pack to make contact the limb or an insulating wrap placed over the limb. The thermal treatment pack can thus be positioned at the desired location on the limb by rolling the thermal treatment pack onto the limb. During rolling, the continuous film of flexible material frictionally engages the limb and does not move relative to the limb as the thermal treatment pack is rolled onto the limb. The continuous film of flexible material stretches and conforms to the shape of the limb, providing compressive force and circumferential thermal treatment at the desired location.

Owner:MOJILITY HLDG

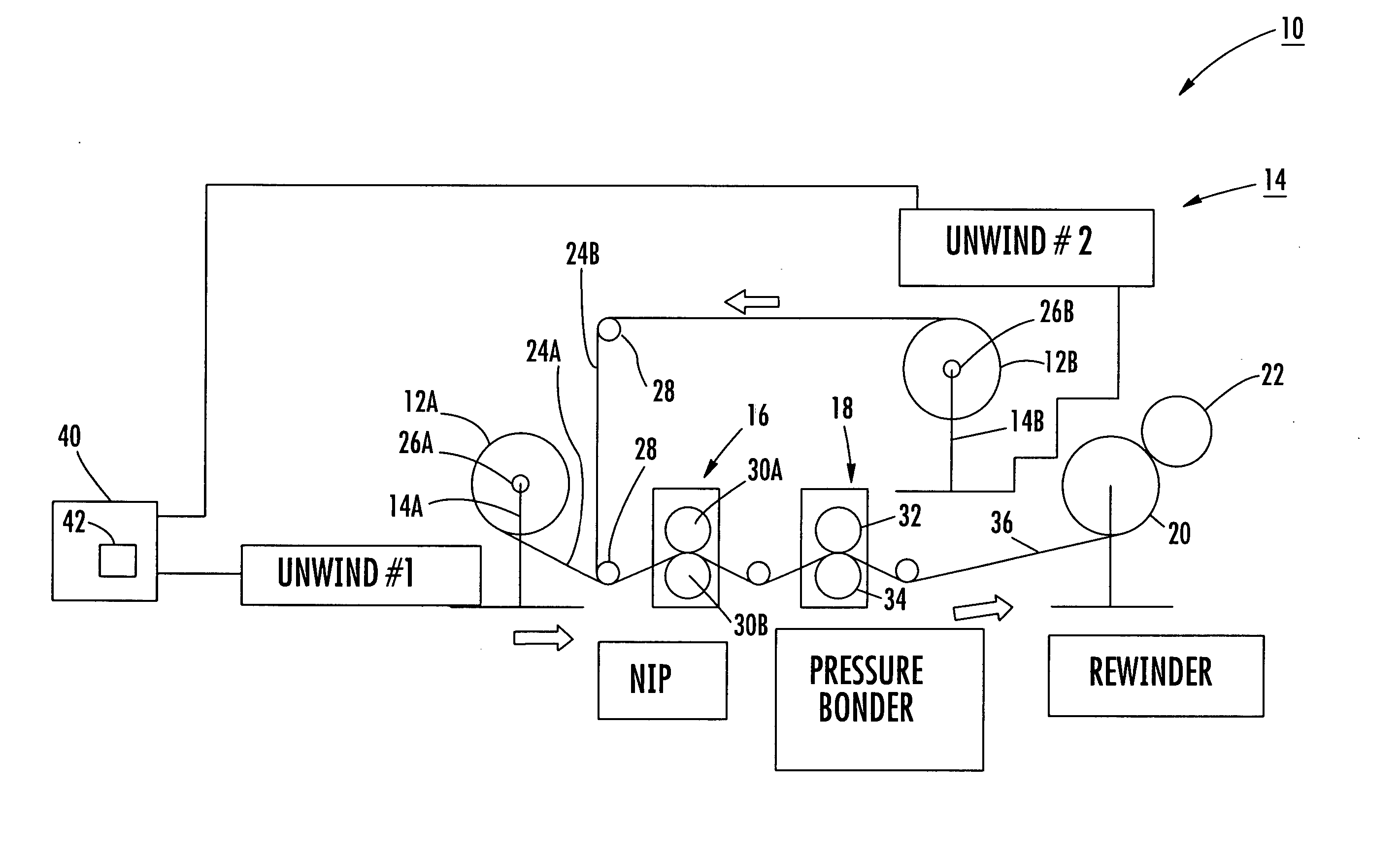

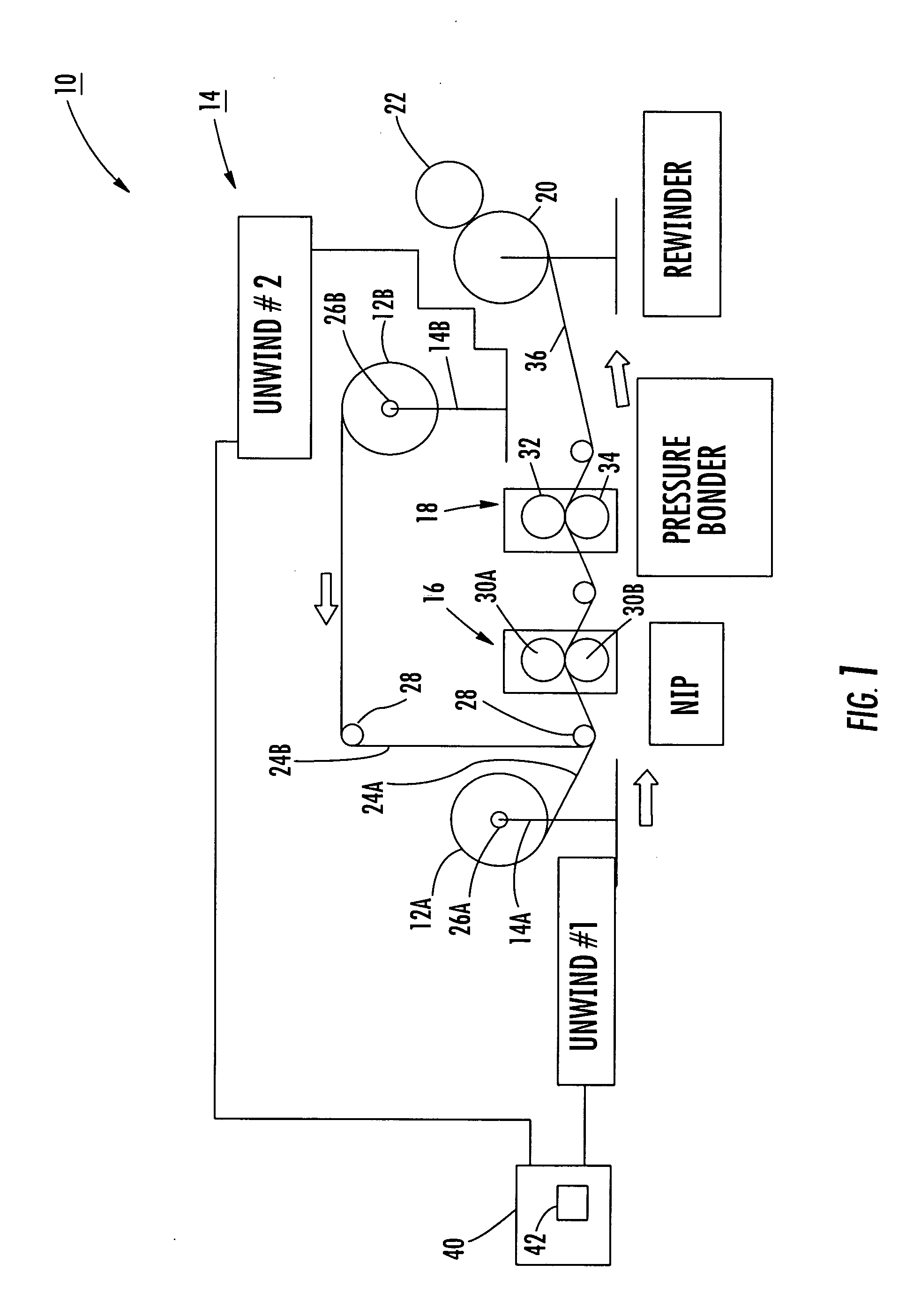

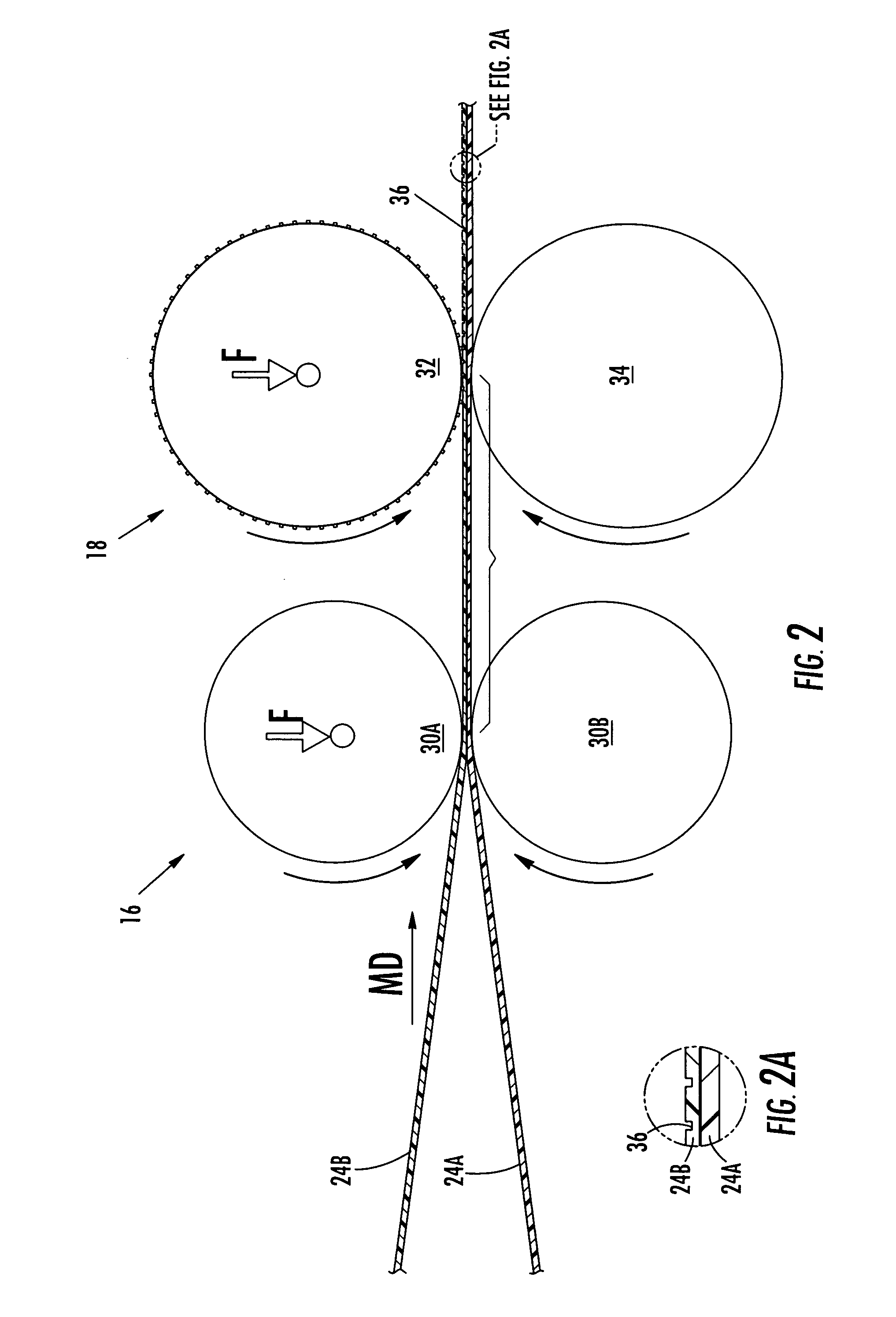

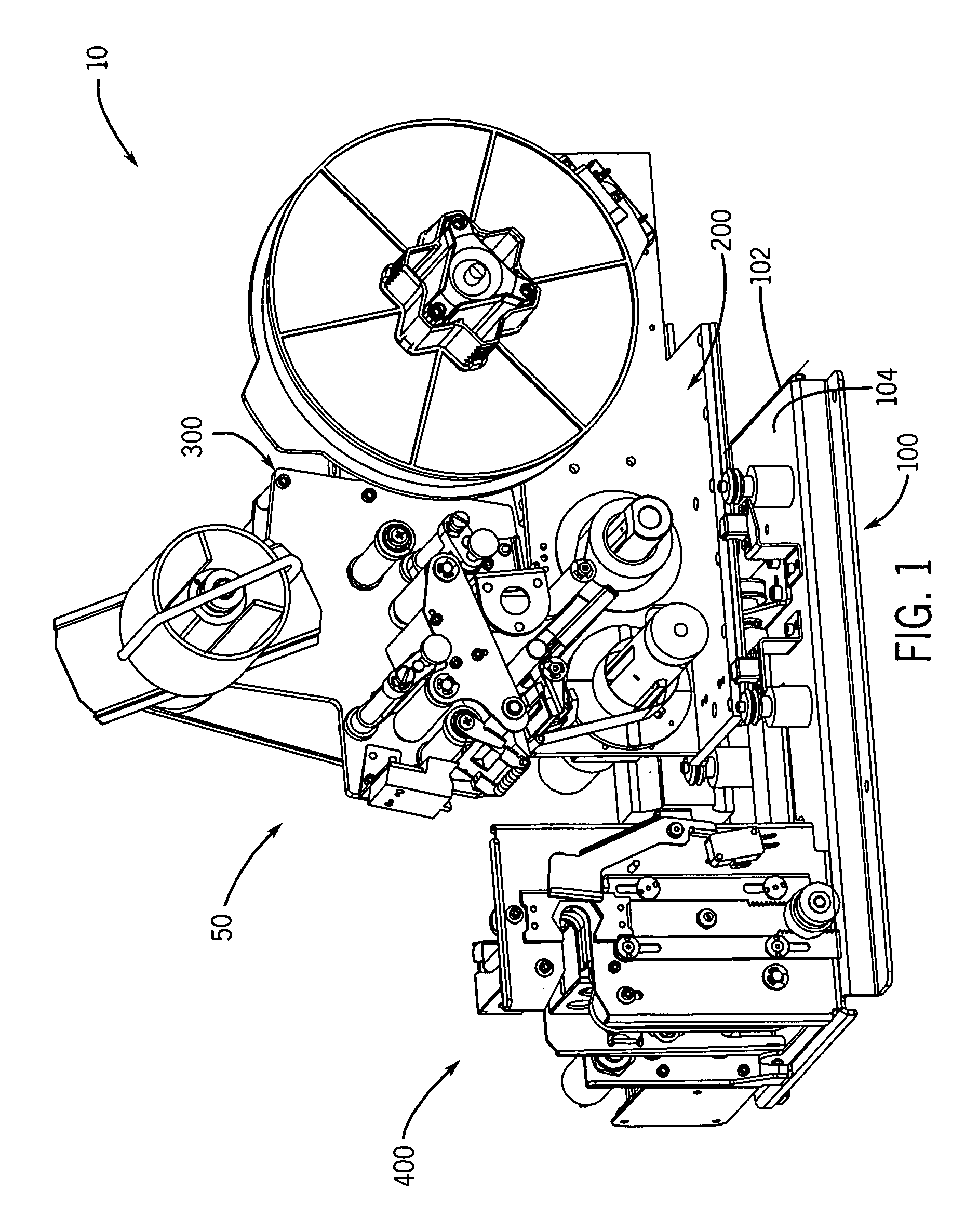

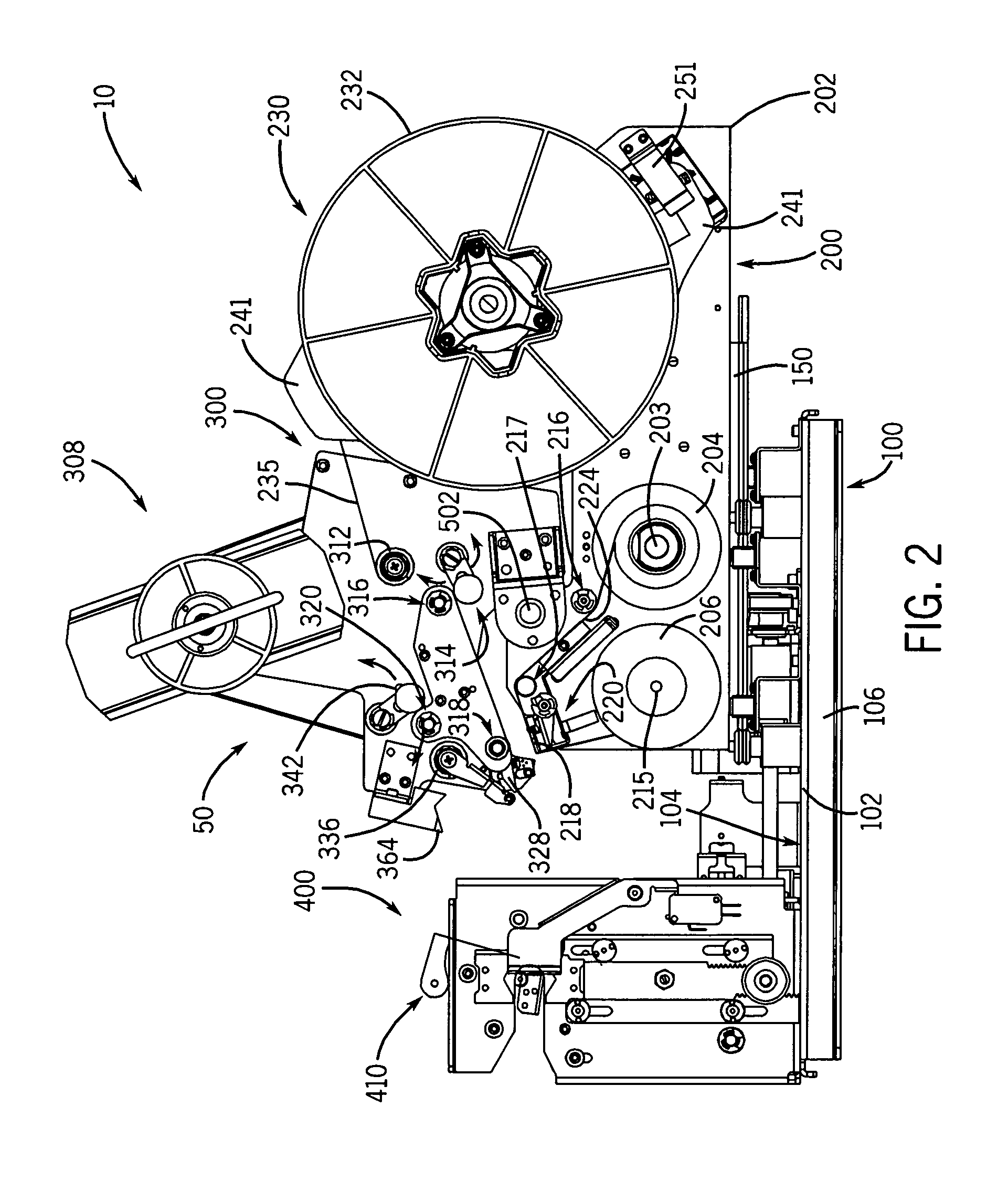

Bonding of elastomeric substrate under stretched conditions

InactiveUS20070131343A1Suitable for bondingEffective combinationAdhesive processesLamination ancillary operationsProcess systemsElastomer

A method of bonding material in a process system for producing a bonded product includes the steps of loading a plurality of rolls of elastomeric material in an unwind system; programming a controller with an unwind speed and a rewind speed, the controller in communication with the unwind system and a rewinder disposed downstream from the unwind system for respective communication of the unwind and rewind speeds to the unwind system and the rewinder; unwinding a quantity of material from the plurality of rolls of elastomeric material into a pressure bonder disposed upstream of the rewinder, the pressure bonder and the rewinder operating faster than the unwind system operating at the unwind speed to generate a speed differential, wherein the speed differential imparts a stretch state to the quantity of material; and bonding the stretched quantity of material with the pressure bonder.

