A constant density biomass gasifier

A technology of gasification furnace and biomass, which is applied in the direction of gasification process, manufacture of combustible gas, petroleum industry, etc. It can solve the problems of furnace cross-section oxide layer, irregular shape of reduction layer, bed overheating, high packing density, etc. Achieve the effect of improving tar cracking efficiency, improving gasification time period, and good economic applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to enable those skilled in the art to better understand the solutions of the present application, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application.

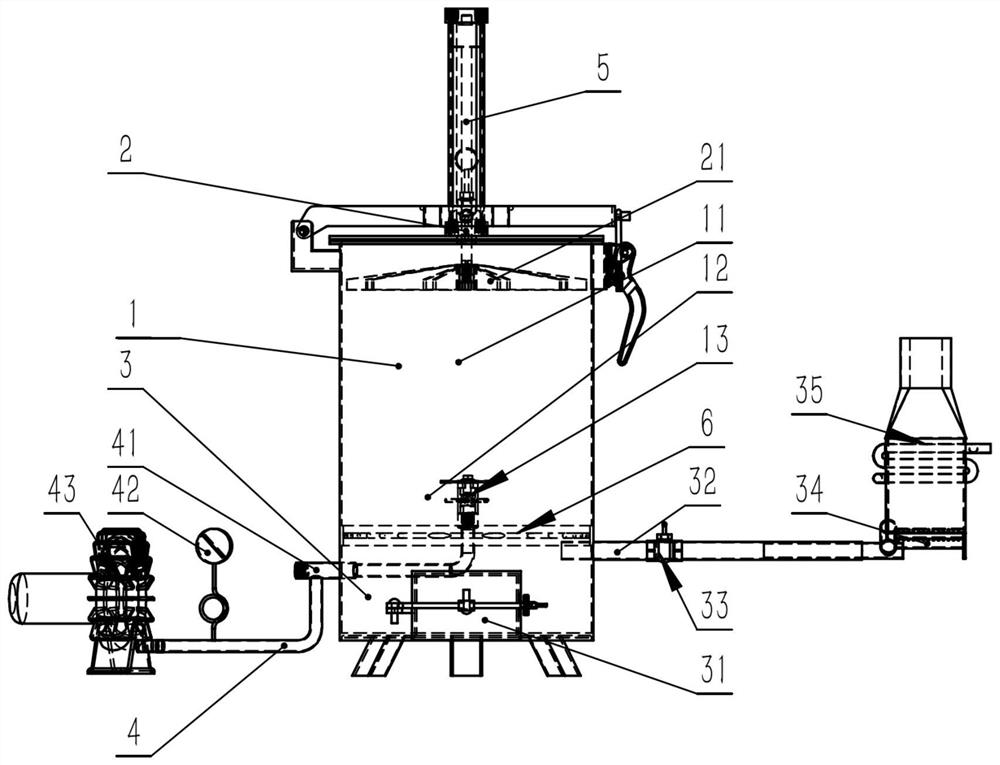

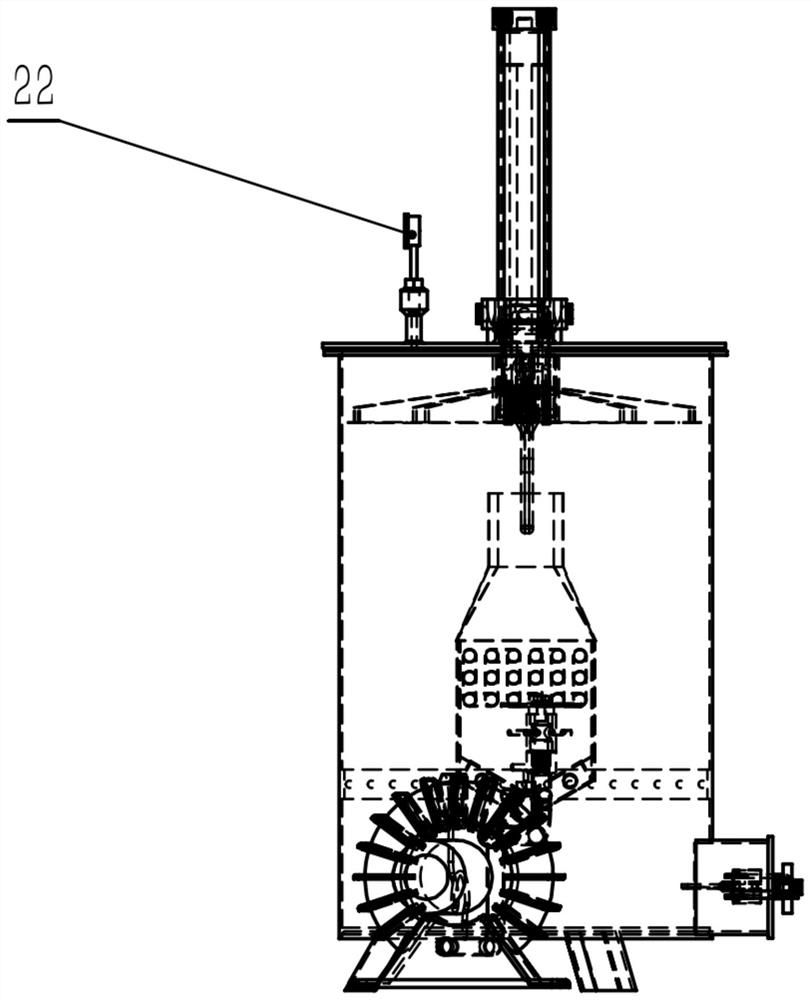

