Laser assisted centering device for assembling large-diameter equipment

A laser-assisted and centering device technology, which is applied in active optical measuring devices, measuring devices, and measurement with tilt sensors, can solve the problems of low precision and cumbersome operation, and achieve high precision, simple operation, and low skill threshold. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

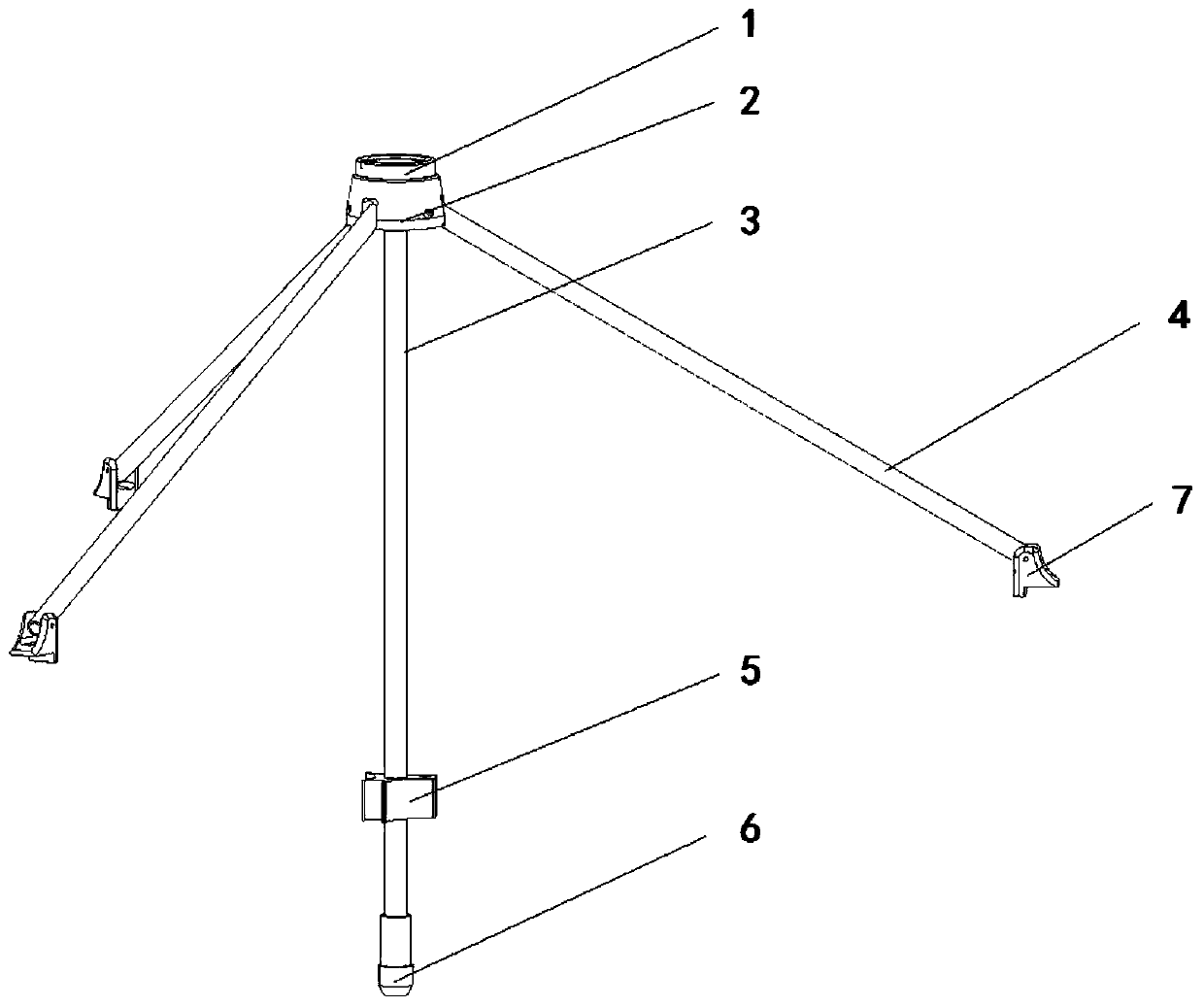