Owner:KIMBERLY-CLARK WORLDWIDE INC

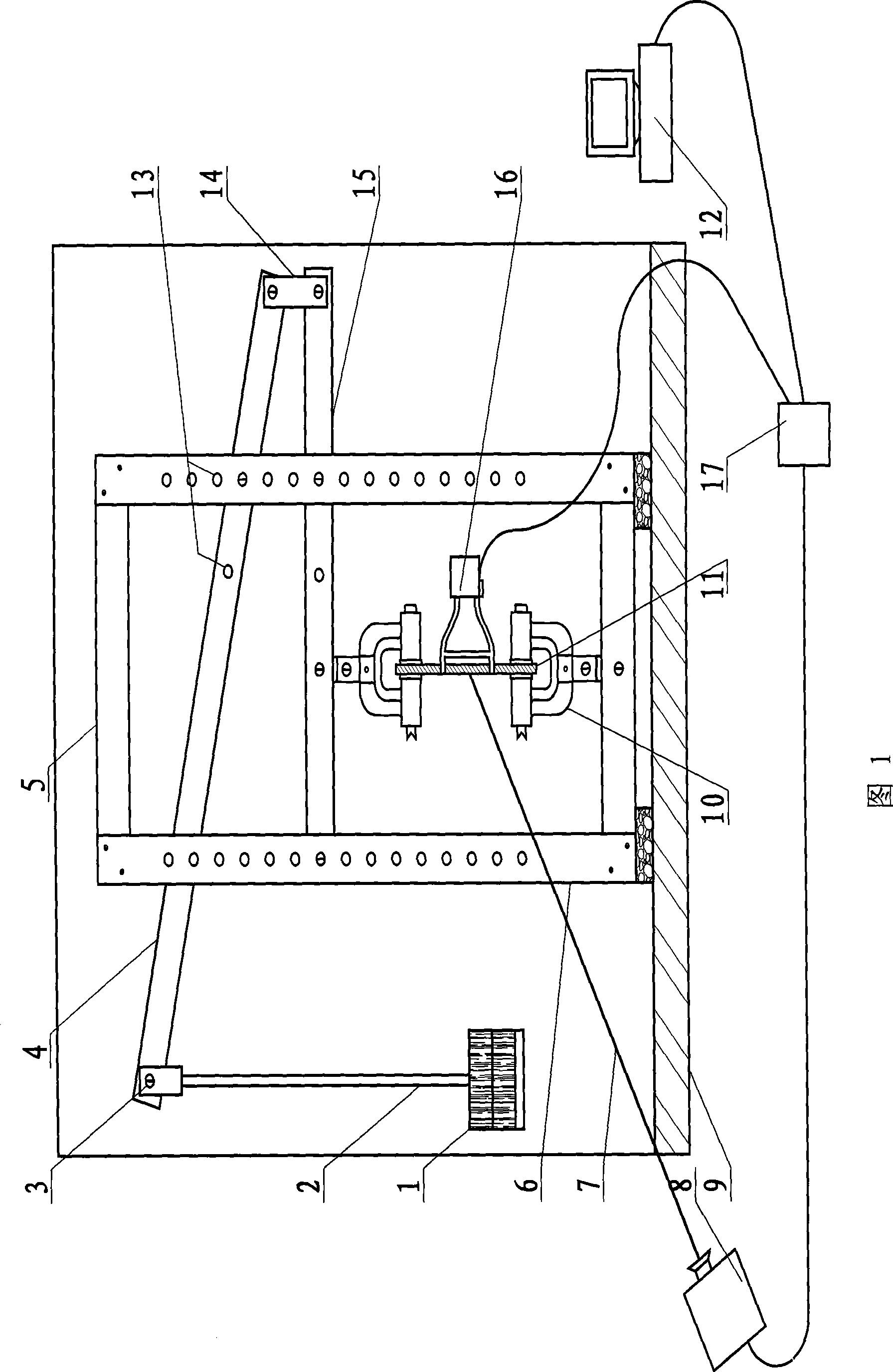

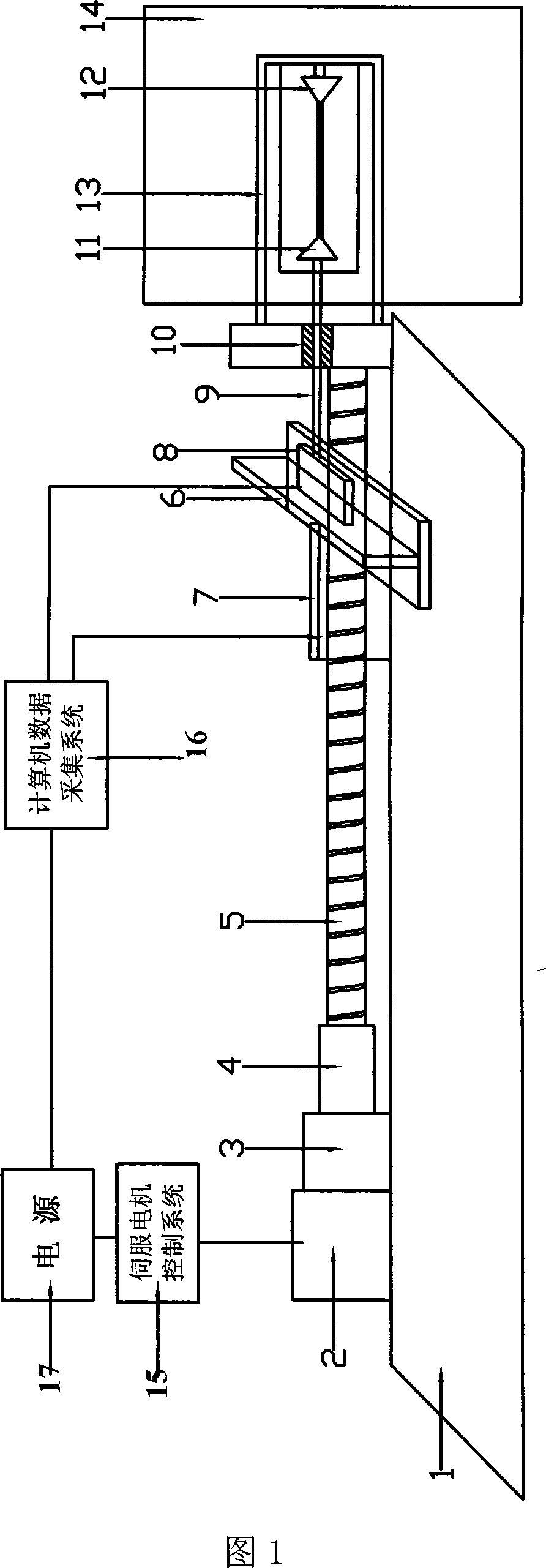

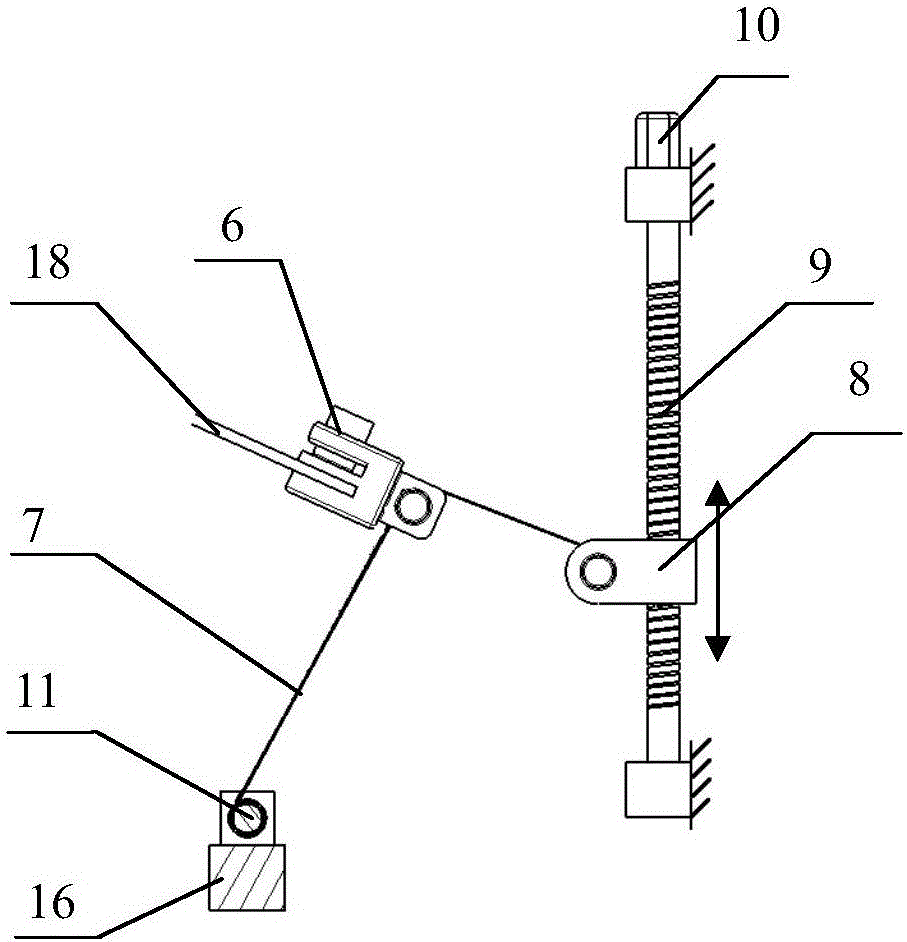

Aging test method and apparatus under wet, heat and power multiple-field coupling

InactiveCN101435811AImplement burn-in testingTest accurateWeather/light/corrosion resistanceMulti fieldData acquisition

The invention relates to an aging test method and an aging test device under the multi-field coupling of humidity, heat and force. The method is used for testing polymer materials and test specimens produced by composite materials of the polymer materials, and the test is based on the dynamic monitoring to the tensile creep compliance of the materials under the multi-field coupling of the humidity, the heat and the force. The device is based on a standard humid and hot environmental box controlled by a microcomputer, a test specimen clamping and loading mechanism is arranged in a box of the device, and an electronic extensometer and a laser extensometer are arranged to form a double displacement sensor and are connected to the microcomputer through an acquisition device after the data acquisition. The method and the device have the advantages of accurate and convenient test and low cost, and are suitable for the research of viscous-elastic mechanical properties and aging performances under the operation of polymers and composite materials of the polymers.

Owner:SHANGHAI UNIV

Absorbent article with a multifunctional side panel

An absorbent article may comprise a chassis having a front waist region, a rear waist region, a crotch region between the front waist region and the rear waist region, a pair of longitudinal edges, and a pair of side panels extending between and connecting the front waist region and the rear waist region to form a leg opening. Each side panel may comprise a uniformly colored stretch laminate. The stretch laminate may comprise a colored elastomeric member and a first substrate joined to the elastomeric material. The side panels may be joined by a mechanical bond which may form an informational indicia.

Owner:PROCTER & GAMBLE CO

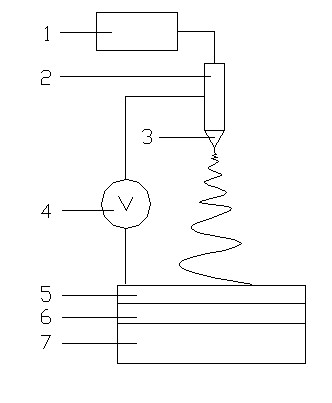

Metal wire material stretching mechanical property testing device

ActiveCN101196450ASimple structureEasy to operateInvestigating material ductilityTest fixtureMechanical property

The invention relates to a metal wire material drawing force performance testing device for testing the drawing force performance of metal wire material, which utilizes measuring the drawing deformation displacement of the metal wire material and the drawing force loaded on the metal wire material, according to the length and diameter of the metal wire material, counts the strain and stress of engineering, and obtains the drawing force performance of the metal wire material according to the gotten engineering stress-strain curve under different temperature. The invention also provides a device used for testing the drawing force of the metal wire material. The device has simple structure, small volume, light weight and low cost, which makes the combining testing accuracy of the method and the device in the invention high. The measured data is reliable and the operation is simple.

Owner:GRIMAT ENG INST CO LTD

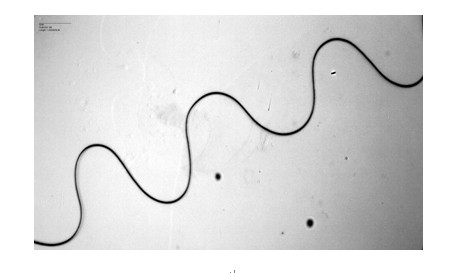

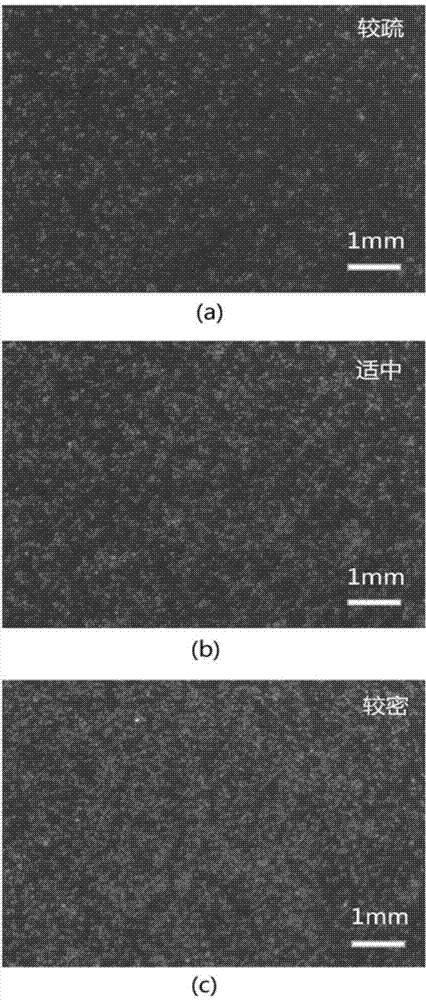

Micro-nano corrugated structure and preparation method thereof, and device and application of preparation method

InactiveCN102162176AGood repeatabilityImprove controllabilitySpinnerette packsFilament/thread formingFiberMicro nano

The invention discloses a preparation method of a micro-nano corrugated structure. The preparation method comprises the following steps of: (1) adding electrostatic spinning macromolecular solution into a syringe of a syringe pump, and fully filling the solution into a metal nozzle connected with the anode of a high pressure generator; (2) placing a metal cathode collecting plate connected with the ground electrode of the high pressure generator below the metal nozzle of the syringe, placing a flexible base material on the collecting plate, controlling the macromolecular solution to flow out at certain velocity, and electrifying the macromolecular solution to form jet flow; and (3) moving the metal collecting plate so that the jet flow falls on the flexible base material, namely the corrugated structure is formed on the whole base material. The invention also discloses the micro-nano corrugated structure prepared by using the method, a device for implementing the method and application of the method. When the elastic rubber base material stretches, the formed nano fiber graph can produce great deformation together with the elastic rubber base material and does not break, so that effective interconnection and stretching of flexible electrons are realized, and the invention has broad application prospect on the aspects of electronic skin, artificial muscles, bioelectronics and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

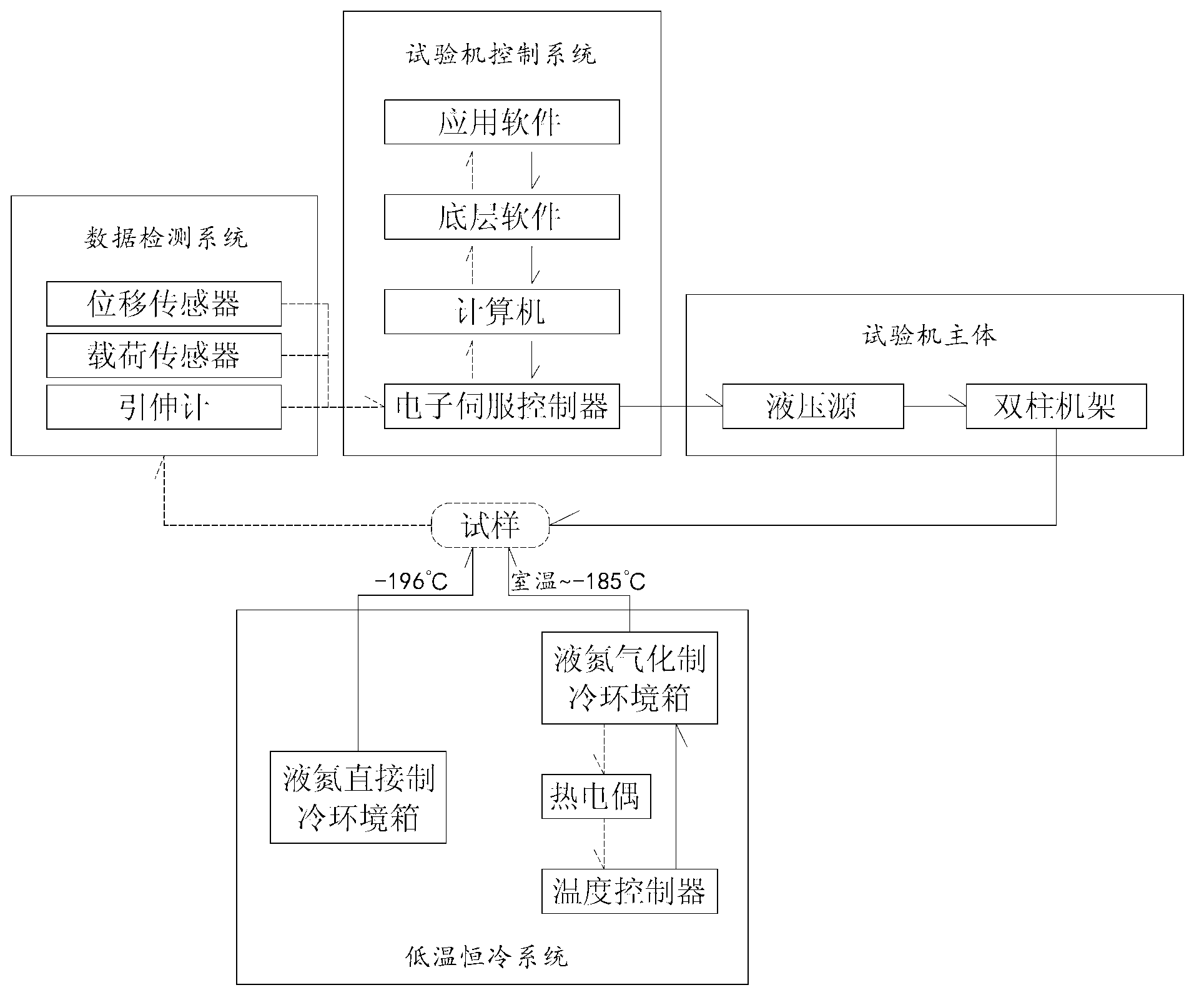

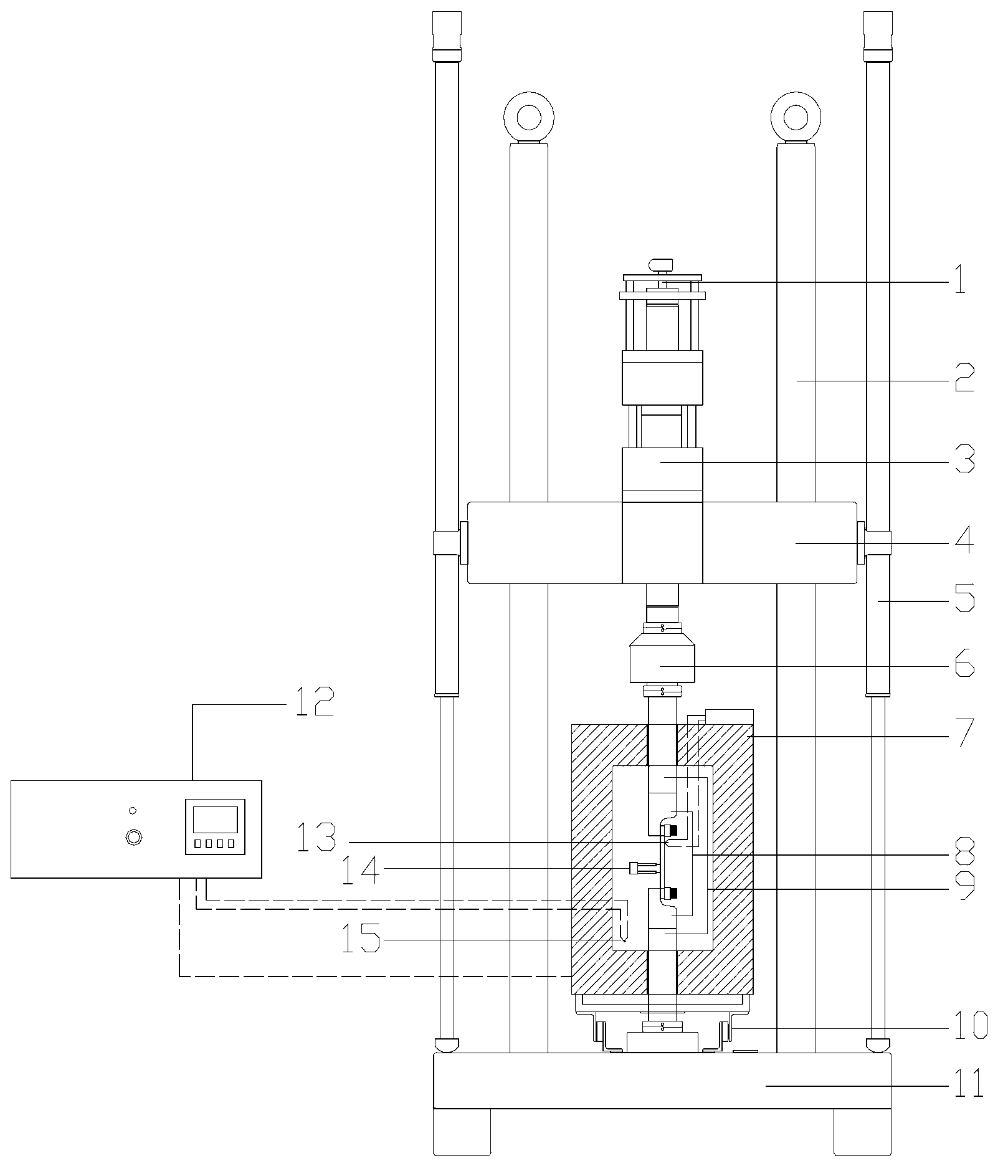

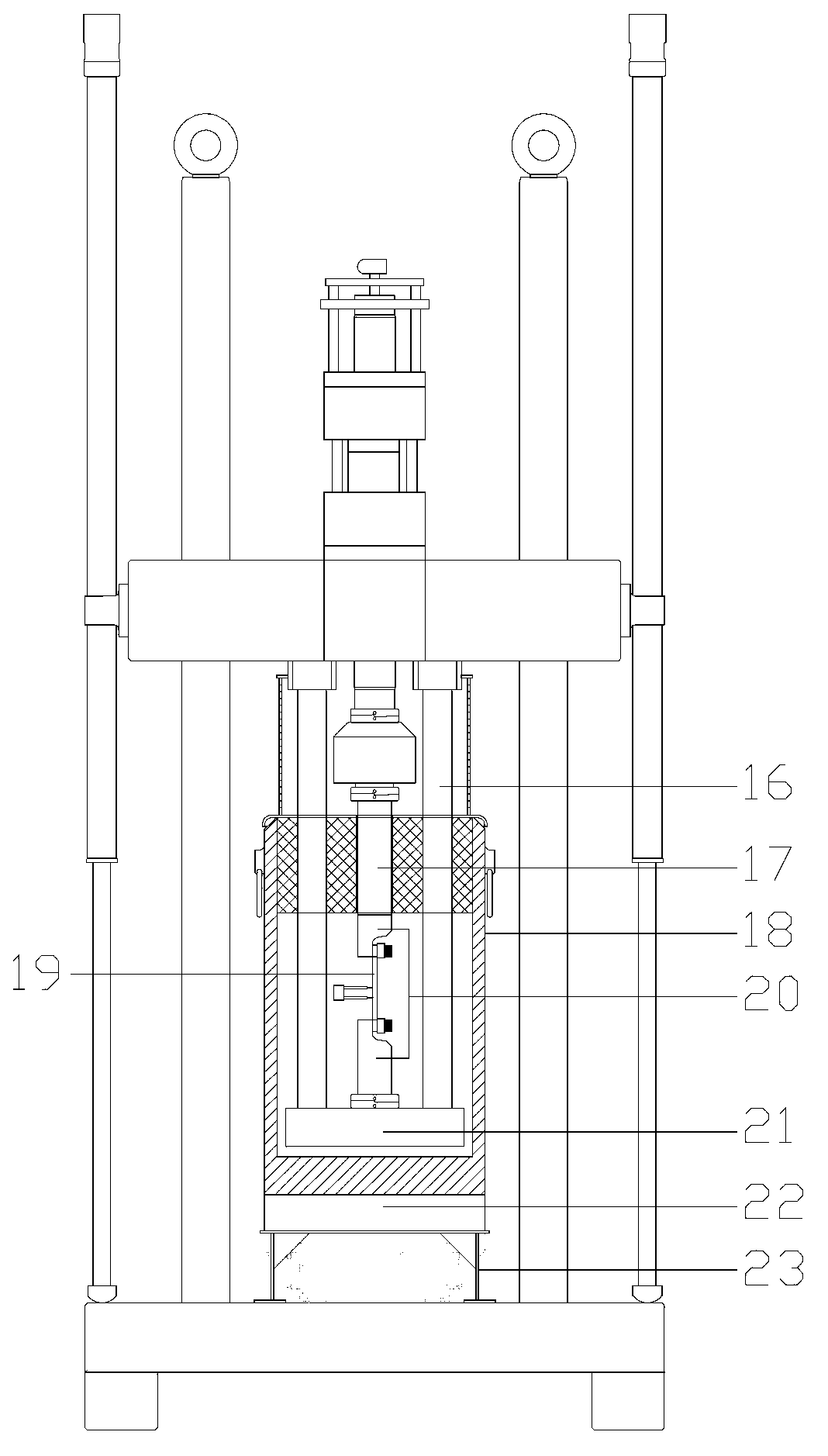

Cryogenic environment material mechanical performance detection test device

ActiveCN102798573AEasy to switchLarge test temperature rangeMaterial strength using tensile/compressive forcesMachine controlControl system

Relating to the field of material mechanical performance testing, the invention aims to provide a cryogenic environment material mechanical performance detection test device. The device comprises a testing machine control system, a data detection system, a low temperature and constant temperature system, and a testing machine main body. The testing machine control system includes an electronic servo controller connected to a computer. The testing machine main body consists of a hydraulic source and a double-column rack. There exist two sets of mutually switchable low temperature and constant temperature systems, i.e. a liquid nitrogen gasification refrigeration system and a liquid nitrogen direct refrigeration system. With the device, material stretching and fatigue tests under a temperature ranging from normal temperature to minus 185DEG C can be realized. Switching between the two modes of liquid nitrogen gasification refrigeration and liquid nitrogen direct refrigeration can be realized conveniently. And the device has the advantages of large test temperature range and high detection accuracy, etc.

