Ball-planting device of semiconductor packaging equipment

A technology for packaging equipment and semiconductors, which is used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc. It can solve the problems of high quality requirements for stencil hardware, low ball-mounting efficiency, and complex action mechanisms, and achieve control and debugging. Simple, less damage to solder balls, and the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

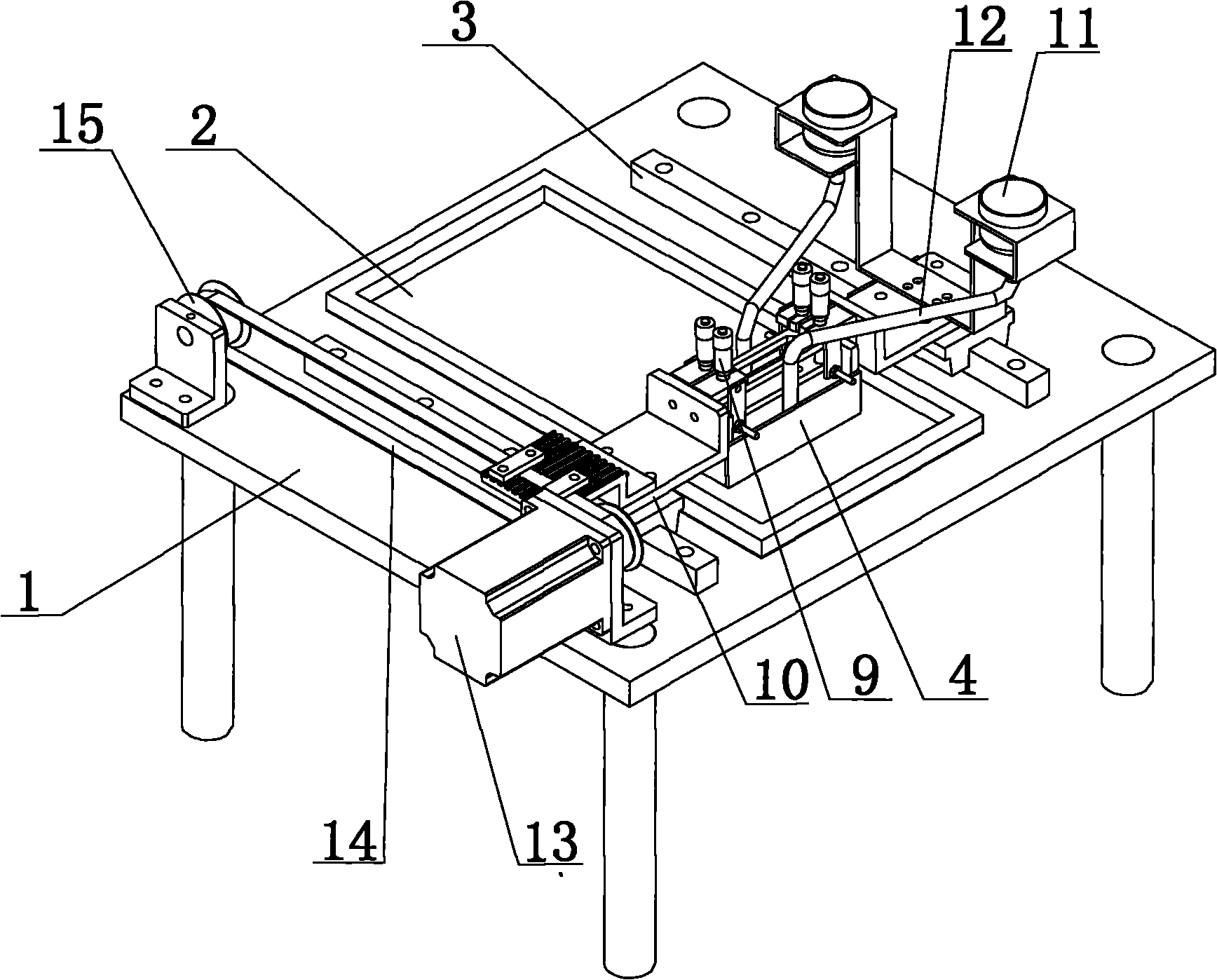

