Aging test method and apparatus under wet, heat and power multiple-field coupling

A technology of aging test and test steps, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of overestimating the anti-aging properties of materials, hidden dangers of engineering design, etc., and achieve the effect of low cost and accurate test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

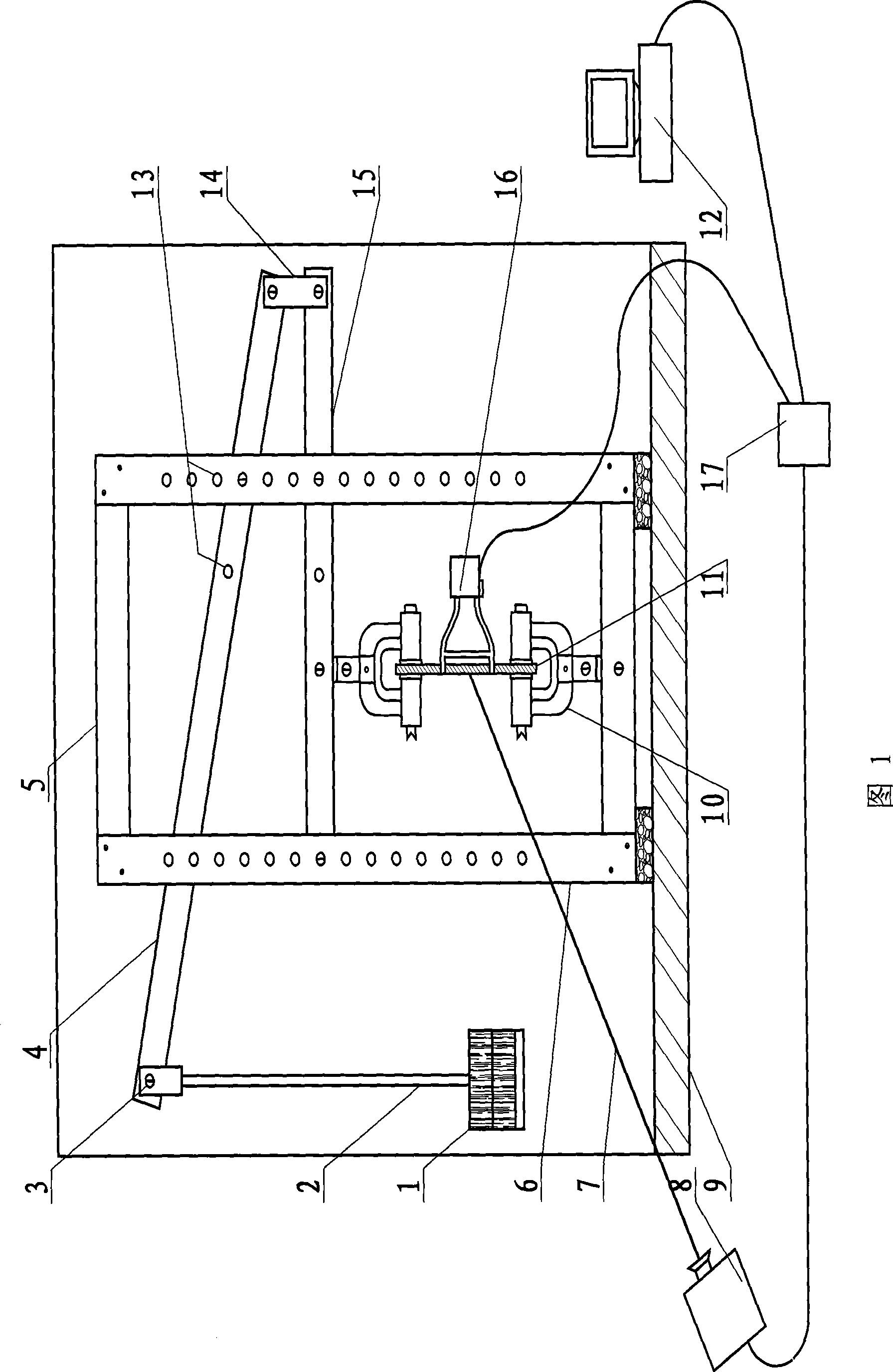

[0021] The preferred embodiments of the present invention are described in detail in conjunction with the accompanying drawings as follows: as shown in Figure 1, this humidity, heat, force multi-field coupling aging test device comprises an environmental chamber 9 with an environmental control system, is characterized in that described environment A sample clamping and loading mechanism 5 is placed in the box 9; the two clamping heads of an electronic extensometer 16 are respectively clamped to the two ends of the extension gauge length of the sample 11, and the laser beam 7 of a laser extensometer 8 is aligned with the sample. At the extension gauge length of the sample 11, the output terminals of the electronic extensometer 16 and the laser extensometer 8 are electrically connected to an input terminal of a collector 17 containing an amplifier circuit, a filter circuit and a conversion circuit, and the collector 17 The output is connected to a computer 12 .

