Large-bore pipe ring welded seam phased-array ultrasonic automatic detection system

An automatic detection technology for large-diameter pipes, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves. It can solve the problems of subjective factors in the detection results, difficulty in measuring its own height, and decreased human white blood cells. It has a wide range of probe adaptation. , small number of probes and great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

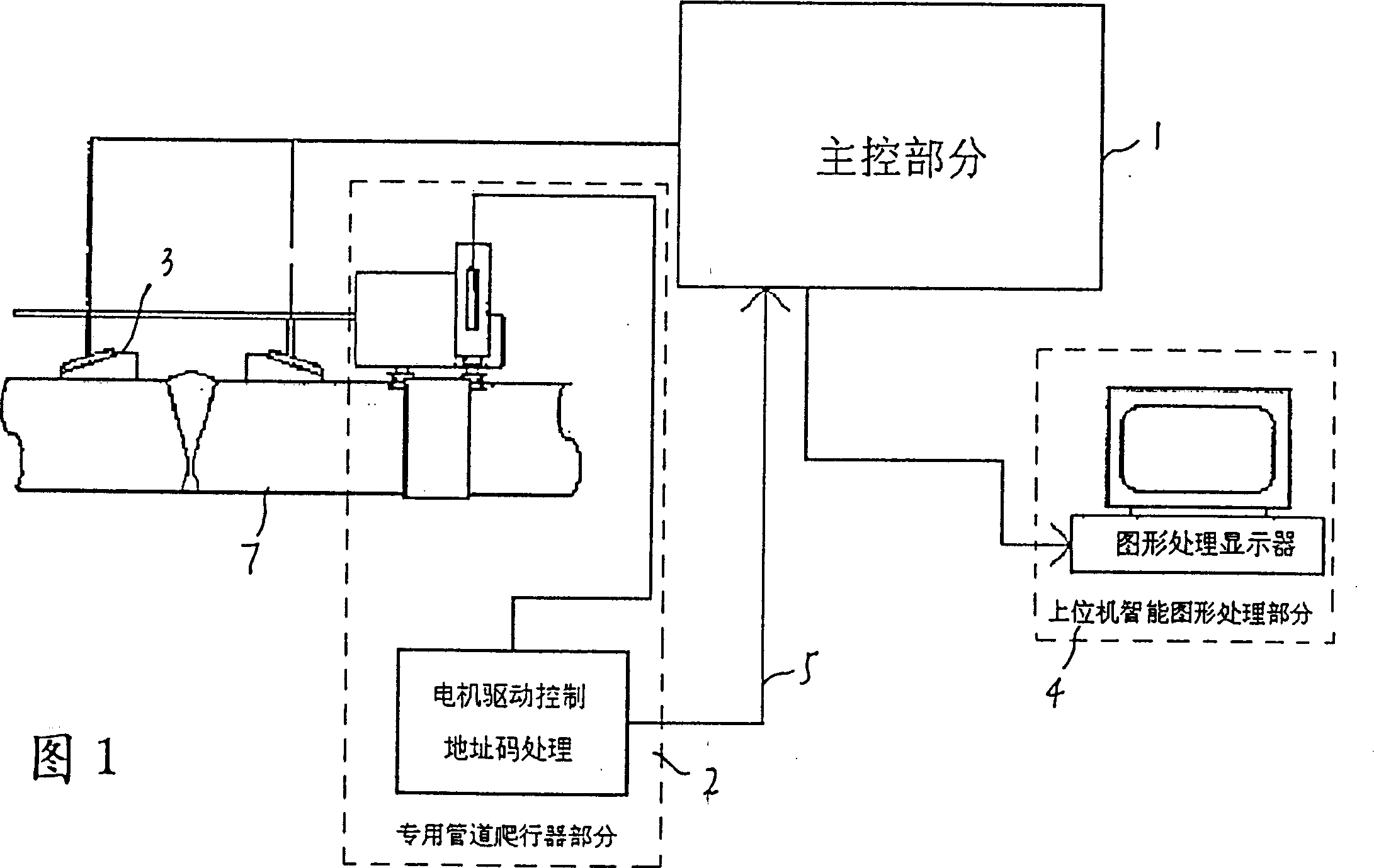

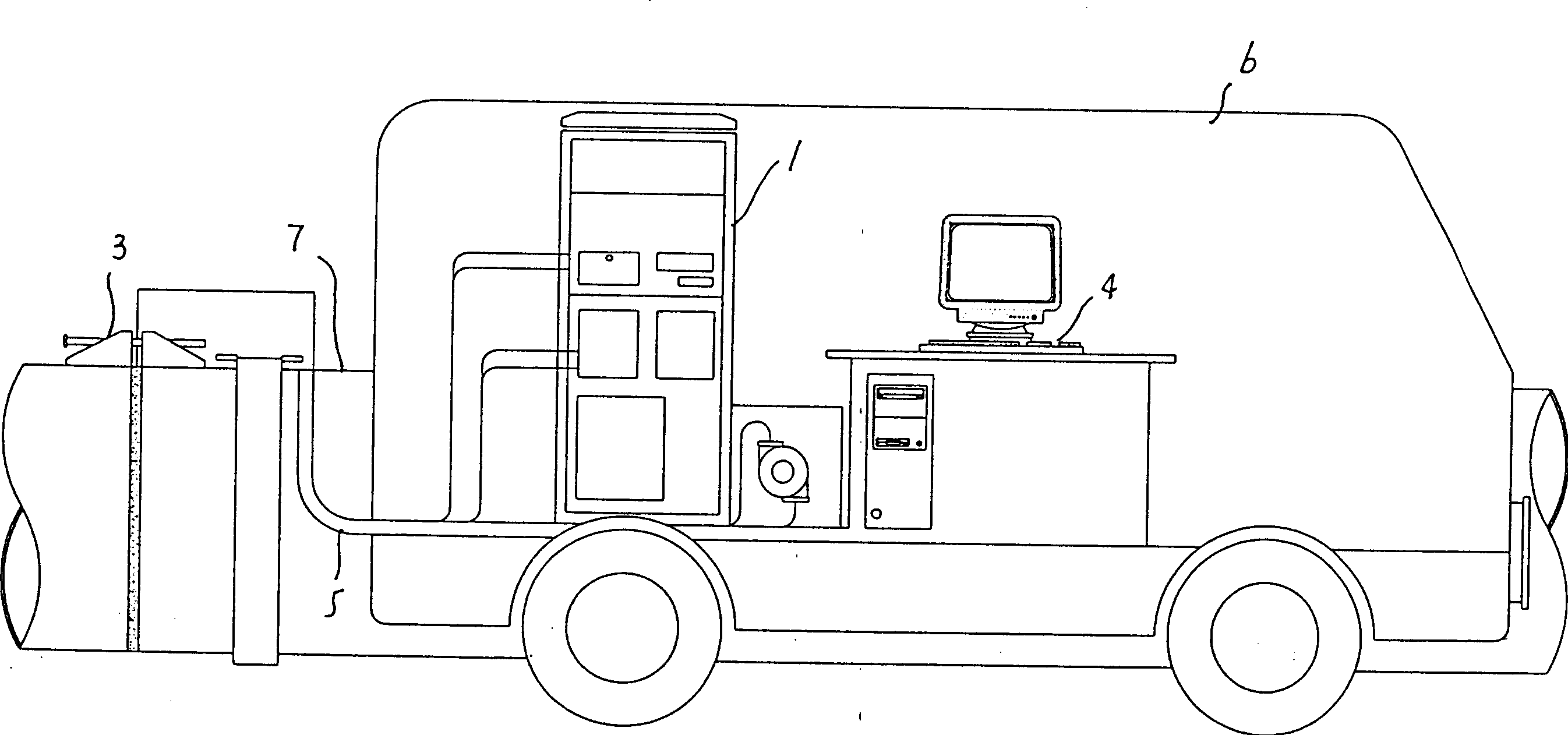

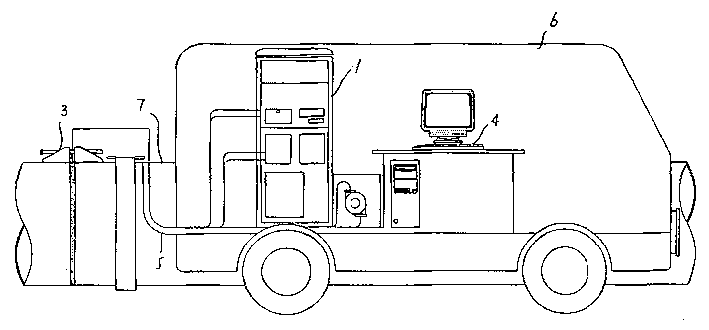

[0041] Please refer to Figure 1 and combine figure 2 As shown, the phased array ultrasonic automatic detection system for large-diameter pipeline girth welds of the present invention includes a main control part 1, a special pipeline crawler part 2, an ultrasonic chip array probe part 3, an upper computer intelligent graphics processing part 4, and a cable part 5 , special equipment vehicle 6, wherein,

[0042] The ultrasonic chip array probe part 3 is installed on the special pipeline crawler part 2,

[0043] The main control part 1 and the upper computer intelligent graphics processing part 4 are placed in the special equipment car 6,

[0044] The main control part 1 and the upper computer intelligent graphics processing part 4 in the special equipment vehicle 6 are connected with the special pipe crawler part 2 through the cable part 5 .

[0045] The main control part 1 is actually a phased array detector (the specific structure and principle of the detector are disclosed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com