Tapered tube made of glass fiber and carbon fiber hybrid composite materials and method for manufacturing tapered tube

A glass fiber and composite material technology, applied in chemical instruments and methods, glass/slag layered products, synthetic resin layered products, etc. Low modulus and other problems, to achieve good magnetic permeability and photostability, simple and easy molding process, and improved tensile modulus.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

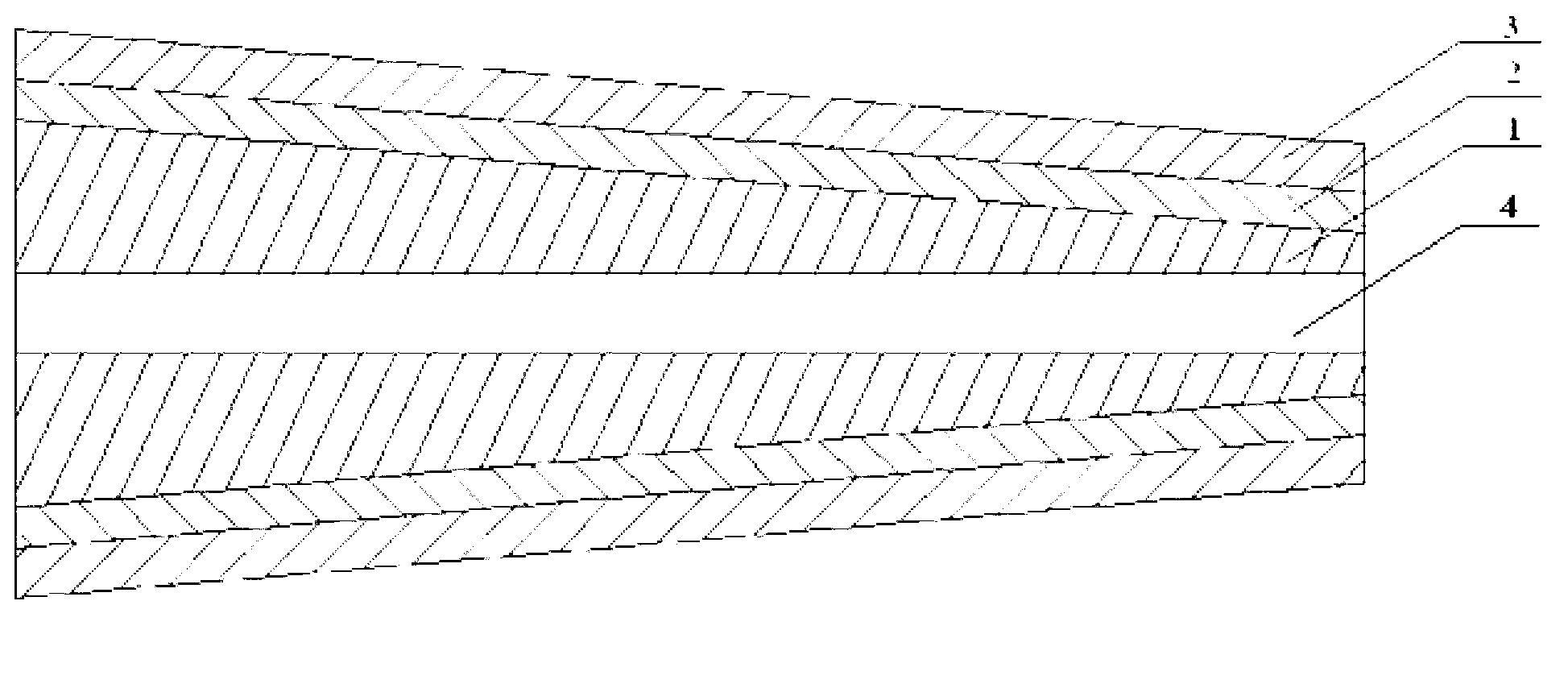

[0015] Embodiment 1: The pipe wall of the glass fiber and carbon fiber hybrid composite tapered pipe of this embodiment is a three-layer composite structure, the inner layer is the first glass fiber layer 1, the middle layer is the carbon fiber layer 2, and the outer layer is The second glass fiber layer 3, the through hole 4 in the middle of the tapered tube is cylindrical, the length of the through hole 4 is 7.0-15.0m, the diameter of the through hole 4 is 50-200mm, and the thickness of the bottom end of the tapered tube is 19.0 ~32.0mm, the wall thickness at the top is 9.0~17.0mm.

specific Embodiment approach 2

[0016] Embodiment 2: This embodiment differs from Embodiment 1 in that: the thickness of the first glass fiber layer 1 at the bottom of the tapered tube is 14.0-21.0 mm, and the thickness of the first glass fiber layer 1 at the top of the tapered tube is 4.0-6.0mm, the carbon fiber layer 2 in the middle layer of the tapered tube is uniformly thick from top to bottom, with a thickness of 3.0-8.0mm, and the second glass fiber layer 3 on the outer layer of the tapered tube is uniformly thick from top to bottom, with a thickness of 2.0-3.0mm. Other steps and parameters It is the same as the first embodiment.

specific Embodiment approach 3

[0017] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the thickness of the first glass fiber layer 1 at the bottom of the tapered tube is 16.0-19.0 mm, and the first glass fiber layer at the top of the tapered tube is 1 The thickness is 5.0 mm, the carbon fiber layer 2 in the middle layer of the tapered tube is uniformly thick at the top and bottom, and the thickness is 4.0-7.0 mm, and the second glass fiber layer 3 of the outer layer of the tapered tube is uniformly thick at the top and bottom, and the thickness is 2.5 mm. Embodiment 1 or 2 are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com