Double-rocker self-adaptive centering clamp

A centering fixture and self-adaptive technology, applied in manufacturing tools, workpiece clamping devices, etc., can solve the problems affecting the concentricity and cylindricity of workpieces, and achieve the effect of increasing the diameter range of pipe piles and efficient clamping operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

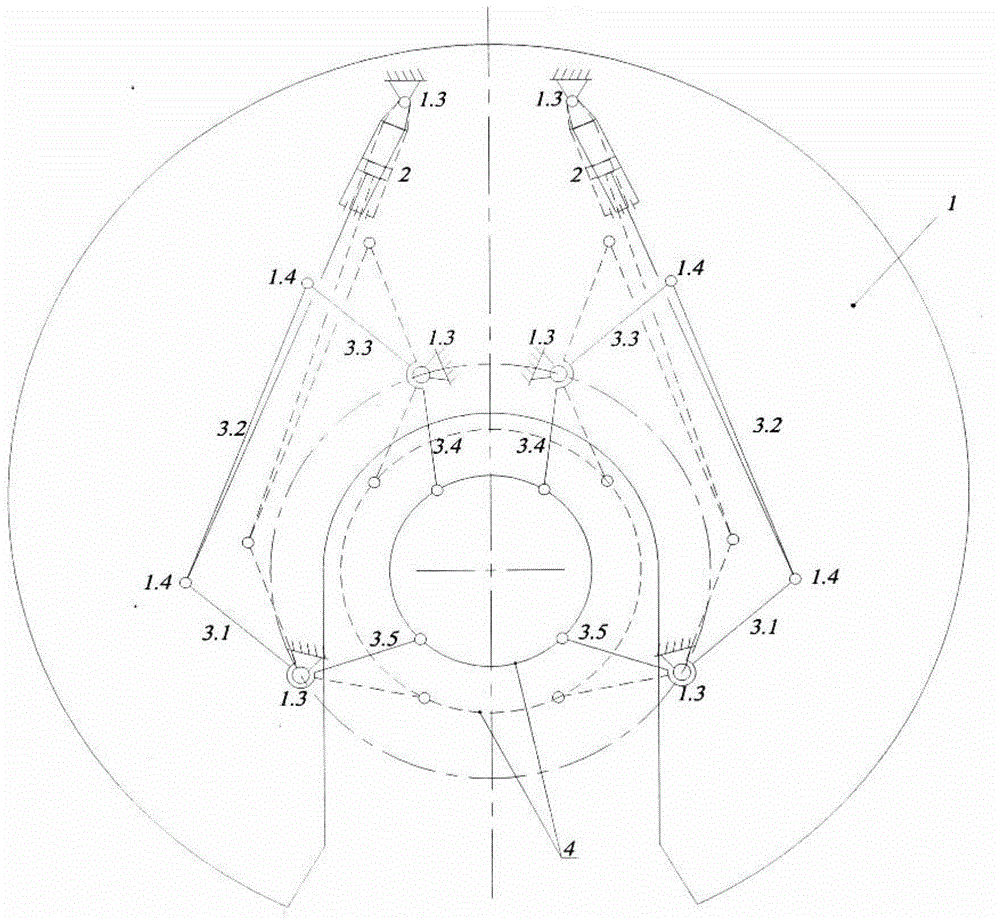

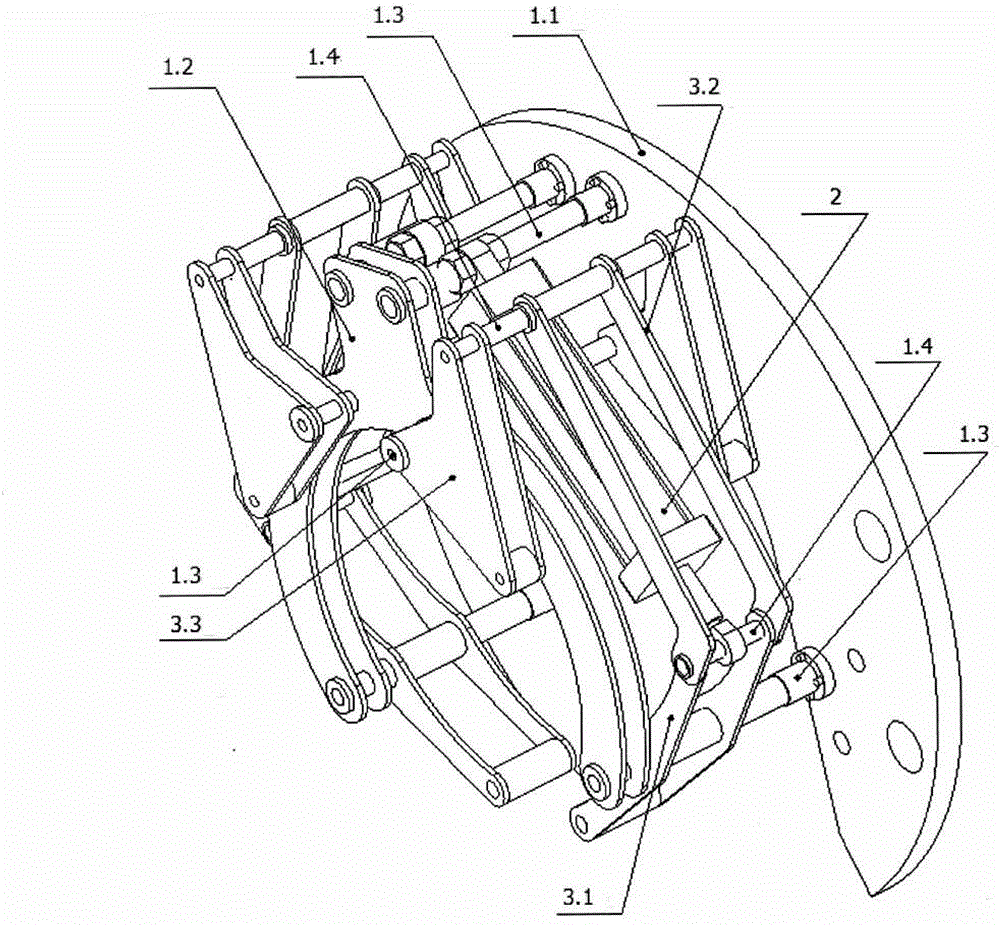

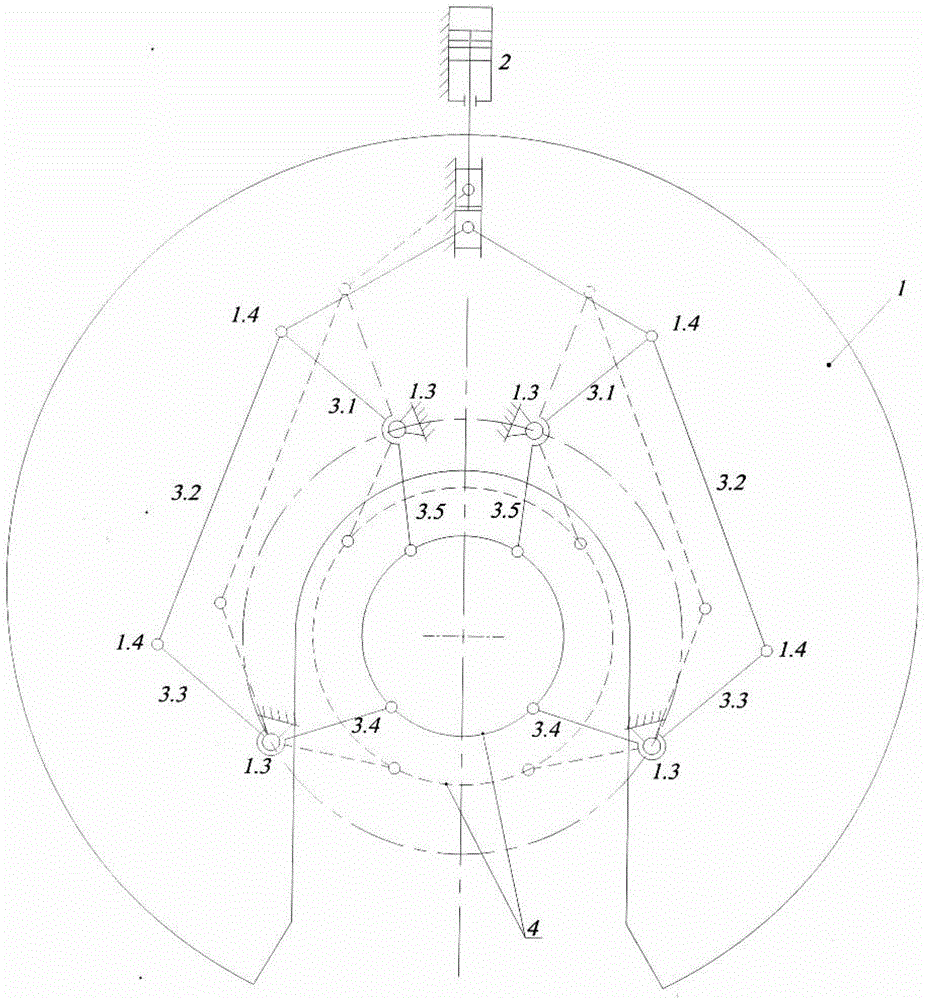

[0022] Such as Figure 1-Figure 2 As shown, the present invention comprises: frame 1, two driving hydraulic cylinders 2, two double rocker mechanisms 3; And an arch bridge-shaped parallel frame formed by connecting several equal-length mandrels 1.3; in the arch bridge-shaped space between the main plate 1.1 and the auxiliary plate 1.2 of the frame 1, two driving hydraulic cylinders 2 and double rockers are arranged Mechanism 3; two hydraulic cylinders 2 are symmetrically arranged on both sides of the frame 1, and the two double rocker mechanisms are parallelogram mechanisms, which are symmetrically arranged on both sides of the frame; wherein, the top of the cylinder driving the hydraulic cylinder 2 is connected to the machine frame The frame 1 is hinged as a whole, and the piston rod end of the drive hydraulic cylinder 2 and the active rocker 3.1 in the double rocker mechanism 3 and the living hinge of the connecting rod 3.2 are combined and hinged as one. The other end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com