Abrasion-proof composite roller, board and manufacturing method thereof

A composite roller and alloy ceramic technology, which is applied in the field of roller or roller plate and its preparation, can solve the problems that the ceramic layer cannot meet the high stress, the size of the roller and the roller plate is large, and it is not easy to compound the ceramic layer, so as to solve the problem that it is difficult to guarantee the quality, Effect of reducing metal consumption, improving wear or abrasion resistance and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

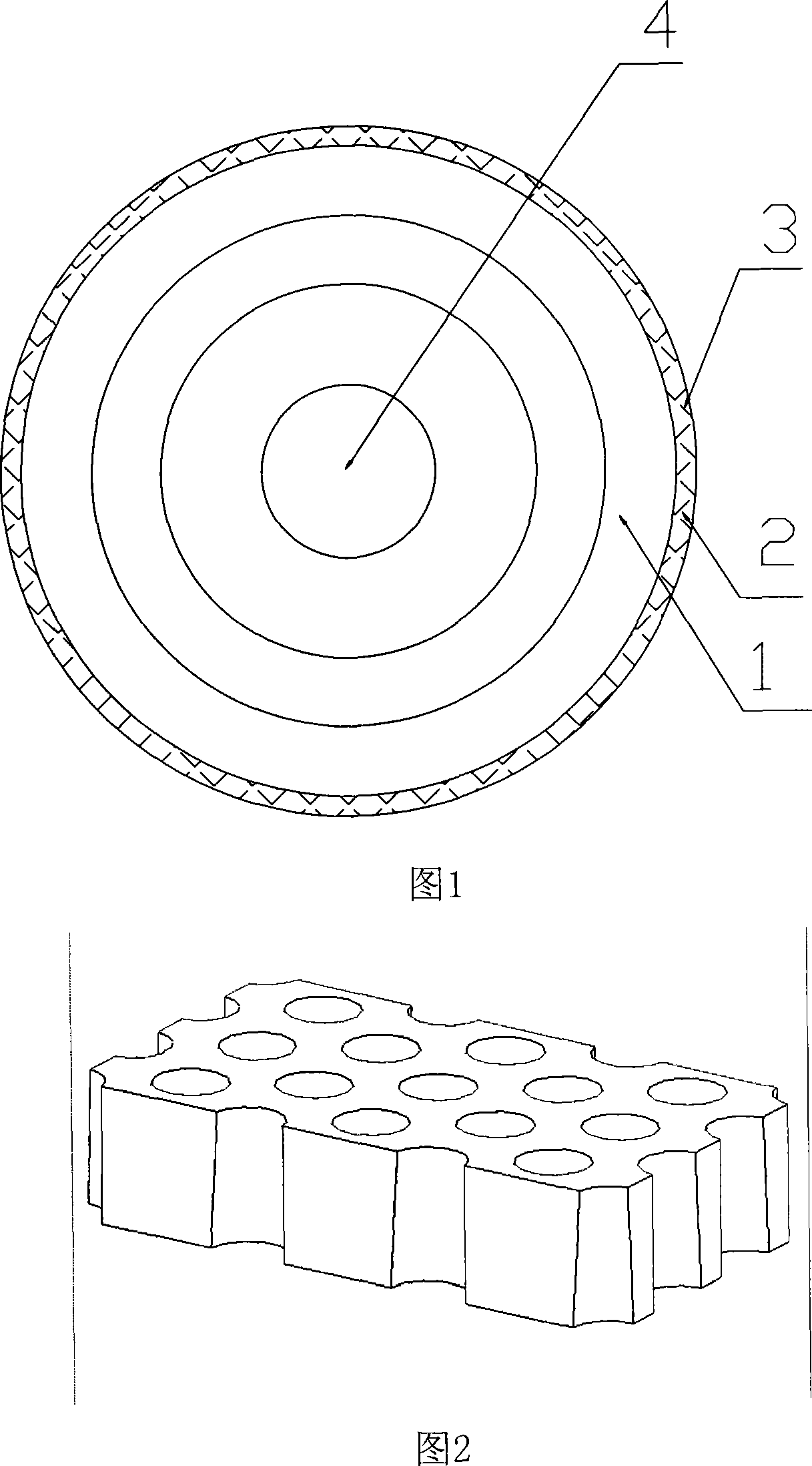

[0020] In the specific embodiment 1 of the present invention, a wear-resistant composite roller 4 is processed.

[0021] Metal or non-metal high-hardness wear-resistant ceramic alloys that match the base material are preferred, such as WC, Ag 2 o 3 , SiC, ZrC, BeO, CaO, MgO, TiC, VC, SiO 2 , ZrO 2 、SiN 4 , B 4 C, NbC, etc., to make a porous alloy ceramic skeleton 3, the porous alloy ceramic skeleton 3 can be in the form of an orifice plate, a mesh plate or a foam plate, as shown in Figures 2 and 3. Its size conforms to the shape and size requirements of the working layer of the roller (plate). The finally formed porous alloy ceramic skeleton 3 preferably satisfies the conditions of porosity (volume ratio) of 15-85%, macro hardness HRC73-115, microhardness HV1100-4000, and compressive strength>1000MPa.