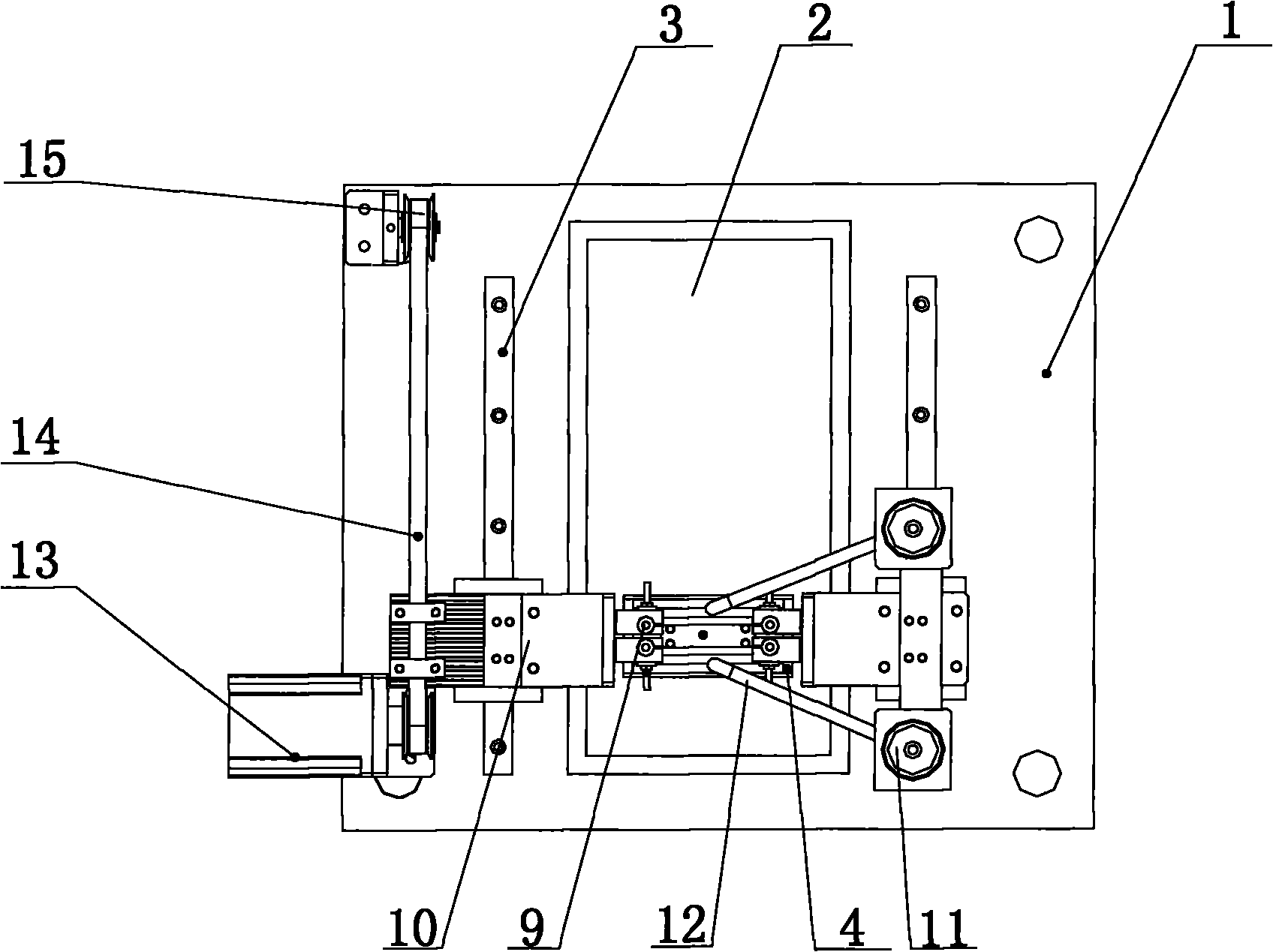

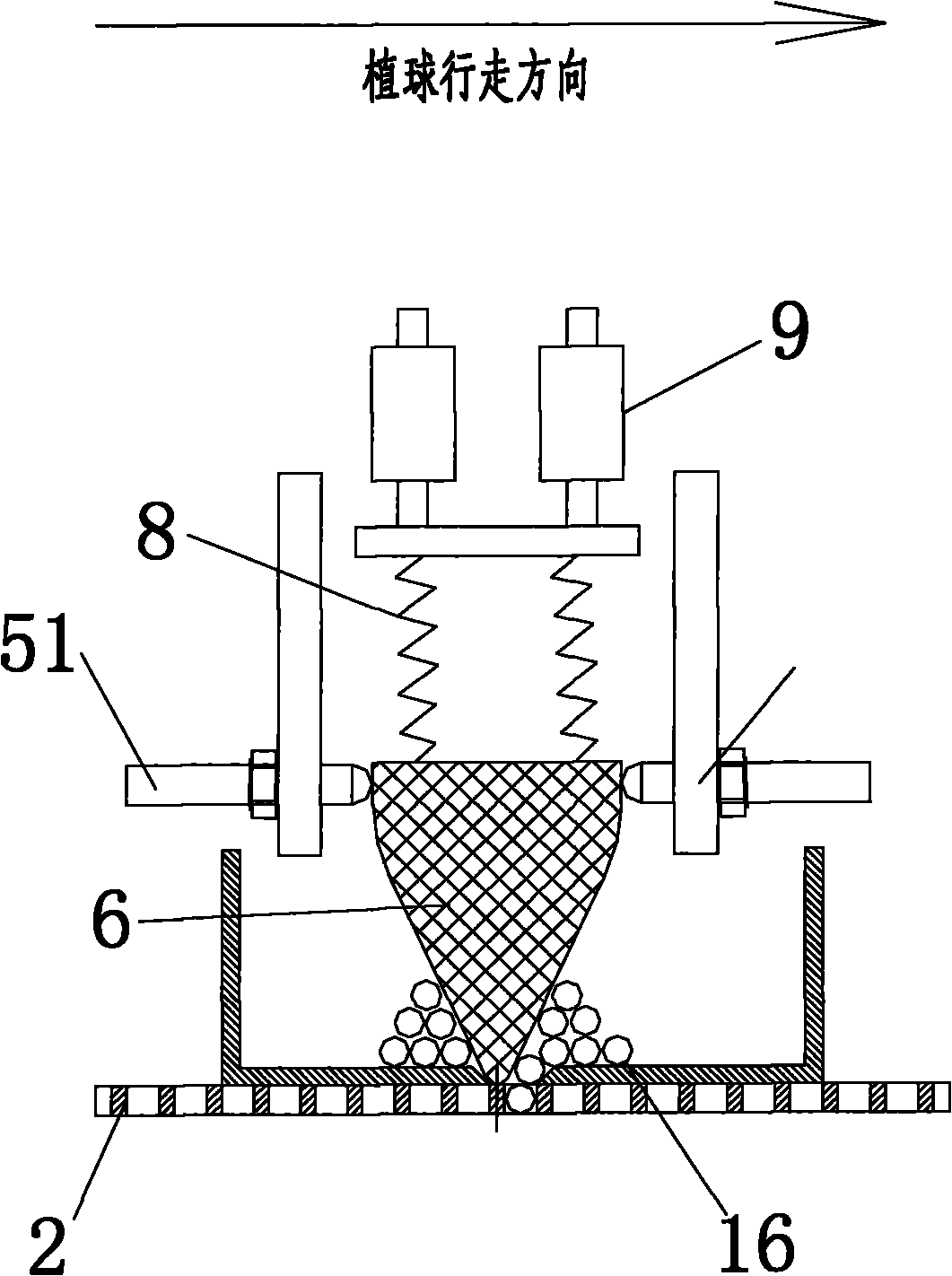

[0020] Such as figure 1 , 2 As shown, a ball planting device for semiconductor packaging equipment includes a frame 1, a screen 2, two guide rails 3, a ball planting mechanism and a drive mechanism, the screen 2 is fixed on the frame 1, and the The two guide rails 3 are respectively arranged on both sides of the screen plate 2, and the ball planting mechanism is located above the screen plate and is slidably fixed with the two guide rails 3. The ball planting mechanism includes a solder ball container 4 and a pair of stoppers 5. A scraper 6, a connecting plate 7, a plurality of springs 8, a plurality of dial gauges 9 and sensors, the solder ball container 4 is arranged on the screen 2, and the bottom of the solder ball container 4 is provided with a groove 40 , the pair of stoppers 5 are fixed on the solder ball container 4, the longitudinal section of the scraper 6 is ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com