Spinning wrench device acting or moving synchronously with spinner wheel

A synchronous action, twist pliers technology, used in drilling equipment, earthwork drilling, drill pipe and other directions, can solve the problems of easy deviation, the twist roller can not be translated synchronously, etc. , the effect of shortening the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

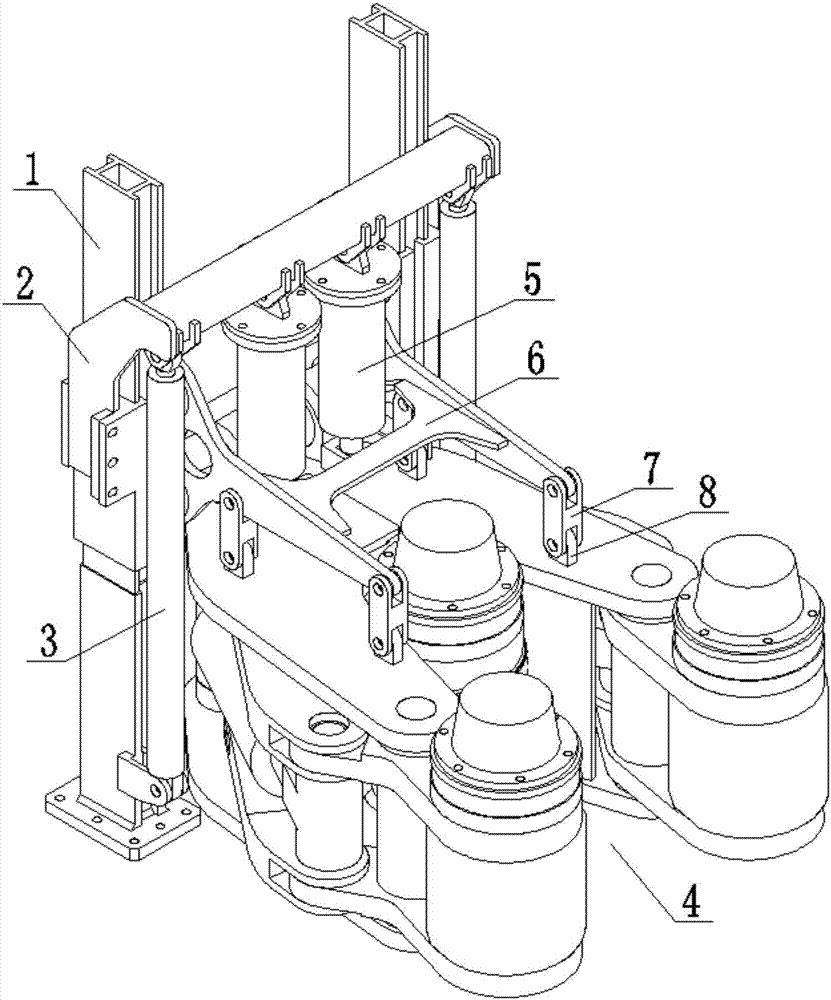

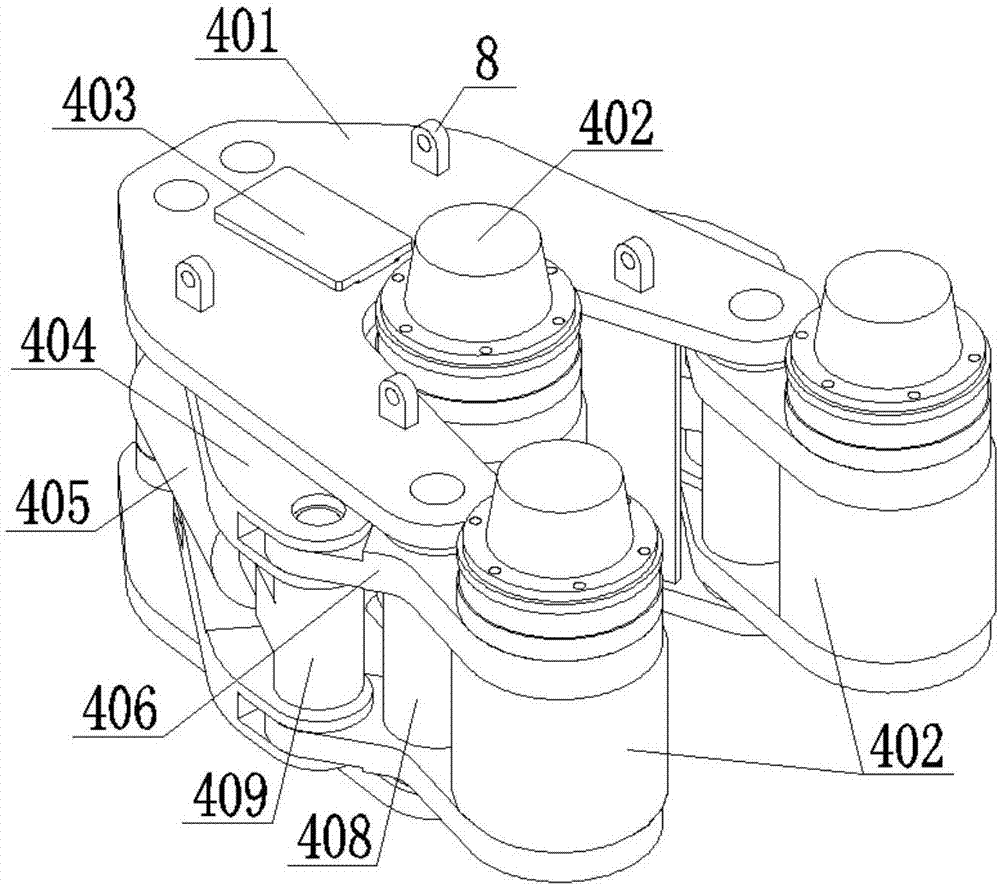

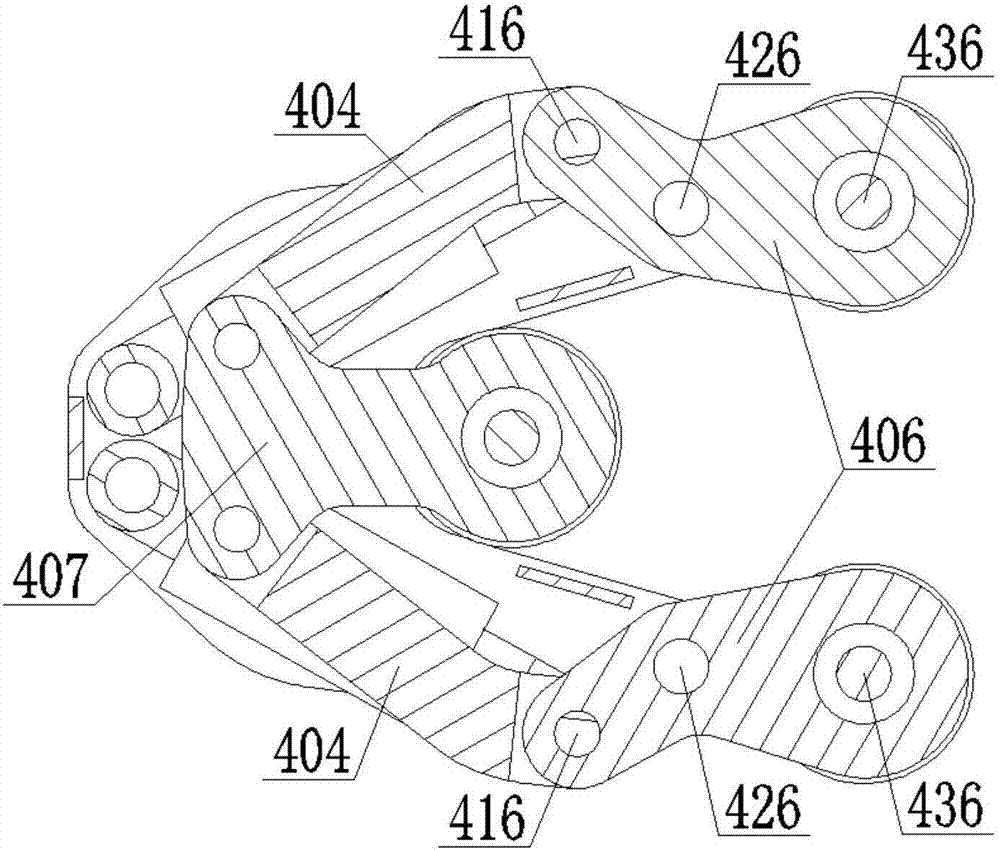

[0036] A turnbuckle pliers device with synchronous action or movement of the turnbuckle rollers, such as figure 1 , Figure 7 to Figure 9 As shown, it includes column 1, lifting tackle 2, oil cylinder 3, turnbuckle pliers 4 and hanger 6, lifting tackle 2 is slidably connected to column 1, and oil cylinder 3 is arranged between column 1 and lifting tackle 2 to drive the lifting tackle 2 Lifting movement on the column. The hanger 6 is also slidably connected on the column 1, so that the stable operation of the hanger 6 can be guaranteed when the lifting tackle 2 moves, and the lifting tackle 2 and the hanger 6 are connected by buffer devices 5 such as buffer springs or buffer hydraulic cylinders. On the one hand, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com