Owner:ZHEJIANG UNIV

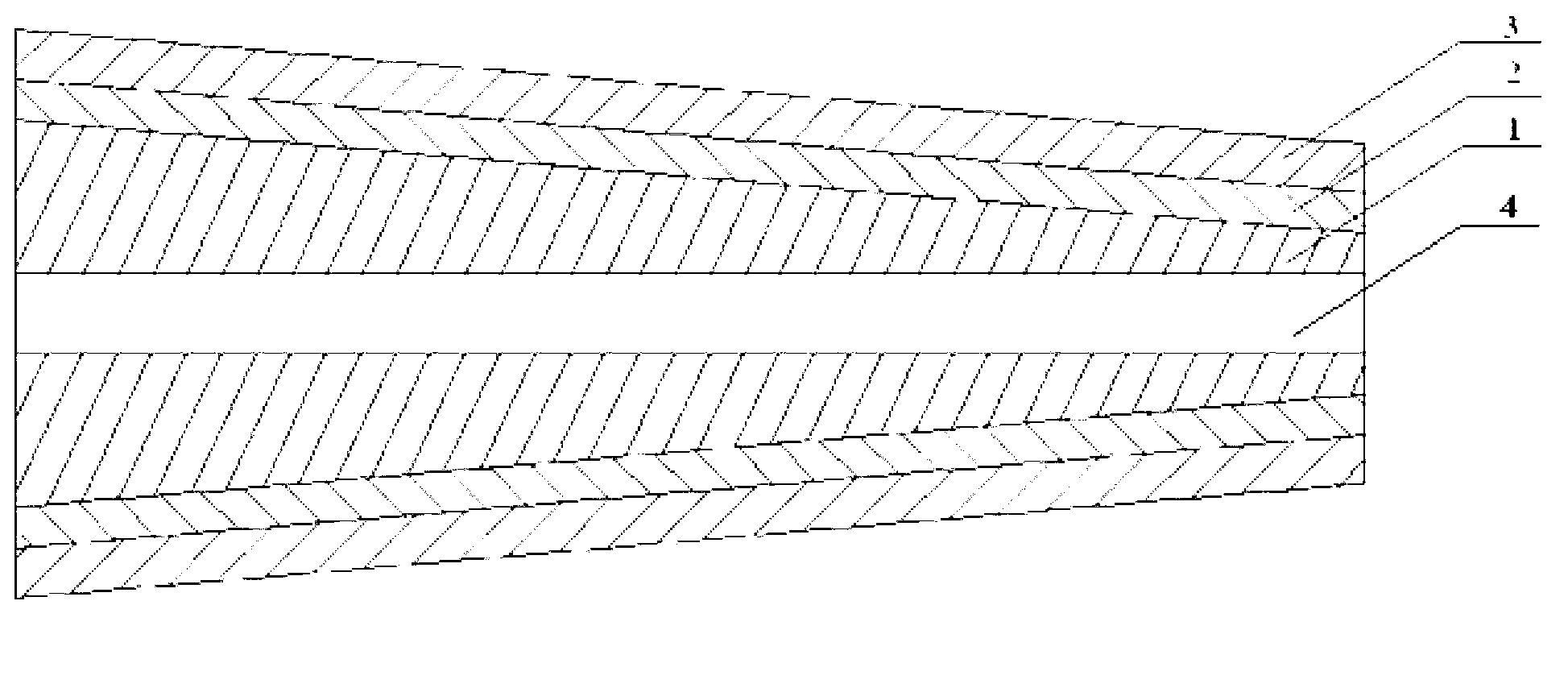

Tapered tube made of glass fiber and carbon fiber hybrid composite materials and method for manufacturing tapered tube

InactiveCN103061565AHas a transparent electromagnetic signalMake up insulationSynthetic resin layered productsLaminationGlass fiberReinforced concrete

The invention discloses a tapered tube made of glass fiber and carbon fiber hybrid composite materials and a method for manufacturing the tapered tube, and relates to tapered tubes made of glass fiber and carbon fiber hybrid composite materials and methods for manufacturing the tapered tubes. The tapered tube and the method aim to solve problems of excessively heavy structure weights and electromagnetic wave reflection of existing metal, cement or reinforced concrete wire poles, low tensile modulus of single glass fiber composite materials and high prices of single carbon fiber composite materials. The tapered tube is of a three-layer composite structure, an internal through hole of the tapered tube is cylindrical, an inner layer and an outer layer of the tapered tube are glass fiber layers, a middle layer of the tapered tube is a carbon fiber layer, wires are wound in a variable-length and variable-winding-angle manner to form the inner layer, and wires are wound in a full-length and single-winding-angle manner to form the inner layer and the outer layer respectively. The tensile modulus of the obtained tapered tube made of the glass fiber and carbon fiber hybrid composite materials ranges from 16.5GPa to 17.5GPa and is increased by 32-40% as compared with that of a single glass fiber composite material, a forming process is simple and is easy to operate, and the tapered tube and the method are applied to the field of wire poles and lamp poles.

Owner:HARBIN INST OF TECH

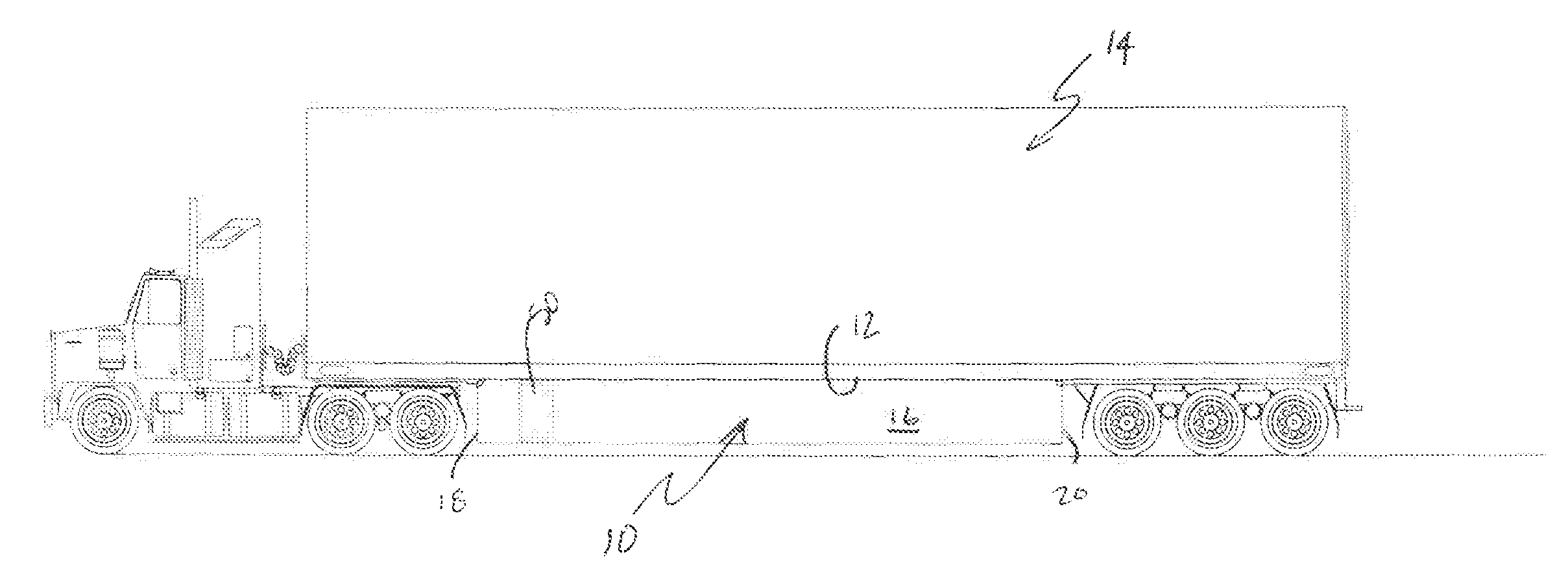

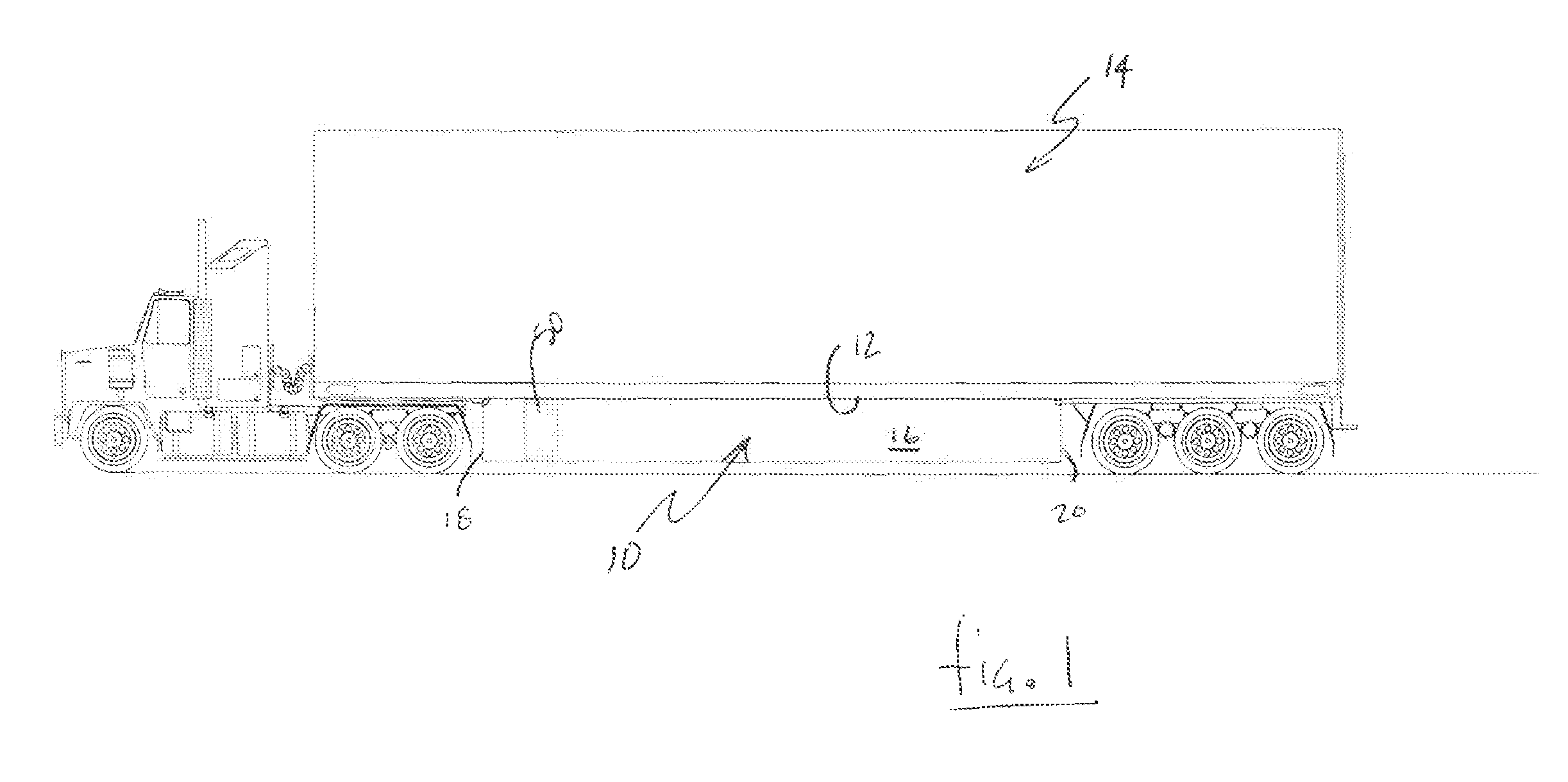

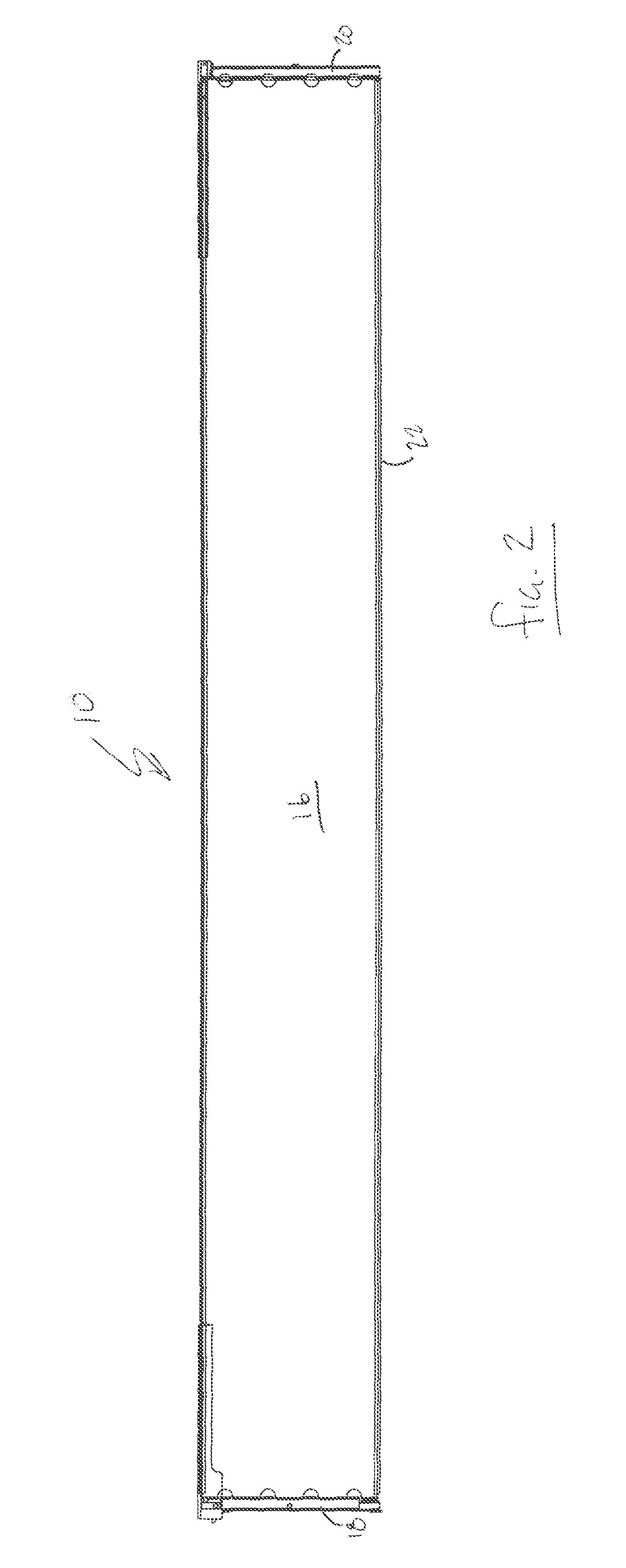

Aerodynamic skirts for truck trailers

InactiveUS20110233960A1Improve fuel efficiencyImprove driving safetyVehicle seatsWindowsTruck-trailerFuel efficiency

A skirt or fairing system is provided that is attachable to a lower, longitudinal edge of a trailer, such as a commercial freight trailer, in a manner that alters the airflow beneath and around the trailer to produce increased fuel efficiency and greater driving safety. The skirt fairing is formed from a deformable skin material stretched tautly over a deflectable frame is provided that is attachable to the lower edge of a trailer. The installation of the skirt fairing deflects and alters the airflow beneath the trailer by creating smooth and cohesive airflow along the side and underneath the trailer of a tractor trailer rig in a manner that improves safety and decreases fuel consumption. Further, the fairing is formed using a deformable skin and deflectable frame that prevents damage or permanent displacement of the fairing should it impact an obstruction.

Owner:HEINZ RICHARD

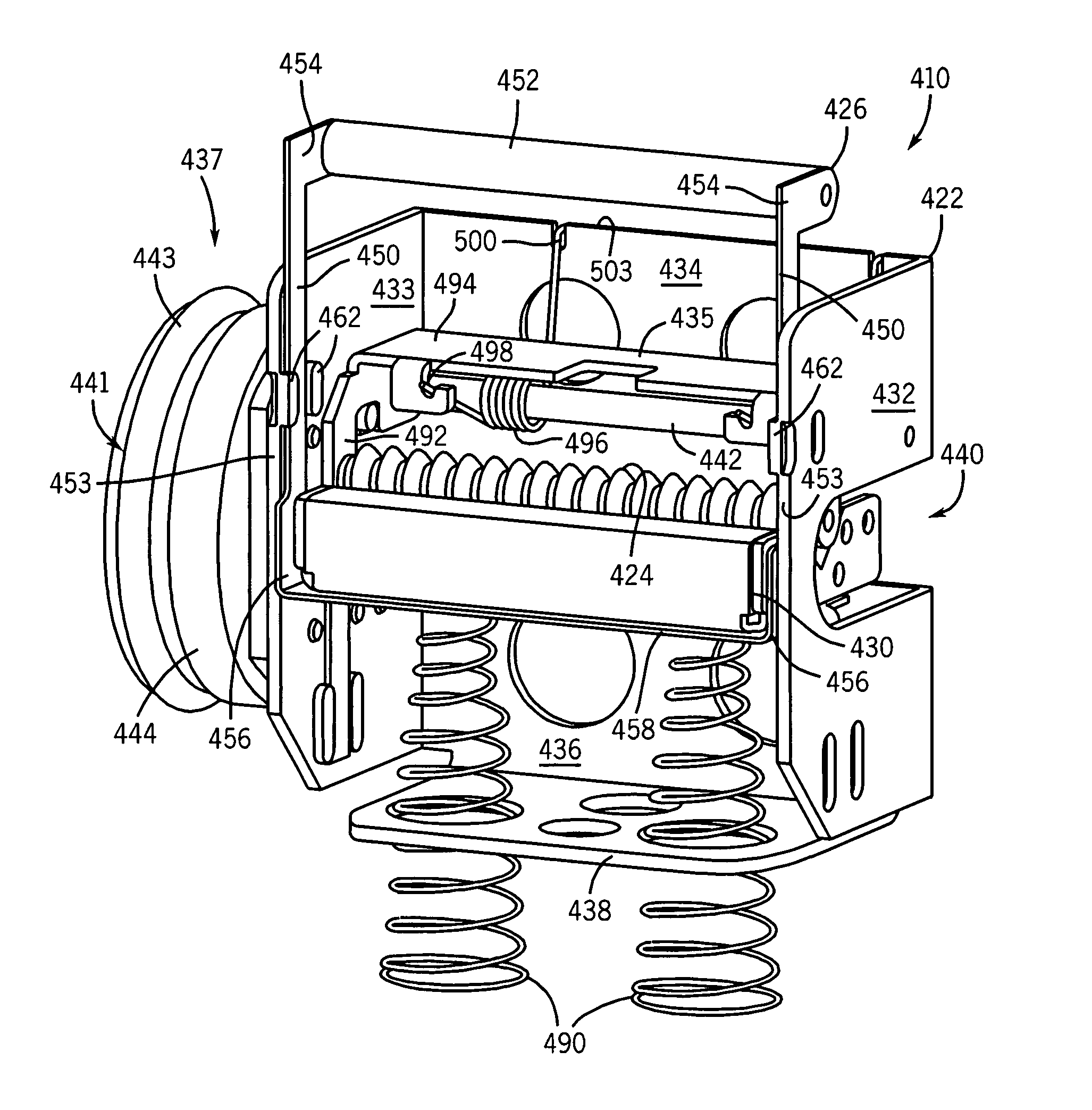

Label wrapper block assembly

ActiveUS7178572B2Mechanical working/deformationWrapper folding/bending apparatusEngineeringMechanical engineering

A label wrapper block assembly for mounting in a rotatably mounted wrapper frame in a label wrapper assembly includes a base having opposing ends joined by a top surface and a bottom surface. A channel extends between the ends in the top surface for receiving an object being wrapped by the label wrapper assembly. At least one biasing member is extendible into the channel for urging the label against the object received in the channel. In one embodiment, the at least one biasing member is a flexible material stretched across the base top surface.

