Blade performance test bench for rotorcraft

A rotorcraft and test bench technology, applied in the direction of aircraft component testing, etc., can solve the problems of low integration, high cost, and small blade diameter range, and achieve the effects of improving measurement efficiency, reducing noise requirements, and increasing lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

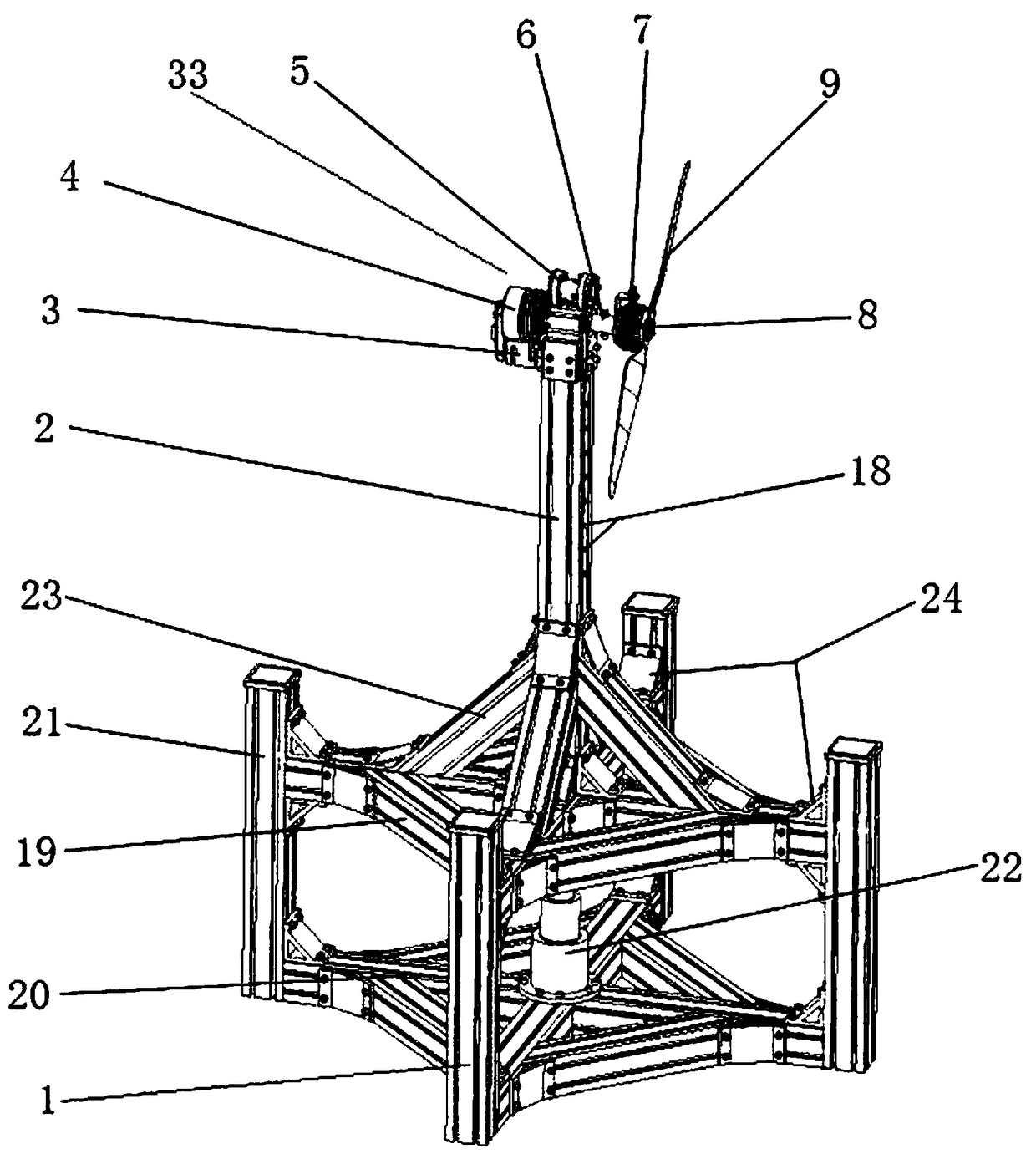

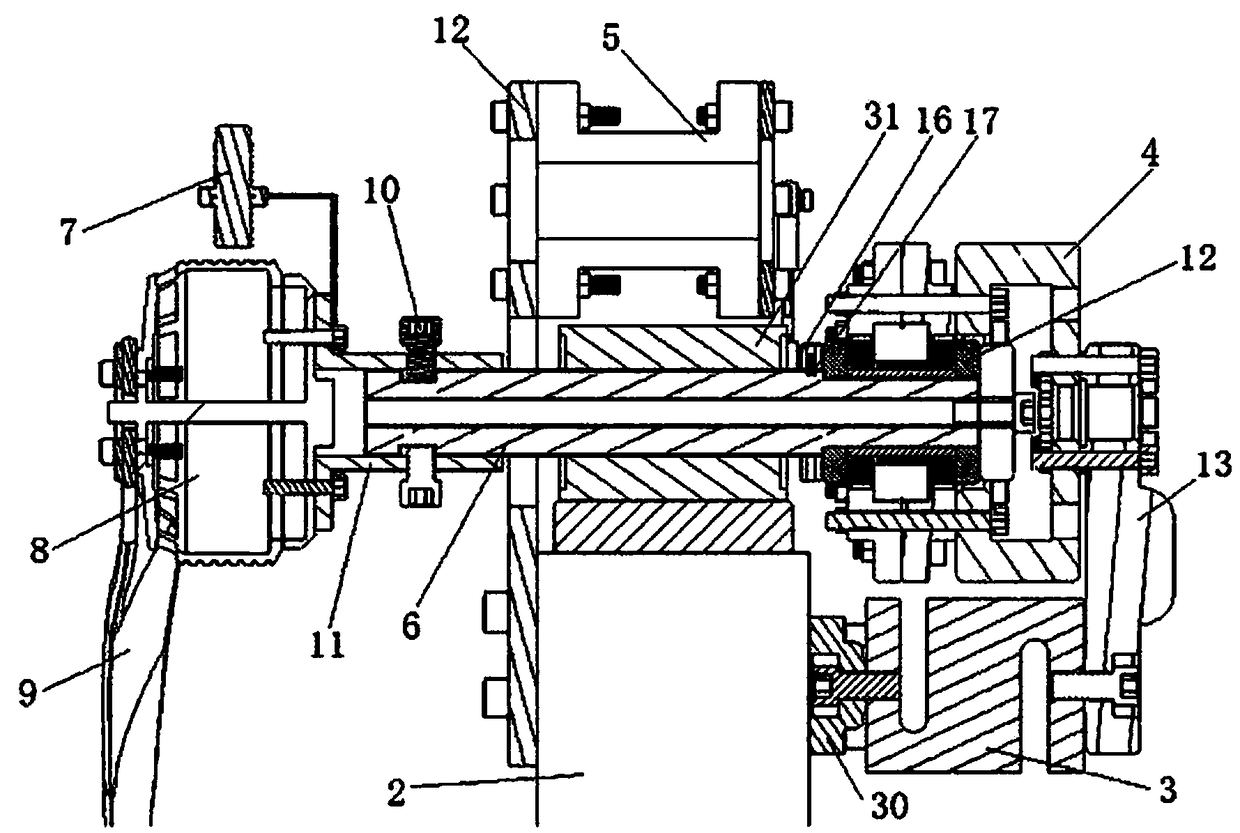

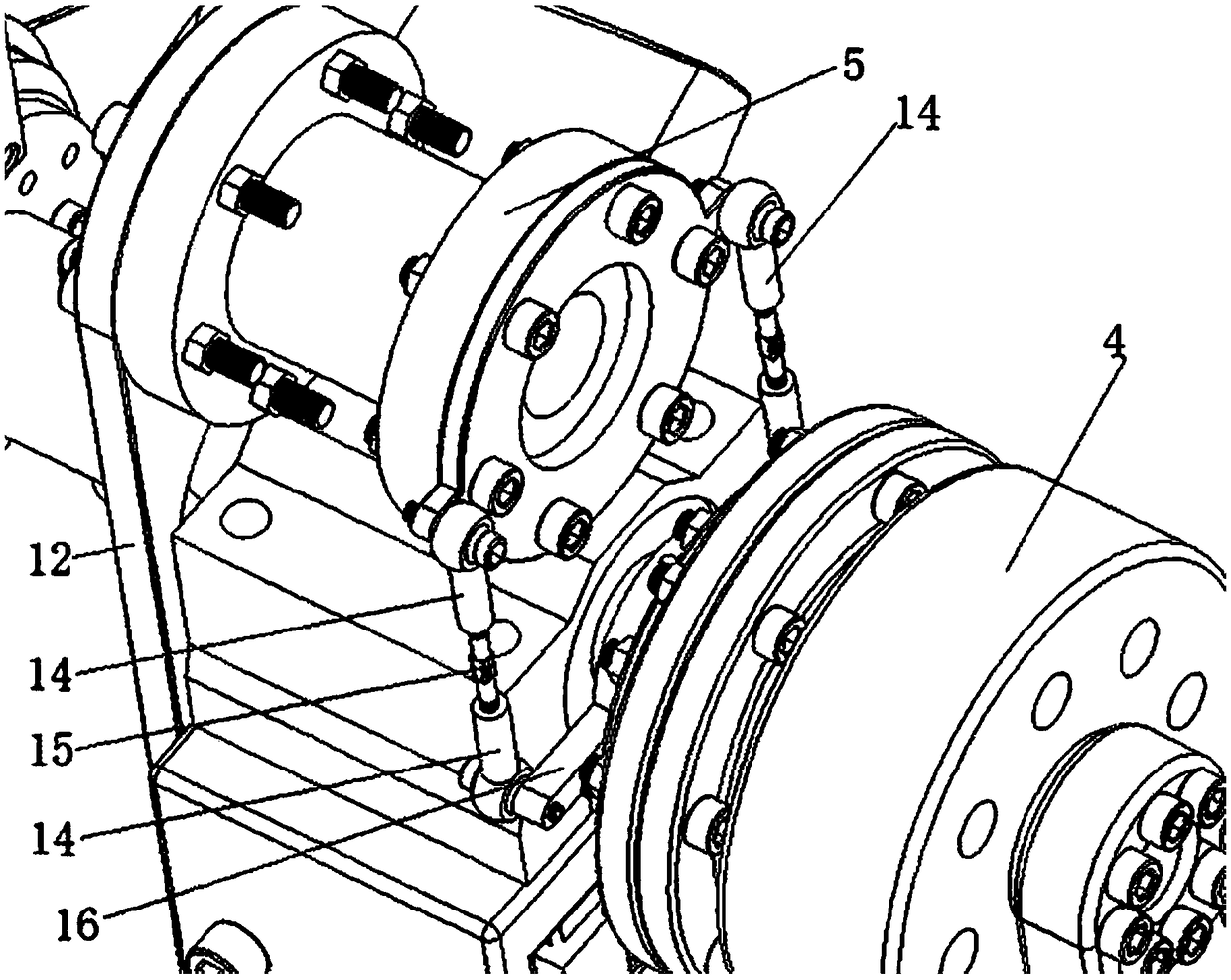

[0018] like figure 1 , the supporting seat 1 plays the role of stabilizing the whole test bench, and the central position of the measuring seat can be reinforced and heightened according to the test environment, and the center of rotation of the blade 9 on the test bench can be adjusted to the proper position of the wind tunnel air outlet. The support base 1 includes an upper support base 19, a lower support base 20, an aluminum profile pole 21, an electric telescopic rod 22 and a diagonal strut 23, the lower support base 20 is fixedly connected with the vertical pole 21, and there is a right-angle connector 24 at the joint. The center of the lower support base 201 has an electrically controlled telescopic rod 22, and the upper support base 19 can be controlled to move up and down along the guide rail on the vertical rod 21 by the electrically controlled telescopic rod 22. Fixed connection, there is a sound pressure measurement unit 18 on the side of the support rod 2 close to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com