A kind of lithium-sulfur battery positive electrode material and its preparation method and lithium-sulfur battery

A lithium-sulfur battery and cathode material technology, which is applied to battery electrodes, lithium storage batteries, non-aqueous electrolyte storage batteries, etc., can solve the problem of reducing ionic conductivity, poor sulfur conductivity, and the improvement effect of lithium-sulfur battery cycle performance and rate performance is not obvious. and other problems, to achieve the effect of alleviating changes in sulfur pressure and volume, improving cycle stability, and inhibiting shuttle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

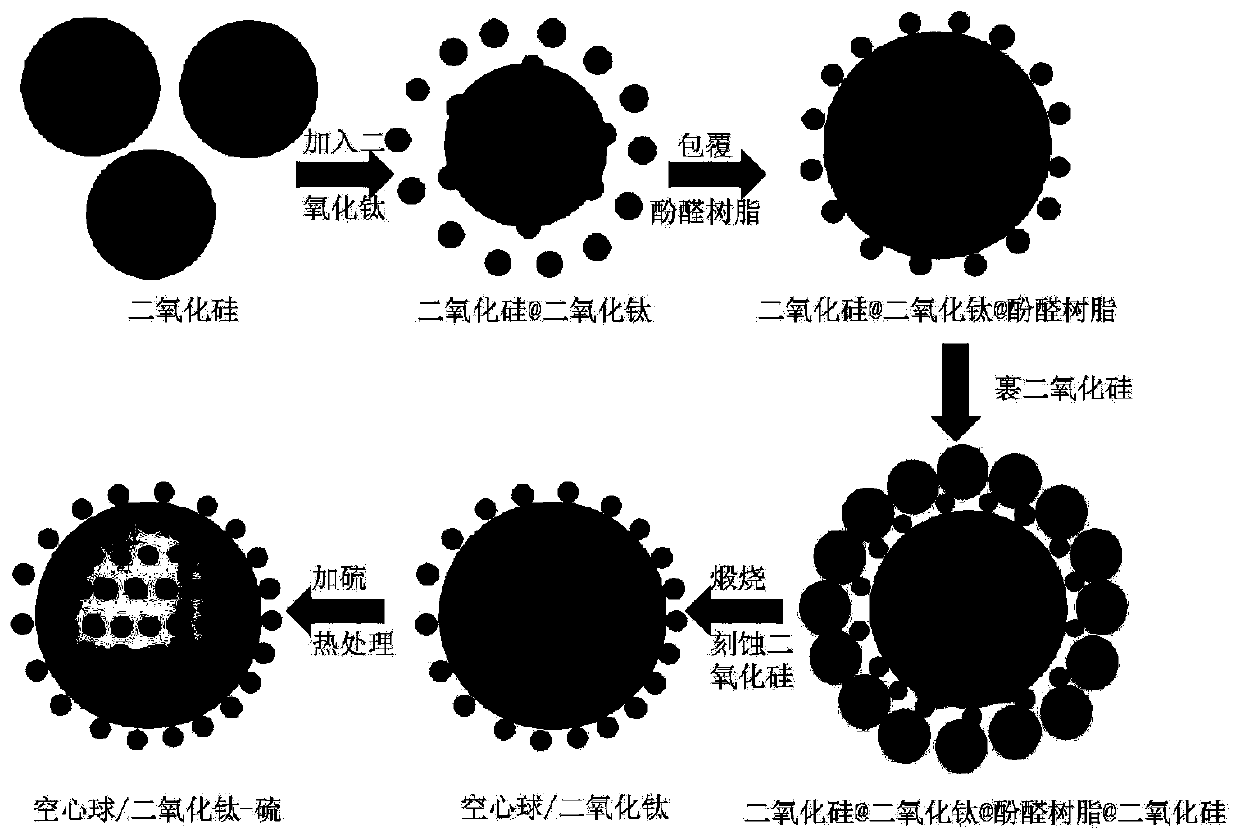

[0033] The present invention also provides a preparation method for the lithium-sulfur battery cathode material described in the above technical solution, comprising the following steps:

[0034] (1) mixing the nano silicon dioxide suspension with the nano titanium dioxide to obtain a mixed suspension;

[0035] (2) adding surfactant, phenols, formaldehyde and catalyst successively to the mixed suspension obtained in said step (1), and polycondensation reaction to obtain the first precursor;

[0036](3) Mix the first precursor obtained in the step (2) with a mixed solvent, add tetraethyl orthosilicate, and perform a hydrolysis reaction to obtain a second precursor;

[0037] (4) Etching the second precursor obtained in step (3) after calcining to obtain a titanium dioxide-carbon hollow sphere composite; the titanium dioxide-carbon hollow sphere composite includes carbon hollow spheres and carbon hollow spheres attached to the Nano-titanium dioxide on the inner and outer surface...

Embodiment 1

[0072] Prepare a mixed solution (75mL ethanol + 3.2mL ammonia water (26wt%) + 10mL deionized water), under the condition of continuous stirring, quickly add 6ml tetraethyl orthosilicate to the above solution within 3s, and react at 20°C for 1h , separating the solid product and drying to obtain silica with a particle size of 250nm;

[0073] Disperse the prepared silicon dioxide and 2.5g of titanium dioxide in a mixed solvent of 130mL deionized water and 50mL ethanol, and stir at 20°C for 20min; then add 0.8g cetyltrimethylammonium bromide, 0.35g Resorcinol, 0.5mL of formaldehyde and 2mL of ammonia water (26wt%) were reacted at 30°C for 15h, and the solid product was separated and dried to obtain a precursor 1;

[0074] Disperse the precursor into a mixed solution of 75mL ethanol, 10mL deionized water and 3.2mL ammonia water (26wt%). Under stirring conditions, 3mL tetraethyl orthosilicate was quickly added to the above solution within 3s to separate the solid product and dry t...

Embodiment 2

[0081] The lithium-sulfur battery cathode material prepared in Example 1 was assembled into a lithium-sulfur battery: the titanium dioxide-carbon hollow sphere / sulfur prepared in Example 1 was used as the cathode material, carbon black (SuperP) was used as the conductive material, polyylidene difluoride Ethylene is the binder, the current collector is an aluminum sheet, the negative electrode is a lithium sheet, the diaphragm is a Celgard2400 film, the supporting sheet is a spring sheet, and the electrolyte is 1M lithium bistrifluoromethanesulfonylimide (LiTFSI) dissolved in 1,3 - dioxolane (DOL) / ethylene glycol dimethyl ether (DME) = 1:1 V%, and 1% lithium nitrate was added.

[0082] The charge-discharge curve of the lithium-sulfur battery prepared in this example is as follows Figure 4 shown. from Figure 4 It can be seen that at 1C, the discharge capacity of the battery remains 691mAh g after 200 cycles -1 .

[0083] The rate performance of the lithium-sulfur battery p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com