Patents

Literature

47results about How to "Eliminate bridging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

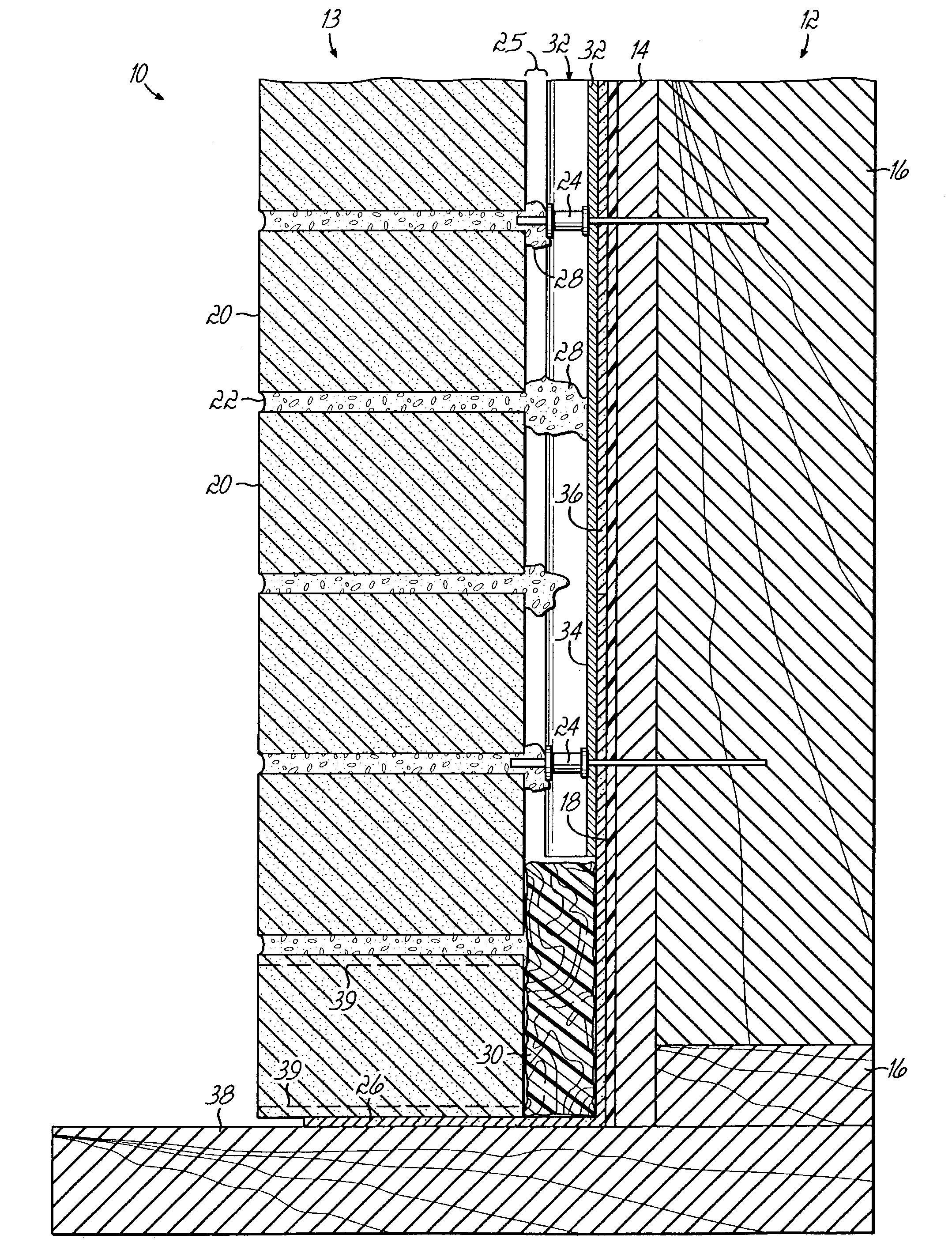

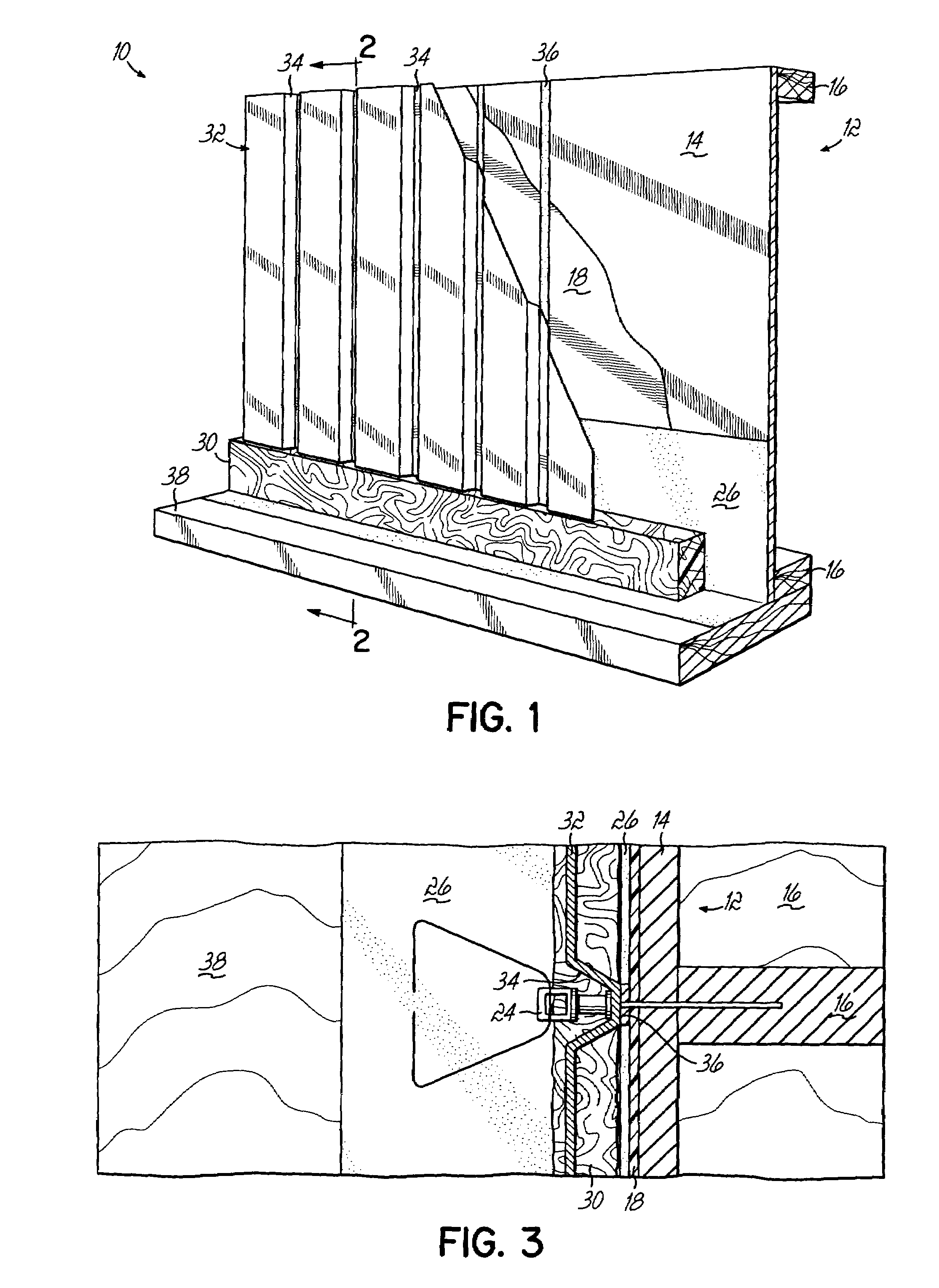

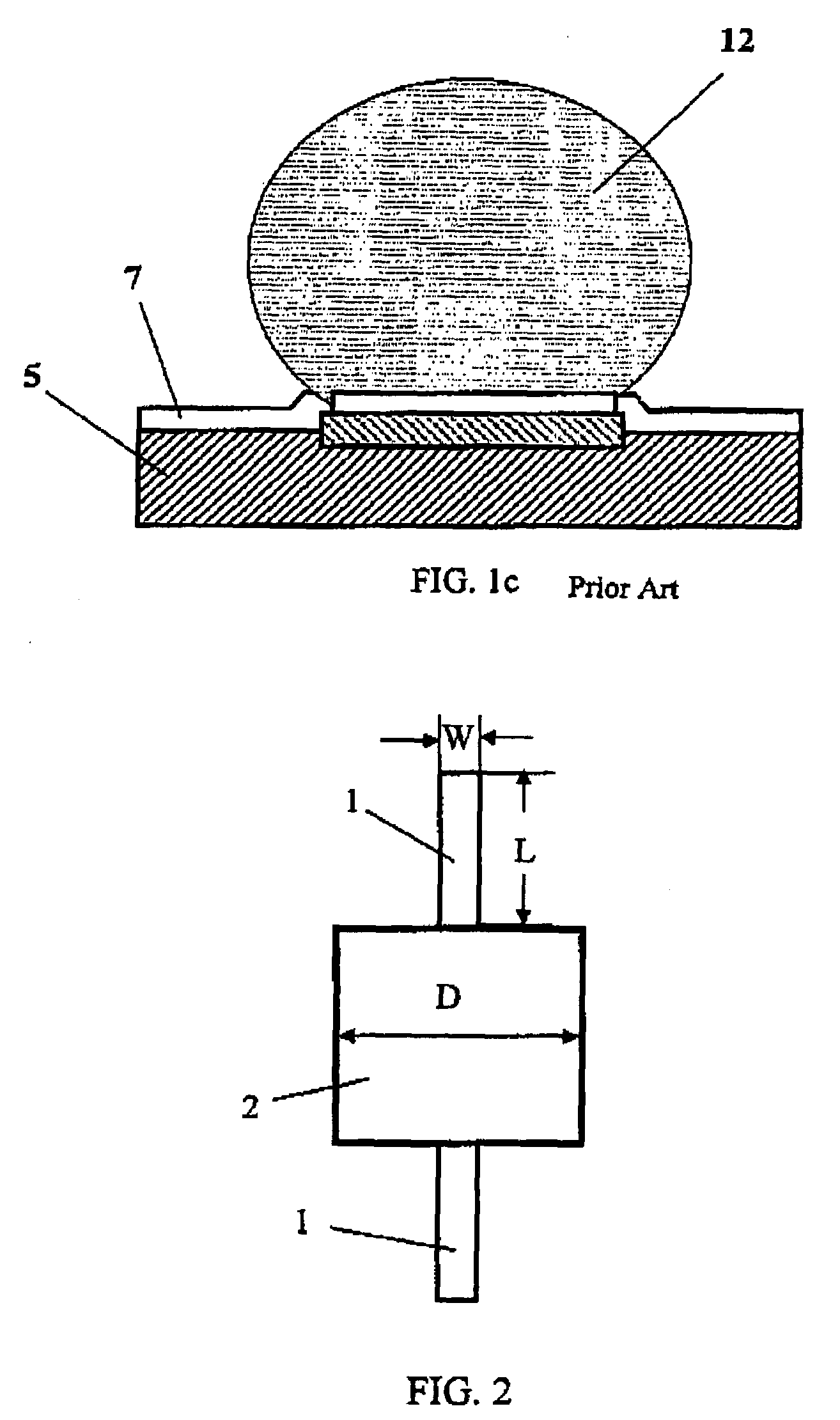

Air circulation board for cavity wall construction

A corrugated board is secured to the inner wall of a cavity wall construction to establish a defined spacing between the inner and outer walls and prevent excess mortar from bridging to the inner wall. The corrugated board has a series of spaced channels, furrows or grooves into which an anchor projects into the studs of the inner wall to secure the outer wall. The corrugated board is installed prior to the construction of the outer wall and establishes a minimum spacing or gap between the walls based upon the thickness of the board. The outer wall is constructed immediately adjacent to the outer face of the corrugated board. The grooves or channels of the corrugated board create a chamber for vapor and air circulation. The board eliminates bridging by the mortar and provides an air conduit to exhaust even the minimal amounts of vapor that will occur in the cavity.

