Pneumatic path drifting machine and drifting method

A borer and borer technology, applied in the direction of mechanical diameter measurement, etc., can solve the problems of high investment and maintenance costs, expensive air pumps, damaged air pumps, etc., and achieve the effects of wide diameter range, compact equipment structure, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

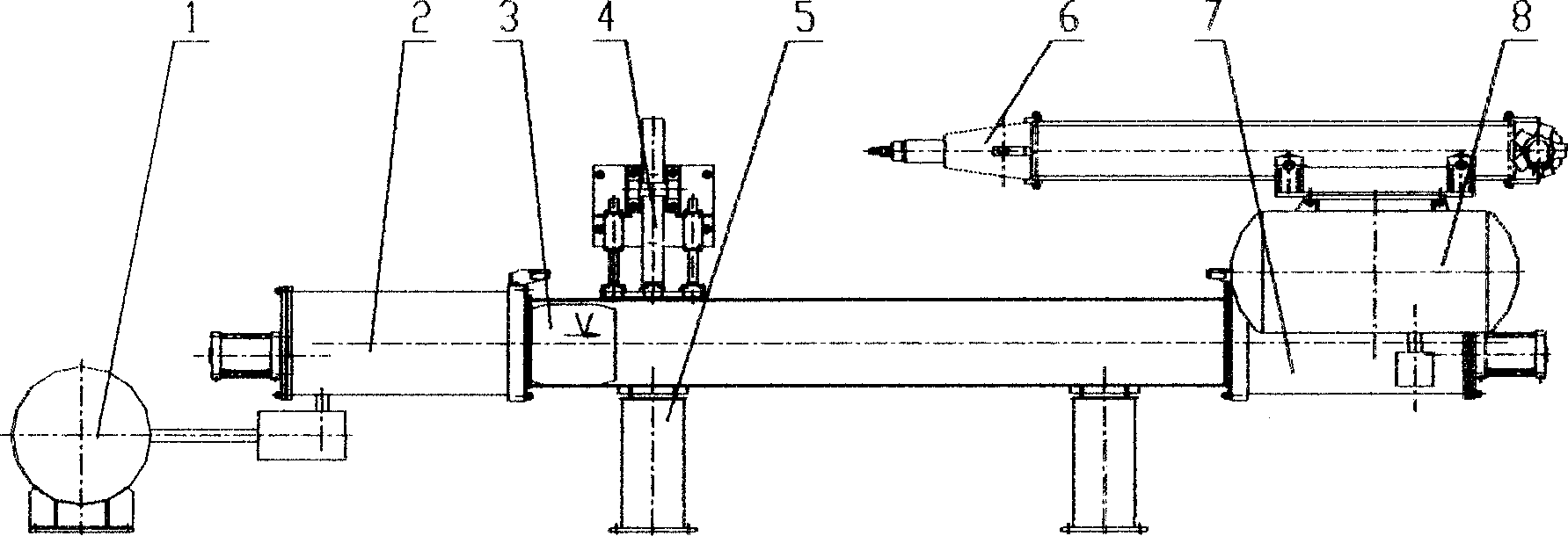

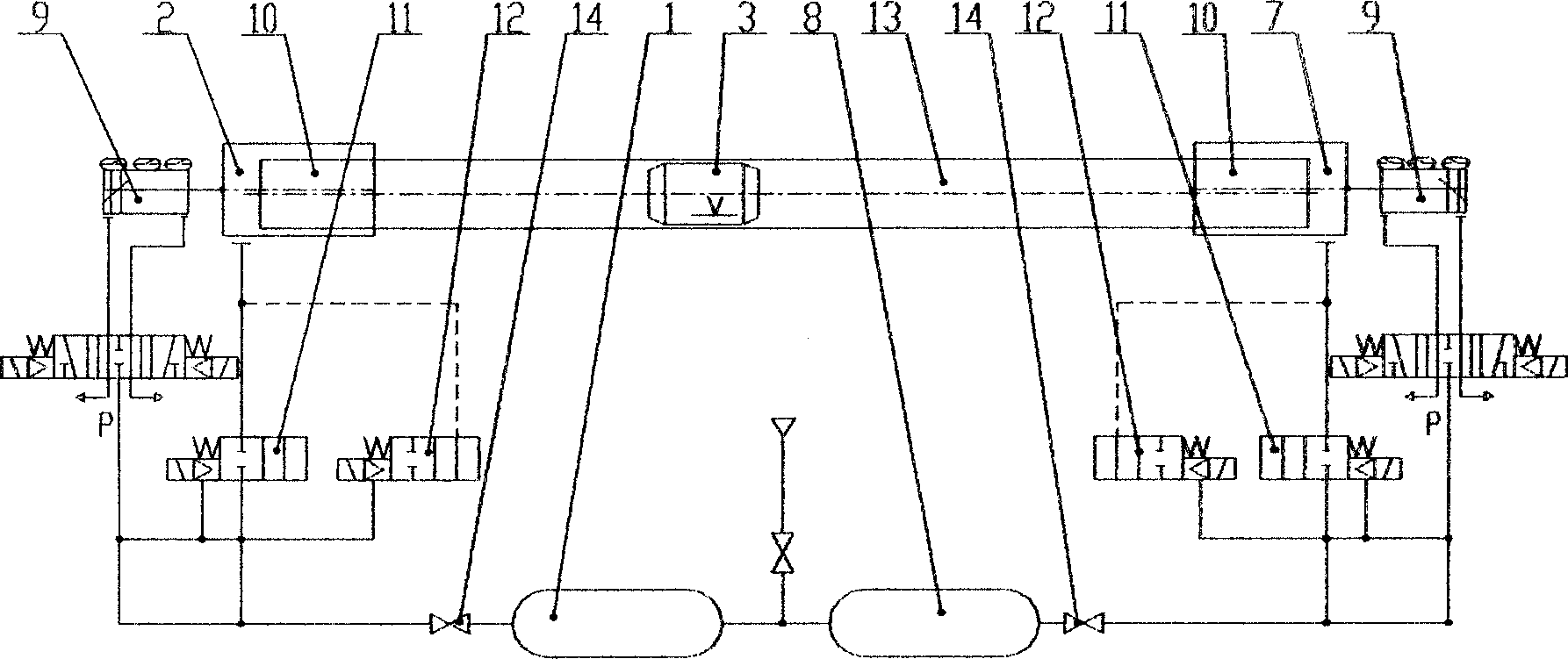

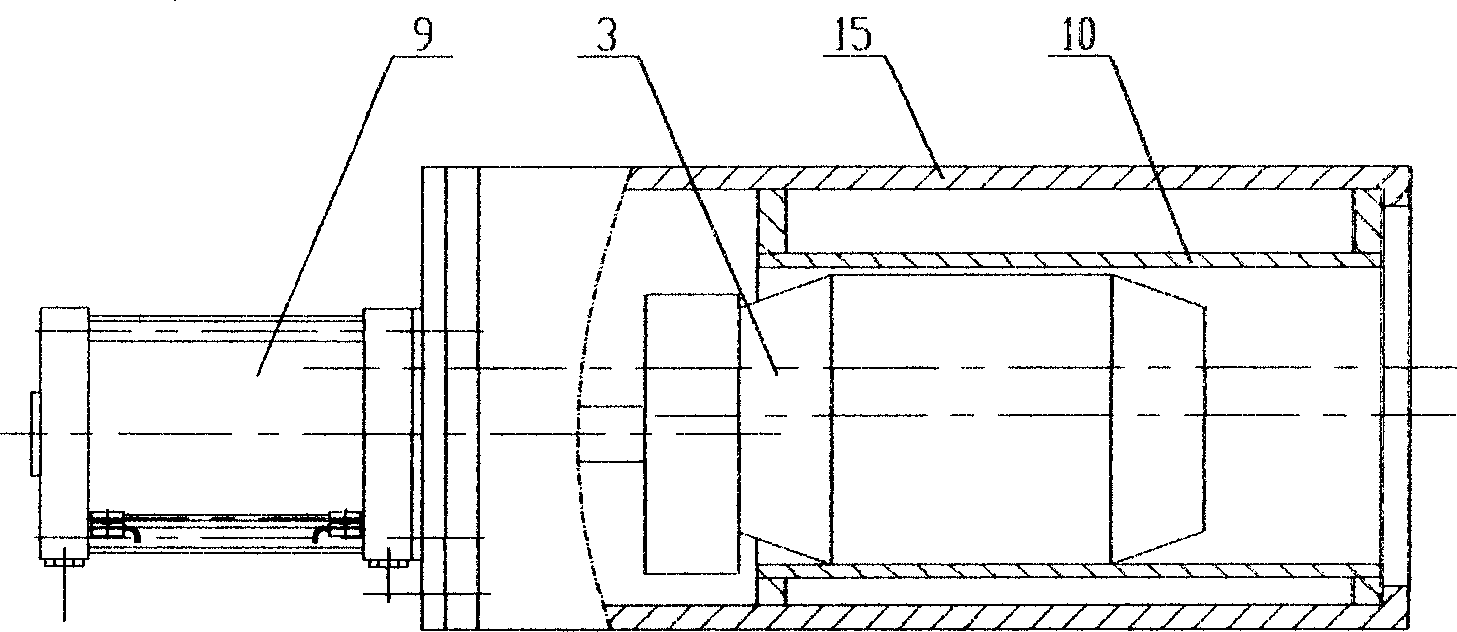

[0026] like figure 1 As shown, it includes front diameter gun 2, rear diameter gun 7, mobile trolley 6, front gas storage tank 1, rear gas storage tank 8, pressing device 4 and platform 5, front diameter gun 2 and rear diameter gun The mandrel sleeve 10 is fixed in the barrel of the gun 7, and the inner diameter of the mandrel sleeve 10 is the same as the inner diameter of the pipe, and the center is consistent; diameter mandrel 3; the steel pipe 13 is placed on the stand 5, and is tightly connected to the outer diameter surface of the steel pipe 13 by the pressing device 4, and the front diameter gun 2 is connected to the left end face of the steel pipe 13; The right end faces of the steel pipes 13 are butt-connected; the front and rear diameter guns are connected to the air storage tank through pipelines, and the air storage tank is directly connected to the compressed air in the workshop. The front and back ends of the steel pipe 13 respectively have a bore gun, and the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com