Flange positioner

A flange positioner and flange technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as low efficiency, cumbersome adjustment operations, and inconvenient construction, so as to improve work efficiency and save labor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

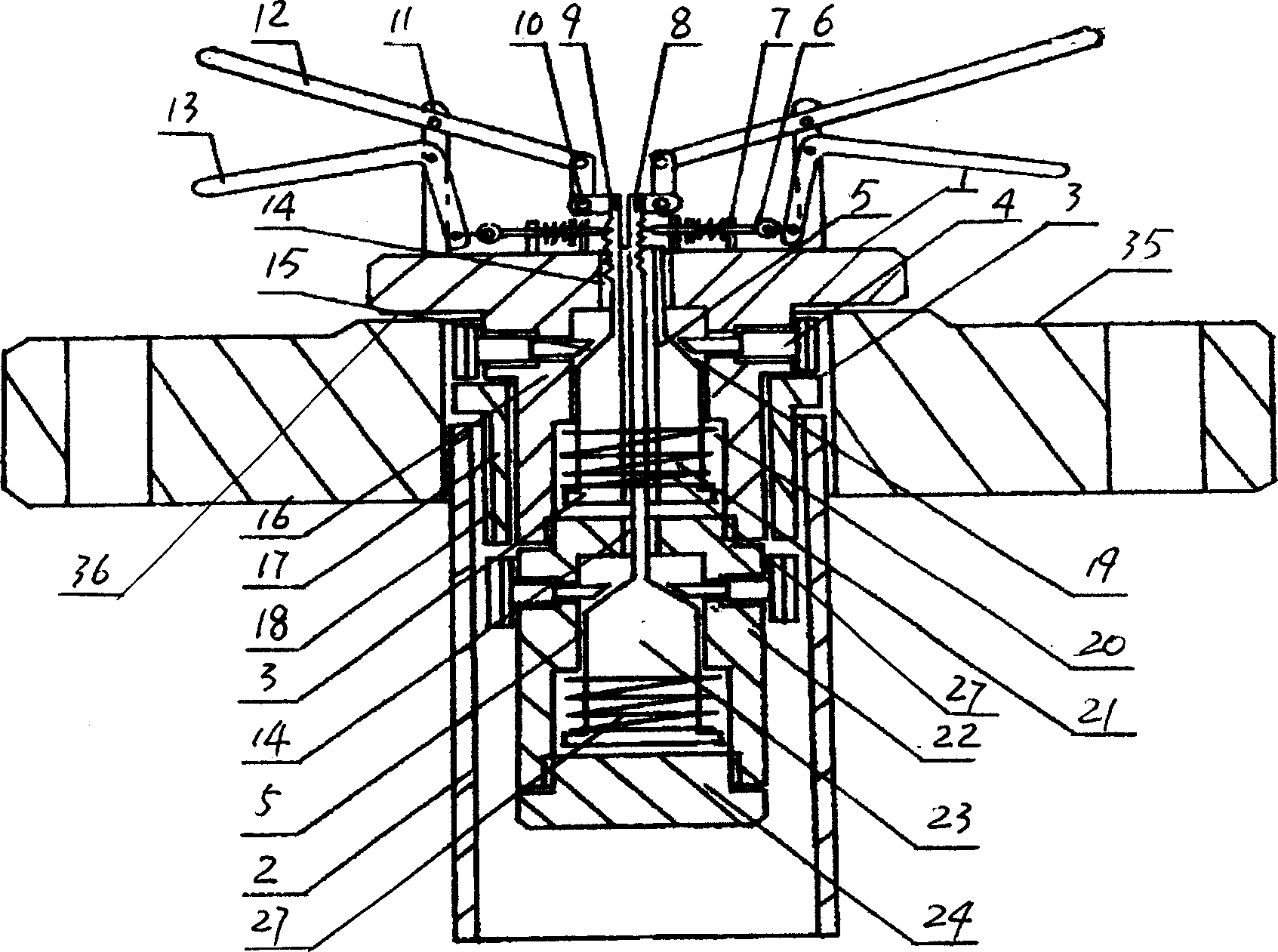

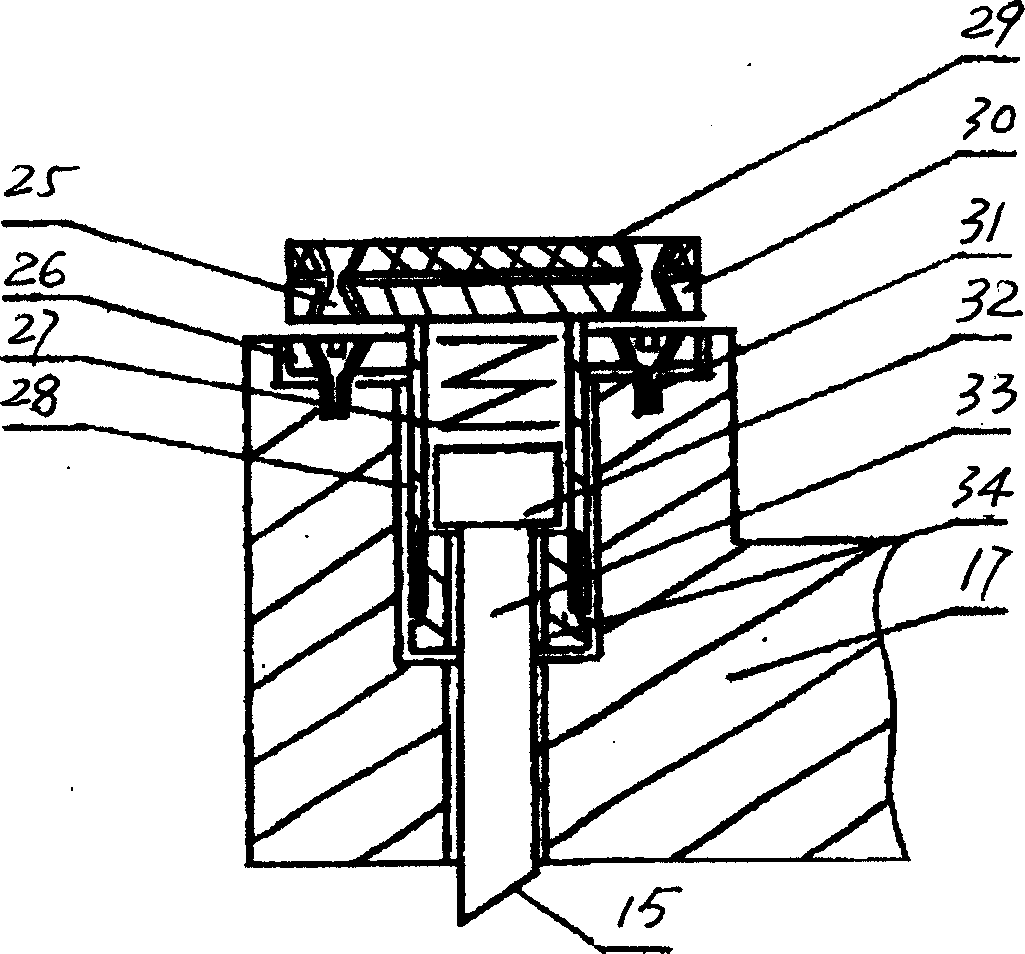

[0018] figure 1 Among them, the double-locking flange positioner is equipped with two sets of locking devices 5 and locks the flange 35 and the pipe 2 on the same axis respectively, and the locking device 5 of the locking flange 35 is evenly spaced in the radial direction of the positioning shaft 16. Several tensioning mechanisms 4 are installed, the positioning shaft 16 is equipped with a shaft sleeve 17, and the front end of the positioning shaft 16 is equipped with a toothed tube 9 and a hollow front cone column 21 inside. 15 mating in pairs, frictional contact. The toothed tube 9 passes through the hole 14 of the positioning plate 1 and is connected with the locking bar 12 through the hinge 10. The fulcrum of the locking bar 12 and the brake bar 13 is positioned on the hinge fixing bar 11 with the hinge 10, and the brake bar 13 The gear tube 9 can be braked by the brake rod 6 and the spring 27 on the brake rod seat 7.

[0019] The locking device 5 of the locking pipe 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com