Ni-W-added Al alloy target material and manufacturing method thereof

A manufacturing method and alloy target technology, which are applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of uneven structure and micro-segregation of materials, and achieve precise composition control, uniform composition distribution, The effect of high purity of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

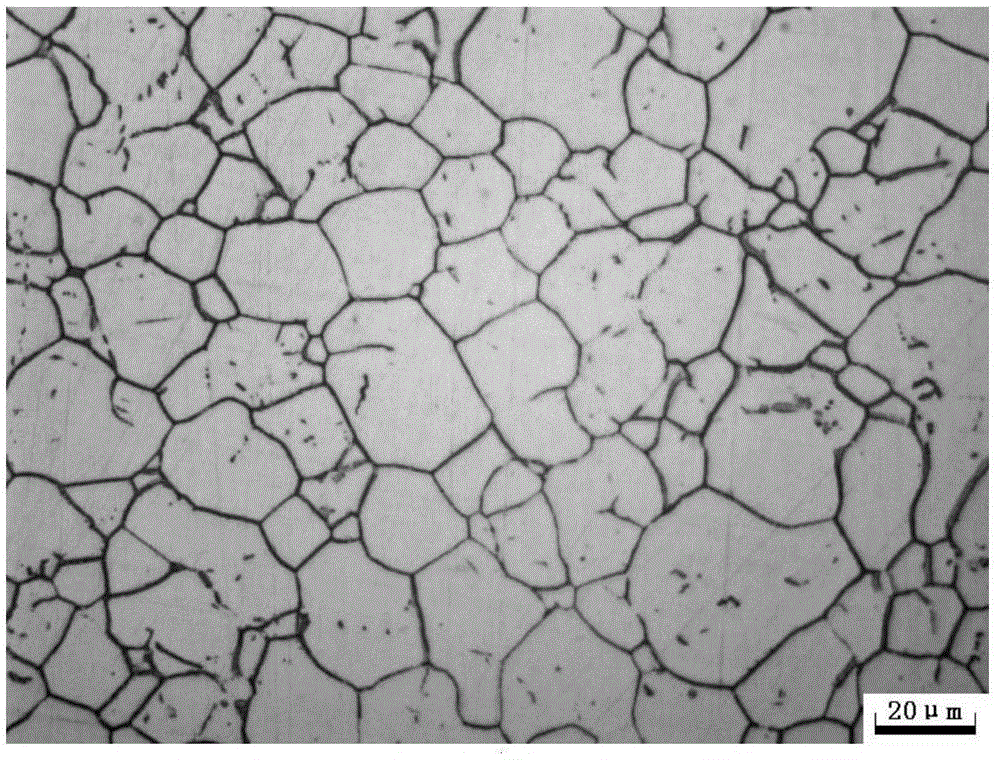

[0046] The Ni-W-Al alloy disk prepared in this embodiment is composed of the following elements in atomic percent: Ni: 89.5%, W: 10%, Al: 0.5%.

[0047] The specification of the alloy disk prepared in this embodiment is Φ170×6.35 mm.

[0048] The manufacturing method is as follows:

[0049] (1) Ingredients: According to the design requirements of the above alloy target composition, weigh nickel blocks with a purity of 99.95%, high-purity aluminum blocks with a purity of 99.95%, and high-purity tungsten rods with a purity of 99.95%;

[0050] (2) Master alloy smelting: put the weighed nickel and tungsten metal blocks into a vacuum induction melting furnace, and smelt them according to the normal smelting process (i.e., smelting according to the process well known in the art), wherein the vacuum degree is controlled at 0.1 during smelting Below Pa, the smelting temperature is controlled at about 1690°C, and the refining time is 15 minutes. After the smelting is completed, the po...

Embodiment 2

[0060] The Ni-W-Al alloy disk prepared in this embodiment is composed of the following elements in atomic percent: Ni: 82%, W: 8%, Al: 10%.

[0061] The specification of the alloy disk prepared in this embodiment is Φ170×6.35 mm.

[0062] The manufacturing method is as follows:

[0063] (1) Ingredients: According to the design requirements of the above alloy target composition, weigh nickel blocks with a purity of 99.95%, high-purity aluminum blocks with a purity of 99.95%, and high-purity tungsten rods with a purity of 99.95%;

[0064] (2) Master alloy smelting: Put the weighed nickel and tungsten metal blocks into a vacuum induction melting furnace, and smelt them according to the normal smelting process (ie, smelting according to the well-known process in the art), wherein the vacuum degree is controlled at 0.085 during smelting Pa, the smelting temperature is controlled at about 1650°C, and the refining time is 15 minutes. After the smelting is completed, the power is tur...

Embodiment 3

[0073] The Ni-W-Al alloy disk prepared in this embodiment is composed of the following elements in atomic percentage: Ni: 93.5%, W: 3.5%, Al: 3%.

[0074] The specification of the alloy disk prepared in this embodiment is Φ170×6.35mm.

[0075] The manufacturing method is as follows: (1) Ingredients: according to the design requirements of the above-mentioned alloy target composition, weigh a nickel block with a purity of 99.95%, a high-purity aluminum block with a purity of 99.95%, and a high-purity tungsten rod with a purity of 99.95%;

[0076] (2) Master alloy smelting: put the weighed nickel and tungsten metal blocks into a vacuum induction melting furnace, and smelt them according to the normal smelting process (ie, smelting according to the well-known process in the art), wherein the vacuum degree is controlled at 0.08 during smelting Pa, the smelting temperature is controlled at about 1680°C, and the refining time is 10 minutes. After the smelting is completed, the power...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com