A 2.5d automatic programming method of stamping die based on data intelligent identification technology

A technology for stamping dies and automatic programming, applied in presses, manufacturing tools, comprehensive factory control, etc., can solve problems such as low programming efficiency and unstable program quality, simplify programming steps, solve low programming efficiency, and lower skill thresholds Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

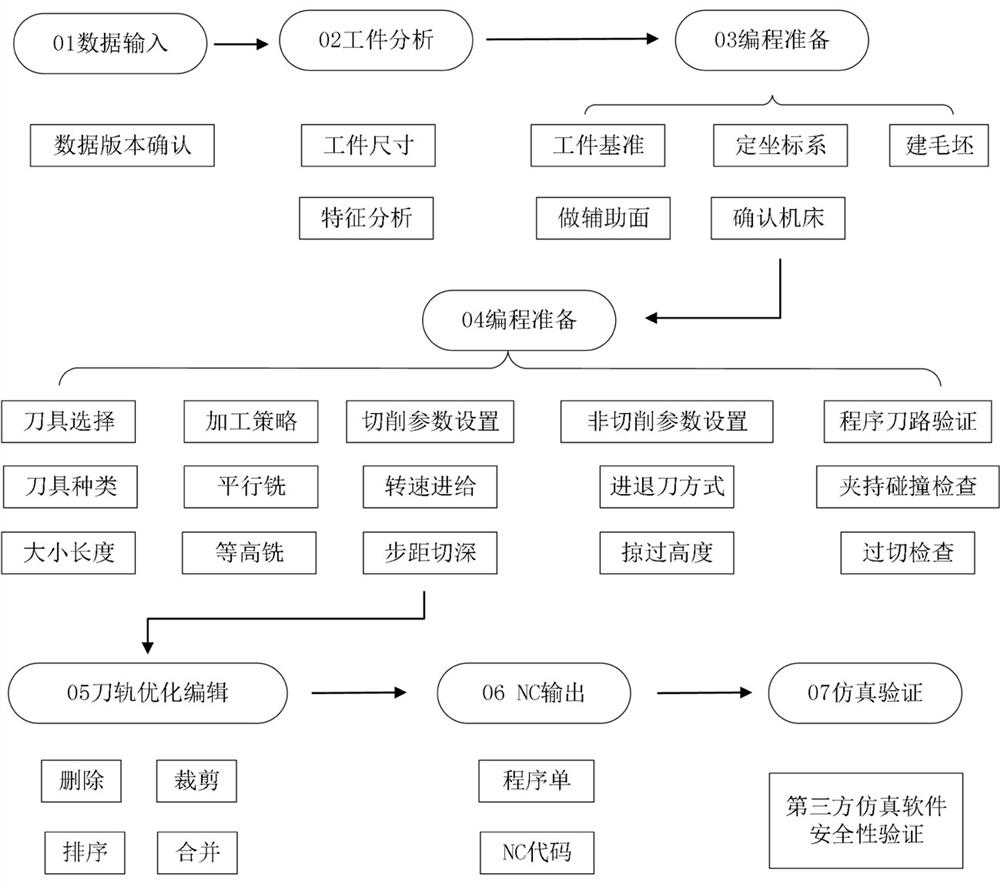

[0042] The technical solutions of the present invention will be further described below with reference to the accompanying drawings and embodiments.

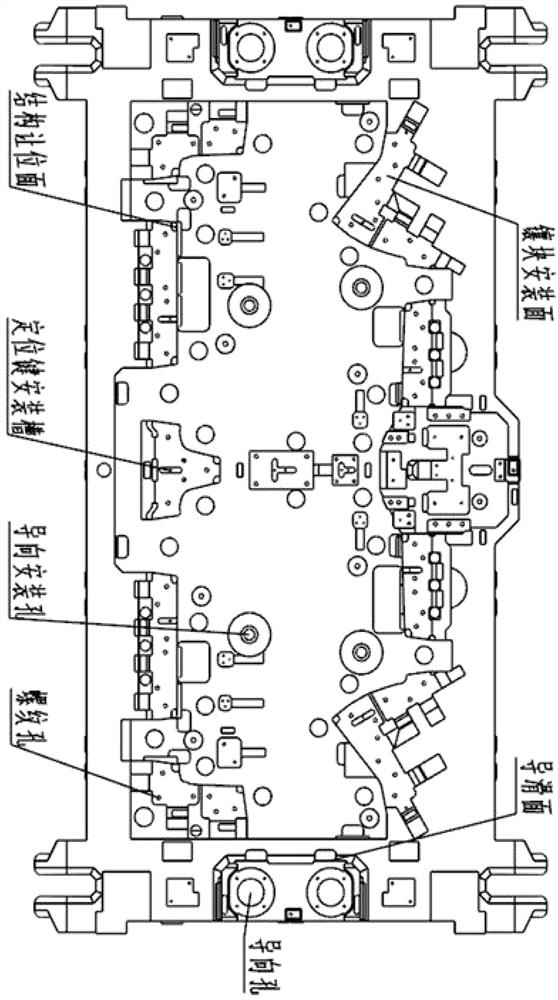

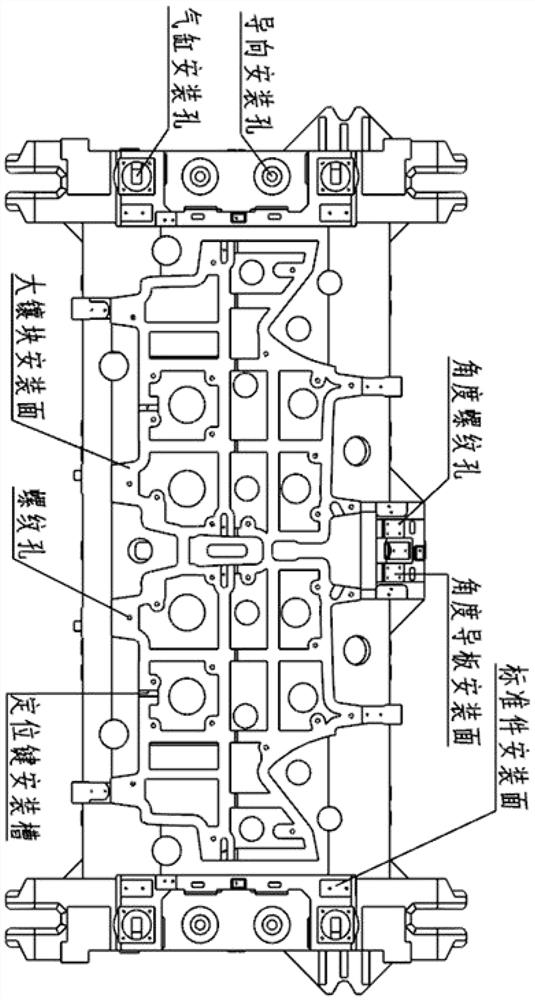

[0043] like Figure 4-5 As shown, a 2.5D automatic programming method of stamping die based on data intelligent identification technology, including WorkStep intelligent selection, processing area, process intelligent identification, processing range intelligent control, tool path all-round verification and other links. Through the collection of enterprise manufacturing process standards and historical manufacturing experience, the company's exclusive parametric programming database is developed and improved, and the interconnection of manufacturing elements is realized through parameterization, conditionalization, and templateization. The features of the machined parts are automatically identified and matched, and finally a highly standardized, high-security and high-efficiency NC program is generated.

[0044] The specific pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com