[0022] The formed porous alloy ceramic skeleton 3 is preset on the working layer 2 on the metal substrate 1, preheated at 150-800°C for 3-10 hours; then the metal substra...

specific Embodiment 2

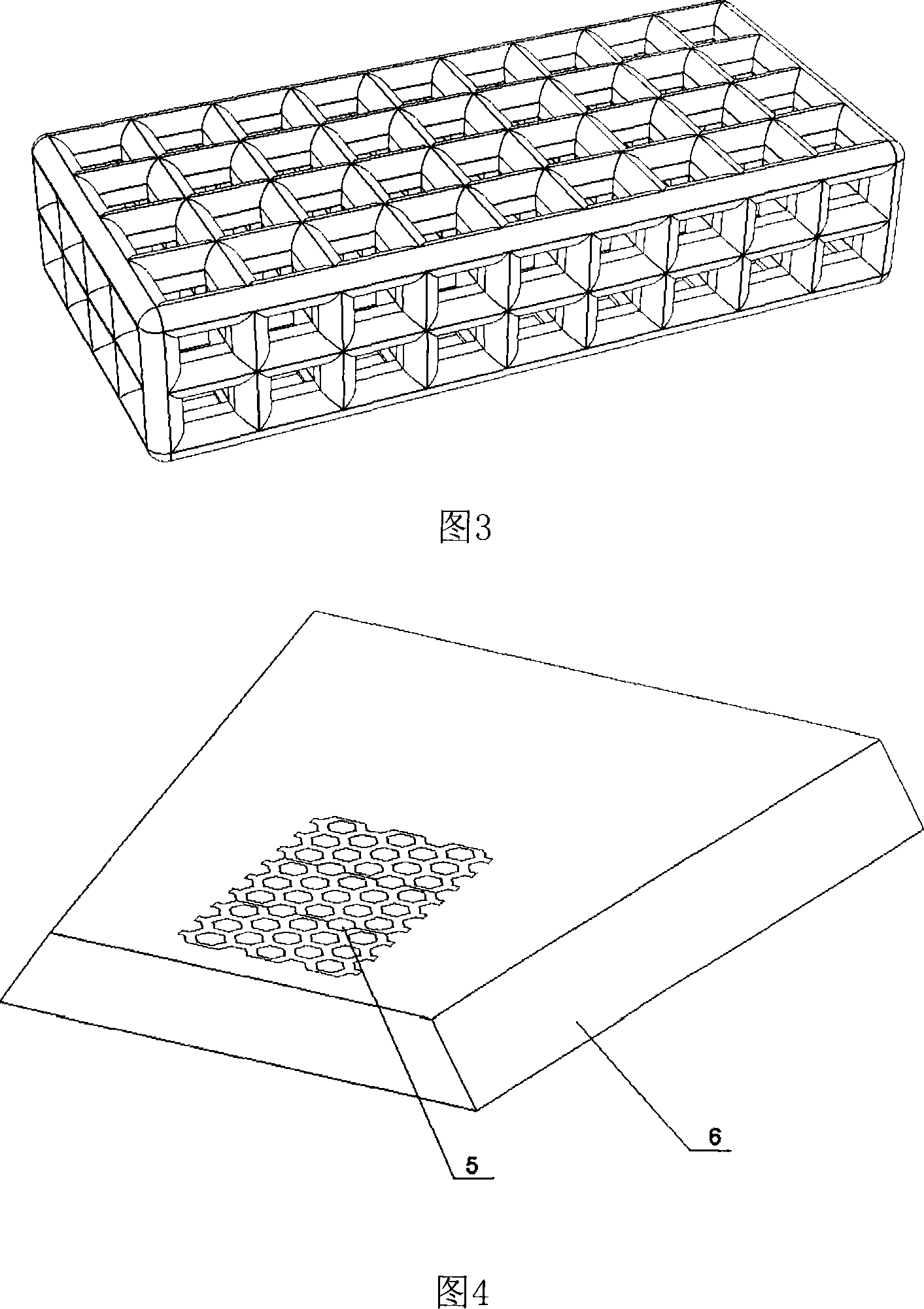

[0024] In the specific embodiment 2 of the present invention, a wear-resistant composite roller plate 6 is processed.

[0025] Form the porous alloy ceramic skeleton 5 similarly to Example 1, then pre-set the formed porous alloy ceramic skeleton 5 on the working layer on the metal substrate of the wear-resistant composite roll plate 6, and preheat it under the condition of 150-800°C for 3-10 hours; then heat the metal matrix of the wear-resistant composite roll plate 6 to 1200-1700°C to form a liquid state, and then adopt a vacuum casting process to form a metallurgically bonded whole, and the wear-resistant composite plate is made as shown in Figure 4.

[0026] When selecting the alloy material in the porous alloy ceramic skeleton 5 in the above embodiment, the alloy material that can fuse with the matrix metal material should be preferred.

[0027] The above-mentioned wear-resistant composite roller and plate have passed industrial trials, and their comparative wear speed ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com