Iron runner castable containing 80% of waste refractories or above

An iron ditch castable and castable technology, applied in the field of iron ditch castables, can solve the problems of insufficient recycling of waste materials, low utilization ratio of waste refractory materials, single application type of waste refractory materials, etc., and achieve mass production. The effect of strong operability, good on-site use effect and excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

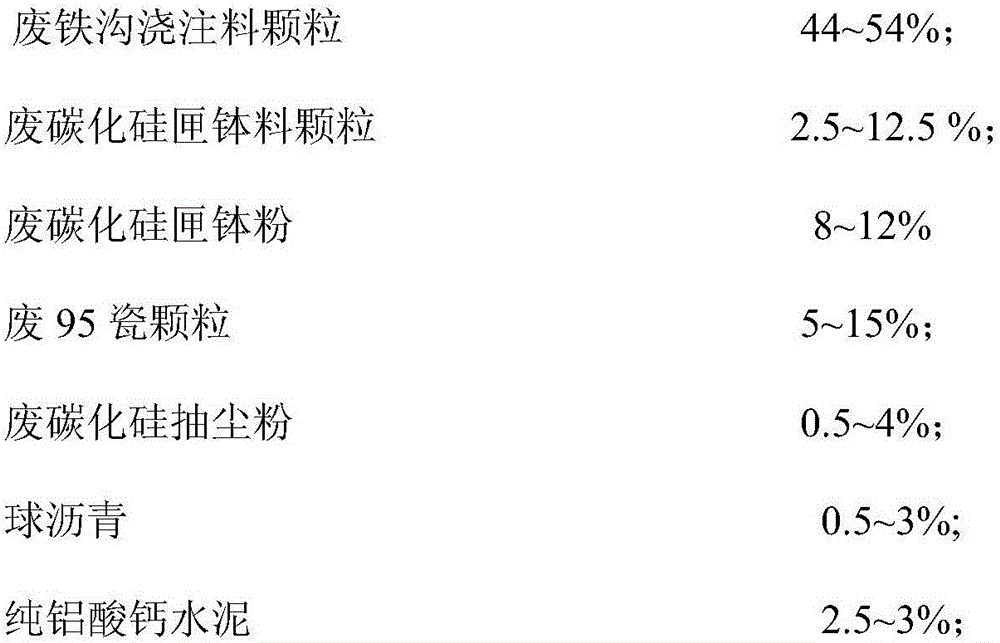

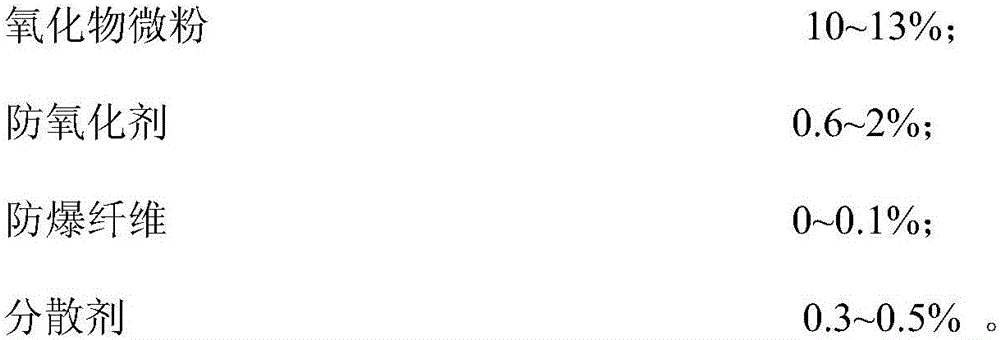

Method used

Image

Examples

Embodiment 1

[0031] An iron ditch castable containing more than 80% waste refractory materials, 44% (weight percentage, the same below) scrap iron ditch castable particles, 12.5% waste silicon carbide sagger material particles, 8% waste silicon carbide sagger Bowl powder, 15% waste 95 porcelain particles, 4% waste silicon carbide dust collection powder, 0.5% ball pitch, 3% pure calcium aluminate cement, 9.3% alumina micropowder, 2.5% silica micropowder, 0.5% metal silicon powder, 0.1% metal aluminum powder, 0.1% explosion-proof fiber, 0.5% pc8159 are fully mixed; then add water (the quality of water is 5.8% of the mass of the iron trench castable) and stir evenly before vibration molding . The molded samples were dried naturally for 24 hours, and then heat-treated at 110°C for 24 hours to obtain iron trough castable samples containing 83.5% waste refractories.

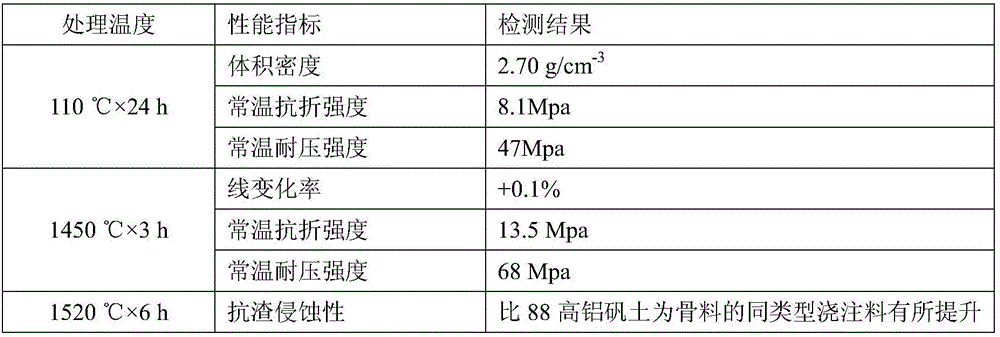

[0032] The iron trough castable sample containing more than 80% waste refractories prepared in Example 1 was tested, and the t...

Embodiment 2

[0036] An iron ditch castable containing more than 80% waste refractory materials, 54% (weight percentage, the same below) scrap iron ditch castable particles, 10% waste silicon carbide sagger material particles, 10% waste silicon carbide sagger Bowl powder, 5% waste 95 porcelain particles, 2% waste silicon carbide dust collection powder, 2% ball pitch, 2.5% pure calcium aluminate cement, 11% alumina micropowder, 2% silica micropowder, 1.03% metal silicon powder, 0.12% metal aluminum powder, 0.05% explosion-proof fiber, and 0.3% pc8159 are fully mixed; then add water (the quality of water is 5.9% of the mass of iron trench castable) and stir evenly before vibration molding . The molded samples were dried naturally for 24 hours, and then heat-treated at 110°C for 24 hours to obtain iron trough castable samples containing 81% waste refractory materials.

[0037] The iron trough castable sample containing more than 80% waste refractories prepared in Example 2 was tested, and the...

Embodiment 3

[0041]An iron ditch castable containing more than 80% waste refractory materials, 49% (weight percentage, the same below) scrap iron ditch castable particles, 8% waste silicon carbide sagger material particles, 12% waste silicon carbide sagger Bowl powder, 11% waste 95 porcelain particles, 0.5% waste silicon carbide dust collection powder, 3% ball pitch, 2.5% pure calcium aluminate cement, 10.5% alumina micropowder, 2% silica micropowder, 1% metallic silicon powder, 0.12% metallic aluminum powder, and 0.38% pc8159 are fully mixed; then add water (the mass of water is 5.9% of the mass of the iron trench castable) and stir evenly before vibration molding. The molded samples were dried naturally for 24 hours, and then heat-treated at 110°C for 24 hours to obtain iron trough castable samples containing 80.5% waste refractories.

[0042] The iron trough castable sample containing more than 80% waste refractories prepared in Example 3 was tested, and the test performance results are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com