Grinder for charging roller of full-automatic printer

A technology for printers and charging rollers, applied in grinding machine tools, grinding devices, metal processing equipment, etc., can solve the problems of weakened numerical control function, high labor intensity of workers, low production efficiency, etc., to increase safety, ensure quality stability, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

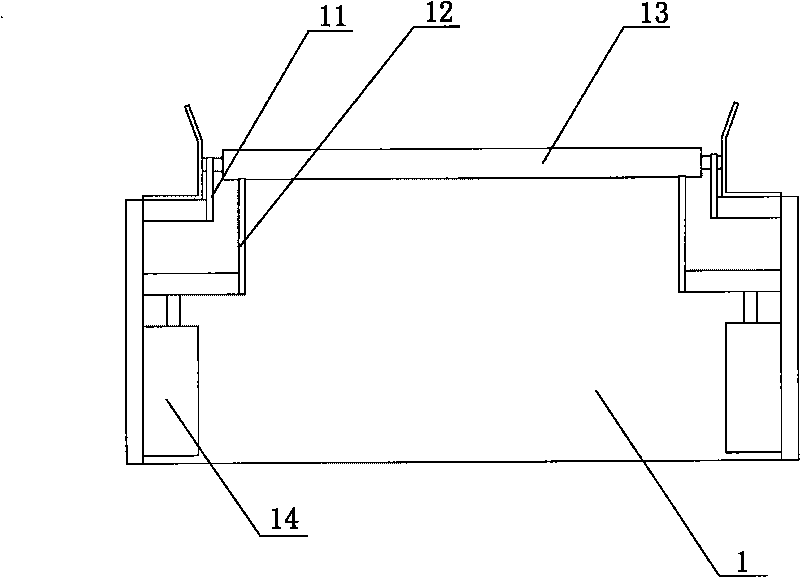

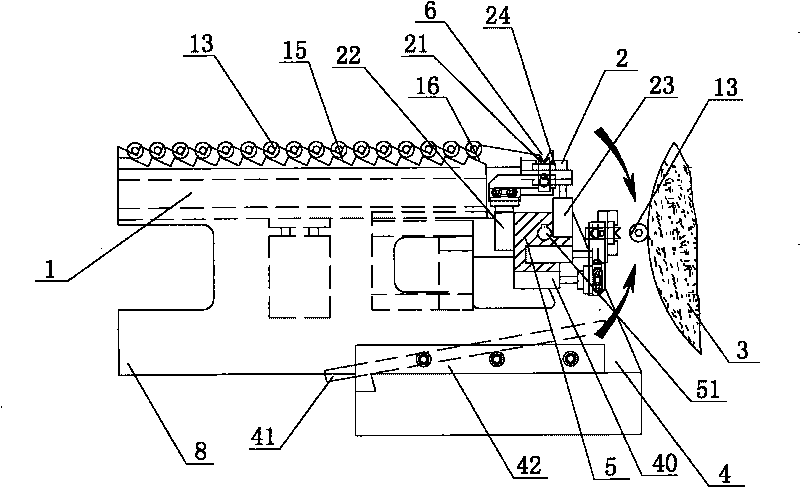

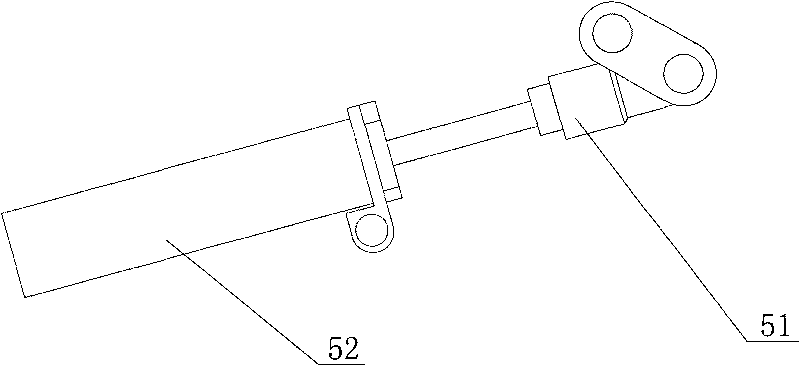

[0019] Please refer to figure 1 and figure 2 As shown, the present invention provides a fully automatic printer charging roller grinding machine, the fully automatic printer charging roller grinding machine includes a fixed bracket 8, and the fixed bracket 8 is provided with a feeding device 1, a material receiving and grabbing device 2, Grinding device 3, grasping and unloading device 4 and loading and unloading cylinder seat 5, described feeding device 1 comprises fixed feeding plate 11 and movable feeding plate 12, and described fixed feeding plate 11 and movable feeding plate 12 are all provided with most Arranged sawtooth-shaped tooth grooves 15, said sawtooth-shaped tooth grooves 15 are used to place the charging roller 13 to be processed, manually put the charging roller 13 into the sawtooth-shaped tooth grooves 15 of the feeding plate, and arrange them in order to realize the above The function of material and storage; and the movable feeding plate 12 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com