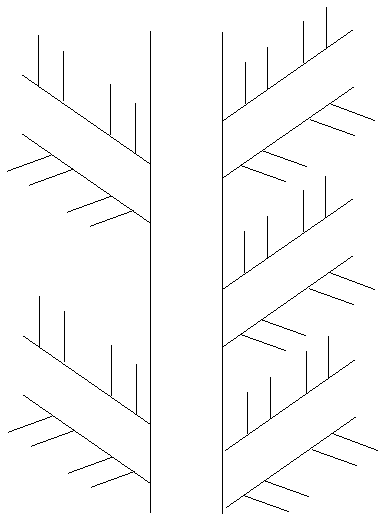

A device for preparing nonlinear dendritic wicks by selective laser melting

A selective laser melting and non-linear technology, which is applied in the field of electronic manufacturing industry, can solve the problems that mechanical processing and sintering methods are difficult to complete, processing methods cannot be directly prepared, and the working capacity of the liquid-absorbing core structure is slow, etc., to achieve simple structure, The effect of low production cost and small backflow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

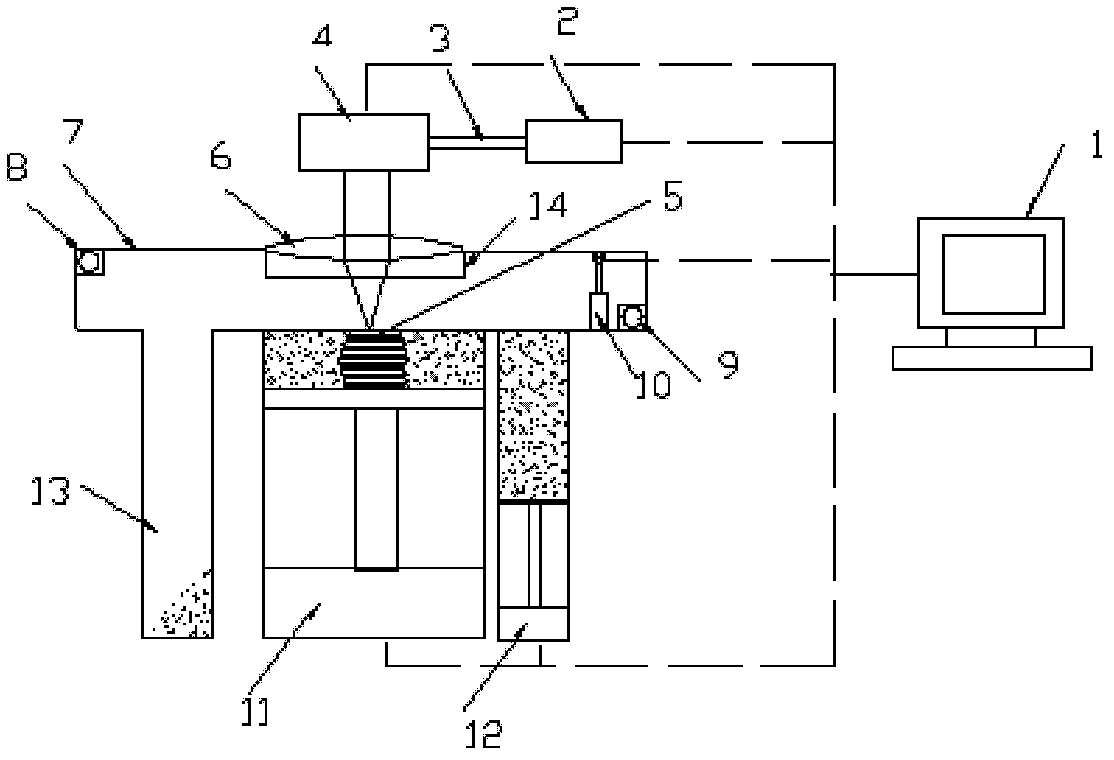

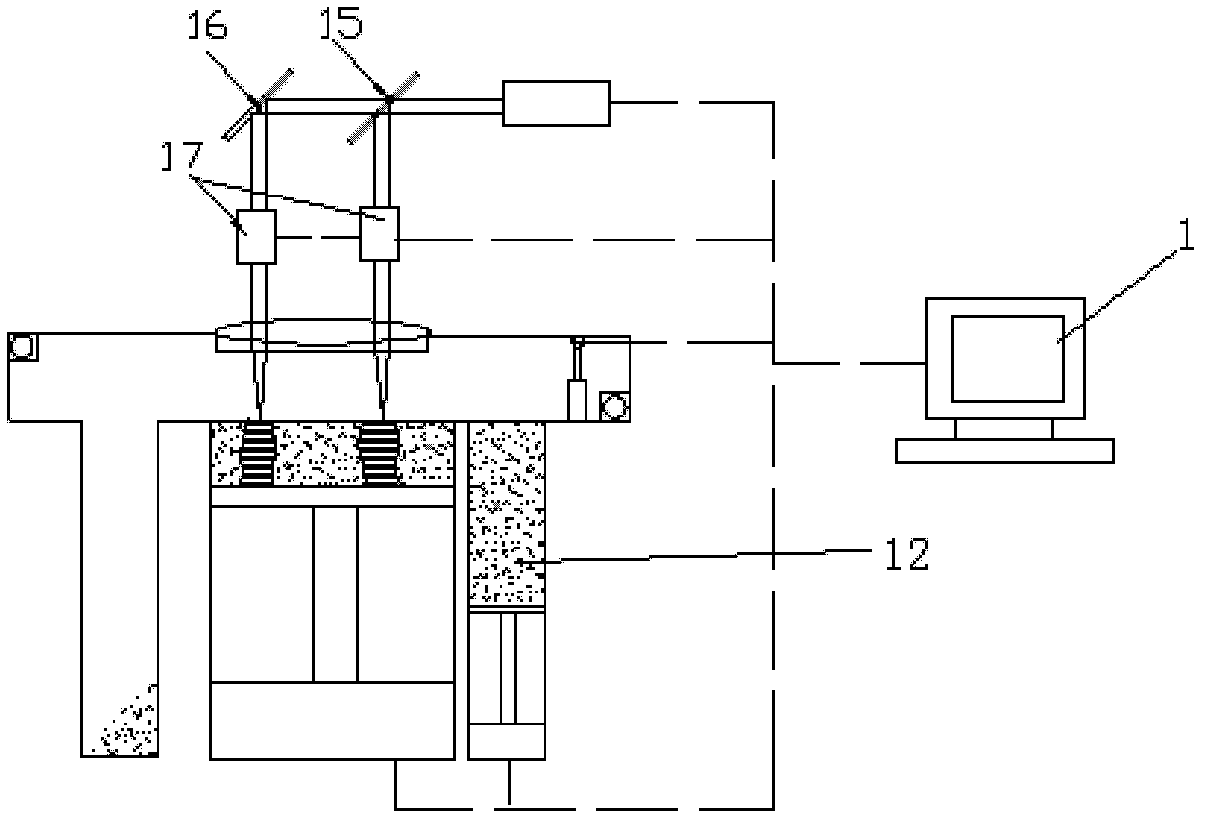

[0032] Such as figure 1 . The non-linear tree-shaped liquid-absorbing core device prepared by selective laser melting of the present invention includes a controller 1, a laser generator 2, an optical path transmission original 3, a scanning galvanometer system 4, an F-θ mirror 6, a molding chamber 7, and an air inlet 8. Air outlet 9, CNC mobile brush 10, forming part lifting cylinder 11, powder lifting cylinder 12, powder recovery cylinder 13; the laser generator 2, optical transmission original 3, scanning galvanometer system 4, F-θ mirror 6. Set the connection in the optical path in turn;

[0033] The F-θ mirror 6 is arranged in the middle of the upper end of the molding chamber 7, the air inlet 8 is arranged at the upper end of the inner wall on one side of the molding chamber 7, and the gas outlet 9 is arranged at the lower end of the inner wall on the other side of the molding chamber 7, The molding chamber 7 is also provided with a digitally controlled movable brush pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com