Micro-nano corrugated structure and preparation method thereof, and device and application of preparation method

A corrugated and injector technology, applied in textiles and papermaking, filament/thread molding, spinneret assemblies, etc., can solve the problems of long time-consuming, complicated process, high cost, etc., to avoid residual stress, simple preparation process, Graphically Accurate Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A: Prepare a polyethylene oxide solution with a concentration of 6% by weight, stir with a magnetic stirrer at 30°C for 20 hours, and stand still for 2 hours;

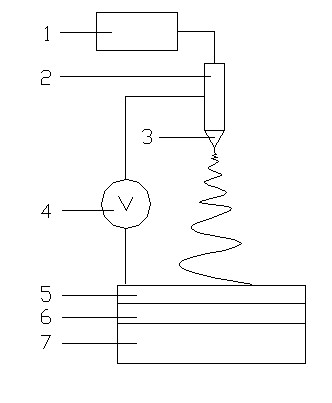

[0031] B: inject the above solution into the syringe 3, the inner diameter of the metal nozzle of the syringe is 0.8mm, and the metal nozzle is connected to the positive electrode of the high-voltage generator; use a gold-plated silicon chip as the metal collecting plate 5, and the distance between the metal collecting plate 5 and the metal nozzle 4 is 5cm; the metal collecting plate 5 is fixed on the moving platform X, moves in one direction at a speed of 5mm / s, and applies a voltage of 7KV for electrospinning.

Embodiment 2

[0033] A: Prepare a polyethylene oxide solution with a concentration of 6% by weight, stir with a magnetic stirrer at 30°C for 20 hours, and stand still for 2 hours;

[0034] B: inject the above solution into the syringe 3, the inner diameter of the metal nozzle of the syringe is 0.8mm, and the metal nozzle is connected to the positive electrode of the high-voltage generator; use a gold-plated silicon chip as the metal collecting plate 5, and the distance between the metal collecting plate 5 and the metal nozzle 4 is 5 cm; the metal collecting plate 5 is fixed on the moving platform X, the PDMS rubber substrate 6 is placed on the metal collecting plate 5, moves in one direction at a speed of 5mm / s, and is electrospun with an applied voltage of 8KV.

Embodiment 3

[0036] A: Prepare a PEDOT:PSS conductive solution with a concentration of 6% by weight, stir it with a magnetic stirrer at 25°C for 10 hours, and stand still for 2 hours;

[0037]B: inject the above-mentioned solution into the syringe 3, the inner diameter of the metal nozzle of the syringe is 0.6 mm, and the metal nozzle is connected to the positive electrode of the high-voltage generator; a gold-plated silicon wafer is used as the metal collecting plate 5, and the distance between the metal collecting plate 5 and the metal nozzle 4 is 3cm; the metal collecting plate 5 is fixed on the moving platform X, the PDMS rubber substrate 6 is placed on the metal collecting plate 5, moves in one direction at a speed of 7mm / s, and is electrospun with an applied voltage of 10KV.

[0038] The above embodiments only provide illustrative steps, wherein the concentration, voltage, inner diameter of the nozzle, and speed of the moving platform can be selected according to the experimental cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com