Rare earth electrolysis cell tapping device and method

A rare earth metal and electrolytic cell technology, which is applied in the electrolysis process and electrolytic components, etc., can solve the problems of easy absorption of molten salt, fast metal absorption, and high carbon content of rare earth metals, so as to ensure surface quality, prevent surface oxidation, internal Uniform quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

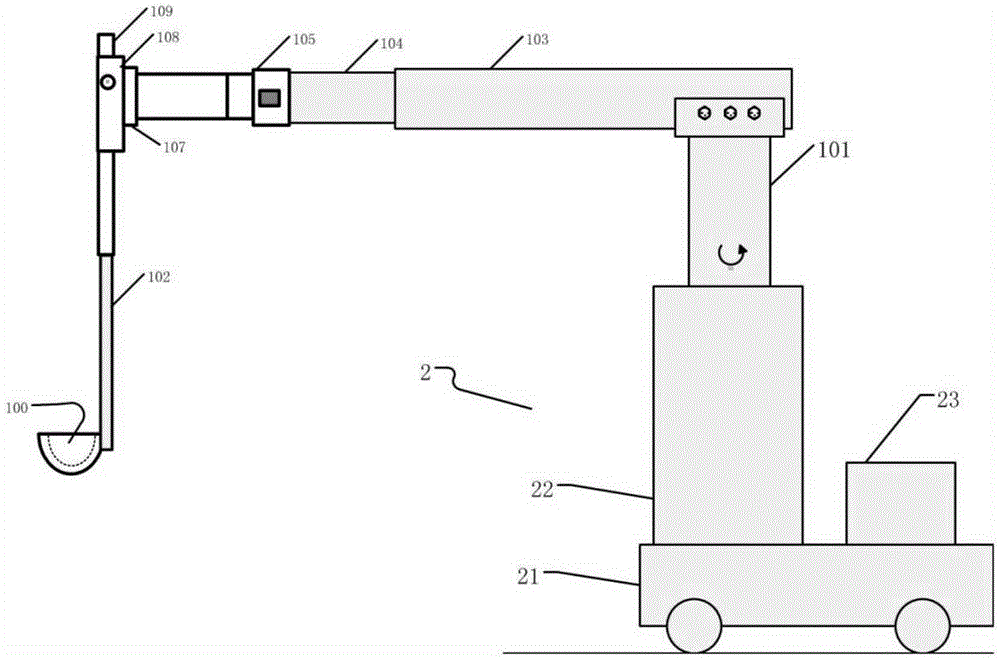

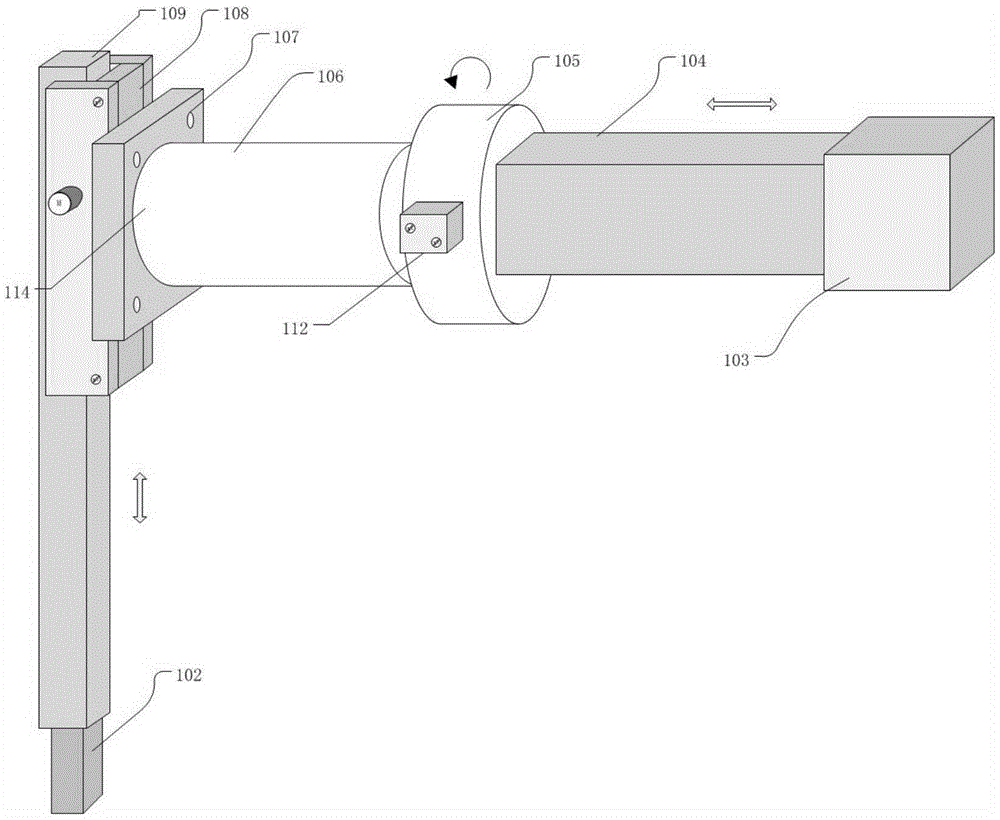

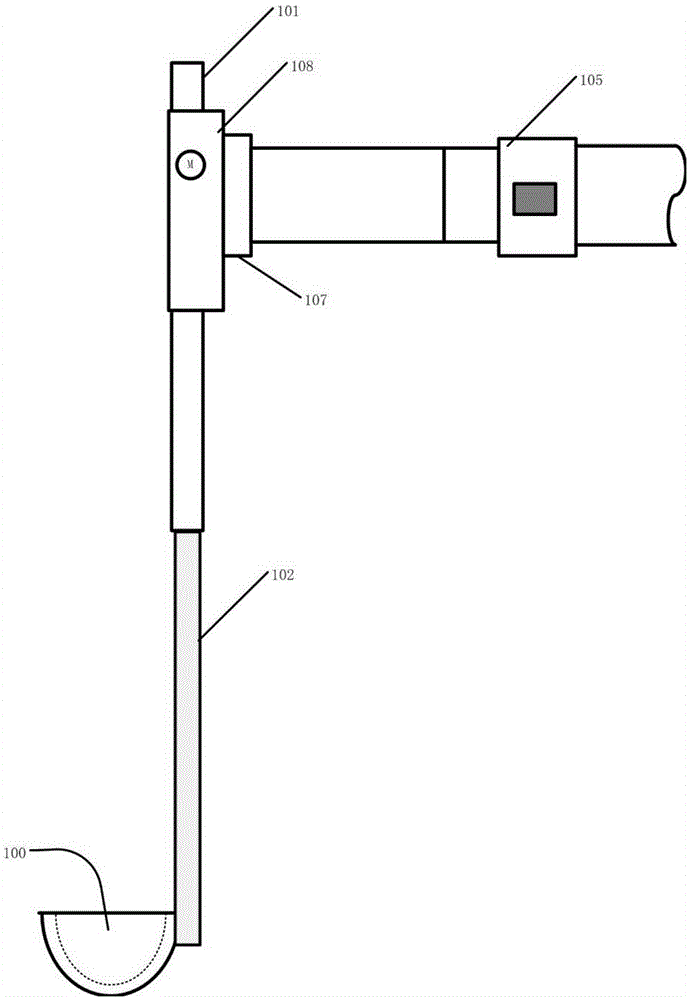

[0048] Such as figure 1 , 3 A device for extracting metal from a rare earth electrolytic cell shown in 5, comprising: a metal ladle 100, which is used to scoop liquid rare earth metal from the bottom of the rare earth electrolytic cell 1; a ladle handle 102, the ladle The lower end of the handle 102 is fixedly connected with the scoop 100, the metal scoop 100 is selected from titanium material or niobium material; a multi-degree-of-freedom mechanical arm, the multi-degree-of-freedom mechanical arm includes a longitudinal movement mechanism 108, a turning mechanism 105, and a lateral movement mechanism 103. The rotation mechanism 101, the lower end of the first lifting rod 109 of the longitudinal movement mechanism 108 is fixedly connected with the upper end of the scoop handle 102, and the longitudinal movement mechanism 108 is used to drive the metal scoop 100 to rise and fall; the turning mechanism 105 Fixedly connected with the vertical movement mechanism 108 through the f...

specific Embodiment approach 2

[0060] Such as Figure 4 The device for extracting metal from a rare earth electrolytic cell is characterized in that it includes:

[0061] A metal scoop 200, which is used to scoop liquid rare earth metal from the bottom of the rare earth electrolytic cell;

[0062] A ladle handle 1091, the lower end of the ladle handle is fixedly connected with the ladle;

[0063] A multi-degree-of-freedom mechanical arm, the multi-degree-of-freedom mechanical arm includes a first longitudinal movement mechanism 108, and the first longitudinal movement mechanism 108 drives the first lifting rod 109 to move longitudinally; the lower end of the first lifting rod 109 is connected to the scoop The upper end of the handle 1091 is fixedly connected to drive the metal scoop 200 to rise and fall; a second longitudinal movement mechanism 111 is fixedly installed on the first lifting rod 109, and the second longitudinal movement mechanism 111 drives a second lifting rod 110 Longitudinal movement; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com