Constant Loading tension-compression test machine

A testing machine and constant load technology, which is applied in the direction of testing material strength by applying stable tension/compression, and testing material strength by applying stable shear force, which can solve the problems of inability to automatically record data, low device accuracy, and floor space Large and other problems, to achieve the effect of simple structure, large measuring range and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

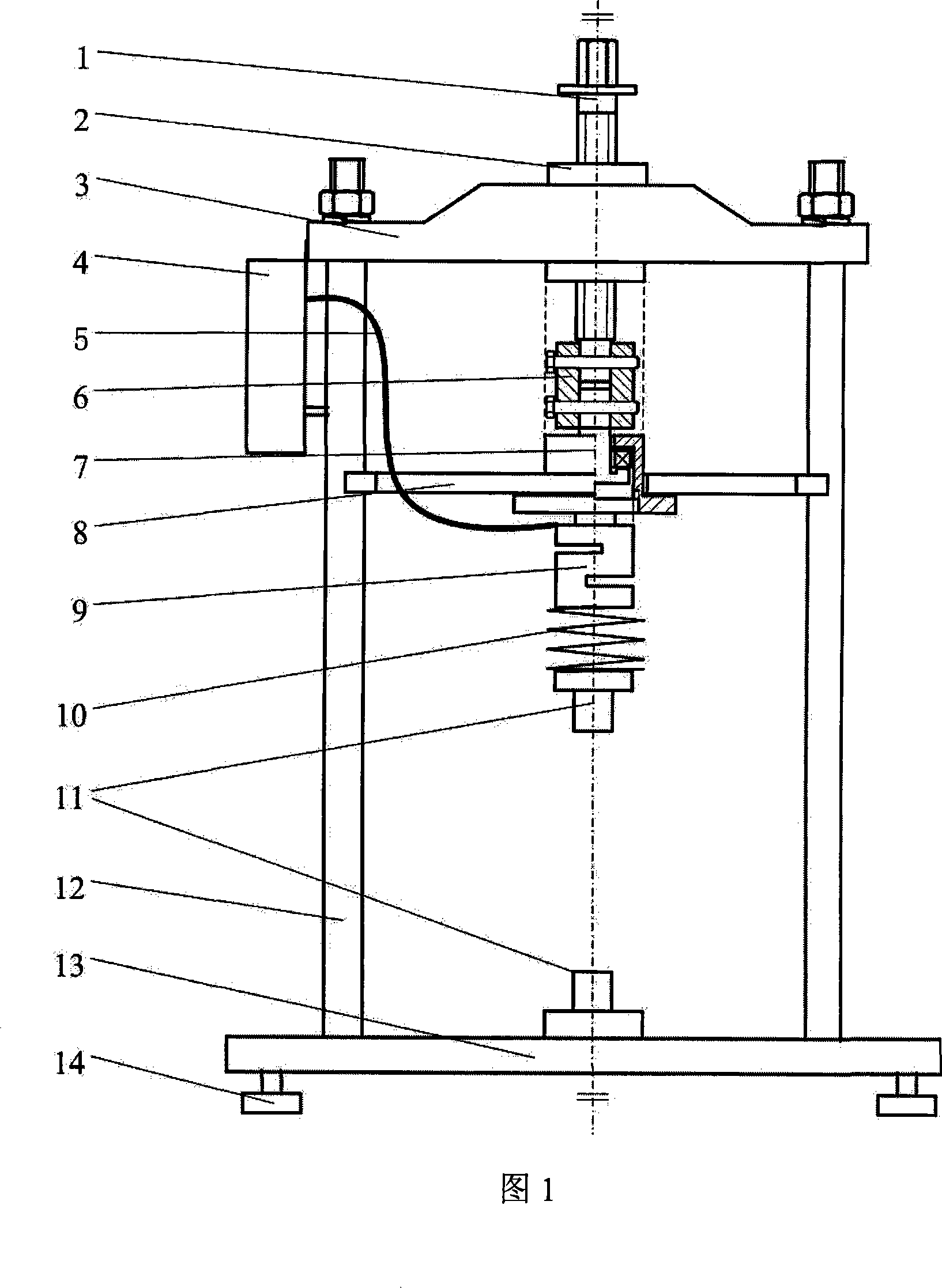

[0011] Fig. 1 is an embodiment of the present invention.

[0012] The frame includes a beam 3 , two columns 12 , a base 13 and four feet 14 . These four components form a strong frame to mount and support the entire installation. The legs are fixed on the four corners below the base 13, and the height can be adjusted by threads to level the base. Two upright posts are installed on the base 13 for supporting the beam 3 and bearing the additional load during work. The crossbeam 3 is installed on the top of the crossbeam, and its two ends are firmly connected with the columns 12 .

[0013] The transmission part is composed of a transmission screw 1, a transmission nut 2, a connector 6, a thrust bearing mechanism 7, and a horizontal limiter 8. In the preferred example, the nut 2 is fixed on the crossbeam 3, the transmission part is connected with the frame through the nut 2, the transmission part is driven up and down by rotating the screw 1, the loading of the equipment is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com