Friction factor measuring and calculating method during metal plastic forming

A technology of plastic forming and friction factor, which is applied to measuring devices, instruments, and mechanical devices, etc., can solve the problems that the influence of metal materials cannot be taken into account, the convenience and accuracy of measurement methods cannot meet the requirements at the same time, and avoid inconvenience. and the effect of bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is further illustrated by an example below.

[0037] Such as Figure 1 to Figure 5 As shown, a method for calculating friction factor in metal plastic forming according to the present invention, the method comprises the following steps:

[0038]1) Use the metal material to be tested (aluminum alloy 1100) to make a tensile test sample, and use the standard metal material tensile test method to measure the strain intensification coefficient of the metal material to be tested n =0.242;

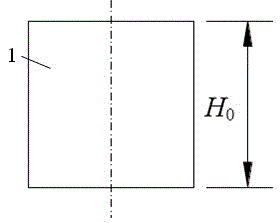

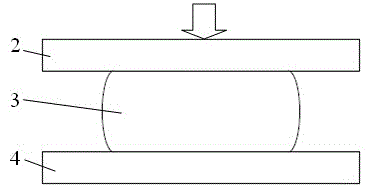

[0039] 2) Use the mold material to be tested (steel H13) to make the upsetting forming mold, including the upsetting forming upper mold 2 and the upsetting forming lower mold 4, install the upsetting forming mold on the universal material testing machine, and set the upsetting forming mold on the upsetting forming mold. Apply the lubricant to be tested (graphite lubricant);

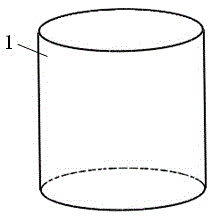

[0040] 3) Use the metal material to be tested (aluminum alloy 1100) to make a cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com