Stretching-compression combined type flexible three-dimensional section material stretch-bend forming process and device

A stretch-bending and profile technology, applied in the field of profile three-dimensional stretch-bending equipment, can solve the problems of low efficiency of manual shape adjustment, poor precision, and high labor intensity, so as to improve production efficiency and forming accuracy, reduce mold manufacturing costs, The effect of reducing artificial strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Specific implementation mode 1: This implementation mode will be described in conjunction with the drawings and embodiments.

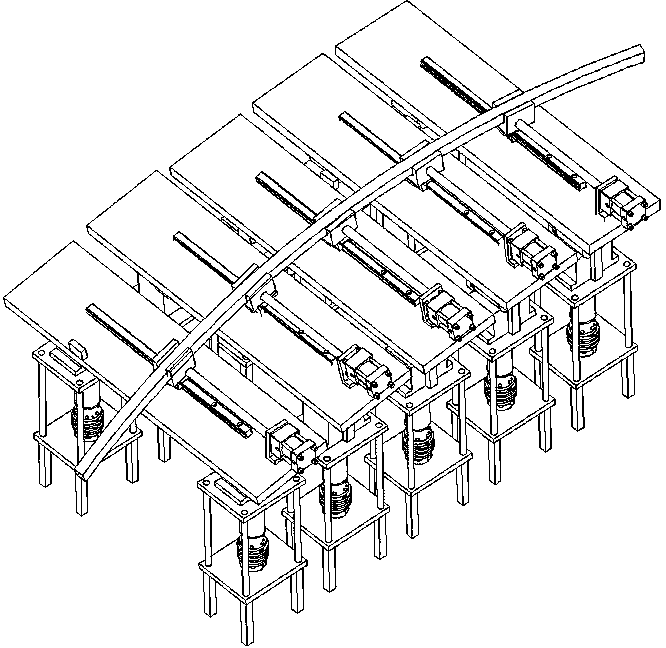

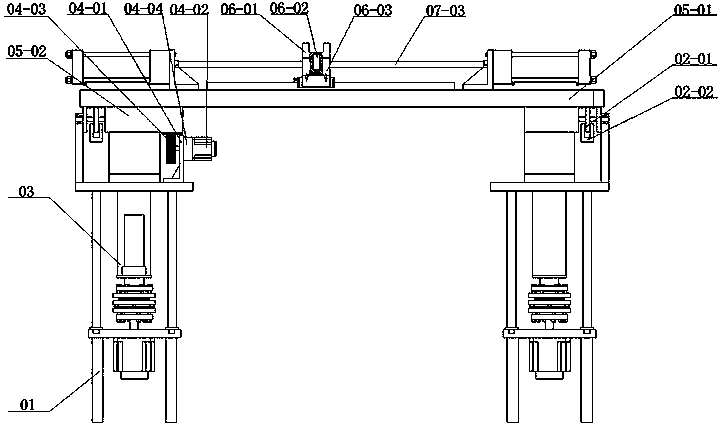

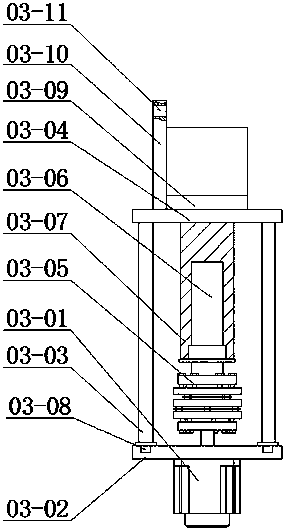

[0018] A flexible three-dimensional stretch-bending forming device for combined tension-compression profiles. This equipment is composed of several regularly arranged and identical forming units, such as figure 2 As shown, each forming unit consists of two ends of the frame (01), two disc brake devices (02), two synchronous vertical lifting devices (03), a rotary shape adjustment device (04), and a workbench (05) , mold assembly (06), hydraulic actuator (07), and sensor (08); the vertical lifting device (03) is installed on the frame (01); the rotary shape-adjusting device (04) is installed at one end of the vertical lifting on the device (03); the workbench (05) is installed on the rotary shape adjusting device (04); the mold assembly (06), hydraulic actuator (07) and sensor (08) are installed on the workbench (05); the clamp (09) are placed ...

Embodiment 1

[0026] Embodiment 1, three-dimensional stretch-bending forming of rectangular cross-section aluminum profile "C" shape:

[0027] In the first step, the target part is projected as a circular arc on the horizontal plane and the vertical plane, and the number of unit bodies used is determined to be 6 according to the drawing of the target three-dimensional stretch-bending forming part;

[0028] The second step is to determine the shape adjustment parameters of the number 1-6 shape adjustment unit, including: the height of the shape adjustment in the vertical direction, the rotation angle of the worktable, and the extension length of the piston rod of the hydraulic actuator;

[0029] In the third step, the material of the part is aluminum profile. After confirming the process parameters and pre-stretching amount, the vertical height and rotation angle of each forming unit are automatically adjusted according to the shape adjustment parameters. After the shape is adjusted to the sp...

Embodiment 2

[0037] Embodiment 2, three-dimensional stretch-bending forming of rectangular cross-section aluminum profile "S" shape:

[0038]In the first step, the target part is projected as an "S"-shaped curve on the horizontal plane, and projected as a circular arc on the vertical plane. According to the drawing of the target three-dimensional stretch-bending forming part, the number of unit bodies used is determined to be 6;

[0039] The second step is to determine the shape adjustment parameters of the number 1-6 shape adjustment unit, including: the height of the shape adjustment in the vertical direction, the rotation angle of the worktable, and the extension length of the piston rod of the hydraulic actuator;

[0040] In the third step, the material of the part is aluminum profile. After confirming the process parameters and pre-stretching amount, the vertical height and rotation angle of each forming unit are automatically adjusted according to the shape adjustment parameters. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com