Owner:BRADY WORLDWIDE INC

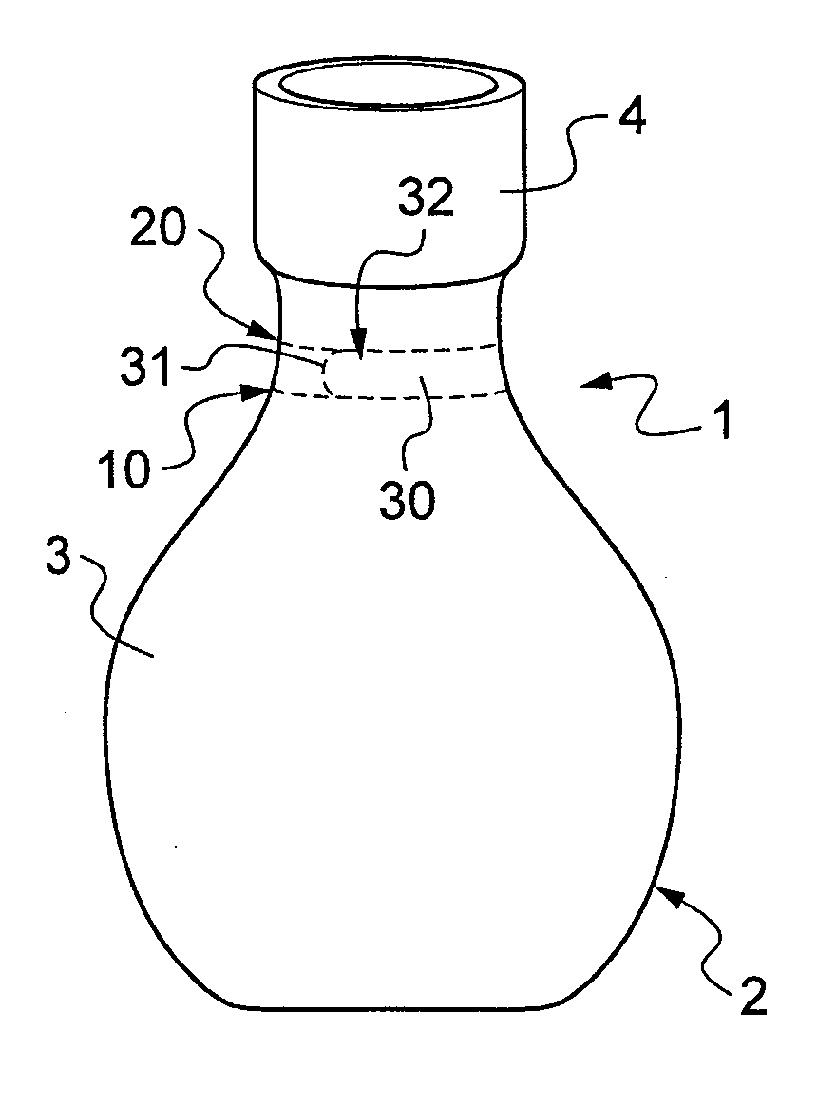

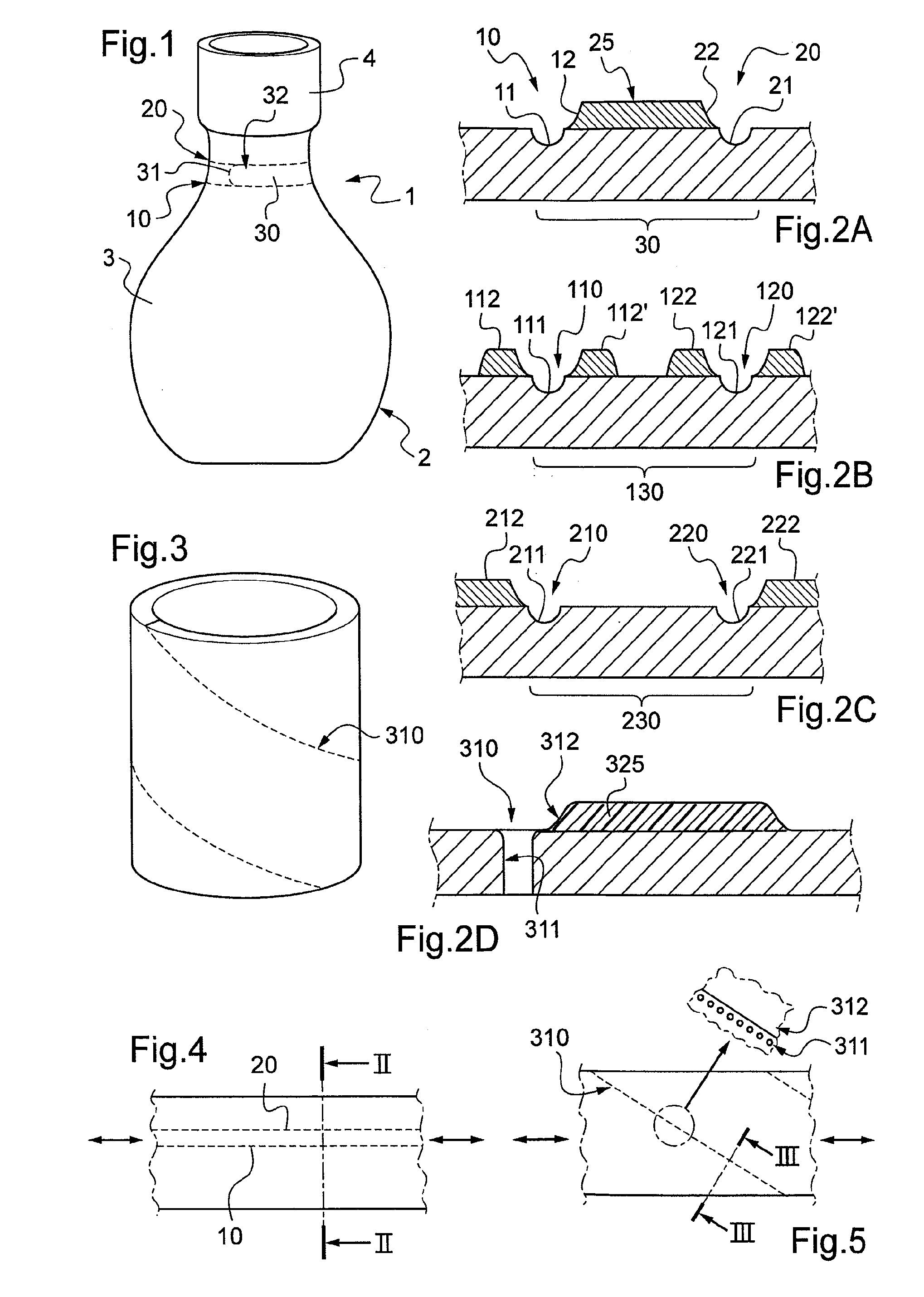

Film of plastics material stretched to present a privileged shrinkage orientation, a heat-shrink sleeve made out of the film, and an article covered in such a sleeve

The invention relates to a film of plastics material stretched to present a privileged shrinkage orientation and used in particular for fabricating heat-shrink sleeves, the film including at least one line of mechanical weakness and at least one local region of extra thickness extending along the line of weakness so as to border it, the line of weakness and the adjacent local region of extra thickness together defining a tear line. According to the invention, the local region of extra thickness is constituted by applying liquid or semi-liquid material to the film, the applied material being applied to the film in a quantity that depends on the expected shrinkage ratio in the portion of the film that includes the tear line while a sleeve made using such a film is being heat-shrunk onto an article.

Owner:SLEEVER INT

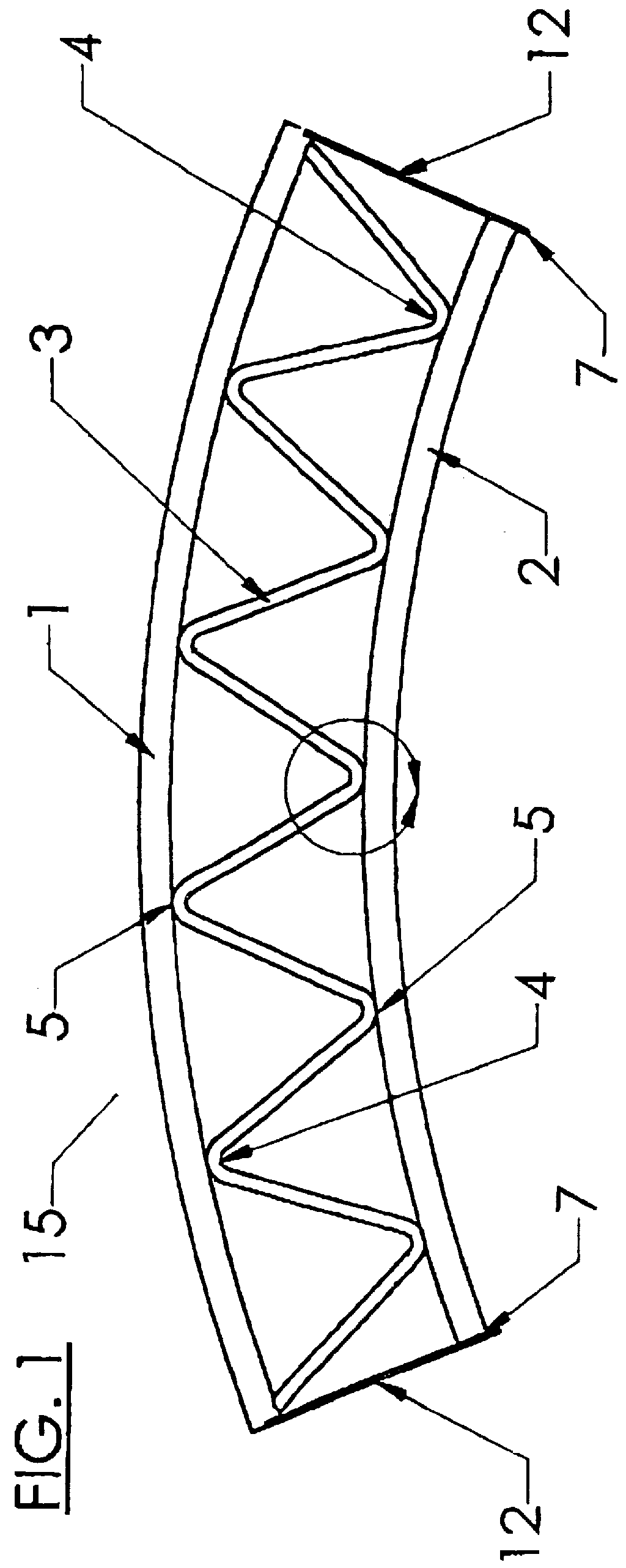

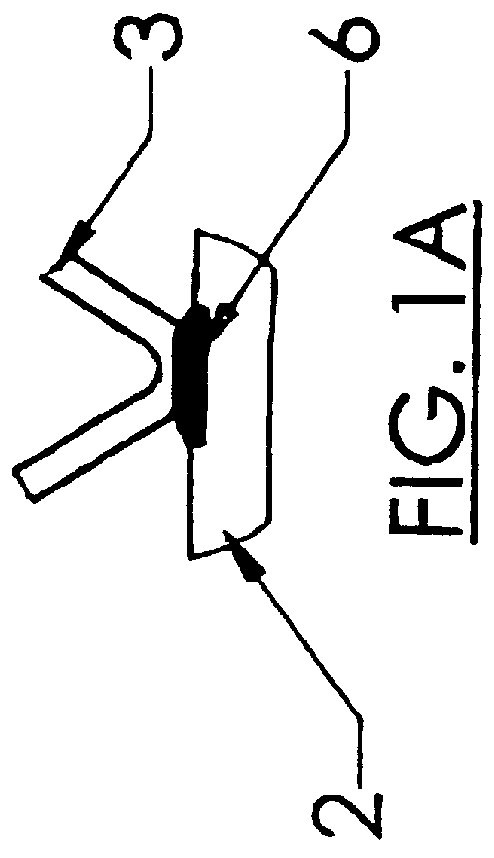

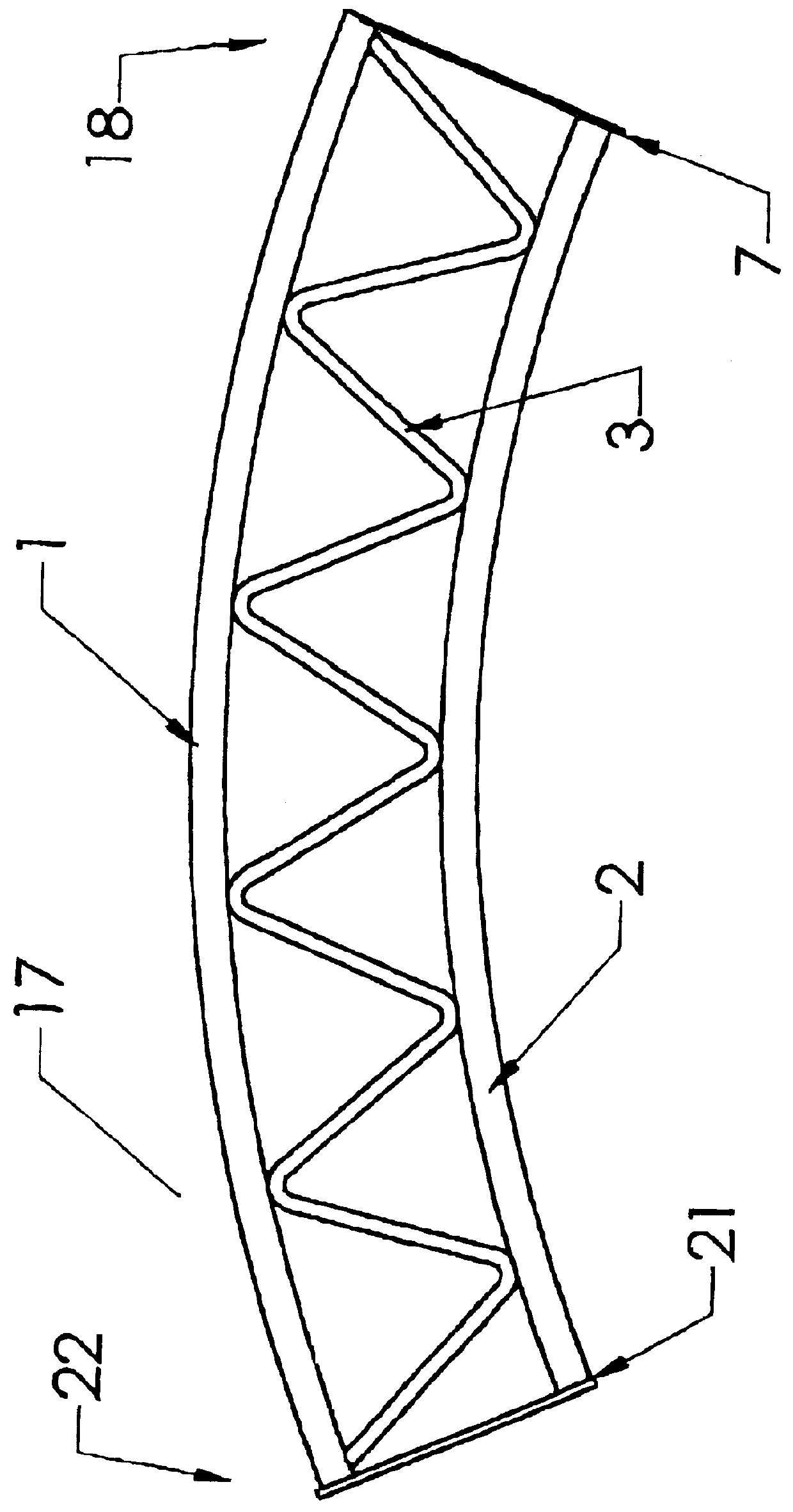

Truss for fabric covered buildings and the like

The present invention provides a strong yet lightweight truss which could be used in many applications, and is adapted particularly to a support framework for those fabric covered structures utilizing a fabric stretched over the top of the supporting framework. The truss can be made up into sections comprising tubular upper and lower truss members separated by a continuous tubular web. The coupling plates may be attached to each end of the sections such that the top edge of the coupling plate is below the upper side of the upper member, providing a smooth upper surface to the truss and eliminating wear points which could damage the fabric or other material stretched over or supported by the truss. The truss is easily transported and manufactured.

