Car hook connecting and hanging method

A coupler and coupling technology, which is applied to railway car body parts, railway couplings, transportation and packaging, etc., can solve the problems of long time consumption, low efficiency and high risk factor, and achieve convenient use, low production cost, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

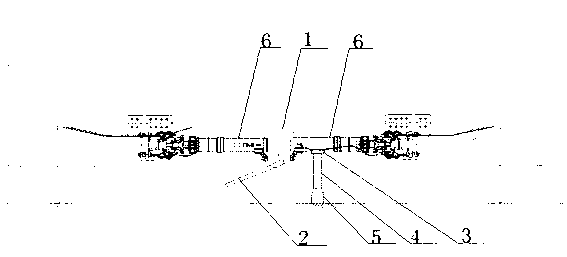

[0010] Referring to the accompanying drawings, the vehicle is arranged in the hanging position, and observe whether the ground under the coupler has a trench or whether it is flat. If there is a trench or unevenness, it is necessary to lay a support plate between the tracks to make it flat. The specific steps for connecting and hanging are as follows:

[0011] 1. Use the sling 1 on the side of the car body to connect the pulling points between the vehicles, and the operator uses the stirrer 2 to stir the vehicle to the distance of the coupler 6;

[0012] 2. After the coupler distance reaches the connecting distance, use the jack 5, the support rod 4 and the pad 3 to cooperate to lift the coupler to reach the connecting height, and continue to stir the sling with a stirring rod to make the connecting coupler tighter and seamless;

[0013] 3. After the jack pushes the coupler to a horizontal state and there is no gap between the two couplers, install the connecting ring accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com