Double-side in-situ placing construction method for CL structure system composite wall board concrete

A composite wallboard and construction method technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of difficult to guarantee construction quality, high construction and transportation costs, and difficult installation, and solve hidden quality problems and construction procedures. The effect of simplification and optimization of construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

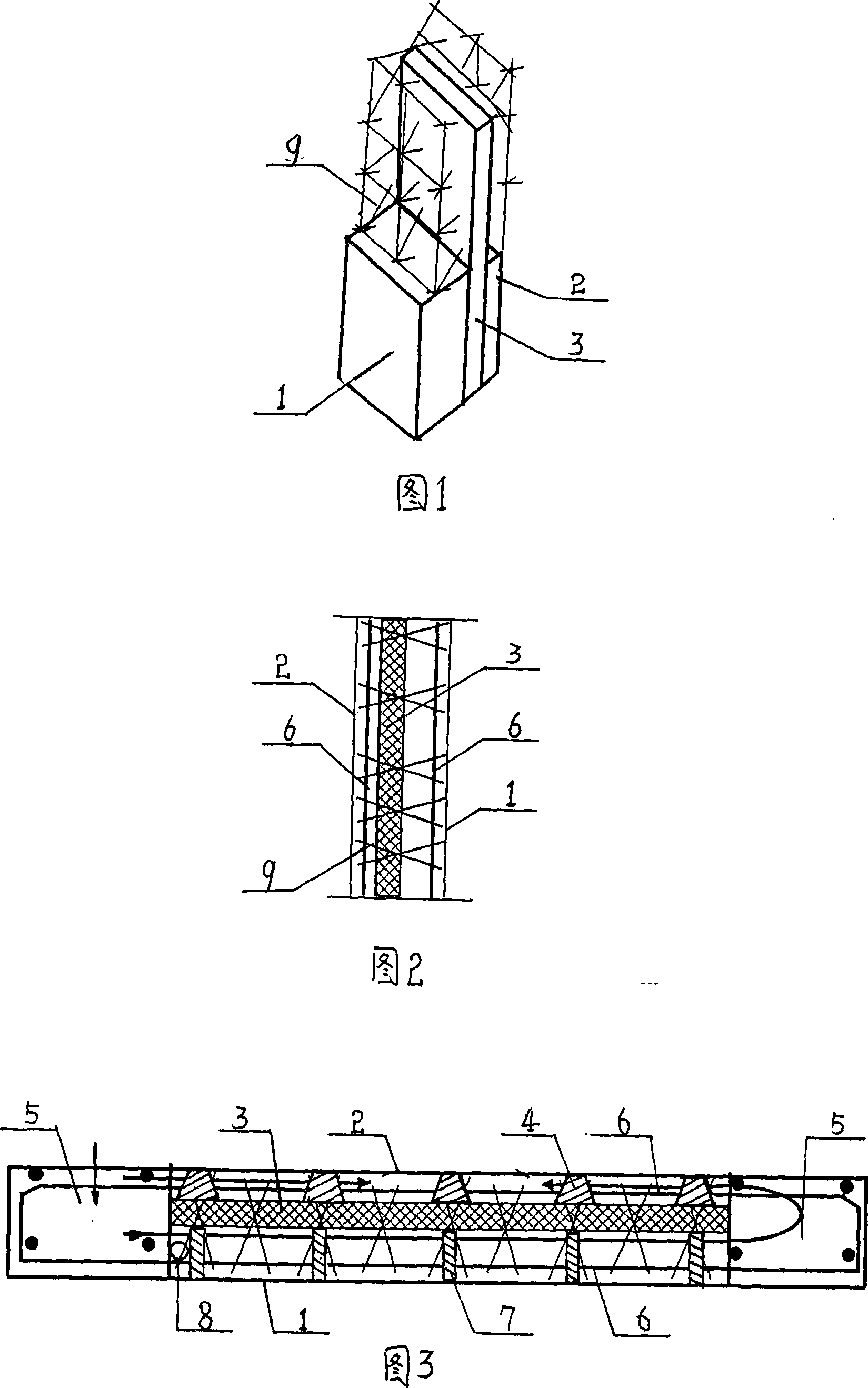

[0029]The double-sided cast-in-place construction method of composite wall panel concrete in CL structural system includes the following steps: (1) Fabrication and blanking of CL grid panels: the node form of CL grid panels is that one side of the outer wall has anchor wires on one side of the CL grid panels , with cold-drawn steel wires on the other side, double anchor wires on one side of the CL grid plate on the 2 sides of the inner wall, and cold-drawn steel wires on the other side; when cutting the material, it is cut according to the design size, and the size of the polystyrene plate is not required to be deducted; (2) Since the pouring thickness of the concrete on both sides of the polystyrene board is different, that is, the outer wall is thicker than the inner wall, the self-compacting fine stone concrete flows quickly on the outer wall side, causing the polystyrene board to be extruded and shifted toward the inner wall side. Directly prefabricate the square cone concr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope angle | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Bottom width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com