Method for controlling whole-course displacement in program-controlled metal material stretching test

A technology of displacement control and tensile test, applied in the direction of electrical program control, program control in sequence/logic controller, using stable tension/pressure to test material strength, etc., can solve the problem of incomparability and influence of test results Accuracy, system flexibility test process complexity and other issues, to achieve the effect of improving work efficiency and simple model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The realization process of the whole process displacement control method of the metal material tensile test for program control of the present invention is described in conjunction with the accompanying drawings and embodiments.

[0040] The whole process displacement control method of the metal material tensile test for program control of the present invention, the test application program of the control method is set in the electro-hydraulic servo or electronic universal testing machine, the control method includes the following steps:

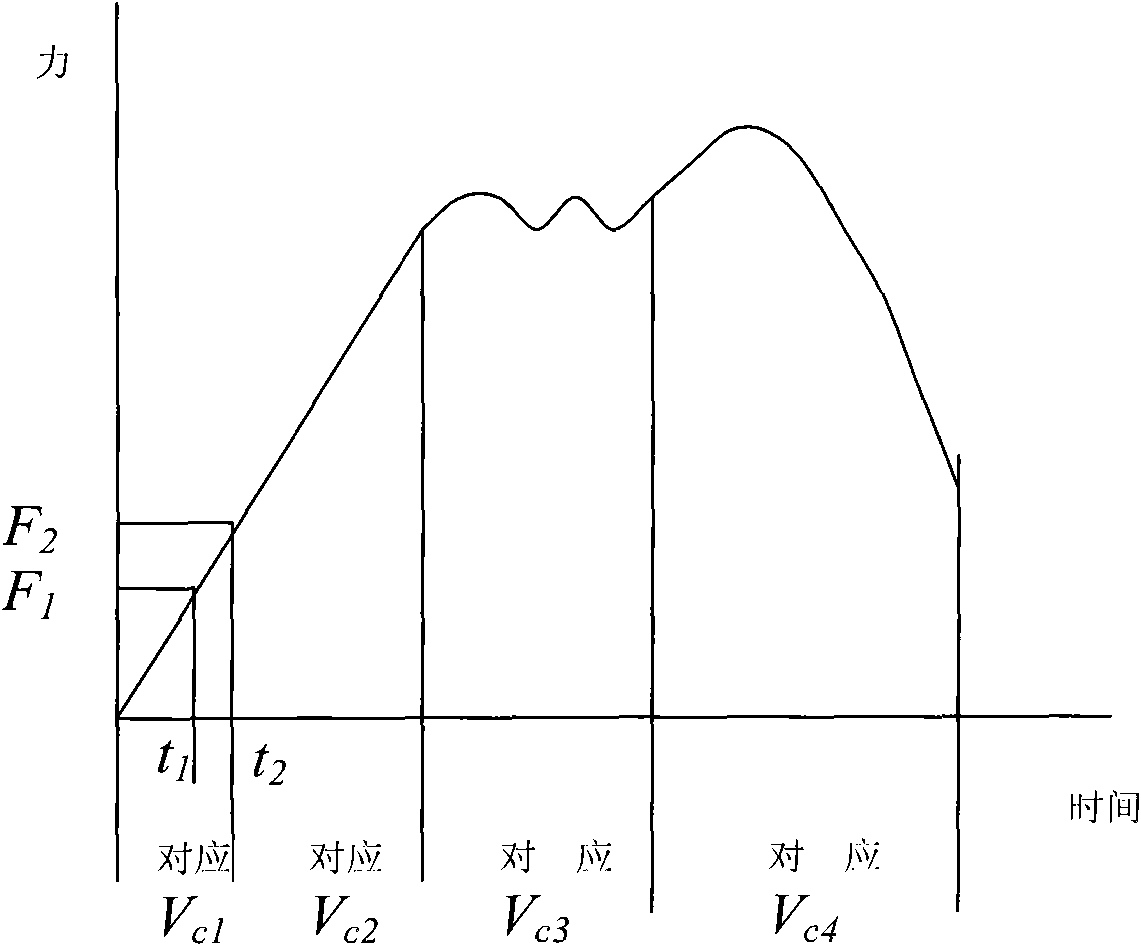

[0041] ①The first stage of displacement control

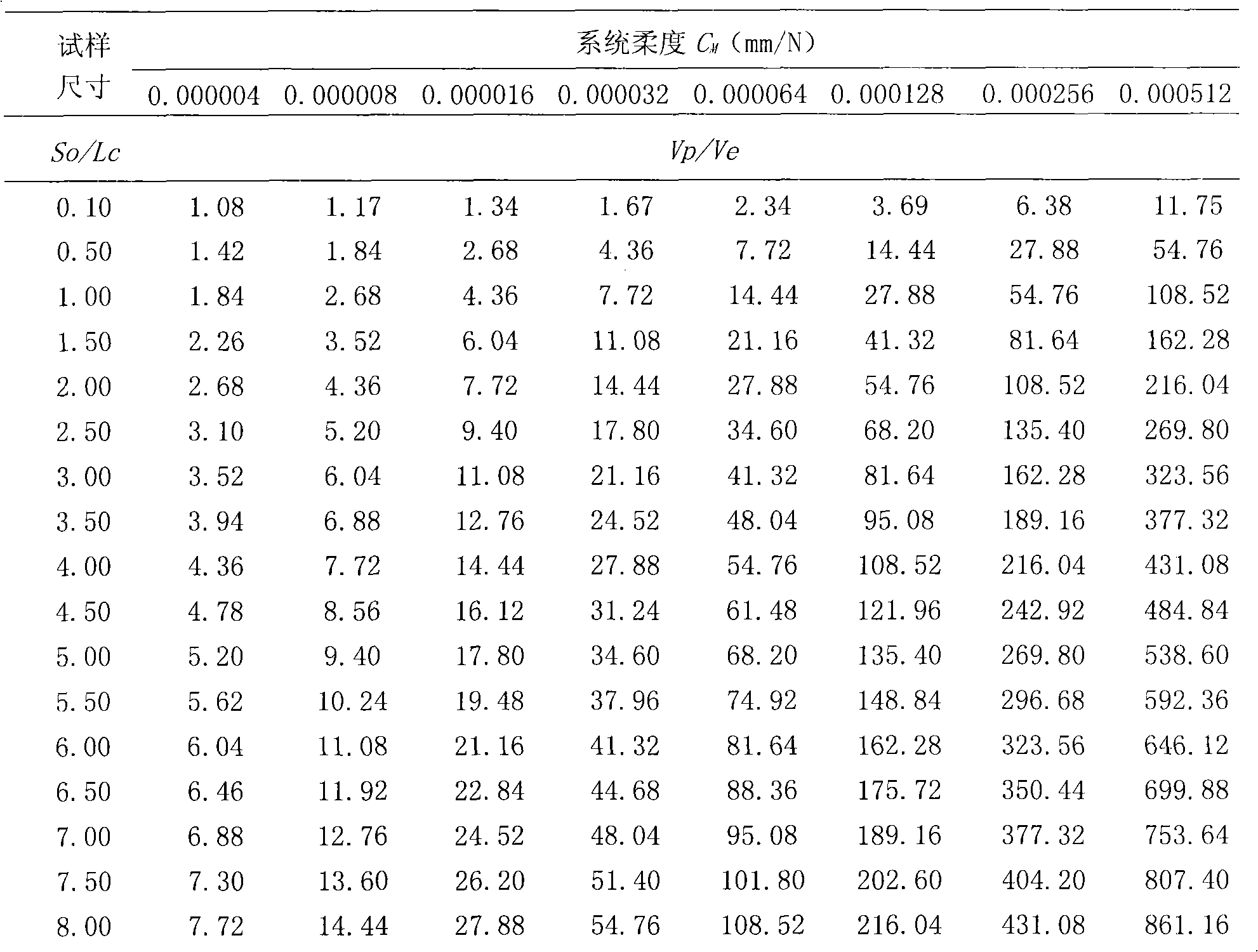

[0042] At the start of the test, the test application program tells the tester to move the grips by v c1 =0.00025(Lc+C M ES O ) to move toward the elongation direction of the sample until the load on the sample is F=F 2 end of time; C M and E take the default value; when F=F 2 , the program automatically calculates Then automatically calculate ready to C M Calculated values ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com