Owner:COVER ALL BUILDING SYST

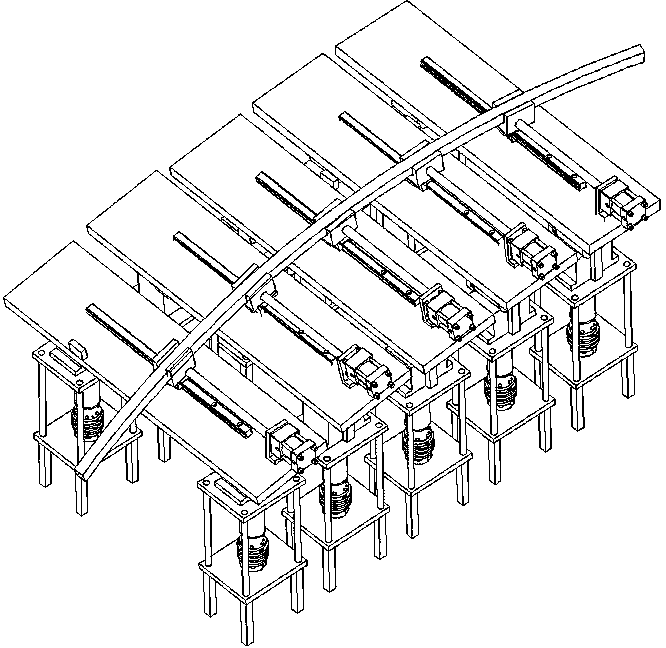

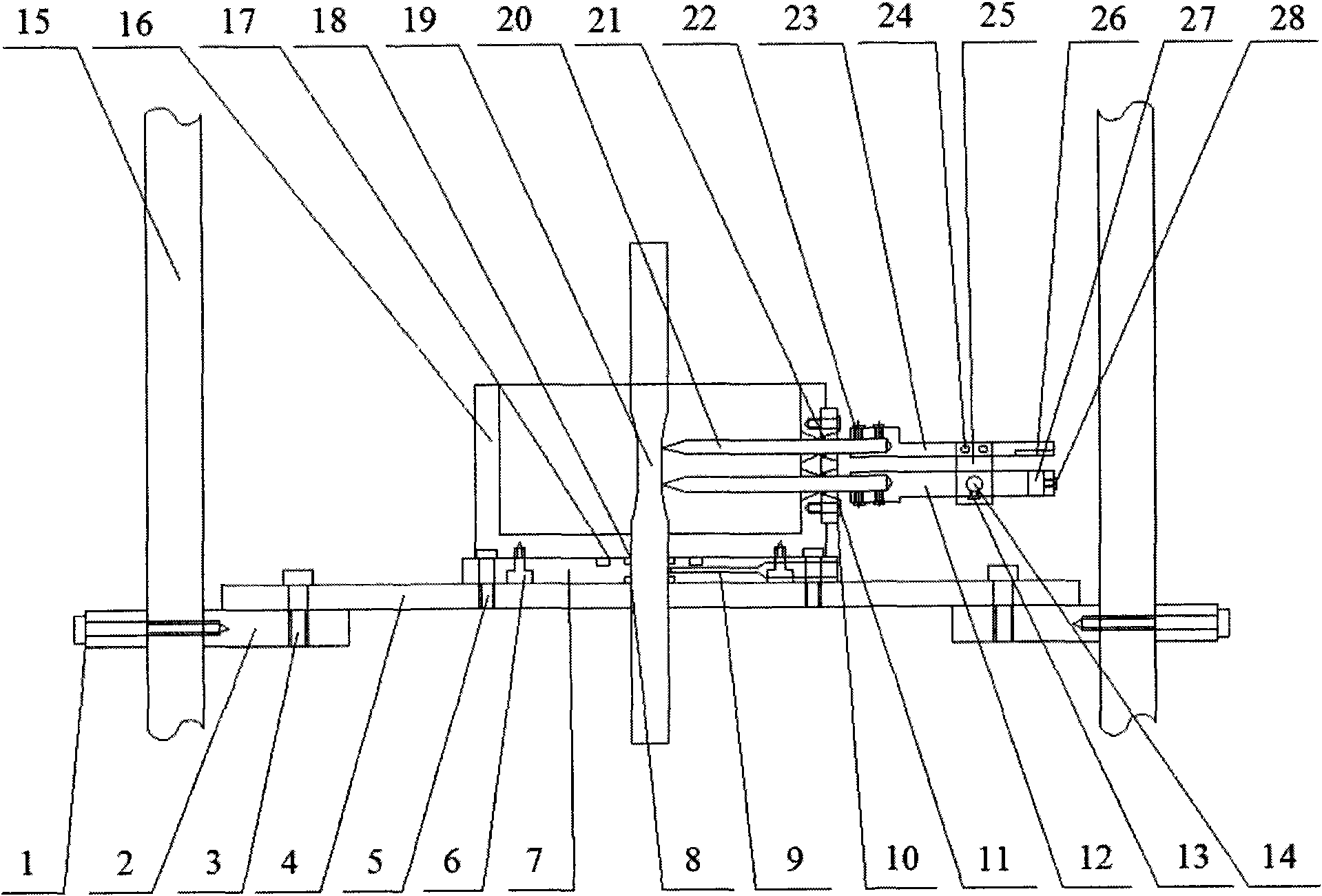

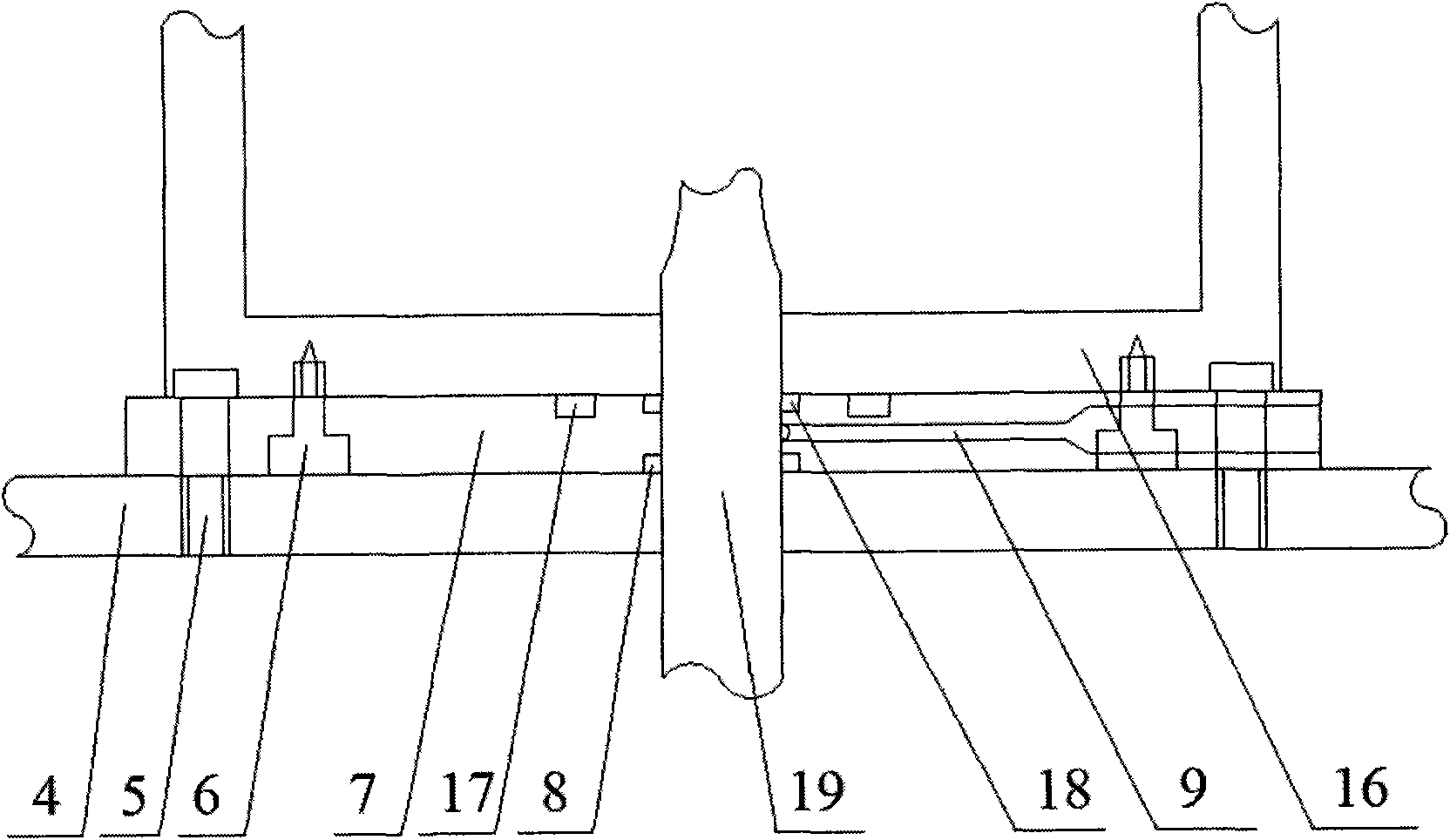

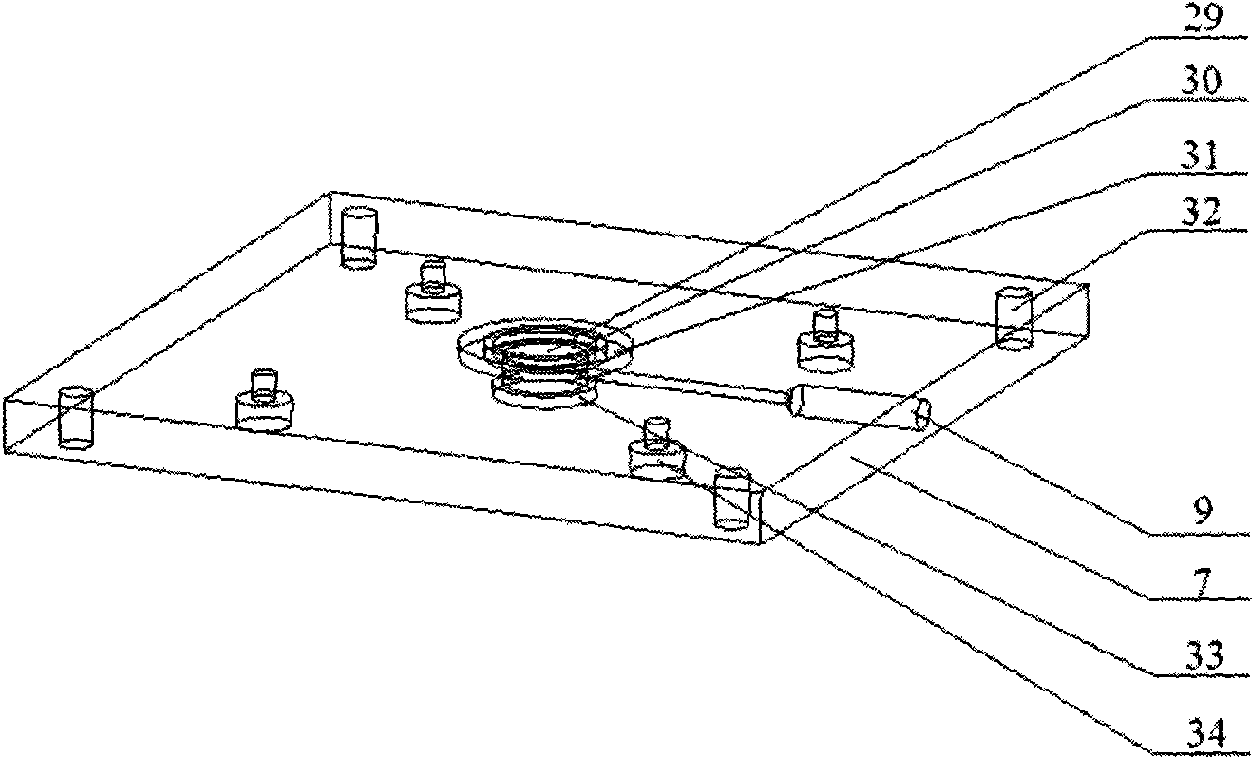

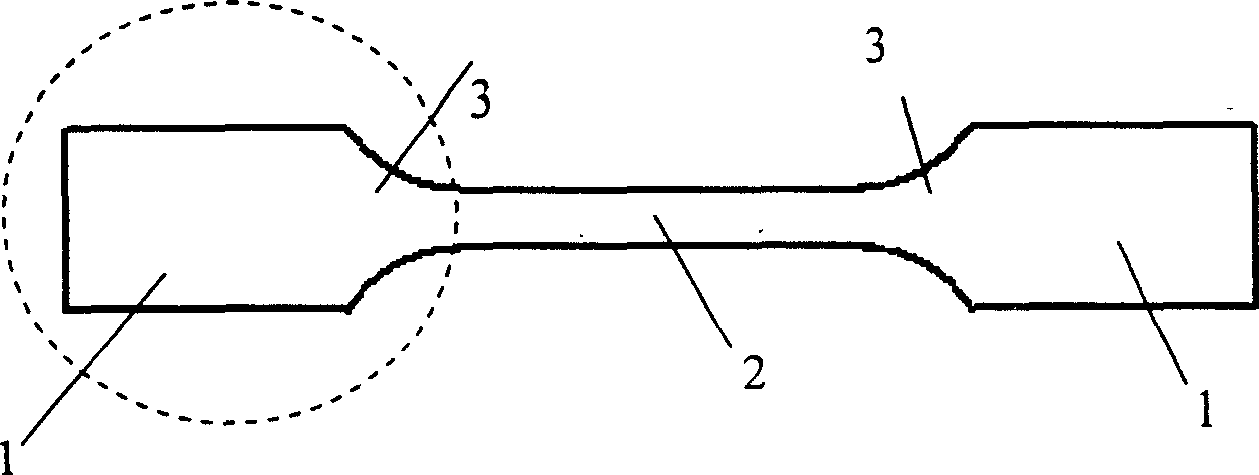

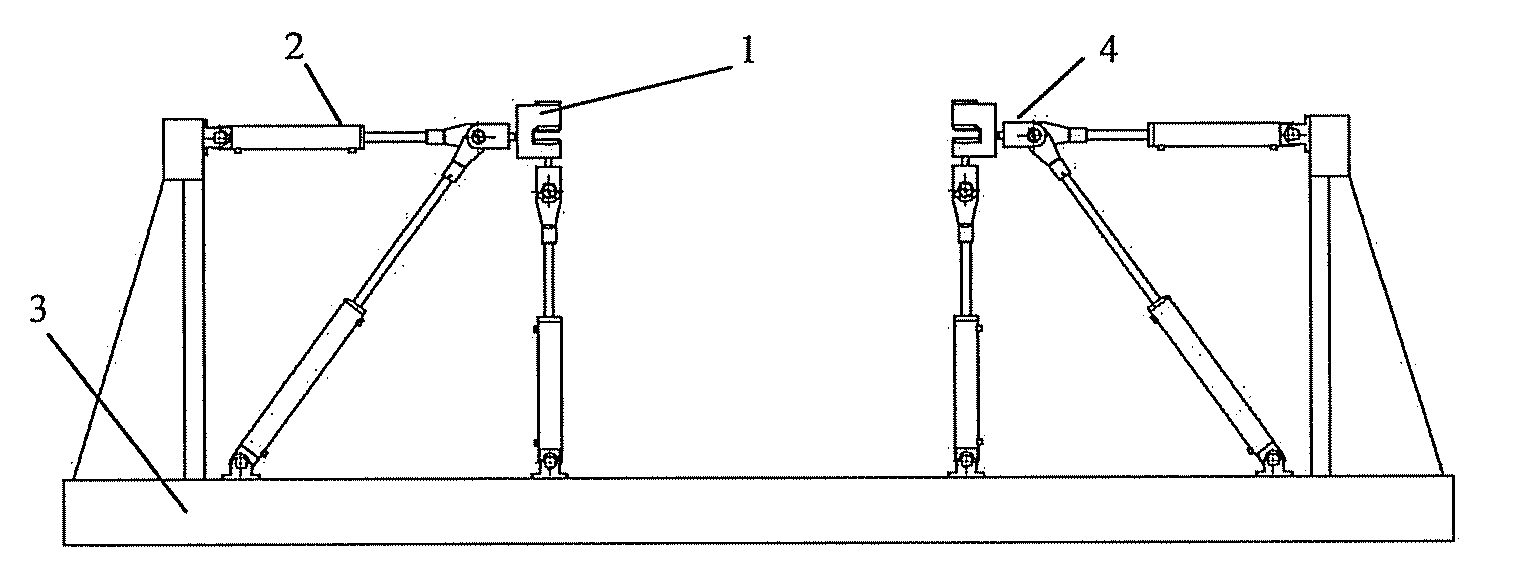

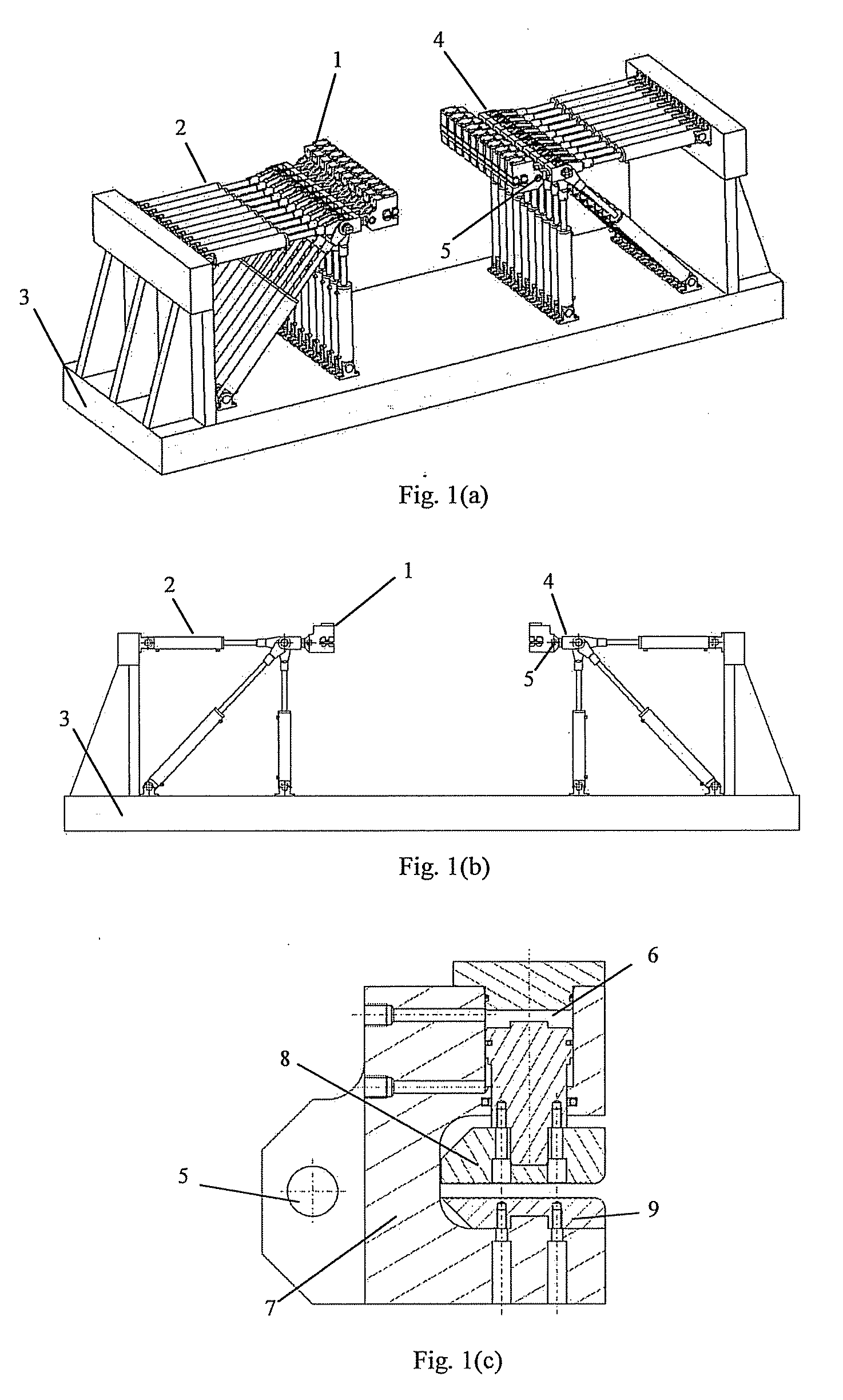

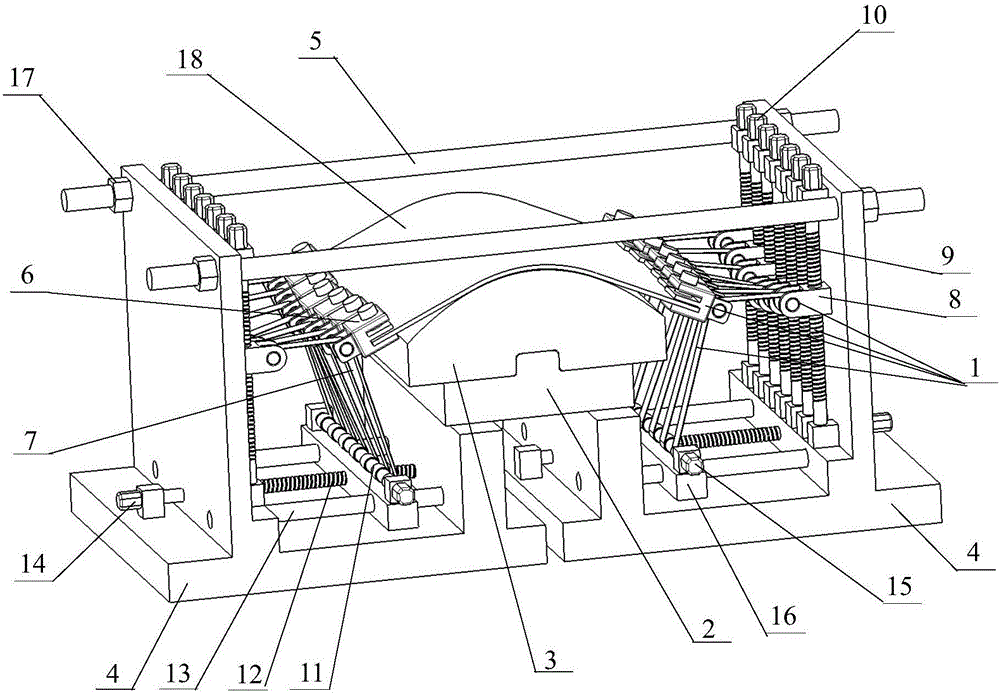

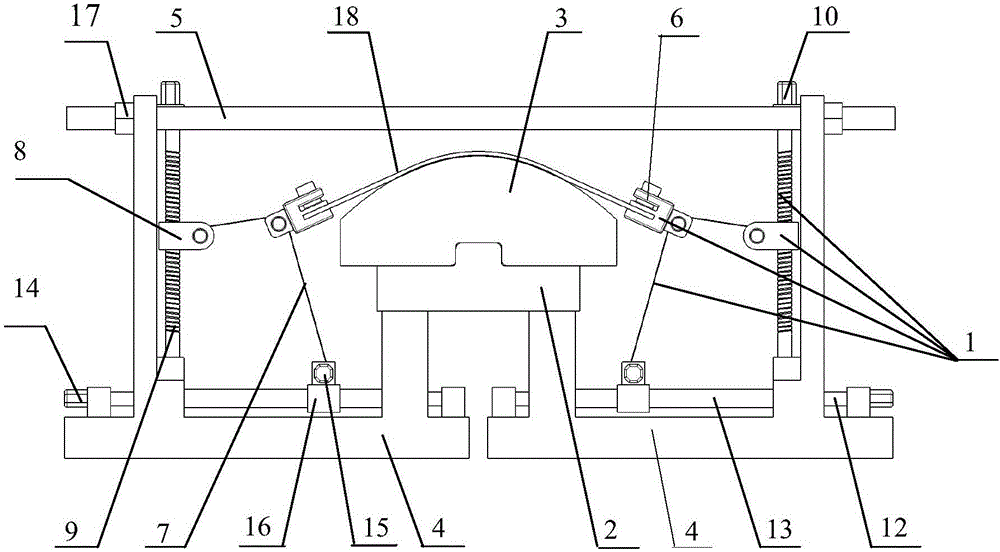

Stretching-compression combined type flexible three-dimensional section material stretch-bend forming process and device

ActiveCN108311578ASolve processing problemsRealize automatic shape adjustmentShaping toolsHydraulic cylinderEngineering

The invention discloses a stretching-compression combined type flexible three-dimensional section material stretch-bend forming device. Each forming unit is composed of two end racks, a disc type brake device, a synchronous vertical lifting device, a rotary shape adjusting device, a worktable, a mold assembly, a hydraulic executing mechanism and a sensor. The invention solves a technical problem of complex bend forming of 'S'-shaped and 'W'-shaped section materials unable to be realized by traditional three-dimensional stretch bending by adopting a method of combining stretch-bending with compression-bending, using clamps to drive the section materials to be closed with a mold in a vertical direction, using a hydraulic cylinder mounted on an end part of a unit body to drive a piston rod ona formed curved surface, and performing stretch-bend forming on the section materials on the vertically bent curved surface. The stretching-compression combined type flexible three-dimensional section material stretch-bend forming device reduces labor intensity, improves production efficiency and molding precision and eliminates influence of rebound deformation uncertainty on forming precision byan automatic shape adjusting technology, realizes two-dimensional or three-dimensional bend forming of section material components with a same cross section and different target shapes, and reduces mold manufacturing costs.

Owner:CHANGCHUN UNIV OF TECH

Multi-gesture trampoline keys

InactiveUS20120327001A1Light weightSmall dimensionInput/output processes for data processingTouchscreenS function

Composite structure trampoline key structures are described for use on top of a touchscreen or other touch, pressure, motion or gesture sensitive components. The aforementioned touch screen may be referred to as a pressure sensitive layer or PSL. The composite structure trampoline key array comprises a frame of one or more physical materials comprising of a perimeter structure and an internal array structure, the frame's function being to position the composite overlay in position in relation to the PSL and to hold a flexible fingertip material in place above the PSL and at a specified surface tension, and (2) a flexible fingertip material integral or attached to the frame which flexible fingertip material stretches in the open areas of the frame's array thereby providing the location for fingertip presses to activate the underlying PSL at specific locations.

