DIC weld dynamic strain measurement based high-temperature speckle preparation method

A dynamic strain and speckle technology, applied in the field of mechanical and optical testing, can solve the problems of large impact, difficult to guarantee the quality of speckle, easy to fall off of speckle, etc., to achieve easy control of density, easy control of speckle quality, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The high-temperature speckle preparation method based on DIC welding dynamic strain test adopts the following steps:

[0026] 1. Cut the base material into the desired shape, perform grinding and polishing treatment, use absolute ethanol to clean the surface of the base material, and dry;

[0027] 2. Prepare watch glasses, glass rods, small flat spatulas, medicine spoons, two-component aluminosilicate materials, and white high-temperature-resistant powder materials;

[0028] 3. In a watch glass, according to the solid-liquid ratio of 0.5 ~ 1.0g: 1mL, prepare the two-component aluminosilicate material into a paste-like high-temperature-resistant glue;

[0029] 4. Use a small flat shovel to take an appropriate amount of high-temperature-resistant glue and place it on the surface of the base material, and use a small flat shovel to evenly coat the high-temperature glue into a thin layer with a thickness of 0.1-0.2mm;

[0030] 5. Use a medicine spoon to take an appropriate...

Embodiment 1

[0035] The base material is aluminum alloy with a size of 75mm×25mm×1.5mm. The process of preparing high temperature resistant speckle on the aluminum alloy surface is as follows:

[0036] 1. Take two pieces of the aluminum alloy, use absolute ethanol to clean the surface of the aluminum alloy, and dry;

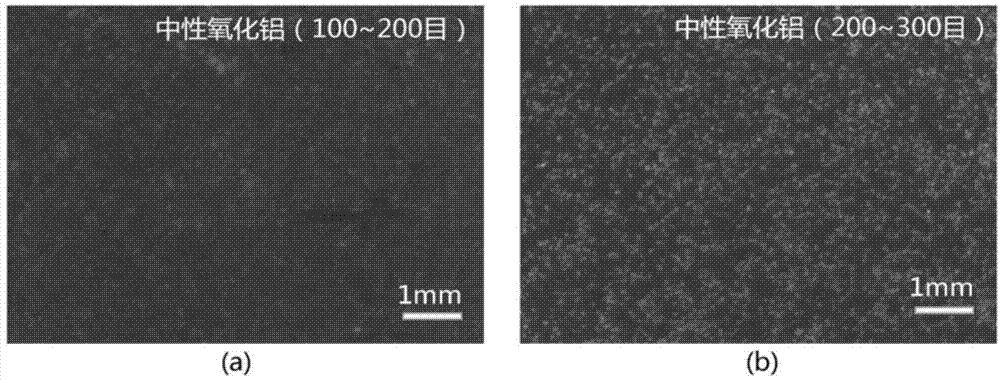

[0037] 2. Prepare watch glass, glass rod, small flat spatula, medicine spoon, two-component aluminosilicate material, neutral alumina (100-200 mesh), neutral alumina (200-300 mesh);

[0038] 3. In a watch glass, according to the solid-liquid ratio of 0.7g:1mL, prepare the two-component aluminosilicate material into a paste-like high-temperature-resistant glue;

[0039] 4. Use a small flat shovel to take an appropriate amount of high-temperature-resistant glue and place them on the surfaces of two aluminum alloys, and use a small flat shovel to evenly coat the high-temperature glue into a thin layer with a thickness of 0.1-0.2mm;

[0040] 5. Use a medicine spoon to take an ap...

