Automatic sprayer of blasting

A spray device and automatic technology, applied in safety devices, mining equipment, earth-moving drilling, etc., can solve the problems of poor construction environment, low work efficiency, and long opening time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

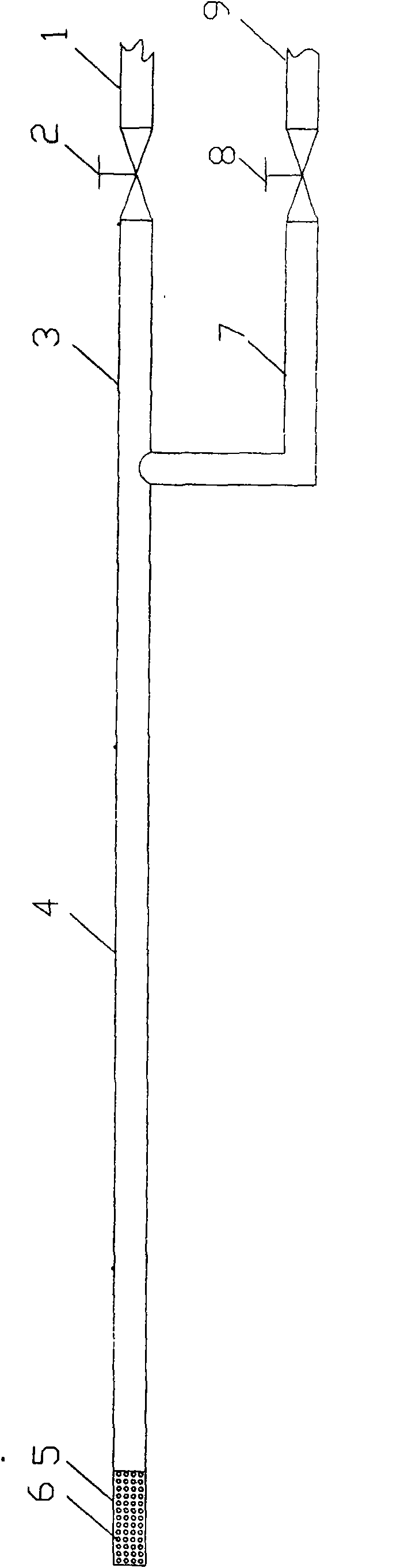

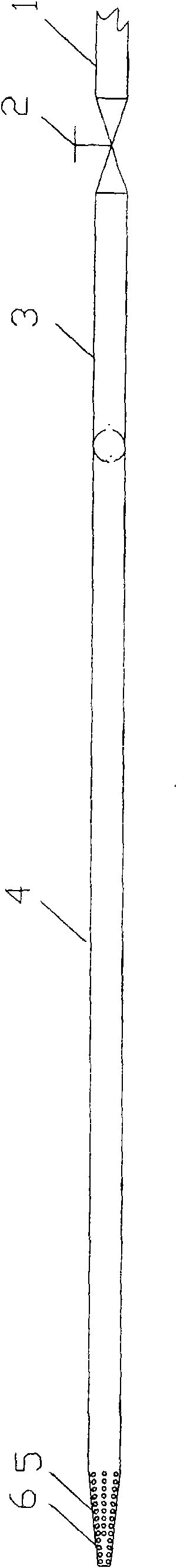

[0016] As shown in the figure, a blasting automatic spraying device is composed of a spray gun body 4 and a spray nozzle 5. A high-pressure air inlet pipe 3 and a high-pressure water inlet pipe 7 are arranged at the tail of the spray gun body 4. The nozzle 5 is a wedge-shaped nozzle. , the upper, lower, front and rear sides of the wedge-shaped nozzle 5 are provided with spray holes 6, the high-pressure blower for supplying air to the high-pressure air inlet pipe 3 is provided with a blasting vibration automatic opening device, and the high-pressure water pump for supplying water to the high-pressure water inlet pipe 7 An automatic opening device for blasting vibration is provided, and the nozzle 5 is installed in the middle of the roadway top 25-30 meters away from the working face. A high-pressure air control valve 2 is installed on the high-pressure air inlet pipe 3, and a high-pressure water control valve 8 is installed on the high-pressure water inlet pipe 7. The high-pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com