Automatic material loading and taking device for LED lamp heat dissipation cup injection molding

A technology of LED lights and automatic feeding, which is applied in the direction of coating, etc., can solve the problems of affecting production capacity and quality, slow feeding speed, and high labor intensity of workers, so as to reduce labor intensity of workers, ensure quality, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

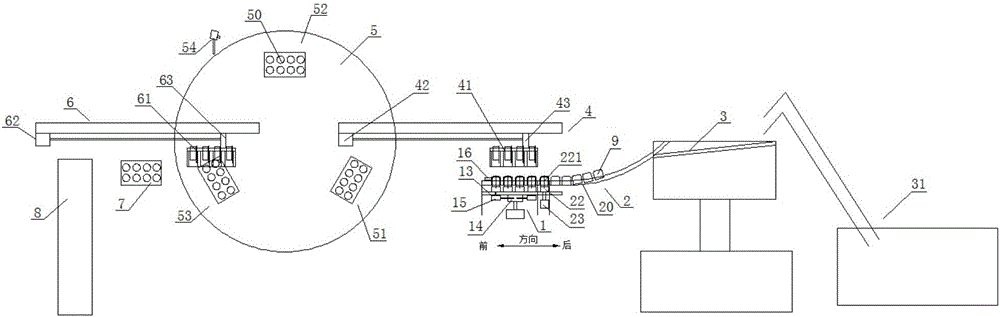

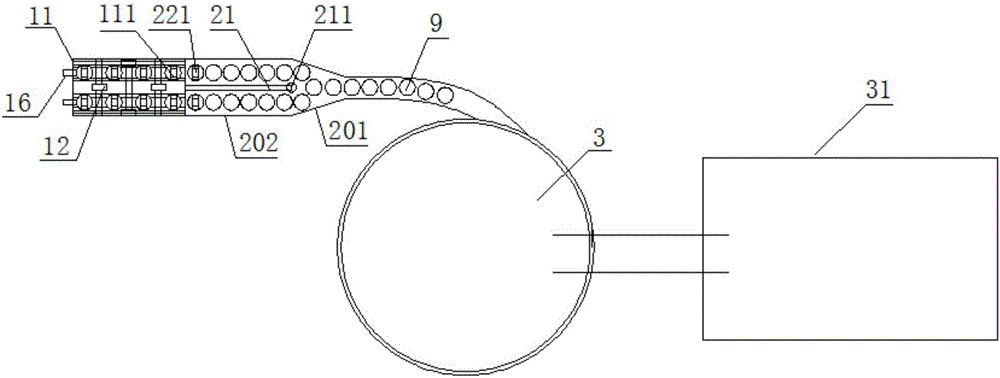

[0020] like figure 1 and figure 2 As shown, the LED lamp cooling cup injection molding automatic loading and unloading device includes a molding turntable 5 with three molding molds uniformly distributed along the circumferential direction. The molding turntable 5 is provided with a feeding station 51, a molding station 52, and a lower Material station 53, and 3 composition molds 50 are evenly distributed at the same time, so that the forming turntable 5 rotates every 120 degrees, and every composition mold will just correspond to the corresponding station, so that feeding, molding, and blanking are completed simultaneously. Wherein, the loading station 51 corresponding to the forming turntable is provided with an automatic feeding mechanism, the unloading station 53 corresponding to the forming turntable is provided with an automatic unloading mechanism, and the forming station 52 corresponding to the forming turntable is provided with a corresponding forming device.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com