Attapulgite clay suspension agent

A technology of attapulgite clay and suspending agent, applied in the direction of coating, etc., can solve the problems of poor anti-sedimentation effect and easy agglomeration of attapulgite clay, and achieve the effects of reduced production cost, abundant storage, and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

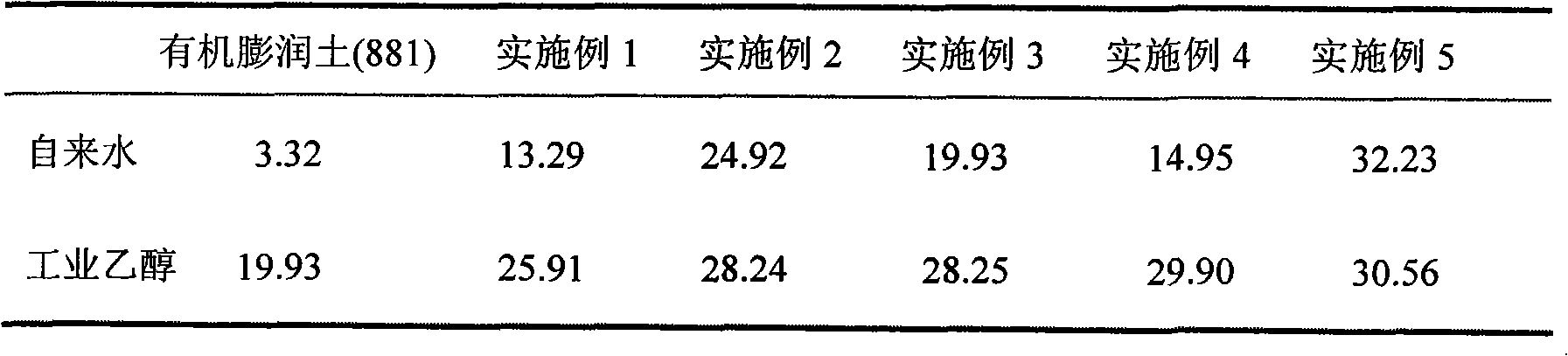

Examples

Embodiment 1

[0013] Dissolve 2g of chitosan in 600ml of 1% acetic acid solution, add 100ml of methanol solution, weigh 95g of attapulgite clay and 5.0g of montmorillonite and disperse them into the above solution, stir and react at 1000rpm for 15min, then add 300ml (27.3g) hexadecyltrimethylammonium bromide, reacted for 2 hours, filtered, dried at 80°C, and measured the suspension degree.

Embodiment 2

[0015] Dissolve 3g of chitosan in 600ml of 1% acetic acid solution, add 100ml of methanol solution, weigh 95g of attapulgite clay and 5.0g of rectorite and disperse them into the above solution, stir and react at 1000 rpm for 15min, then add 300ml (27.3g) hexadecyltrimethylammonium bromide, reacted for 3 hours, filtered, dried at 80°C, and measured the suspension degree.

Embodiment 3

[0017] Dissolve 3.5g of chitosan in 600ml of 1% acetic acid solution, add 100ml of methanol solution, weigh 95g of attapulgite clay and 5.0g of sepiolite and disperse them into the above solution, stir and react for 15min at 1000 rpm, then add 300ml (27.3g) of cetyltrimethylammonium bromide was reacted for 4 hours, filtered, dried at 80°C, and the suspension degree was measured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com