Medical titanium alloy Ti-13Nb-13Zr ingot and preparation method thereof

A titanium alloy and ingot casting technology, which is applied in the field of titanium alloy, can solve problems such as complex preparation process, metallurgical defects, and difficulty in crushing, and achieve the effects of simple and easy preparation method, reduced production cost, and good metallurgical quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

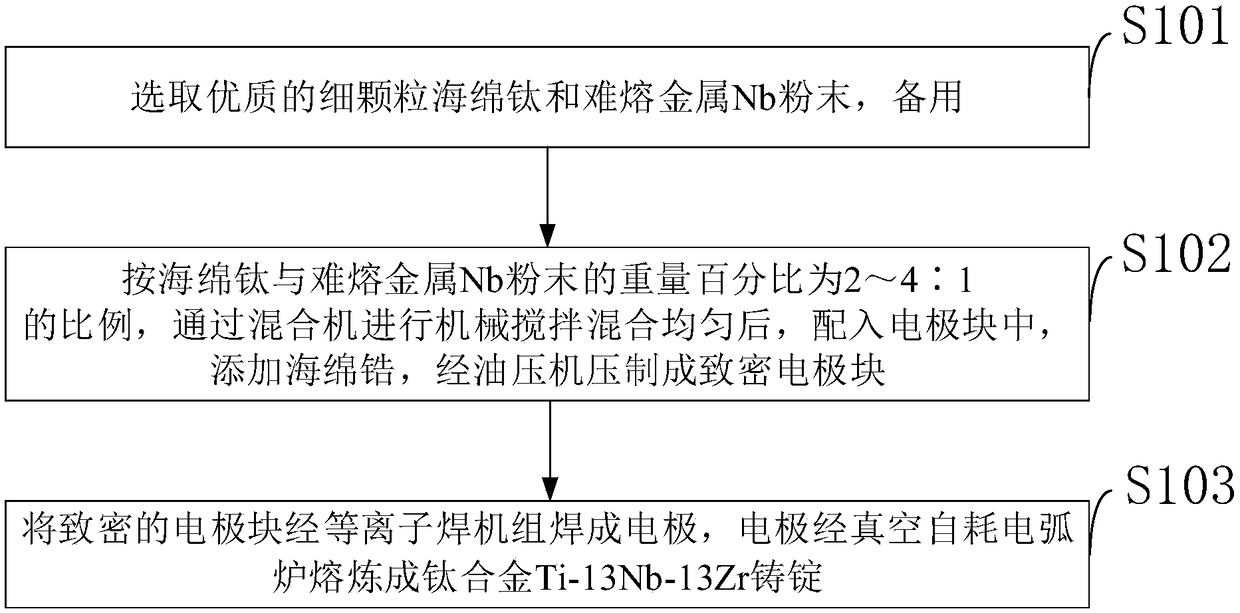

[0029] Such as figure 1 As shown, the preparation method of the medical titanium alloy Ti-13Nb-13Zr ingot provided by the embodiment of the present invention specifically includes the following steps:

[0030] S101: Select high-quality fine-grained titanium sponge and refractory metal Nb powder for later use;

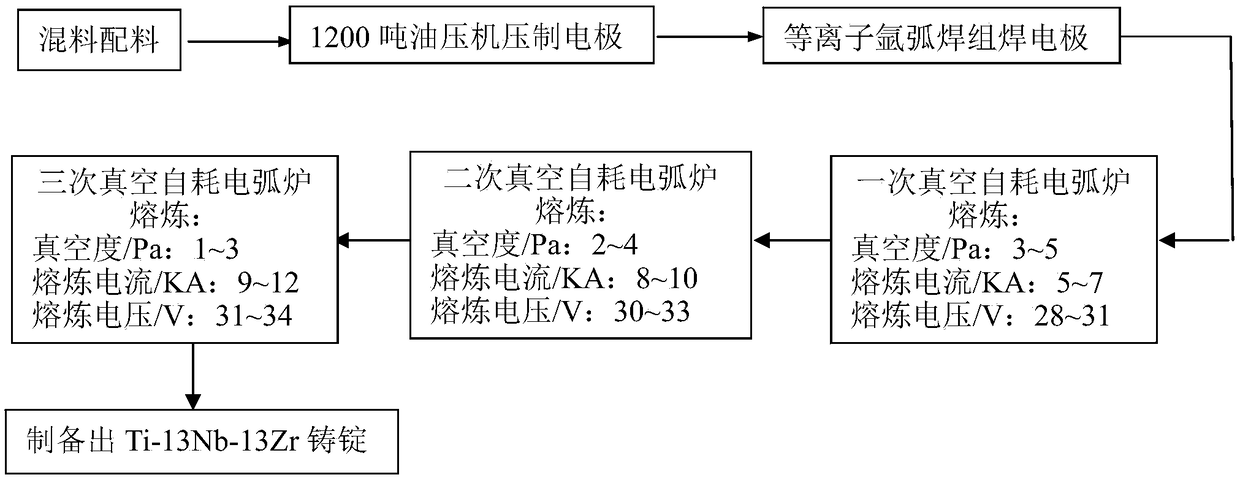

[0031] S102: According to the weight percentage of sponge titanium and refractory metal Nb powder in the ratio of 2 to 4:1, mechanically stir and mix evenly through a mixer, mix it into electrode blocks, add sponge zirconium, and press it into dense electrode blocks by hydraulic press ;

[0032] S103: The dense electrode block is welded into an electrode by a plasma welding machine, and the electrode is melted into a titanium alloy Ti-13Nb-13Zr ingot by a vacuum consumable electric arc furnace.

[0033] In step S101 , according to the embodiment of the present invention, fine particle sponge titanium with an average particle size ranging from 0.83 to 6 mm and refracto...

Embodiment 1

[0039] Low-cost preparation method of Ti-32Mo titanium alloy:

[0040] Fine particle sponge titanium in the range of 0.83 to 6mm and molybdenum powder in the range of -100 to -200 mesh particle size are mechanically stirred and mixed on a mixer for 1 After ~3 hours, put it into the electrode block, press it into a dense electrode block with a hydraulic press, weld the dense electrode block into an electrode with a plasma argon arc welding machine, and melt the electrode into a titanium alloy ingot through a vacuum consumable electric arc furnace. It has been tested as a homogeneous ingot without molybdenum element segregation and inclusions.

Embodiment 2

[0042] Low-cost preparation method of Ti-Mo-V-Fe-Al titanium alloy:

[0043] Fine particle sponge titanium with an average particle size ranging from 0.83 to 6 mm and molybdenum powder with a particle size ranging from -100 to -200 mesh, according to the ratio of 2 to 4:1 by weight of titanium sponge and molybdenum powder, mechanically stir on a mixer After mixing for 1 to 3 hours, it is mixed into the electrode block, and other alloy elements V, Fe, Al are added, and the dense electrode block is pressed by a hydraulic press, and the dense electrode block is welded into an electrode by an argon arc welding machine. The titanium alloy ingot is smelted in an electric arc furnace, which has been tested as a homogeneous ingot without molybdenum element segregation and inclusions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com