Owner:YUZEE INC

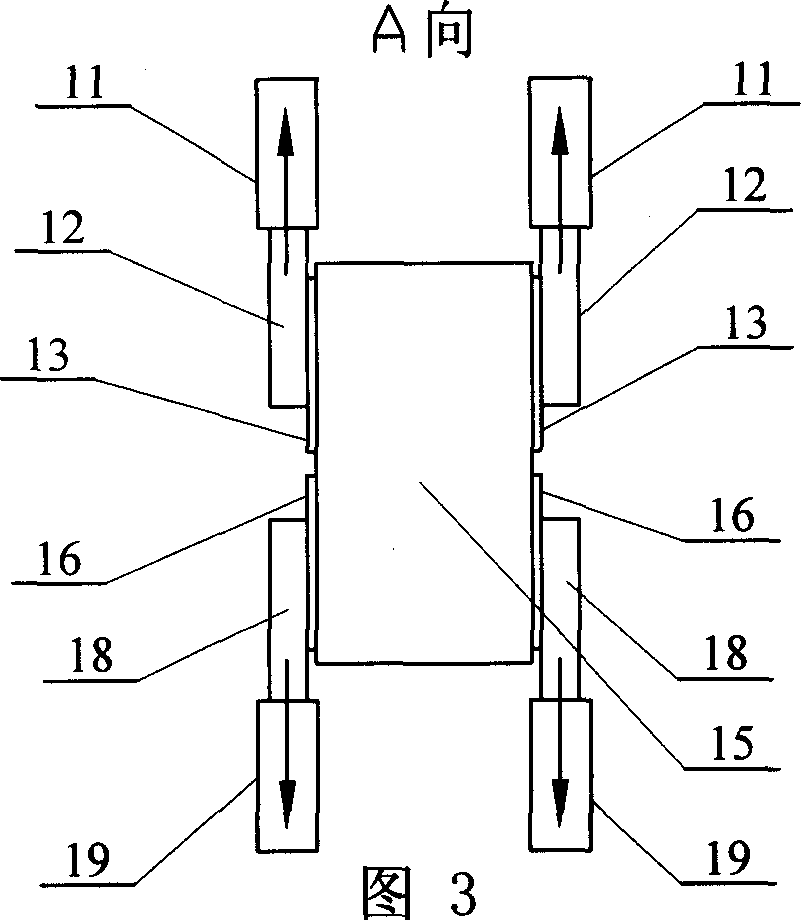

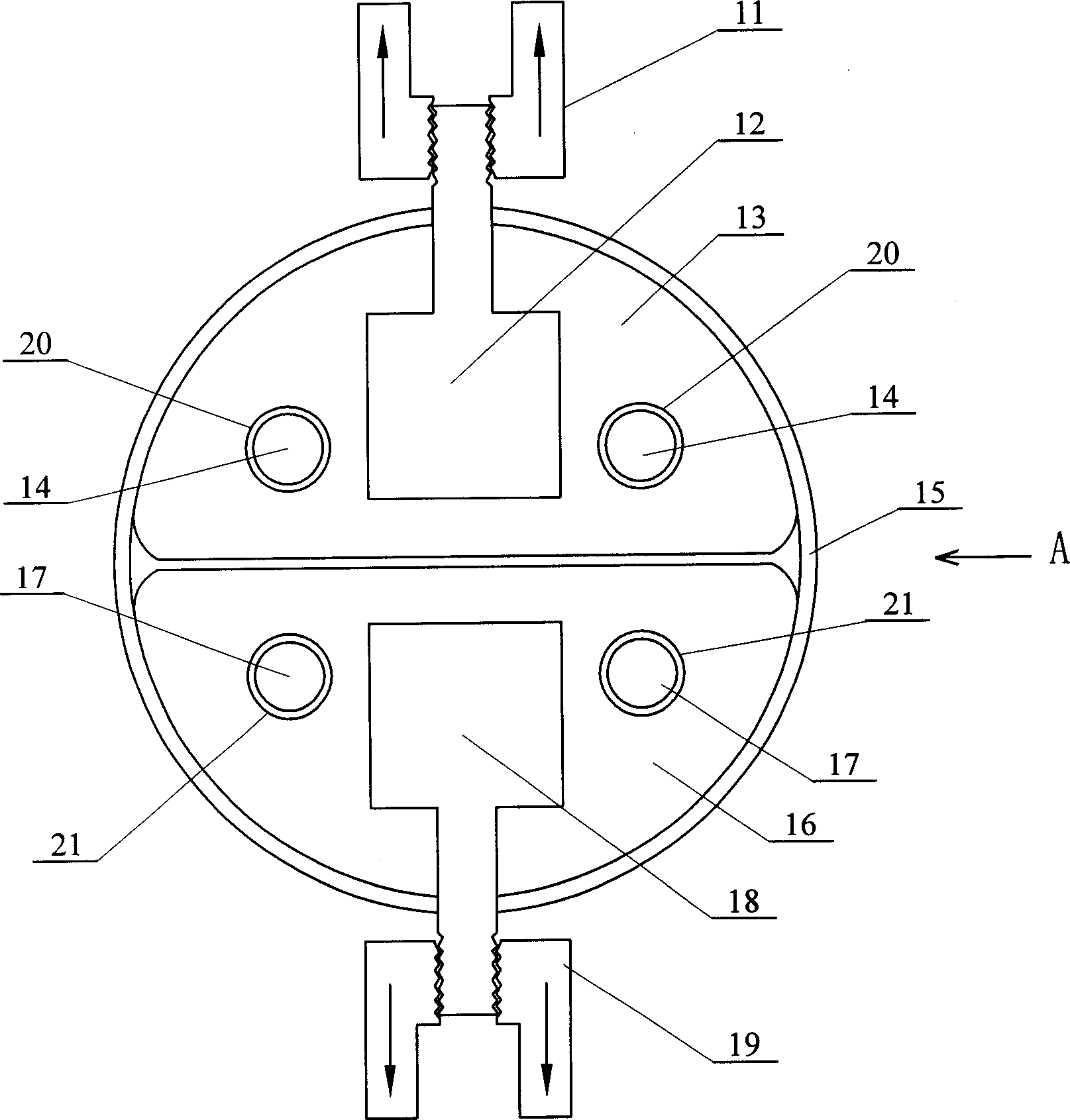

Pipe hoop stress tensility testing method

InactiveCN1865906AAvoid performance changesTest hoop tensile propertiesMaterial strength using tensile/compressive forcesSEMI-CIRCLEEngineering

The disclosed tube circumferential tension performance test method comprises: using a semi-circle bar with same radius to cross the tube, starting up the testing machine to drive the upper and lower clamp, deforming the tube, and obtaining the test data. Compared to prior art, the benefit of this invention include: 1. changing no tube performance; 2. obtaining better testing result.

Owner:HARBIN INST OF TECH

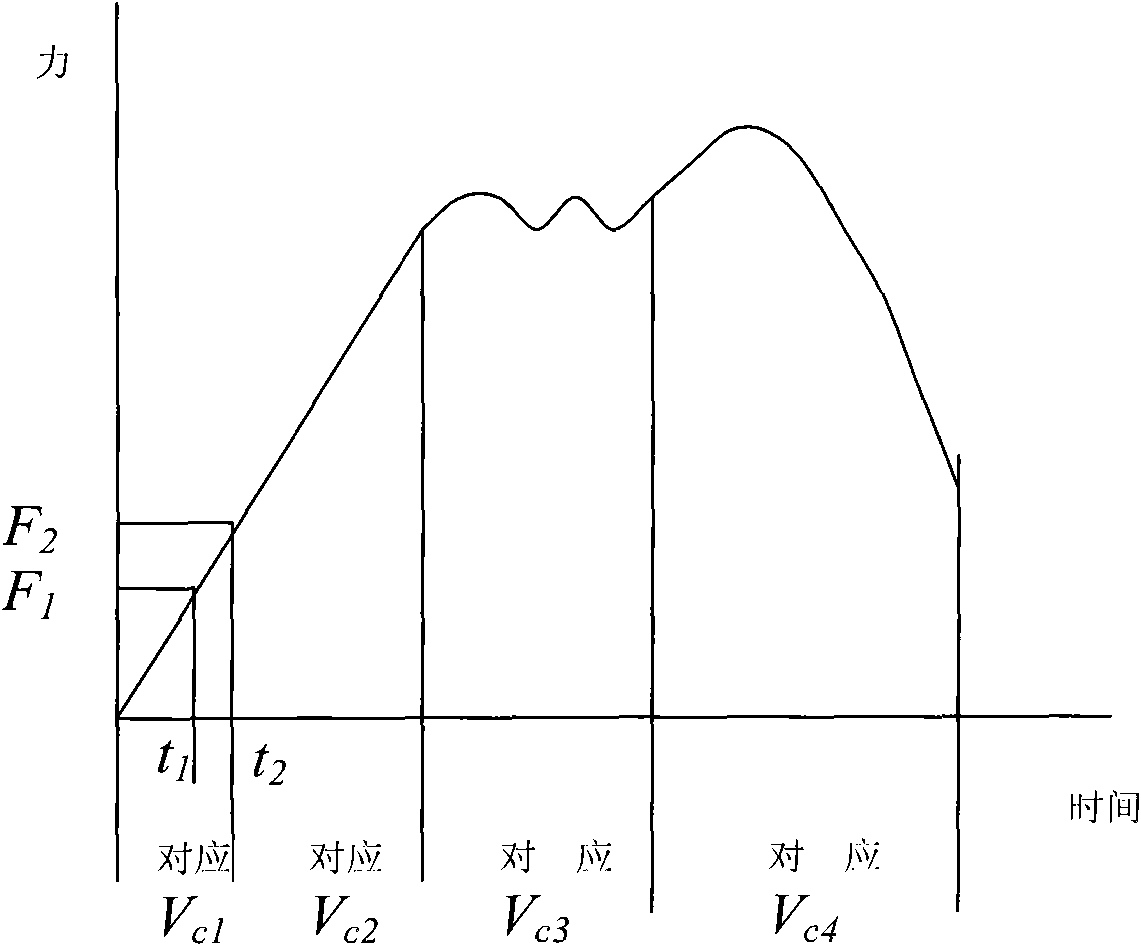

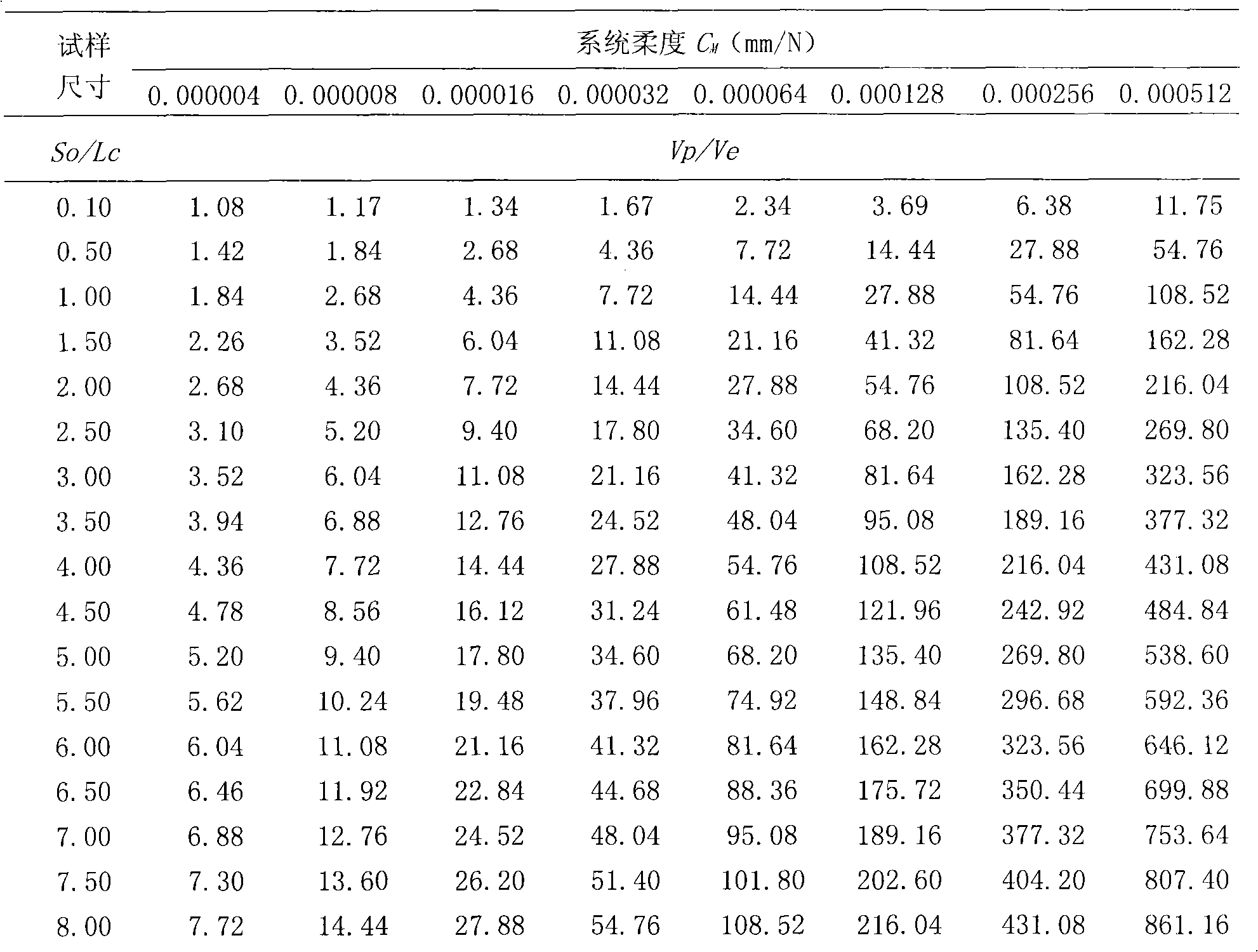

Method for controlling whole-course displacement in program-controlled metal material stretching test

ActiveCN101661271AImprove work efficiencyImprove accuracyMaterial strength using tensile/compressive forcesProgramme control in sequence/logic controllersMathematical modelStress–strain curve

The invention provides a method for controlling whole-course displacement in a program-controlled metal material stretching test. The control method is arranged is a test application program of an electro-hydraulic servo or electronic universal testing machine; the control method comprises the following steps of: displacement control in the first stage, displacement control in the second stage, displacement control in the third stage and the displacement control in the fourth stage. The method has the effects that the control method provides a mathematic model which automatically computes theflexibility of the system in the testing process, and the model is simple and reliable and aims at the system flexibility computation on each testing sample. The whole test is carried out automatically, great convenience is brought to the testing personnel, and the working efficiency and accuracy of the yield strength test are improved obviously. The method is applicable to the requirements on thestretching rates at different stages of various metal material samples; furthermore, rate conversion is smoothly transitional before the yield stage is finished; and the discontinuity is not introduced on the stress-strain curve. The method is applicable to the production, research and technical reconstruction on a stretching testing machine.

Owner:TIANJIN PIPE GROUP CORP

Strain test device for tension-torsion multi-shaft fatigue test under corrosion environment

InactiveCN101620043APrevent leakageGuaranteed normal loadingStrength propertiesCorrosionMaterial Stretched

The invention relates to a strain test device for a tension-torsion multi-shaft fatigue test under a corrosion environment, which is characterized in that an electrobath with a bed sealing system and a lateral-wall sealing system is fixed on a testing machine to form a supporting structure, wherein the bed sealing system is positioned between a support plate and the electrobath and formed by an upper sealing ring, a lower sealing ring, an organic glass plate, an outer sealing ring and a liquor guide opening, and the lateral-wall sealing system is positioned on a joint position of ceramic thimbles and the electrobath and is formed by a lateral sealing ring and a sealing baffle plate; a sample is led into the electrobath and passes through the bed sealing system, one end of each ceramic thimble passes through the lateral-wall sealing system to extend into the electrobath, and the other ends of the ceramic thimbles are connected with an upper induction support frame and a lower induction support frame which are parallel and provided with a tension deformation tester and a torsion deformation tester. The invention designs the more perfect sealing systems, realizes the measurement of material tension and torsion strain under the corrosion environment and has simple structure, difficult leakage, wide measurement range and higher precision.

Owner:EAST CHINA UNIV OF SCI & TECH

Friction factor measuring and calculating method during metal plastic forming

InactiveCN102944513AConvenient and accurate calculation methodAvoid inconvenienceUsing mechanical meansMaterial analysisMetallic materialsLubrication

The invention discloses a friction factor measuring and calculating method during metal plastic forming. Firstly, a standard metal material tensile test is performed to obtain mechanical characteristic parameters of a metal material to be measured, a cylindrical workpiece is subjected to upsetting and compressive deformation, geometric data of the workpiece before and after deformation are obtained by measuring, and the mechanical parameters and the upsetting geometric data are combined to figure out the friction factor between an upsetting forming mold and an upsetting forming workpiece. The measuring and calculating method is convenient and accurate, material characteristics are considered, and inconveniences and deviation caused by curve correlation method and the like are avoided. The method is mainly specific to evaluation of friction and lubrication conditions during metal forming and has an important application value in the metal forming machining technology.

Owner:ZHEJIANG UNIV

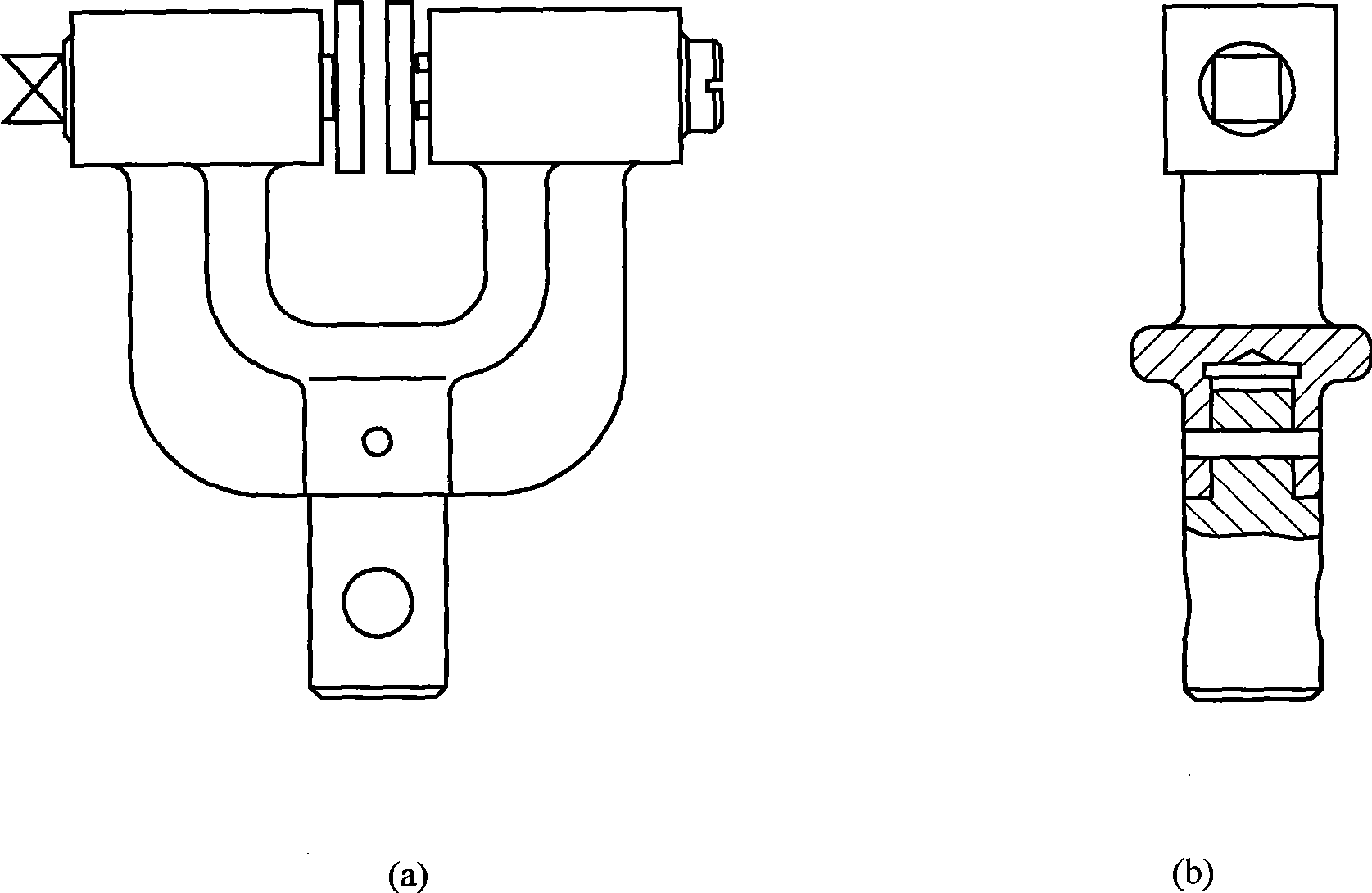

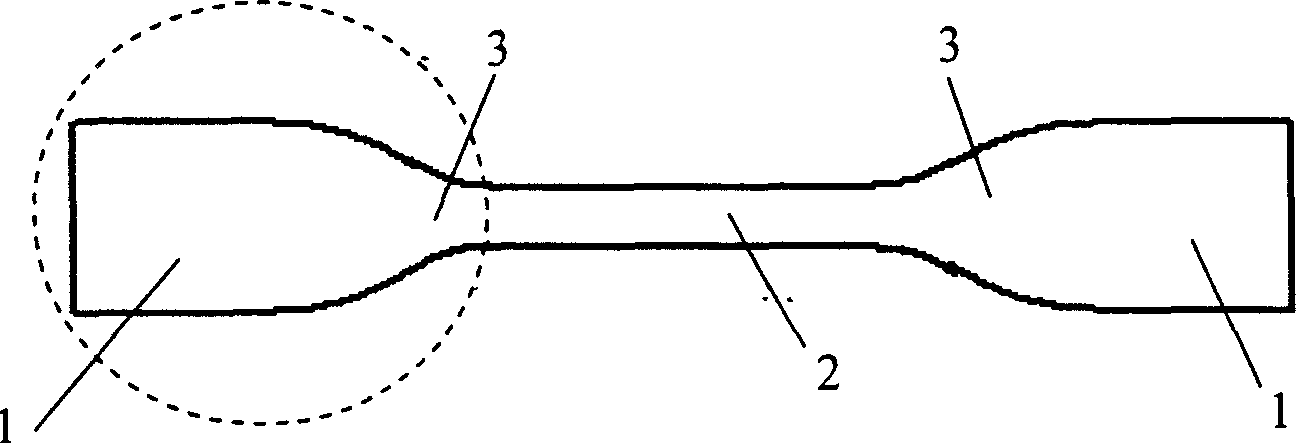

Stretching clamping device used for nonmetal material stretching mechanics performance testing

InactiveCN1619286AOvercome slippageSimple structureStrength propertiesMetallic materialsTensile testing

The present invention disclosed a tension gripping device for testing tension mechanical property of non-metal material. When said gripping device is used, it is fixedly connected with one end portion of dumbbell-like standard sample. Said gripping device includes a plate-shaped main body with upper surface and lower surface, in the main body a recessed zone extended toward lower surface from upper surface is limited, and said recessed zone has an opening end positioned on side of said main body, and the form and size of said zone are basically identical to that of end portion of standard sample.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Tinplate two-piece can stretch-forming processing method and mold, and product thereof

ActiveCN105127267ABreak through the limitations of useLarge capacityShaping toolsCoatingsForm processingMaterials science

The invention relates to the technical field of metal packaging, and particularly discloses a tinplate two-piece can stretch-forming processing method which comprises the following steps: (1) plate preparation; (2) cup pre-stretch-forming; (3) cup secondary stretch-forming; and (4) stretch forming and neck expansion by flanging. The invention also discloses a special mold adopted by the tinplate two-piece can stretch-forming processing method and a tinplate two-piece can prepared by the special mold. The method breaks through the limitations in the existing tinplate two-piece can for food through the innovation on the mold, technique and material; and the diameter of the can body can reach 105mm, and the stretch-forming height is 51.5mm or above. The method has the advantages of accurate technique, fewer steps, low cost and high safety, is free of cleaning, obviously enhances the sealability and safety of the can body, saves the cost, lowers the technical complexity, and can not have the phenomenon of material stretch-forming cracking. The tinplate two-piece can can not be scratched when in use, and can be widely used in packaging canned food and other types of food.