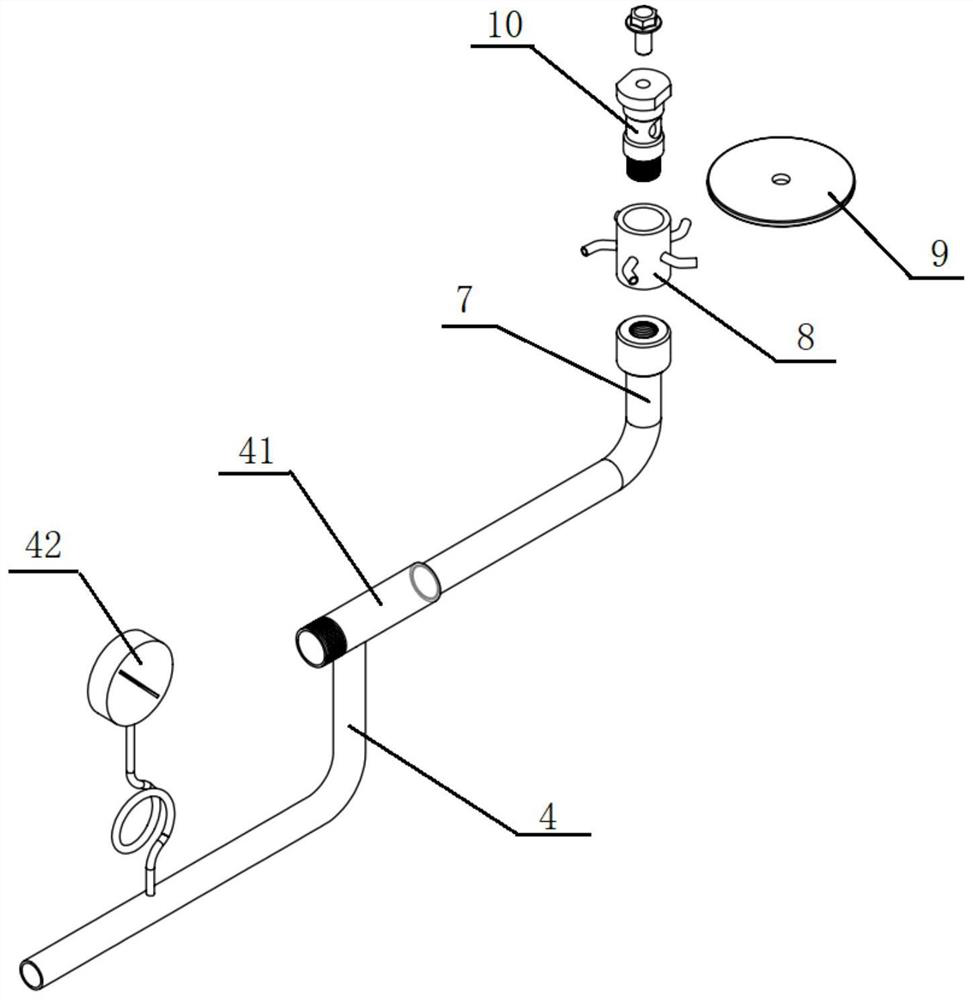

[0048] The object of the present invention is to provide a constant density biomass gasification furnace in which the fuel layer moves down at a constant density, the gasification agent is fed in from the automatic rotating nozzle in the center of the furnace body, the gas distribution is uniform, the reaction of each reaction layer is continuous and stable, and the gas production efficiency is high. . Among them, the fuel factor and combustible gas purification factor are the key factors that limit the development of biomass gasification technology. This invention is designed to solve the two factors that restrict the development of gasification technology, especially f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com