Embodiment 2

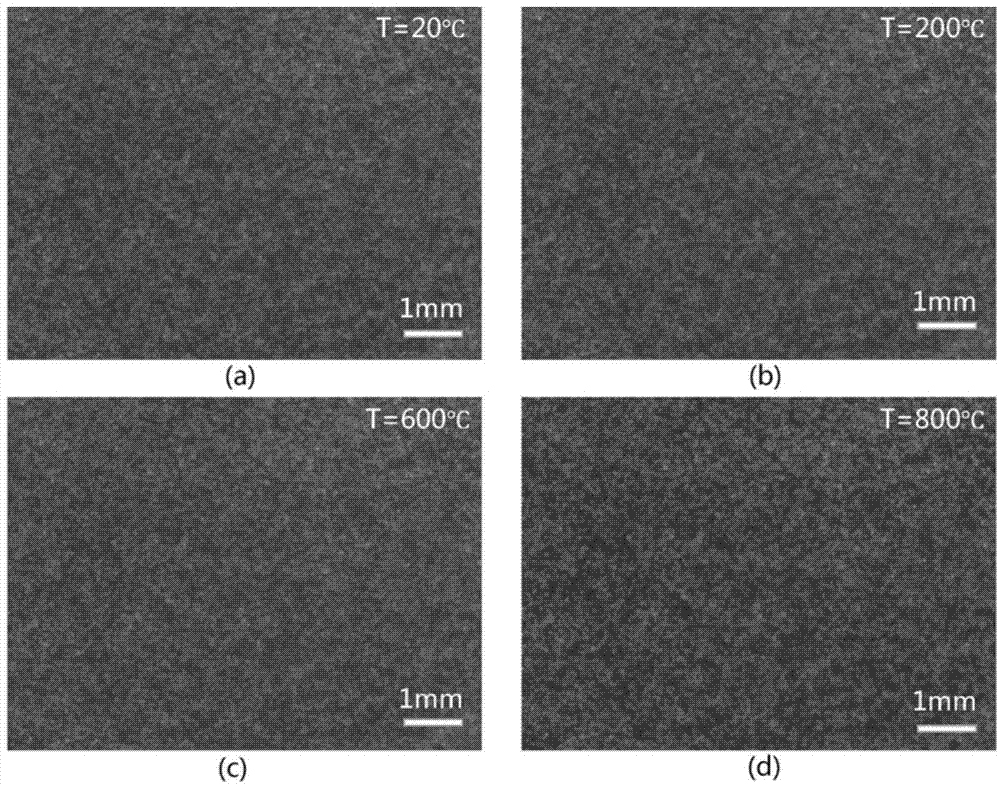

[0044] The base material is a copper plate with a size of 50mm×50mm×2.0mm. The specific steps for preparing high-temperature-resistant speckles on the surface of the copper plate are as follows:

[0045] 1. Take three pieces of the copper plate, grind and polish them, use absolute ethanol to clean the surface of the copper plate, and dry;

[0046]2. Prepare watch glass, glass rod, small flat spatula, medicine spoon, two-component aluminosilicate material, neutral alumina (200-300 mesh);

[0047] 3. In a watch glass, according to the solid-liquid ratio of 0.7g: 1mL, prepare the two-component aluminosilicate material into a paste-like high-temperature-resistant glue;

[0048] 4. Use a small flat shovel to take an appropriate amount of high-temperature-resistant glue and place them on the surfaces of the three copper plates, and use a small flat shovel to evenly coat the high-temperature glue into a thin layer with a thickness of 0.1-0.2mm;

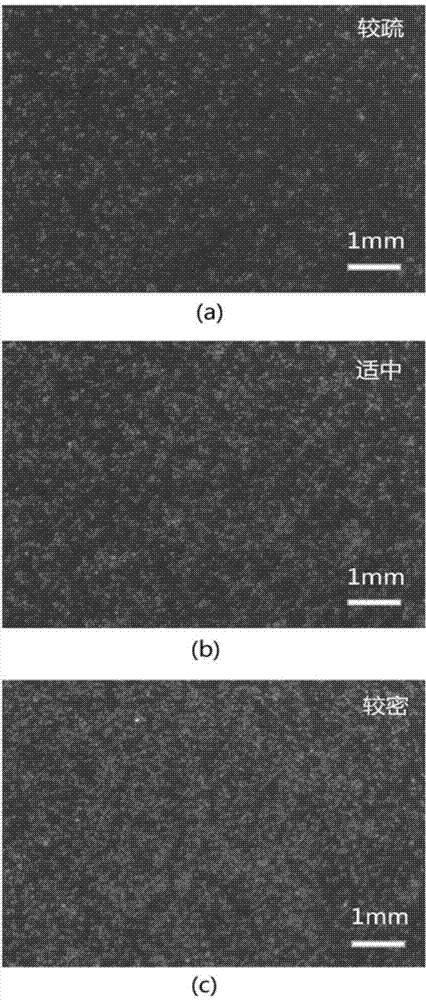

[0049] 5. Use a medicine spoon to ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com