Owner:英联金属科技(汕头)有限公司

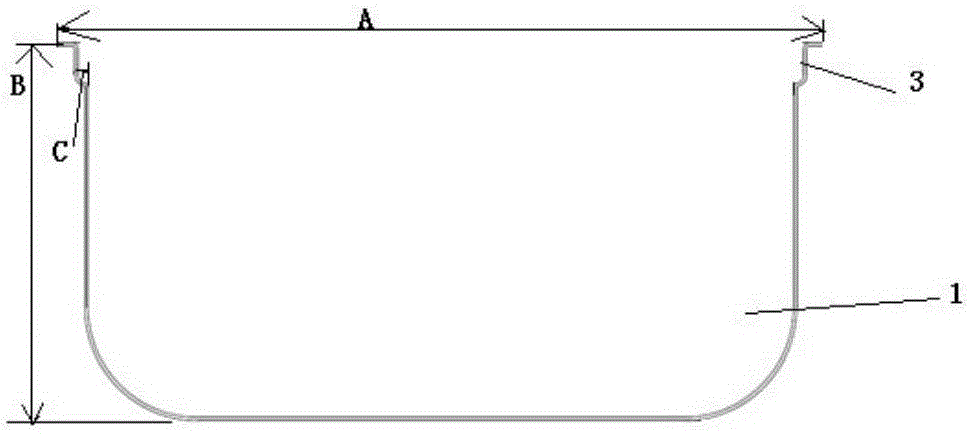

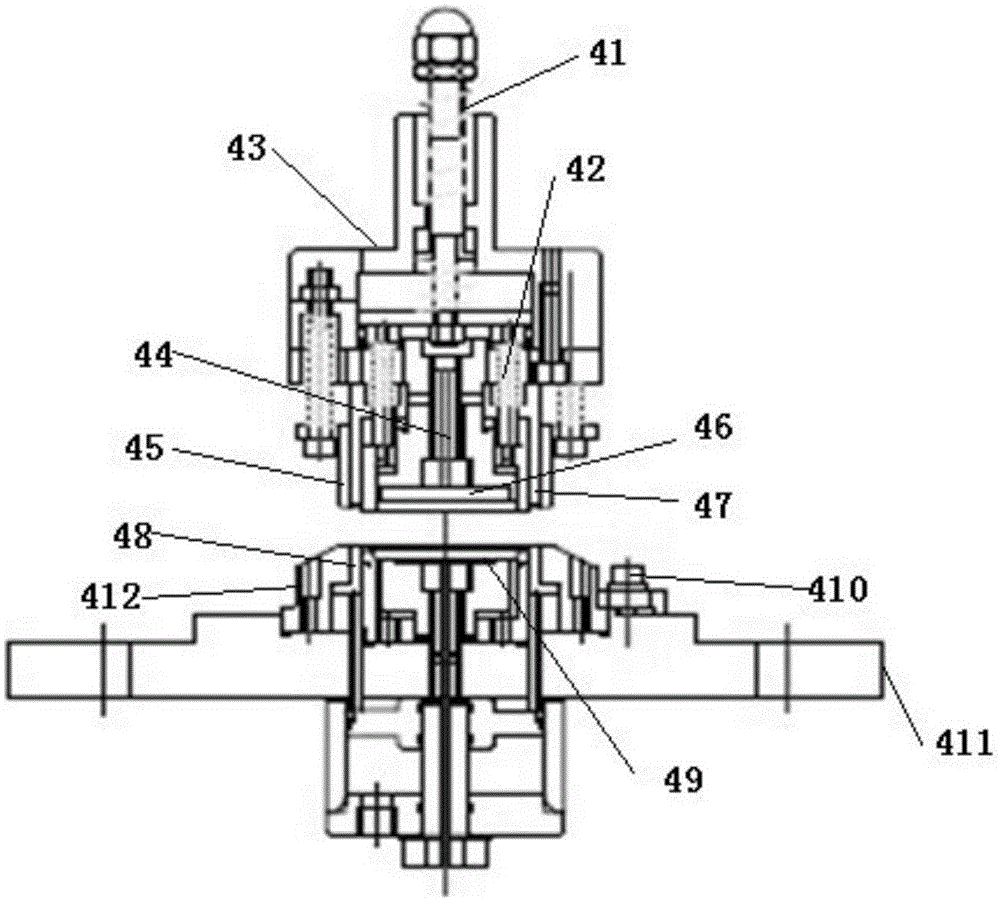

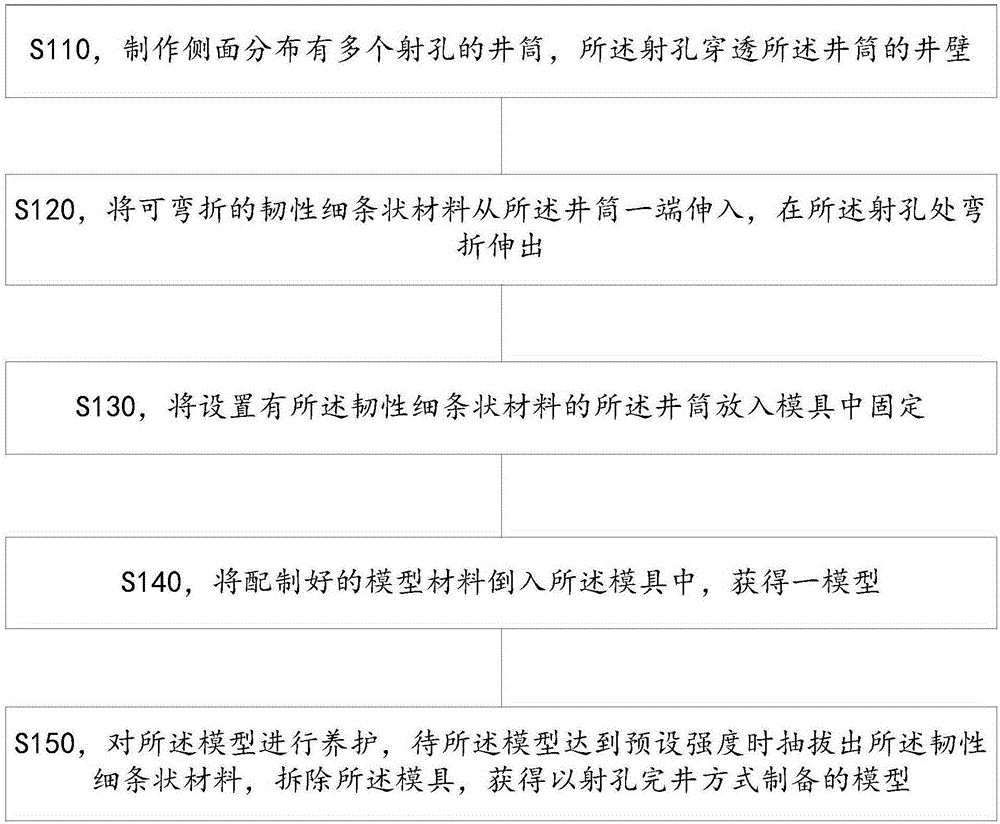

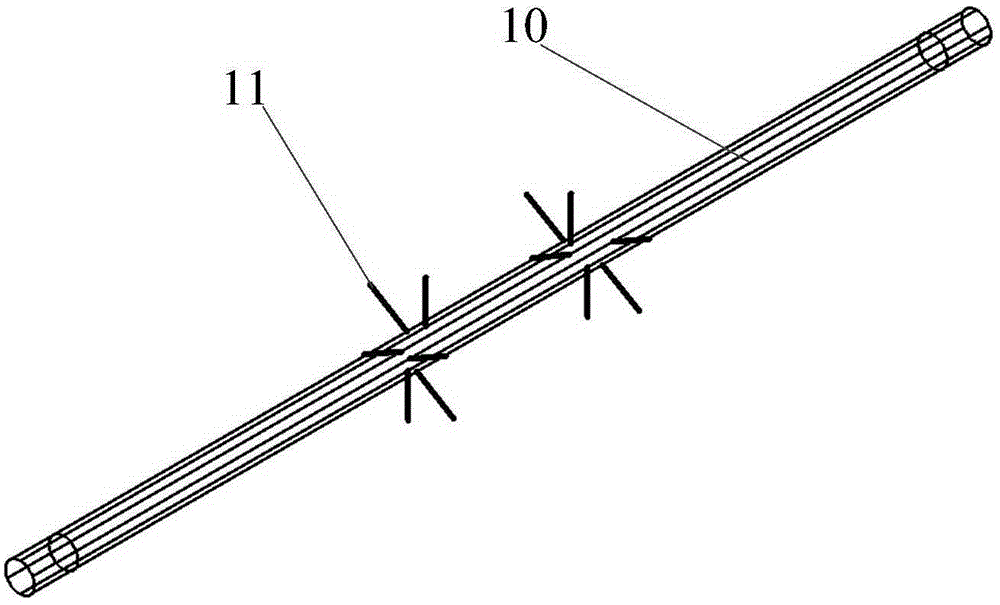

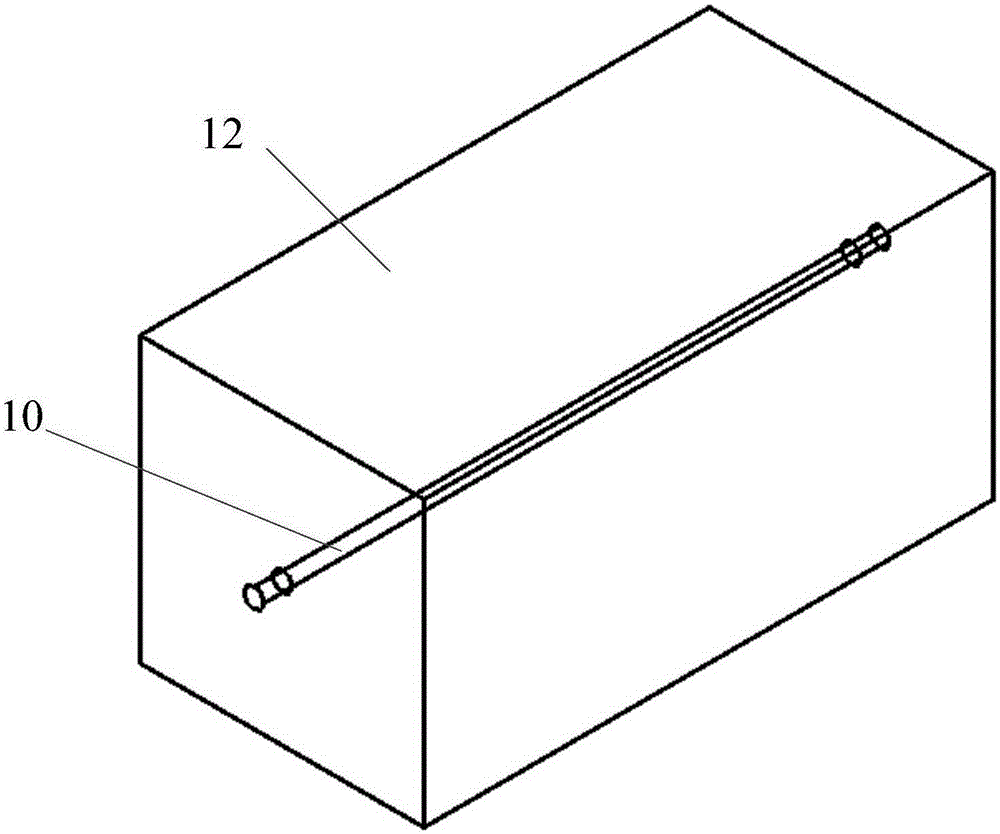

Perforation completion method used for hydraulic fracturing physical simulation test

The invention discloses a perforation completion method used for a hydraulic fracturing physical simulation test. According to the perforation completion method, a bendable, flexible and thin-strip-shaped material stretches into a shaft, in the side surface of which, a plurality of perforations are formed, in addition, the bendable, flexible and thin-strip-shaped material is bent and stretches out at the perforations, then the shaft is put into a mould to be fixed, a prepared model material is poured into the mould, a model is maintained, the flexible and thin-strip-shaped material is pulled out when the model reaches preset strength, and the mould is disassembled, so that the model prepared in a perforation completion manner is obtained. By adopting the perforation completion method disclosed by the invention, the perforation completion is realized more conveniently and flexibly, the application range is wider, a most general spiral perforation completion manner can be realized, and in addition, soluble solid is not used in the method, so that the problem of perforation blockage is not caused, and moreover, by adopting the method, all related parameters such as perforation positions, perforation intervals, perforation diameter, perforation length and perforation phase angle can be set according to requirements.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI +1

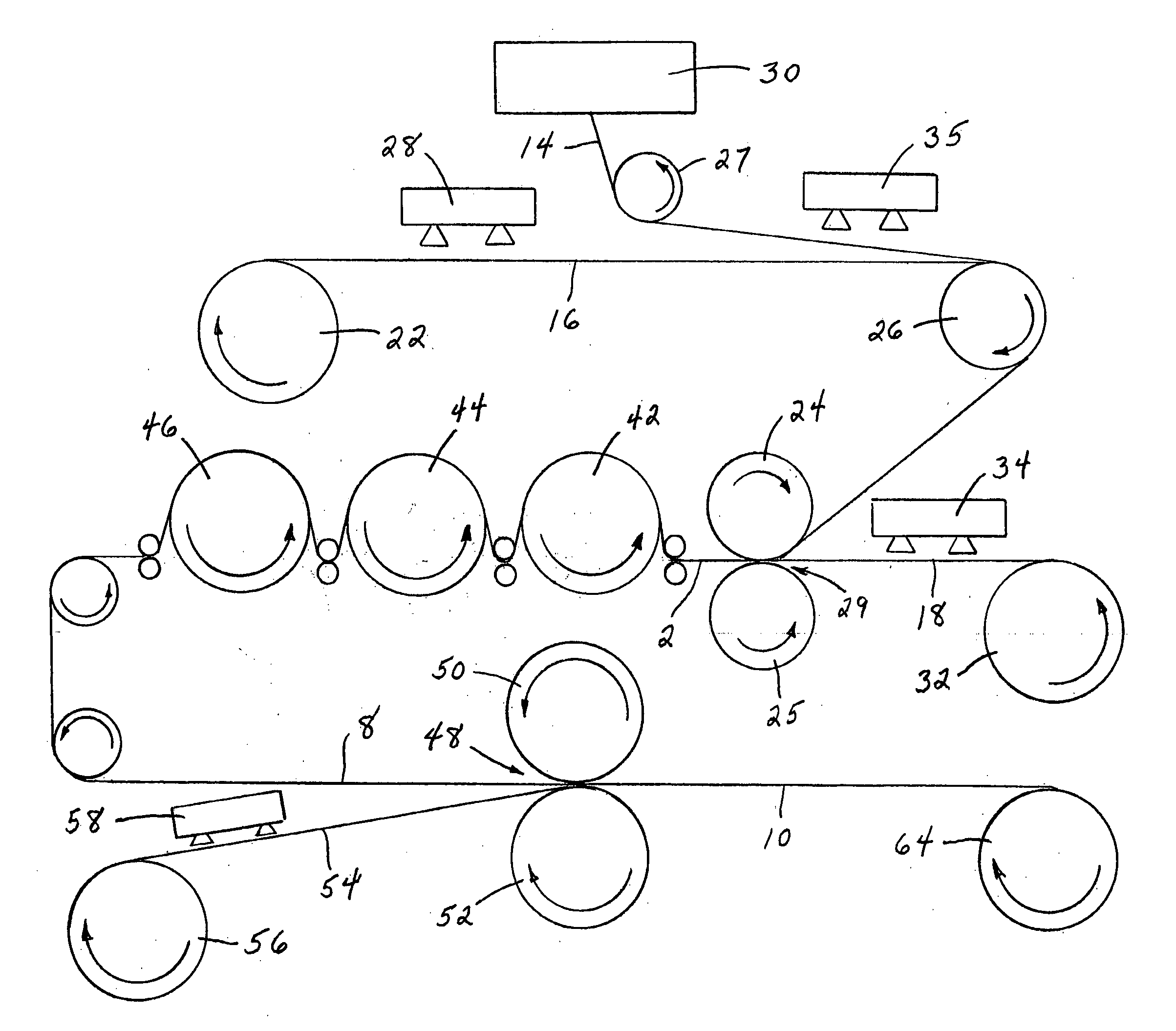

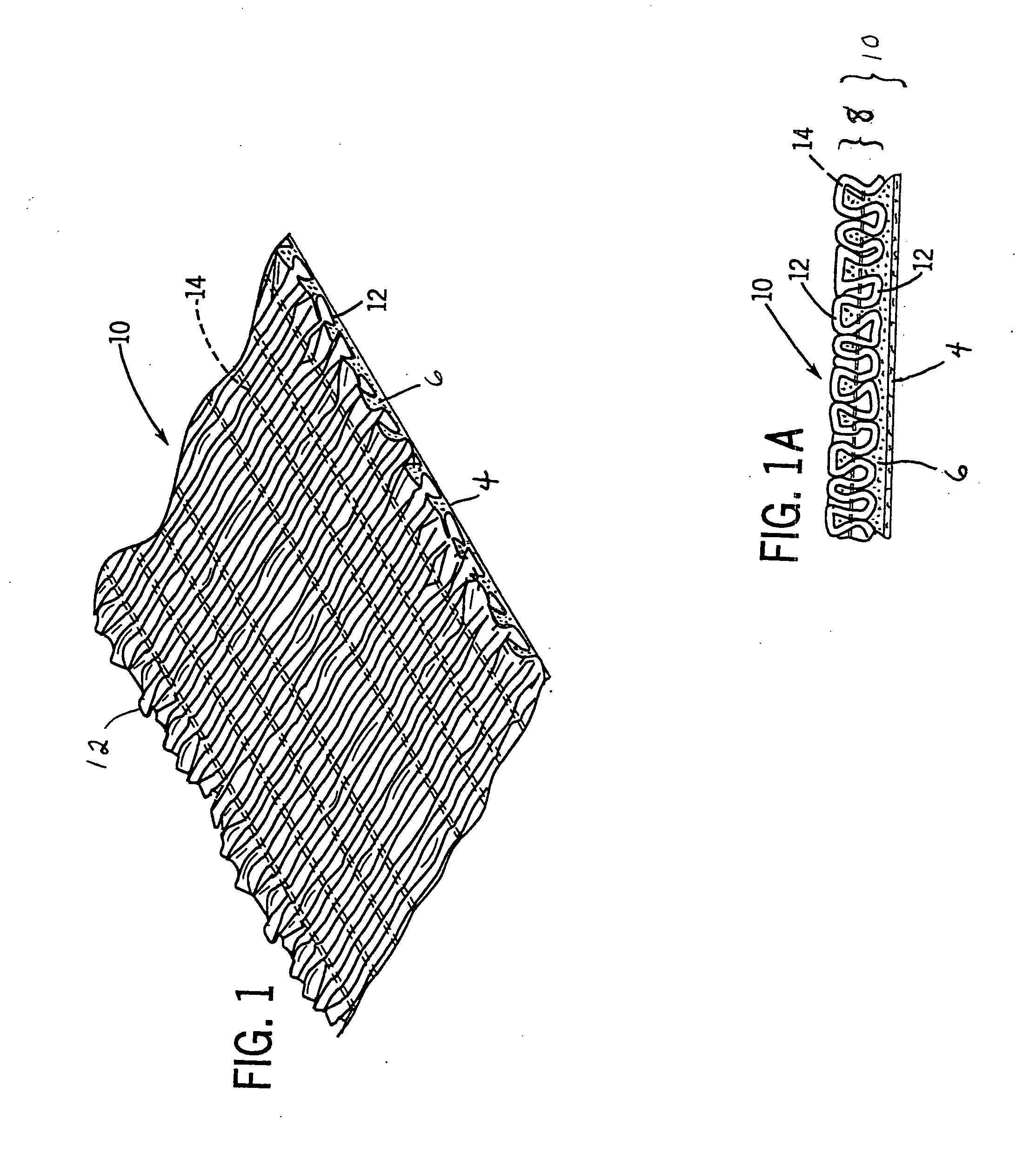

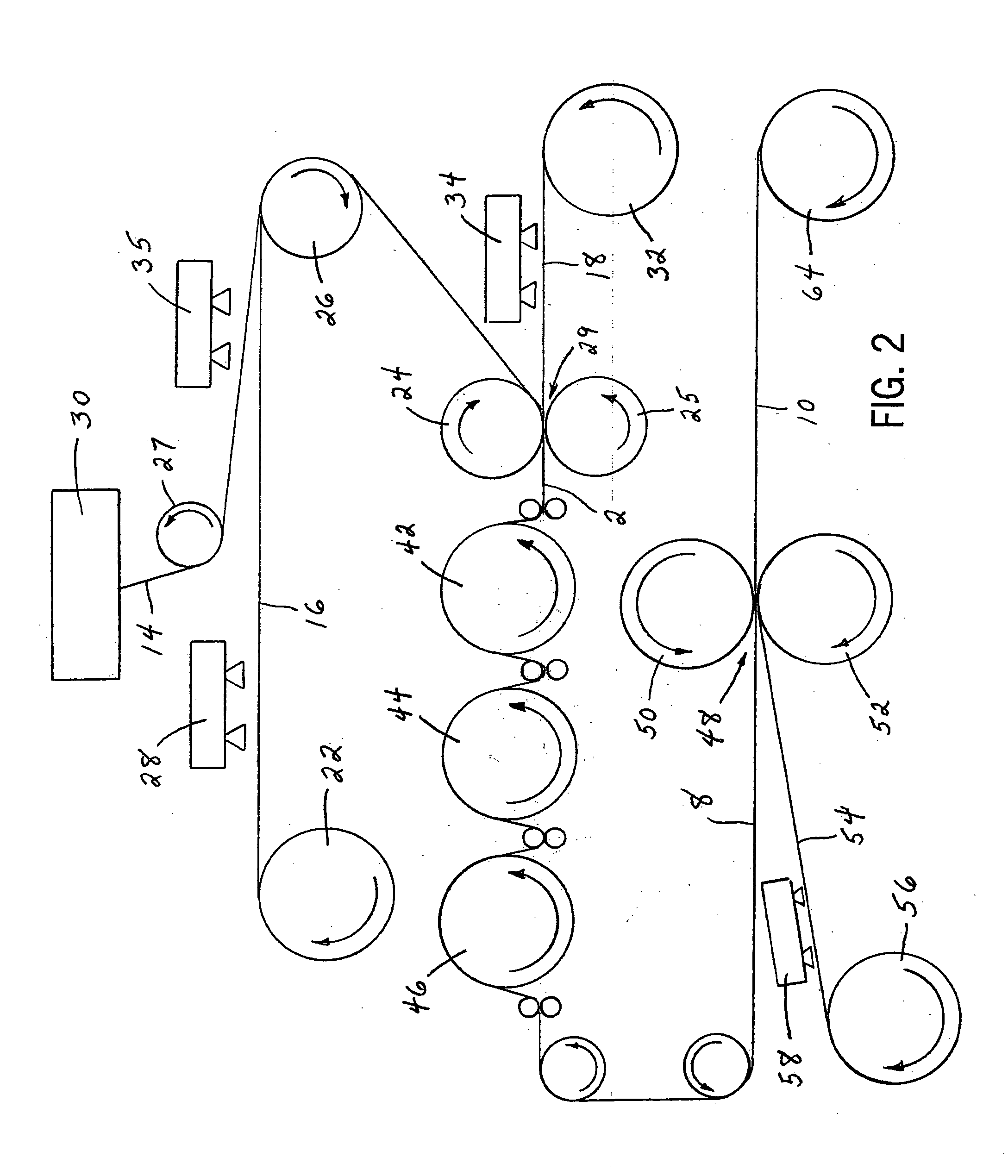

Method of making an elastic laminate using direct contact thermal rolls for controlling web contraction

InactiveUS20060137810A1Undesirable skewingUndesirable stove-pipingLamination ancillary operationsPersonal careElastomerWire rod

A method of making an elastic laminate includes the steps of feeding a first substrate in a machine direction, feeding a second substrate aligned with the first substrate in the machine direction, and feeding an array of elastomeric strand material stretched in the machine direction between the first and second substrates. A hot melt adhesive is applied onto the strand material, and a curable adhesive is applied to one or both of the substrates. The two substrates and the elastomeric strand material are then compressed to form an elastomeric preform web while maintaining the elastomeric strand material in its stretched state. The stretched elastomeric preform web is then heated in line by feeding it over heated rolls, and thereafter allowed to relax and contract in the machine direction as it cools and moves downstream from the heated rolls to form a gathered elastomeric laminate. A release liner is fed in the machine direction and aligned with the gathered elastomeric laminate, and a pressure sensitive adhesive is applied to the release liner. The gathered elastomeric laminate and release liner are then compressed to form the elastic laminate which is particularly useful as window flashing.