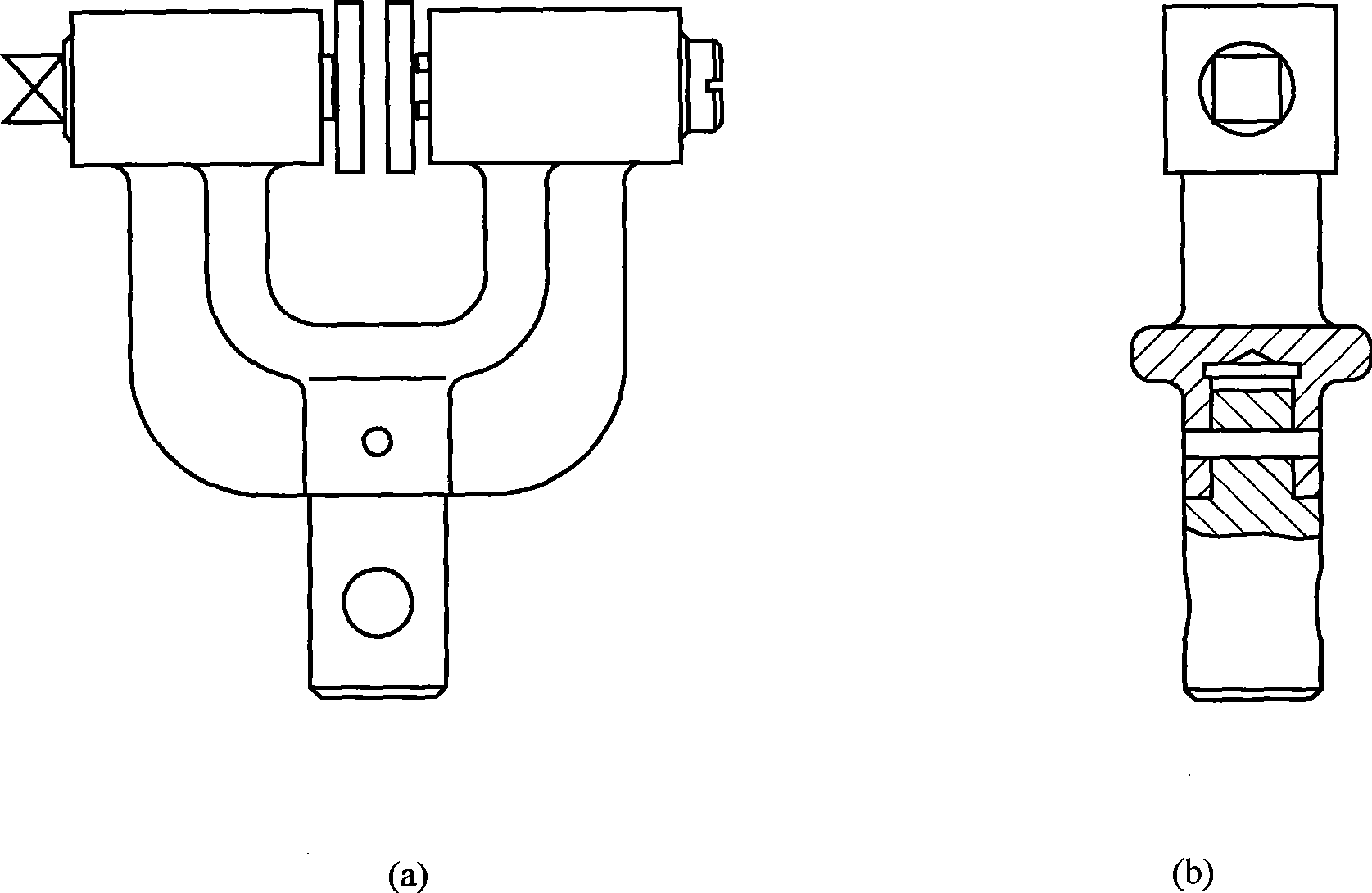

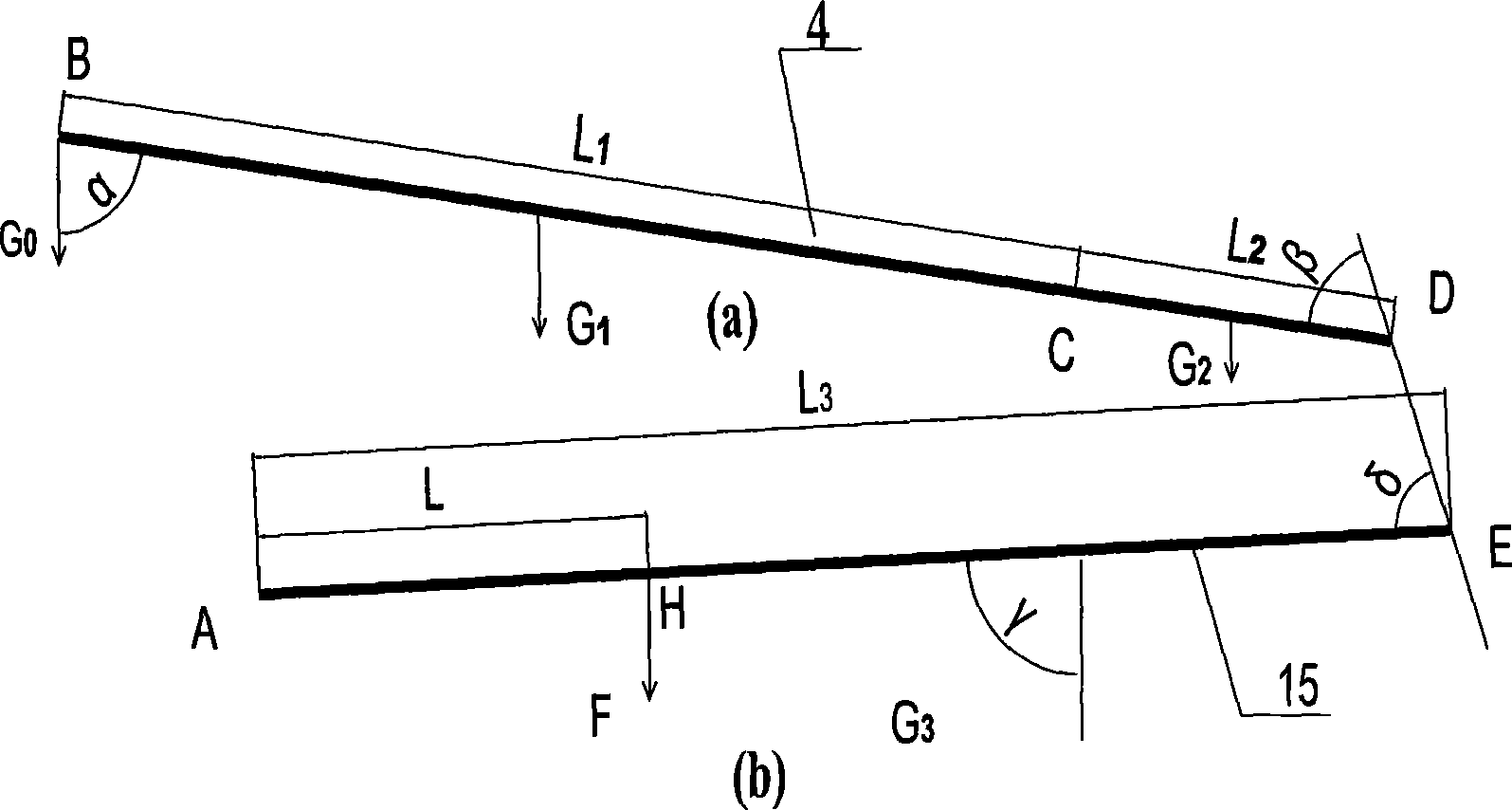

[0022] The stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com