Bottle cultivation method for Hypsizigus marmoreus

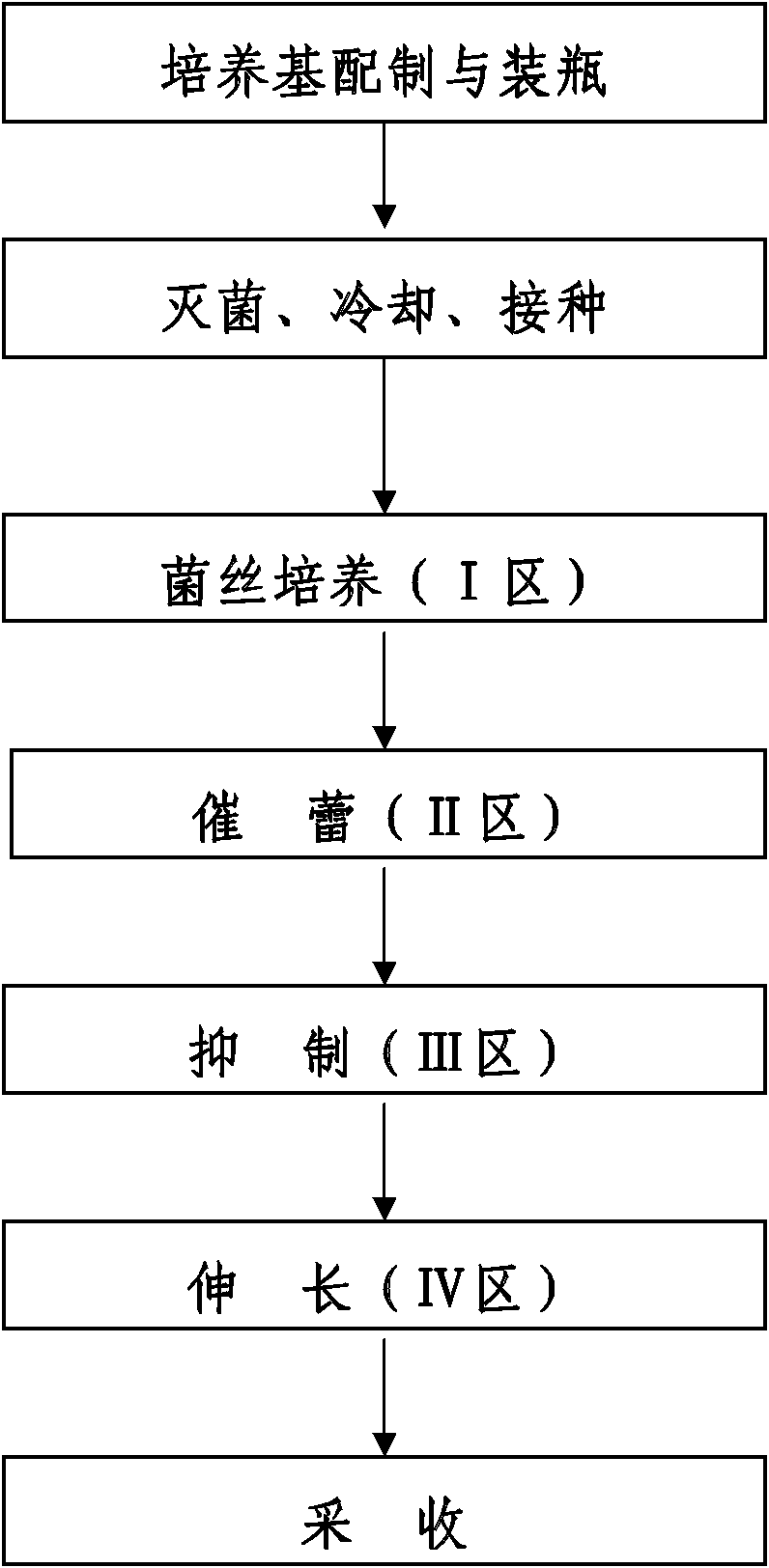

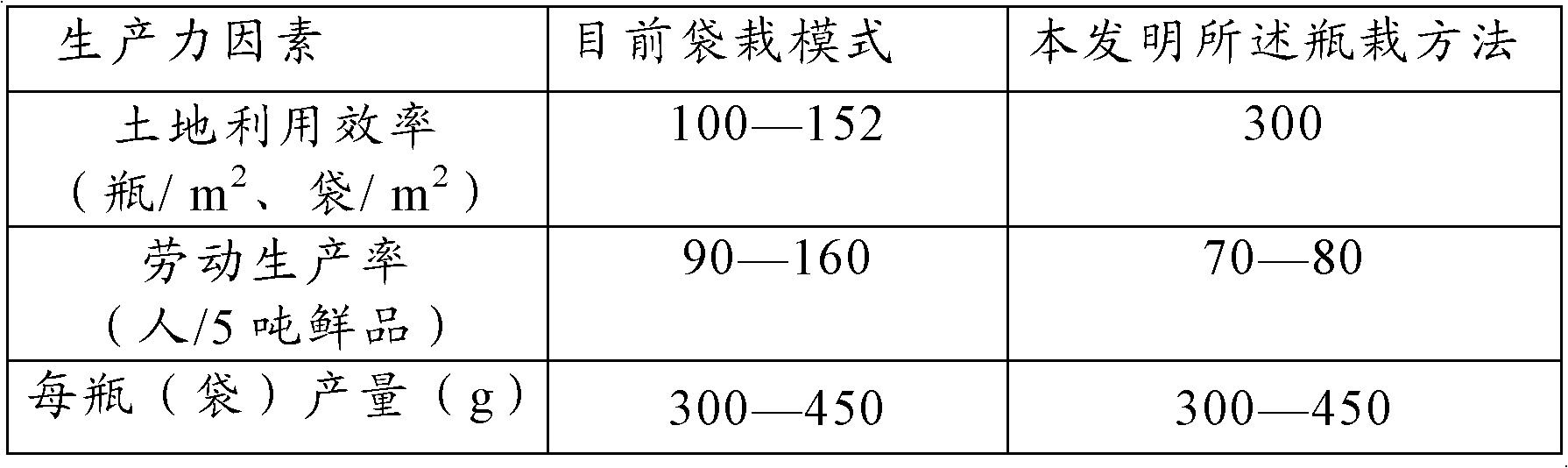

A technology for planting seafood mushrooms in a bottle is applied in the field of bottle planting of seafood mushrooms, which can solve the problems of low level of factoryization and automation, and achieve the effects of improving the degree of automation, improving the level of productivity, and uniform and stable product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: culture medium preparation

[0029] Weigh the solid components by weight percentage. Among them, 23% wood chips, 24% corn cobs, 23% bran, 5% corn flour, and 25% cottonseed hulls. Prepare a culture medium with a water content of 66% by solid component weight, adjust the pH to 7.5 with quicklime, and continue stirring until the bottling is completed. The size of the cultivation bottle is 1400cc.

Embodiment 2

[0030] Example 2: Sterilization and cooling

[0031] A high-pressure sterilizer is used, and the bottle frames to be sterilized are neatly placed on the sterilizer, pushed into the sterilizer, closed the door, and start the operation button. Bacteria for 90 minutes.

[0032] Cooling: After the sterilization is finished, open the back door of the sterilizer, push the sterilizing cart into the cooling room, and set the temperature of the cooling room at 20-22°C.

Embodiment 3

[0033] Example 3: Inoculation and cultivation

[0034] Bottles cooled below 22°C are inoculated by an automatic inoculation machine, which is placed in a fully clean inoculation room, and each bottle of original seed is inoculated with 32 to 40 bottles of cultivars, which are transported to the cultivation room by a conveyor belt after inoculation.

[0035]The temperature of the culture room is set at 22-25° C., the humidity is 60-80%, the carbon dioxide concentration is between 2500-3500 ppm, and the culture time is 80-95 days.

[0036] Embodiment 3: budding stage

[0037] (1) Scratch bacteria and water injection

[0038] When the hyphae of seafood mushrooms are matured after post-ripening, the bacteria can be scratched, that is, the surface of the material is scratched into a steamed bun shape with a knife head, and a little water is added to increase the number of primordia. The bottle baskets that have scratched the bacteria are placed on the bed frame in the breeding ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com