Construction slurry for rotary pile drilling

A technology for constructing mud and rotary digging piles, applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problems of difficulty in ensuring the stability of the slot holes, high slurry concentration and high cost, and achieves good wall solidification effect and purification performance. Good, low water loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A construction mud for rotary excavation piles, which is formed by mixing the following raw materials, water, bentonite, hydroxypropyl methylcellulose solution, clay and soda ash, and each component is prepared according to the following ratio: water: bentonite: hydroxypropyl methylcellulose Base cellulose solution: clay: soda ash solution=0.95: 0.095: 0.000405: 0.095: 0.00195. The concentration of the hydroxypropyl methylcellulose solution is 1.5%, and the concentration of the soda ash solution is 20%. The following steps are used to prepare the above-mentioned slurry: to prepare the construction mud for the above-mentioned rotary excavation pile, the following steps are used to prepare: add bentonite, hydroxypropyl methylcellulose solution, clay, and soda ash solution to the water in sequence according to the weight ratio of the raw materials, and fully stir After 40-50 minutes, the slurry is prepared, and then the slurry is placed at room temperature for 24 hours to ...

Embodiment 2

[0050] A construction mud for rotary excavation piles, which is formed by mixing the following raw materials, water, bentonite, hydroxypropyl methylcellulose solution, clay and soda ash, and each component is prepared according to the following ratio: water: bentonite: hydroxypropyl methylcellulose Base cellulose solution: clay: soda ash solution = 1: 0.1: 0.0005: 0.1: 0.002. The concentration of the CMC (cellulose) solution is 1.5%, and the concentration of the soda ash solution is 20%. The following steps are used to prepare the construction mud for the above-mentioned rotary excavation pile: add bentonite, hydroxypropyl methylcellulose solution, clay, and soda ash solution to water in sequence according to the weight ratio of raw materials, and fully stir for 40-50 minutes to prepare The slurry was obtained, and then the slurry was placed at room temperature for 24 hours to obtain a slurry product.

Embodiment 3

[0052] A construction mud for rotary excavation piles, which is formed by mixing the following raw materials, water, bentonite, hydroxypropyl methylcellulose solution, clay and soda ash, and each component is prepared according to the following ratio: water: bentonite: hydroxypropyl methylcellulose Base cellulose solution: clay: soda ash solution = 1.05: 0.105: 0.000505: 0.105: 0.00205. The concentration of the CMC (cellulose) solution is 1.5%, and the concentration of the soda ash solution is 20%. The following steps are used to prepare the construction mud for the above-mentioned rotary excavation pile: add bentonite, hydroxypropyl methylcellulose solution, clay, and soda ash solution to water in sequence according to the weight ratio of raw materials, and fully stir for 40-50 minutes to prepare The slurry was obtained, and then the slurry was placed at room temperature for 24 hours to obtain a slurry product.

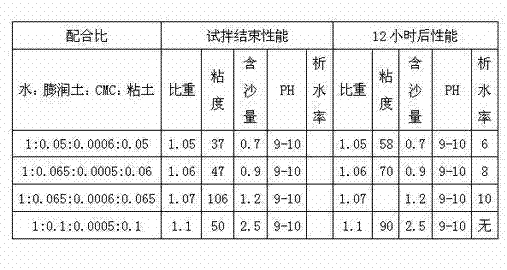

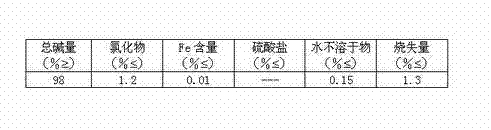

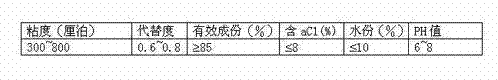

[0053] Table 1 Performance indicators of bentonite mud

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com