Owner:TY DAS BUILDING PROD LLC

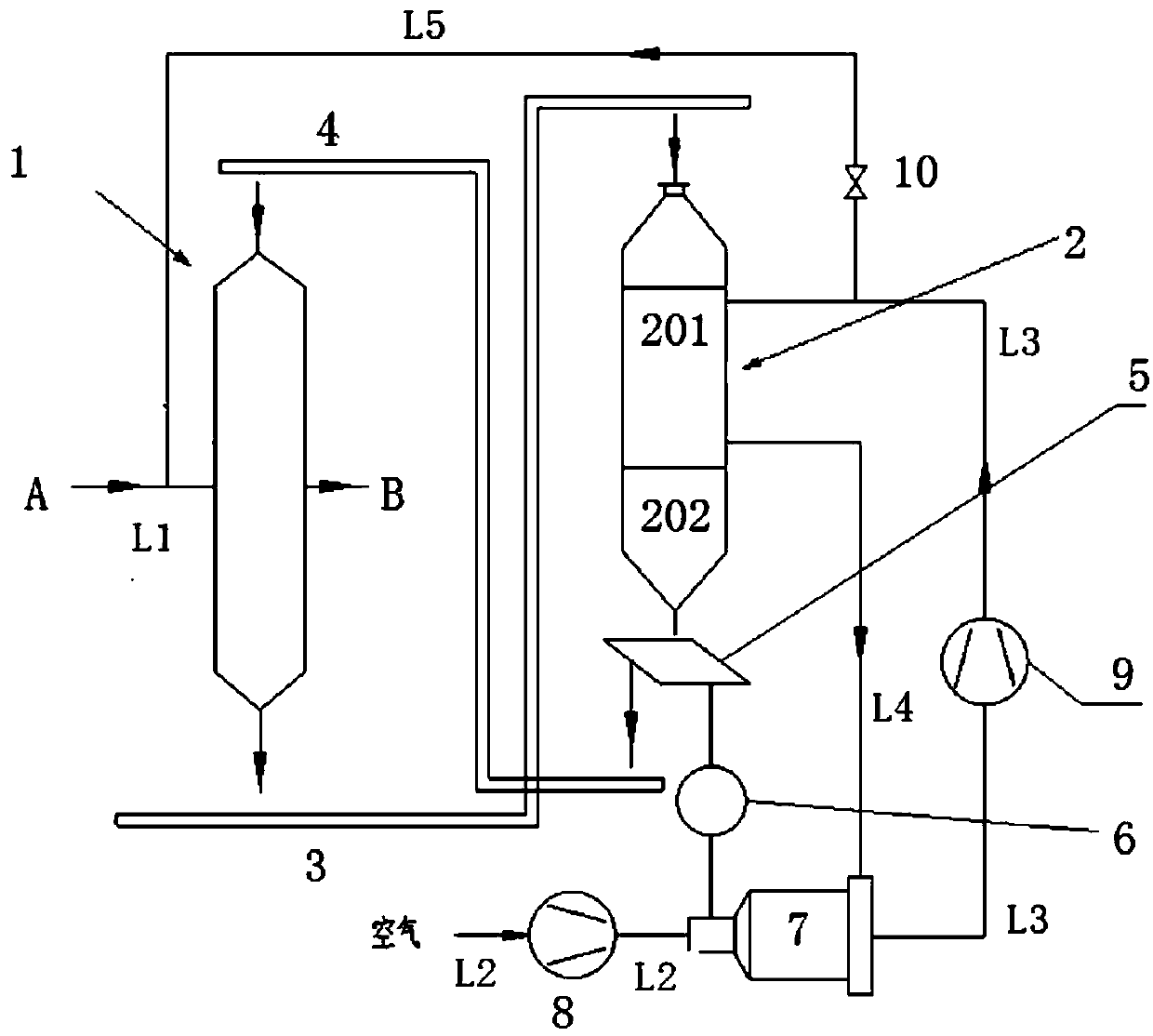

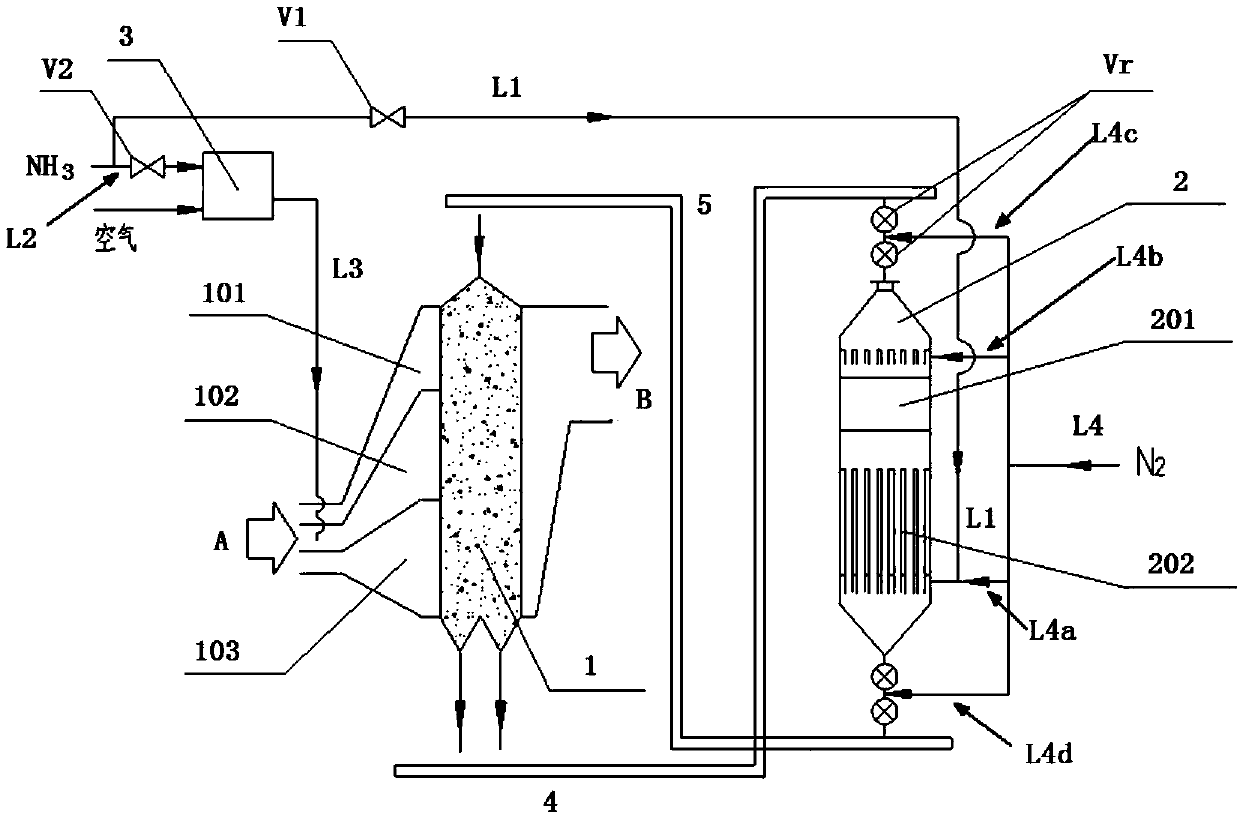

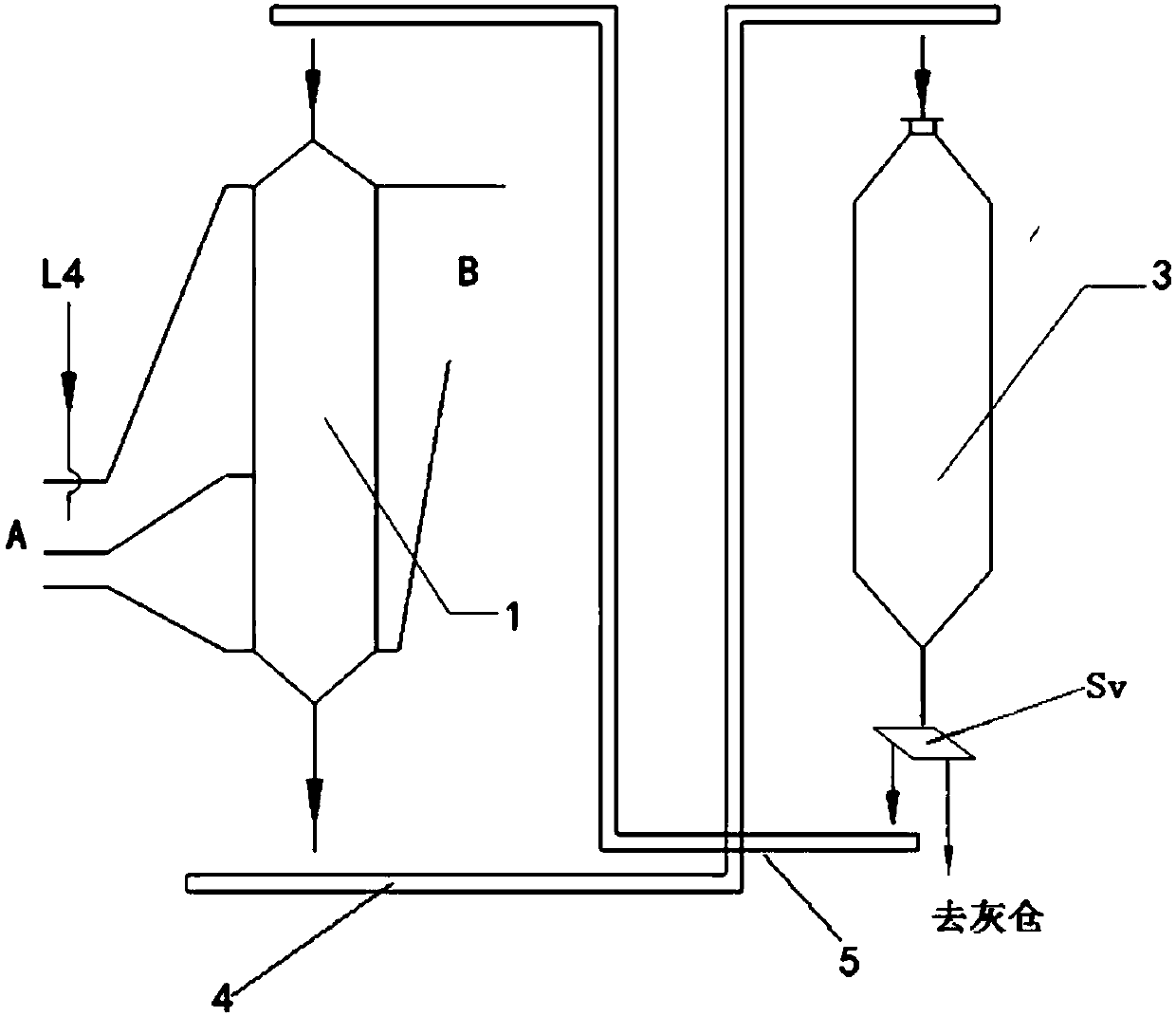

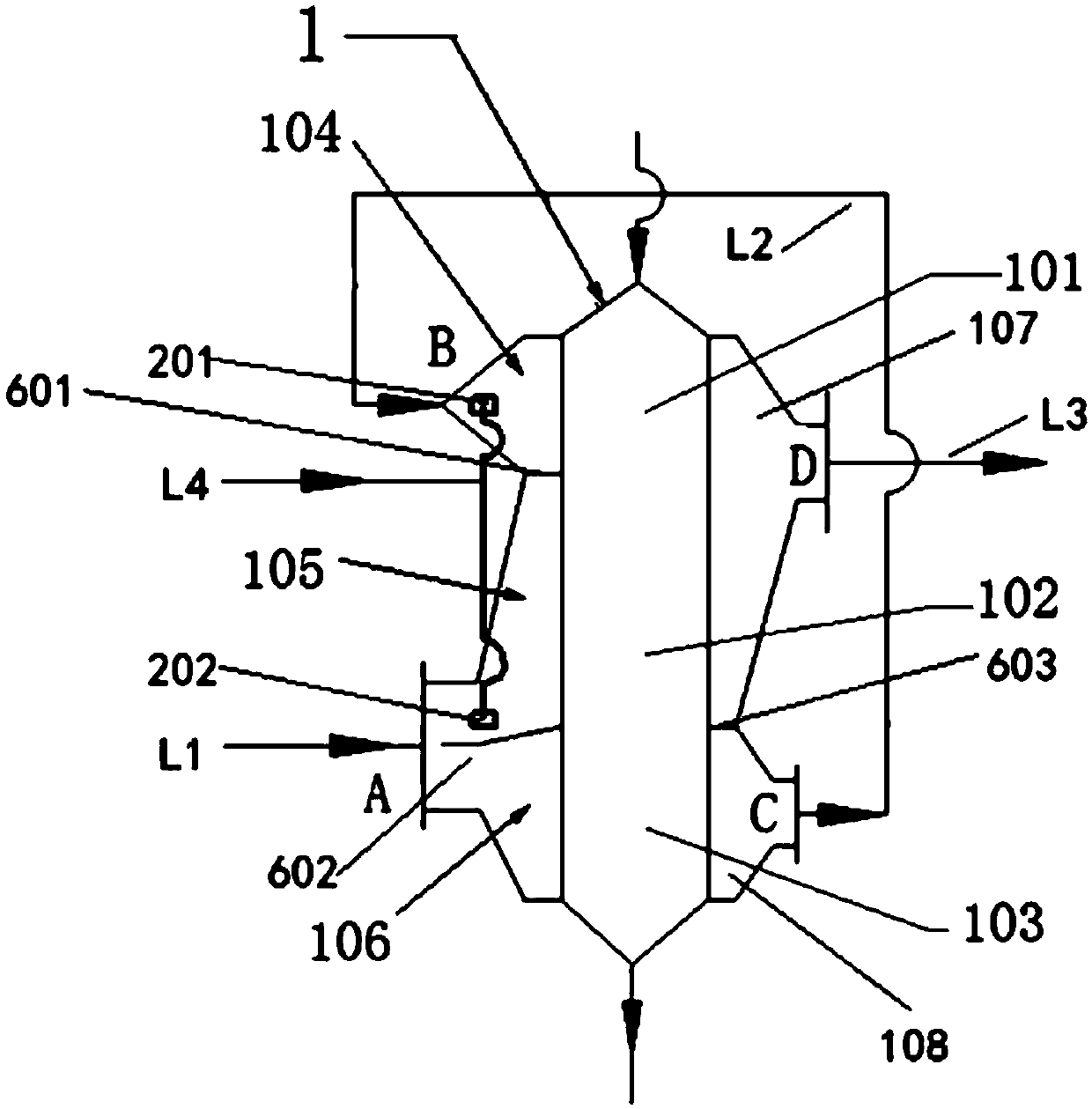

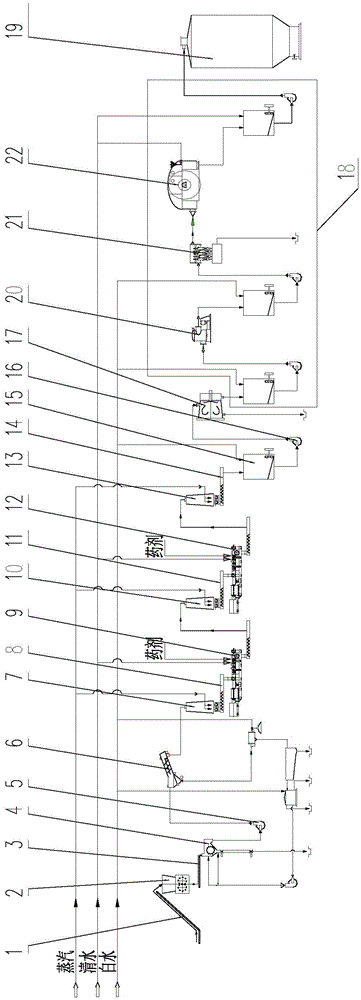

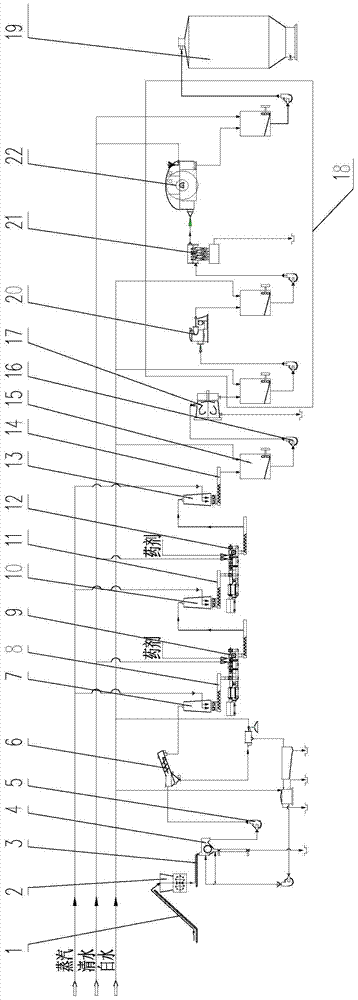

Recycling device for carbon powder

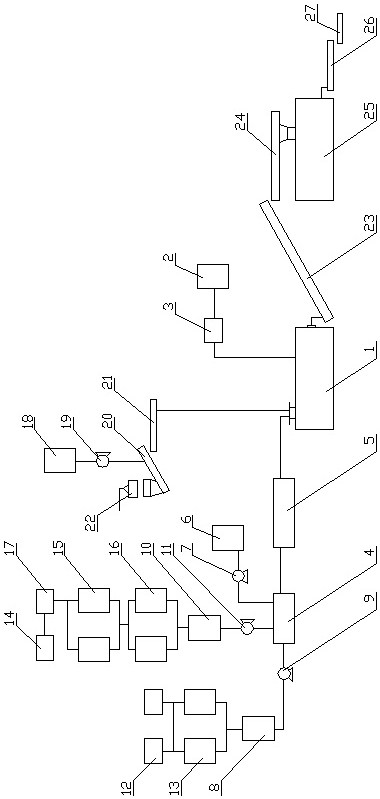

The invention discloses a recycling device for carbon powder. The recycling device for the carbon powder comprises an adsorption tower (1), an analysis tower (2), a first active carbon conveyor (3), asecond active carbon conveyor (4), a vibrating screen (5) or a multi-stage or multi-layer type vibrating screen (C) which is positioned below a discharge hole of the analysis tower (2) or at the downstream of the analysis tower (2), and a heating furnace (7), wherein the analysis tower (2) is provided with a heating section (201) and a cooling section (202); a hot air outlet of the heating furnace (7) is connected with a hot air inlet of the heating section (201) of the analysis tower (2) through a hot air pipeline (L3); an air outlet of the heating section (201) of the analysis tower (2) isconnected to a circulating and cooling air inlet of the heating furnace (7) through a circulating and cooling air pipeline (L4); screened fine carbon powder of the vibrating screen (5) is used as a fuel of the heating furnace (7); and fine active carbon particles screened out by the multi-stage or multi-layer type vibrating screen (C) are conveyed into a pelletizing system (D) for being pelletizedor conveyed into a wastewater purifying system for adsorbing waste acid.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