Owner:BOSTIK INC

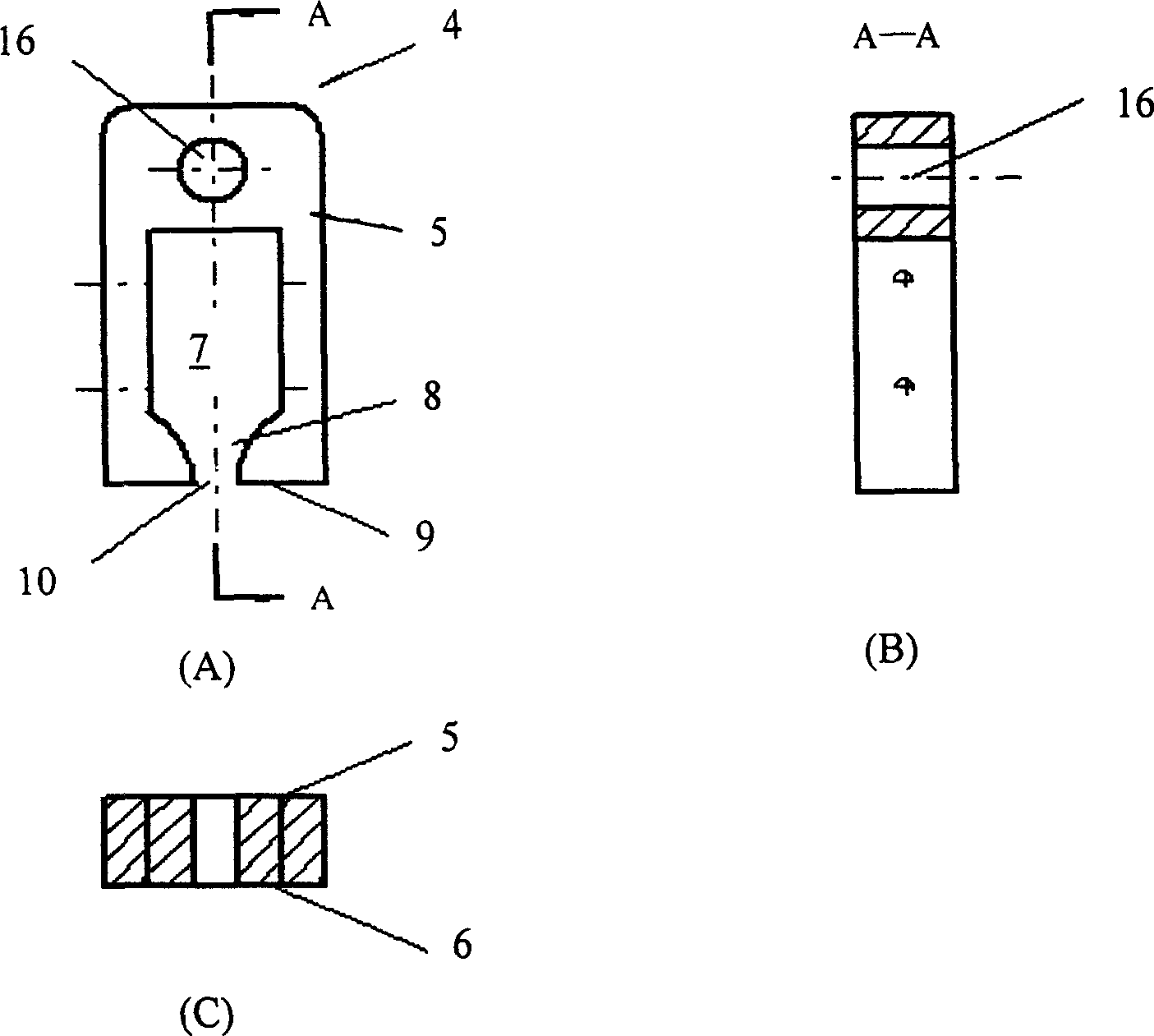

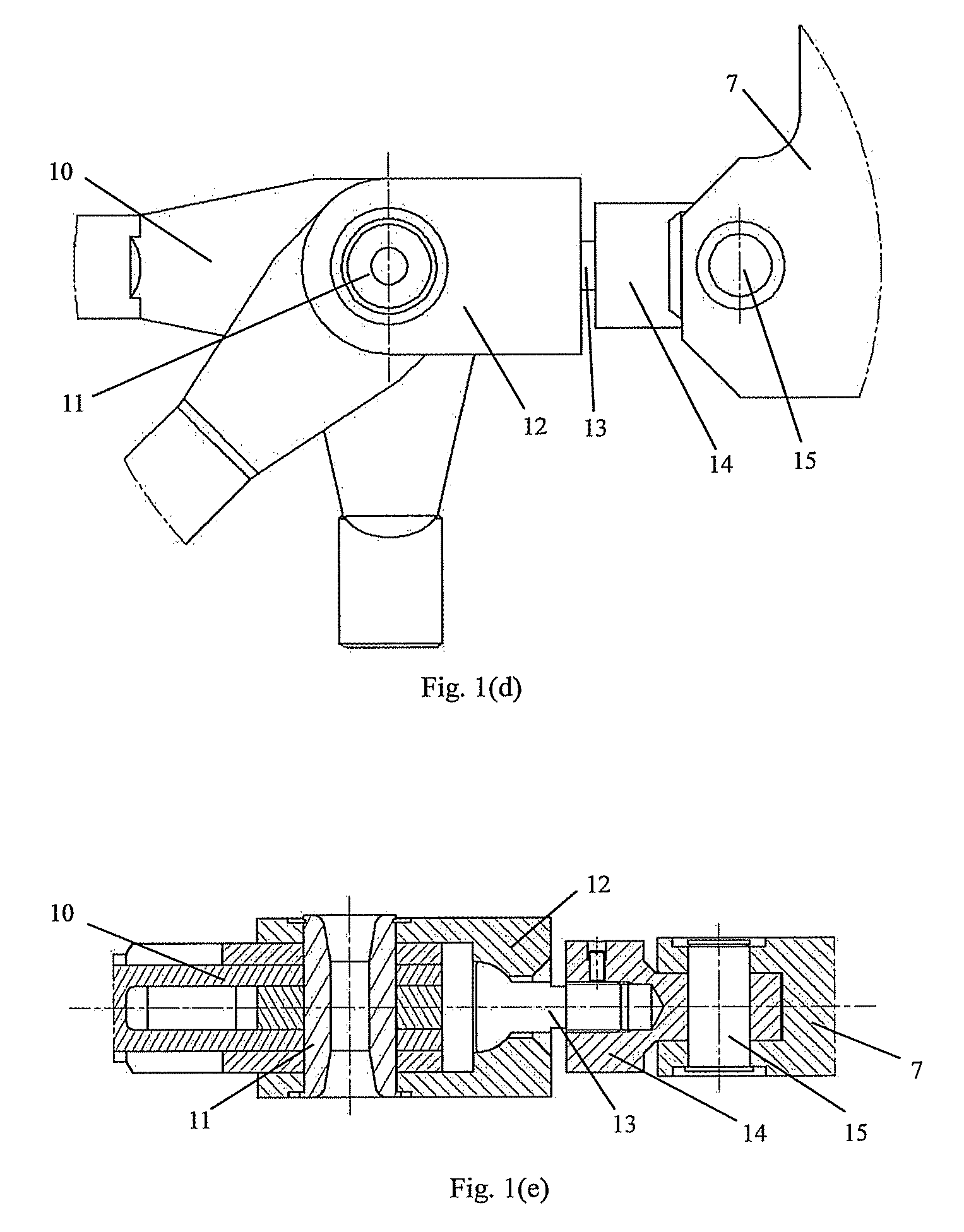

Multiple clamp type stretching and forming machine

ActiveUS20120198904A1Increase flexibilityIncreased material usage and stretch forming qualityHydraulic cylinderManufacturing cost reduction

A multiple clamp type stretching and forming machine is composed of multiple material clamping mechanisms (1), multiple material stretching mechanisms (2) and a frame (3). The material clamping mechanism (1) is composed of a material clamping frame (7), material clamping blocks (8, 9) and a hydraulic cylinder (6) for clamping material. The two sides of the frame (3) are arranged with a row of multiple material clamping mechanisms (1), respectively. The material clamping frame (7) of each material clamping mechanism (1) is provided with one or two connecting holes (5), which connect with one or more material stretching mechanisms (2) through a universal push-pull mechanism (4). The stretching and forming machine can improve the utilization ratio of the material, and reduce the manufacturing cost.

Owner:JILIN UNIV

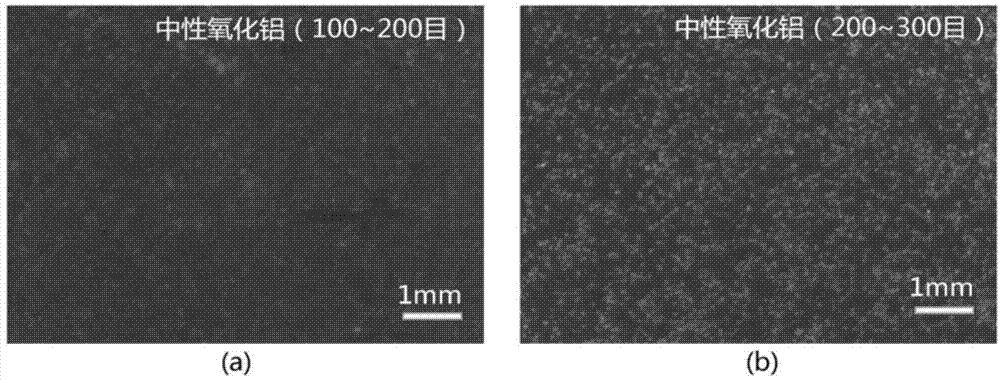

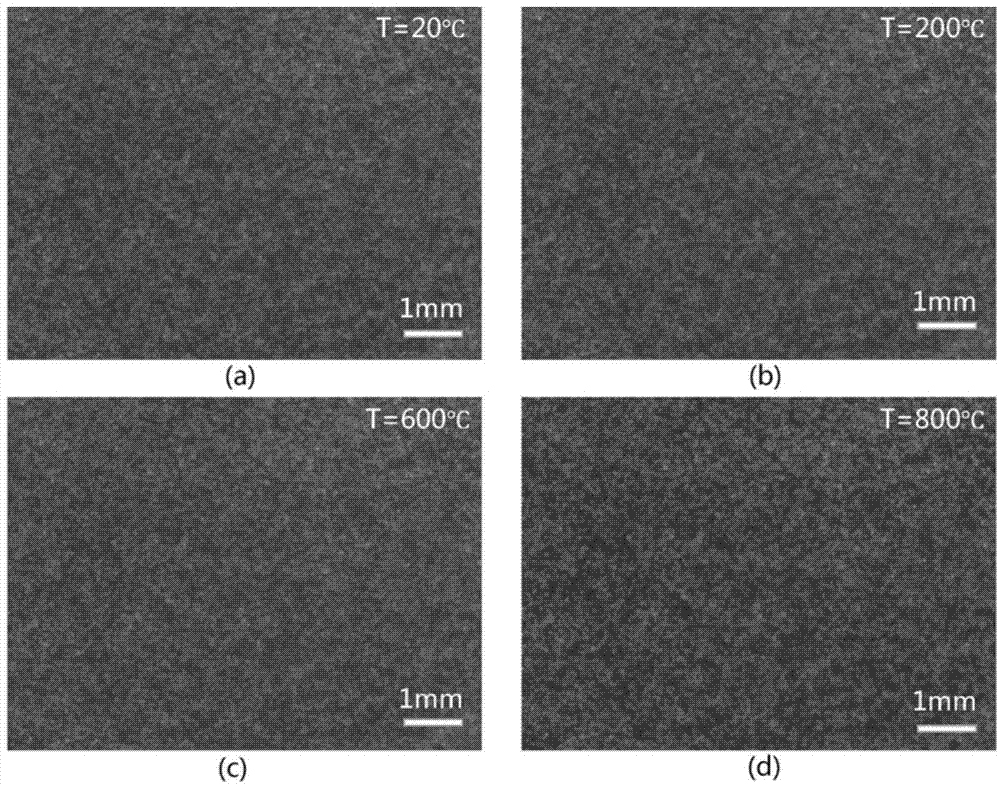

DIC weld dynamic strain measurement based high-temperature speckle preparation method

ActiveCN104777021AImprove bindingLow costPreparing sample for investigationOptical measurementsDigital image

The invention relates to a DIC weld dynamic strain measurement based high-temperature speckle preparation method. The DIC weld dynamic strain measurement based high-temperature speckle preparation method comprises the following steps: preparing a double-component aluminosilicate into pasty high-temperature resistant glue; grinding, polishing, coating the surface of a substrate material cleaned by alcohol with the high-temperature-resistant glue, then scattering a layer of evenly distributed high-temperature-resistant particles on the high-temperature-resistant glue, and modifying the surface of the substrate material; curing the high-temperature-resistant glue, and thus preparing high-temperature-resistant speckles on the surface of the substrate material. Compared with the prior art, the speckles obtained by the method can resist temperature of around 800 DEG C; the preparation method is especially suitable for the measurement of digital images of weld dynamic strain and also can be applied to the measurement of mechanical performance under the conditions of material stretching, crack damage and the like at high-temperature environment, is novel in concept, is simple to operate, is low in preparation cost, and has wide application prospect in the high-temperature optical measurement mechanical performance.

Owner:SHANGHAI JIAO TONG UNIV

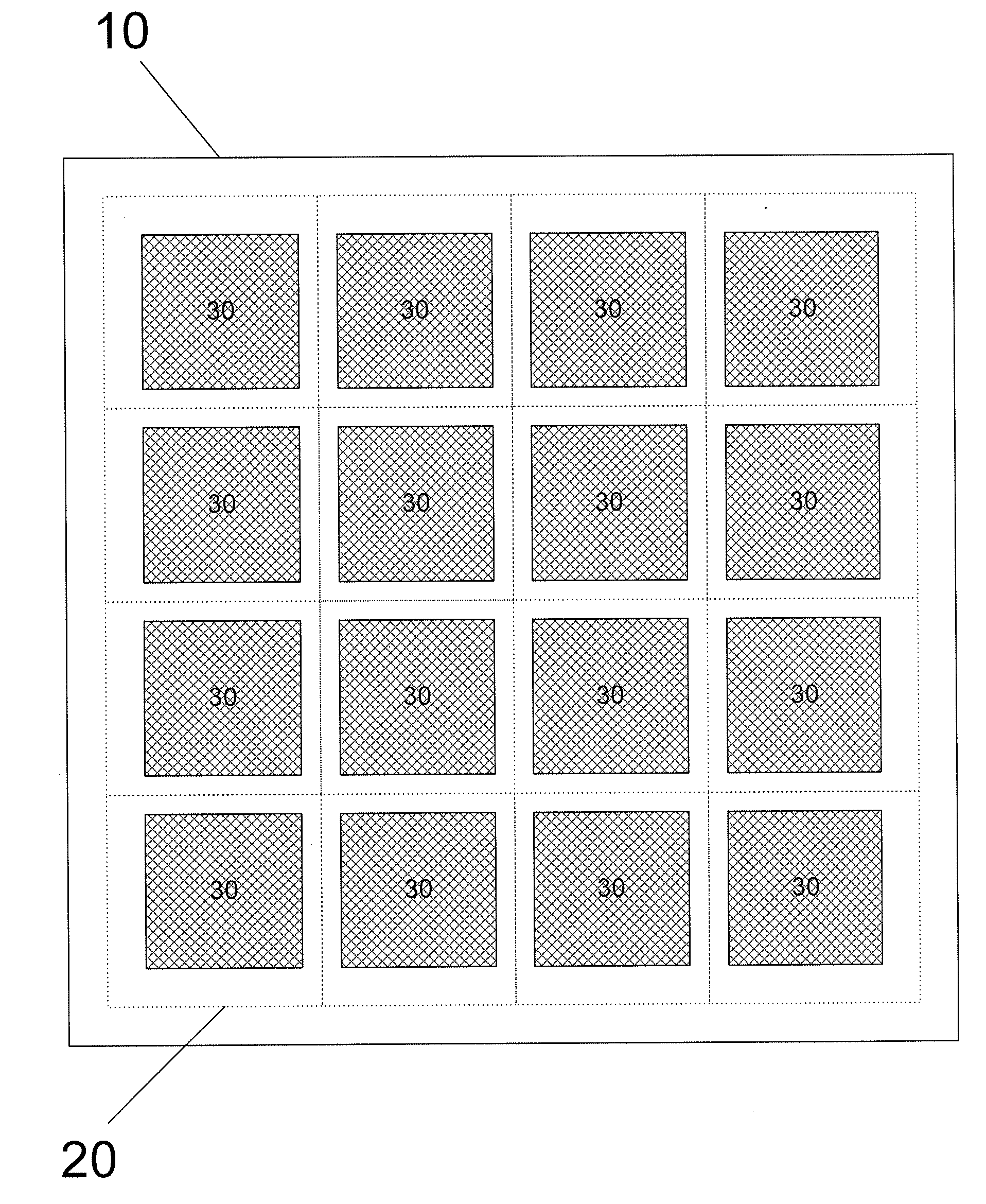

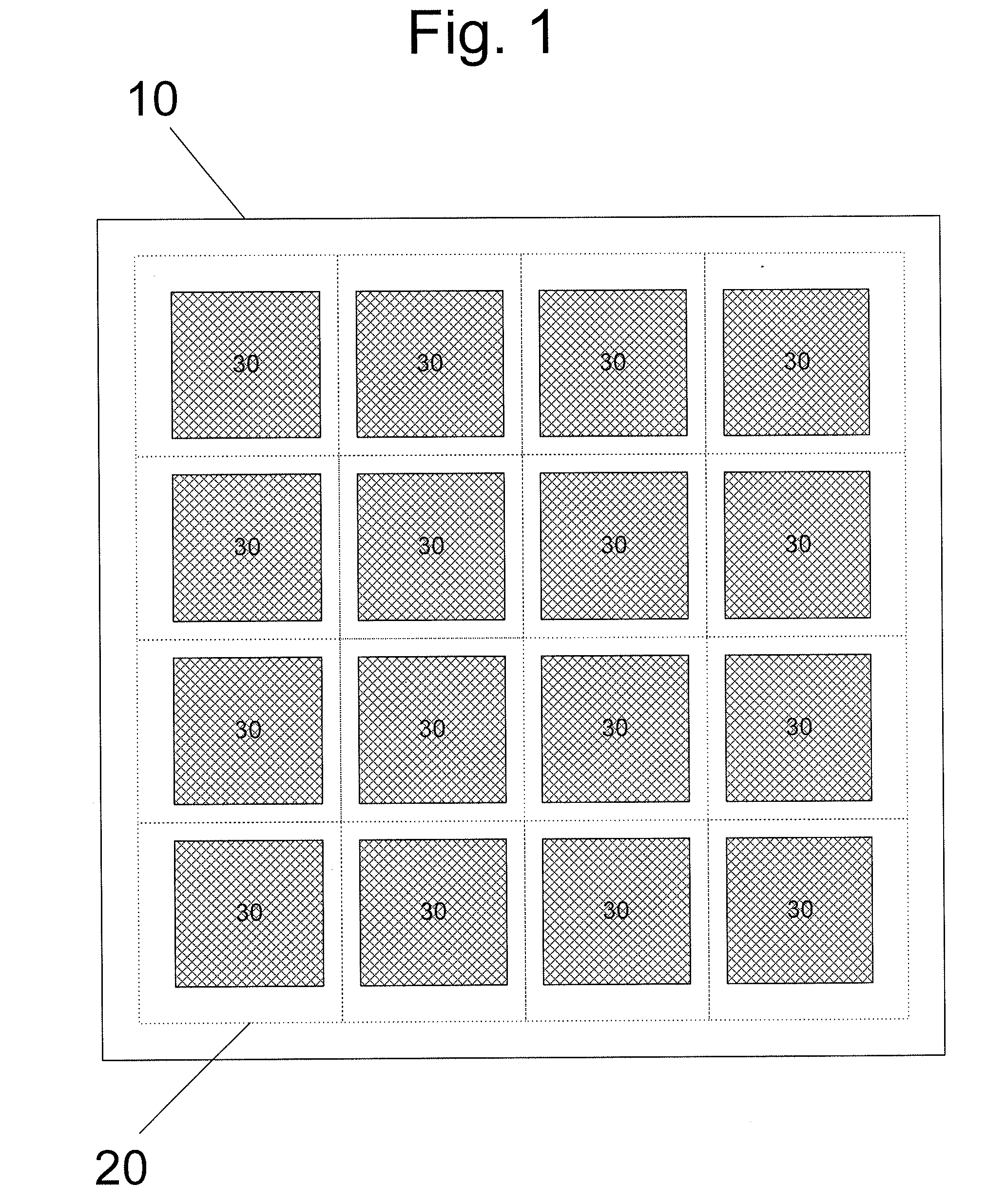

Multi-point loading control curved surface stretch forming device

The invention provides a multi-point loading control curved surface stretch forming device. The device is mainly composed of a machine body framework, a mold installing base, a loading control unit set and a loading control auxiliary mechanism, wherein the loading control unit set and the loading control auxiliary mechanism are distributed on the two sides of the mold installing base; the loading control unit set is composed of a plurality of loading control units; each loading control unit comprises a clamping forcep with the movement capable of being independently controlled, a flexible belt with the work length adjustable, a movable slider capable of moving up and down, a vertical lead screw and a vertical movement control motor; the load in plate material stretch forming is applied by the clamping forceps; the movement trajectories of the clamping forces are controlled through the loading control units; a plate material and a stretch forming mold molded surface can be closely attached in real time, and the optimal curved surface stretch forming effect and an accurate stretch-forming curved surface part are obtained; and the device is adopted for forming the curved surface part, various defects in the curved surface forming process can be avoided, the excessive materials of the process can be remarkably reduced, and materials are saved.

Owner:JILIN UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com