Welding method for overhaul of furnace chamber heat exchange tube

A welding method and heat exchange tube technology, applied in welding equipment, workpiece edge parts, metal processing equipment, etc., can solve the problems of long maintenance cycle, narrow maintenance environment, affecting maintenance quality, etc., to ensure quality, improve maintenance efficiency, Actionable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

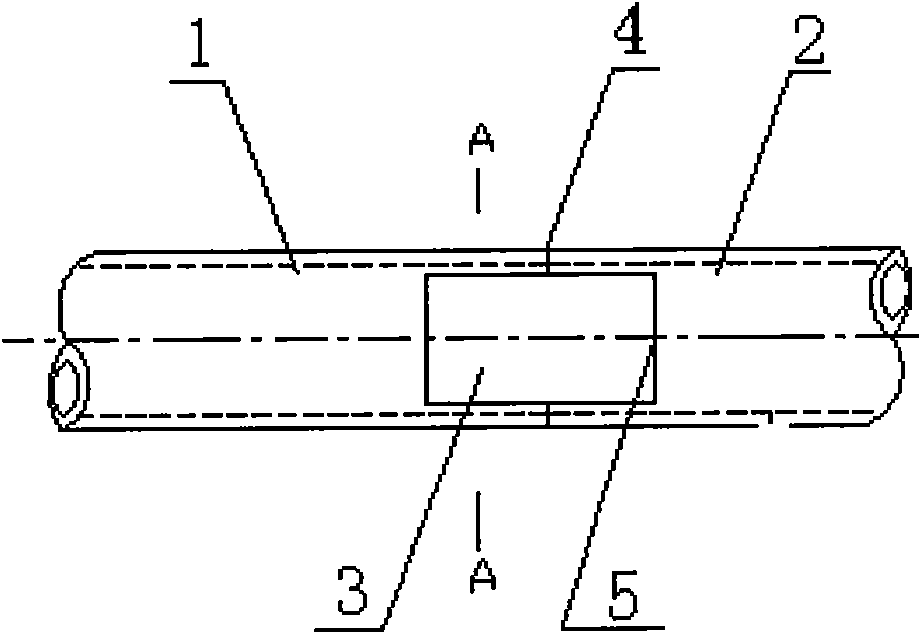

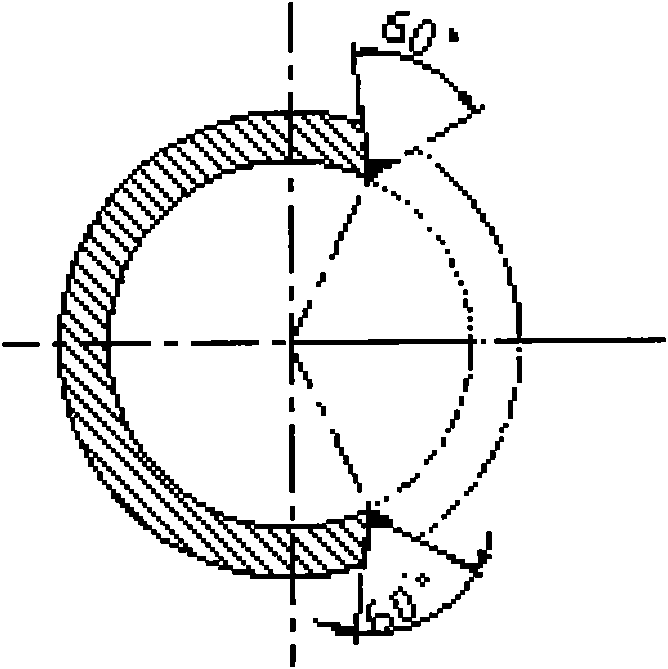

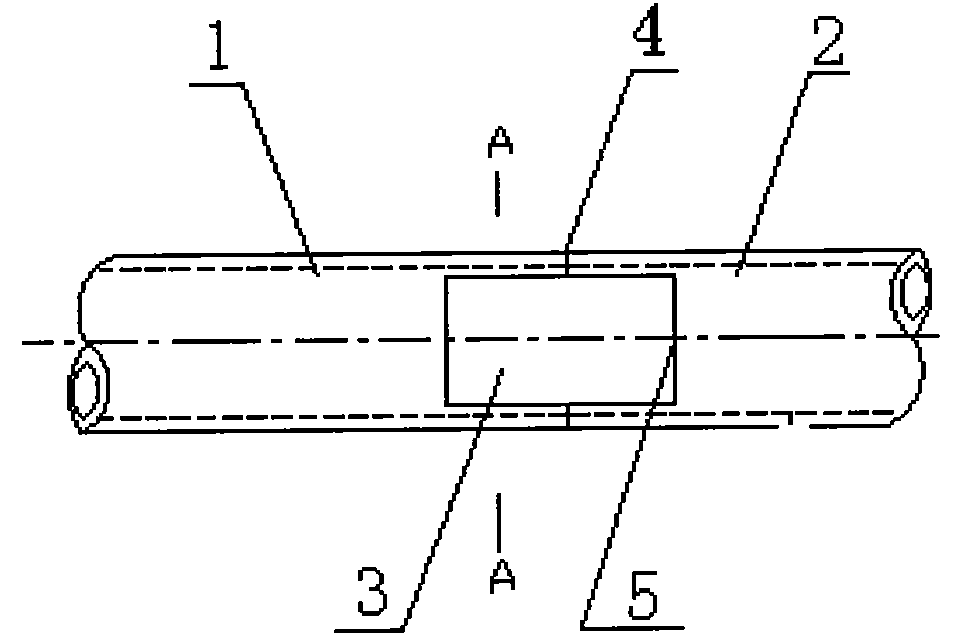

[0009] A welding method for overhauling furnace heat exchange tubes, comprising a butt joint 1, a butt joint 2 and a butt weld 4, a cover plate 3 is cut between the butt joint 1 and the butt joint 2, and the butt joint 1 and B are butt jointed The edge of the joint 2 is milled into an inner groove at a certain angle, and the contact parts of the cover plate 3 and the butt joint 1 and the butt joint 2 are respectively milled into an outer groove at a certain angle. First assemble the butt joint 1 of A and the butt joint 2 of B, weld the butt weld 4 according to the welding process and regulations, and pass the non-destructive inspection after welding (radiography, ultra-detection, magnetic particle, penetration), and then assemble the cover plate 3 and the joint The welding seam 5 of the cover plate at the place shall pass the non-destructive testing after welding, and then carry out the system pressure test inspection after the whole welding seam is qualified for wrapping and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com