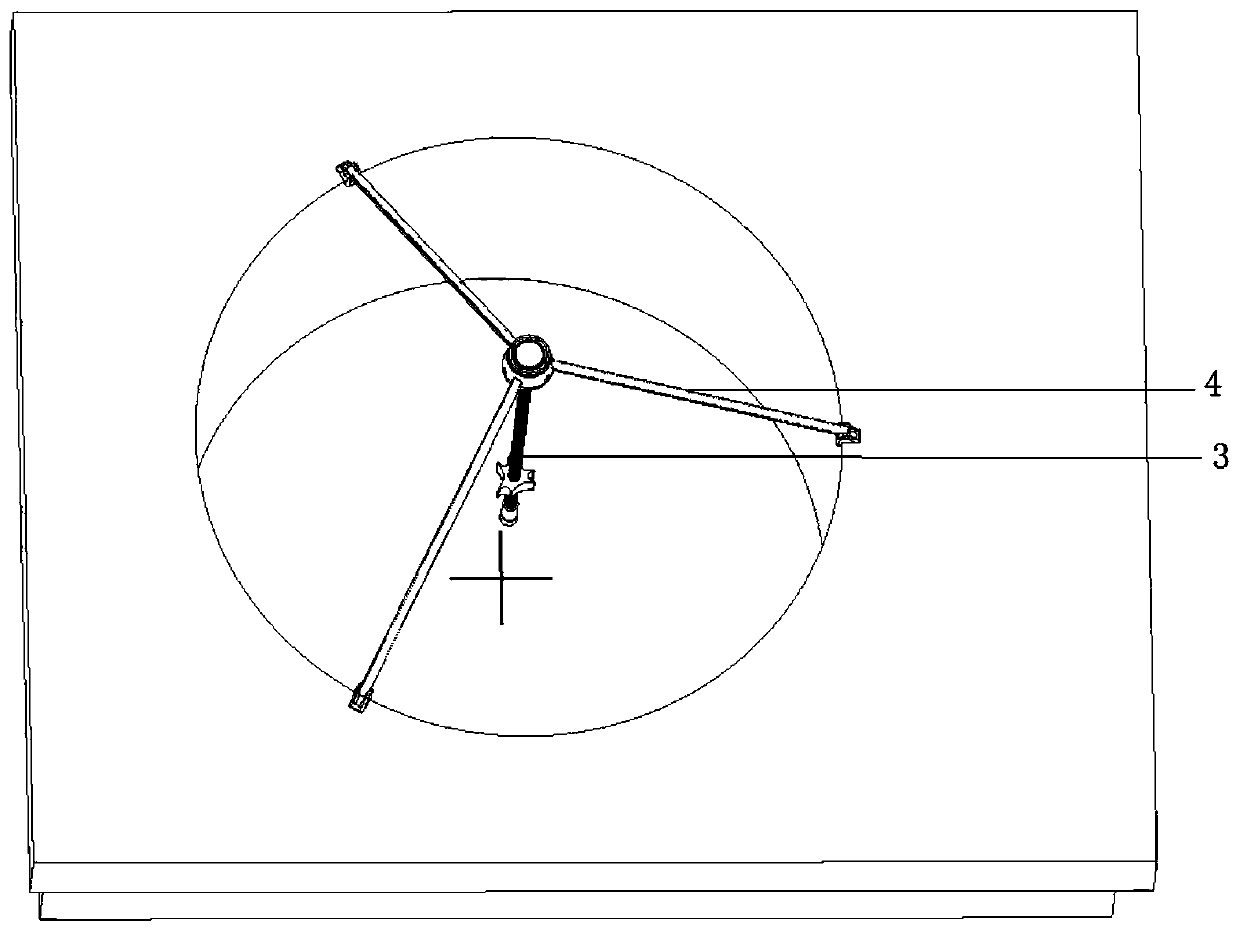

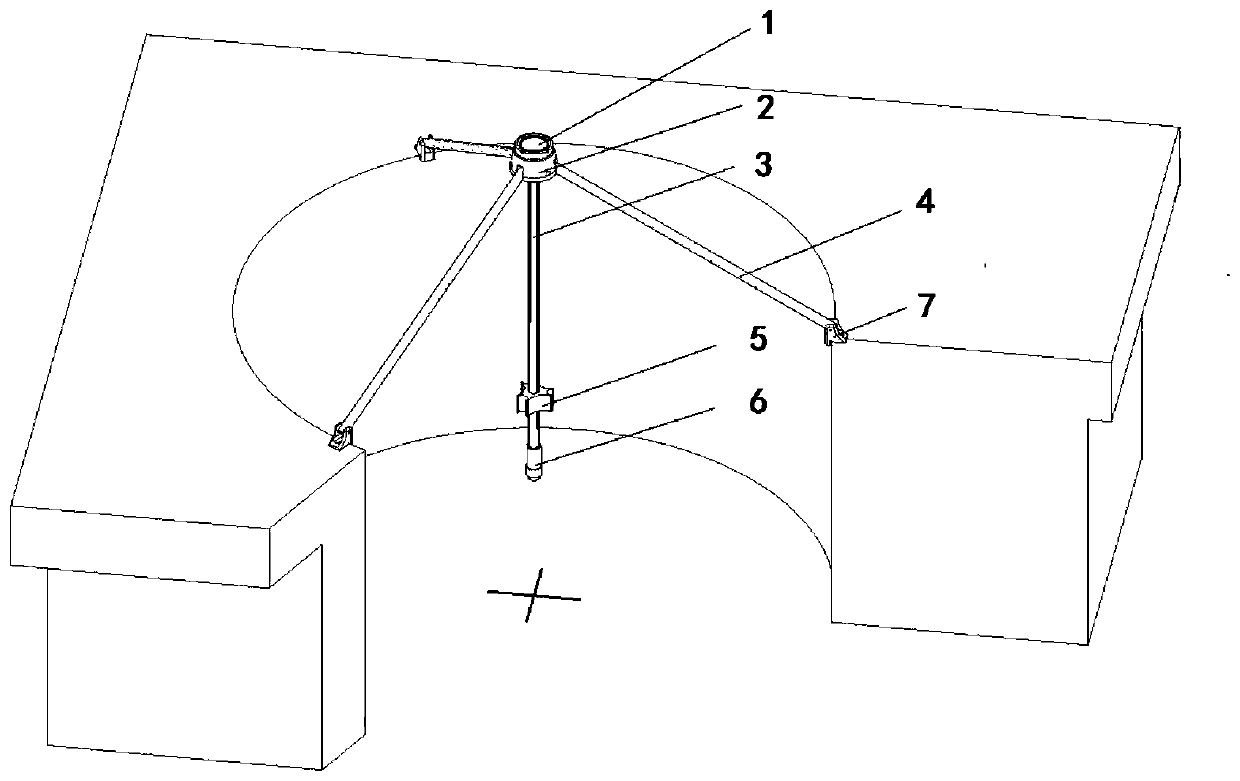

[0016] The invention is a laser-assisted centering device for large-diameter equipment assembly, such as figure 1 , figure 2 with image 3 As shown, it includes a central rod 3, a bubble level 1 is connected to the upper end of the central rod 3, a cross laser head 6 is connected to the lower end of the central rod 3, and an outrigger 4 is connected to the central rod 3.

[0017] The central connecting plate 2 is fixedly connected to the central rod 3, and the central connecting plate 2 is movably connected with three legs 4 along the circumference, and the supporting legs 4 can be expanded to 120°C.

[0018] The bubble level 1 is located above the central connection plate 2 .

[0019] A leg 7 is connected to the lower end of the leg 4 .

[0020] A receiving bracket 5 is fixedly connected to the central rod 3 for receiving the legs 4 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com