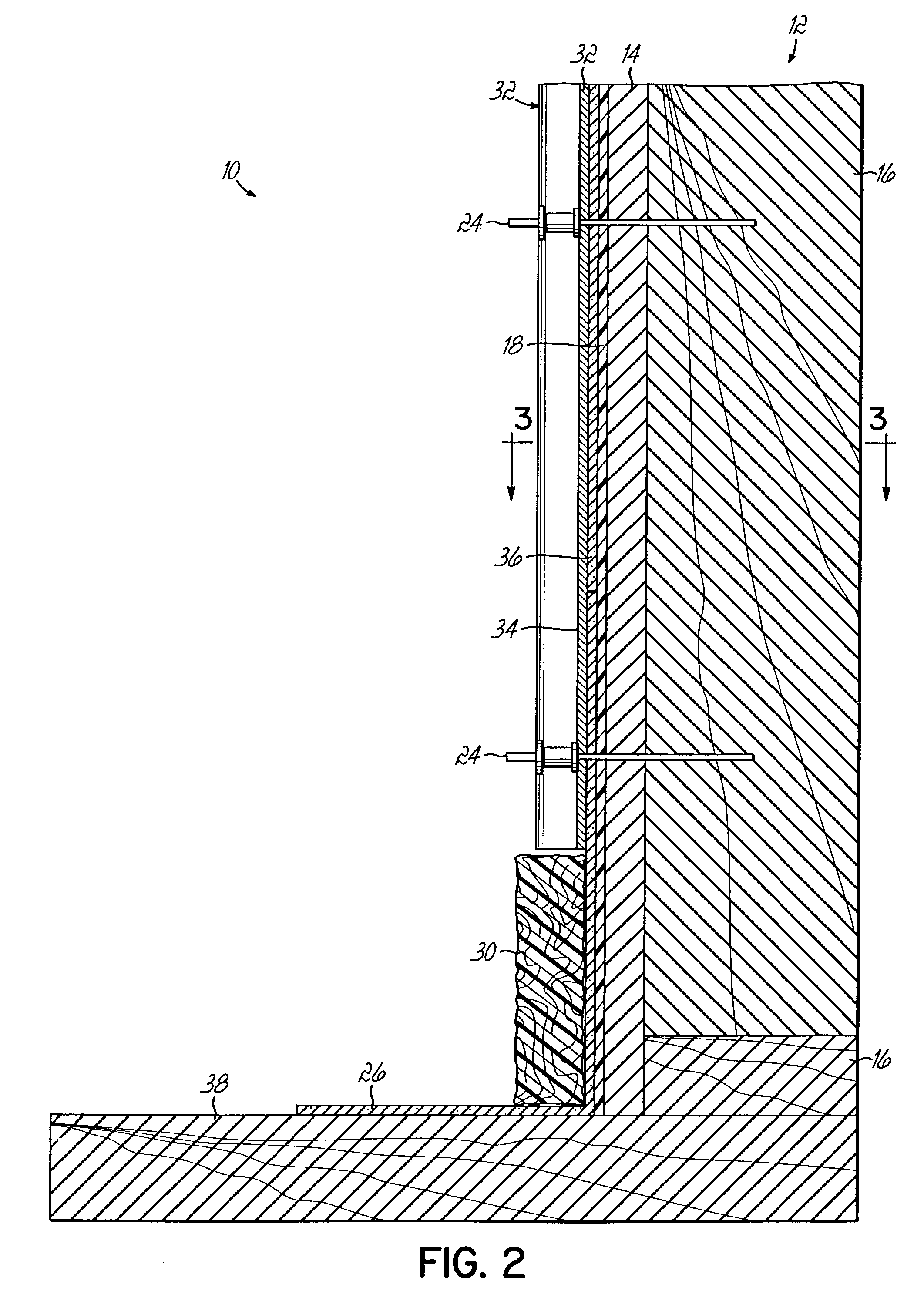

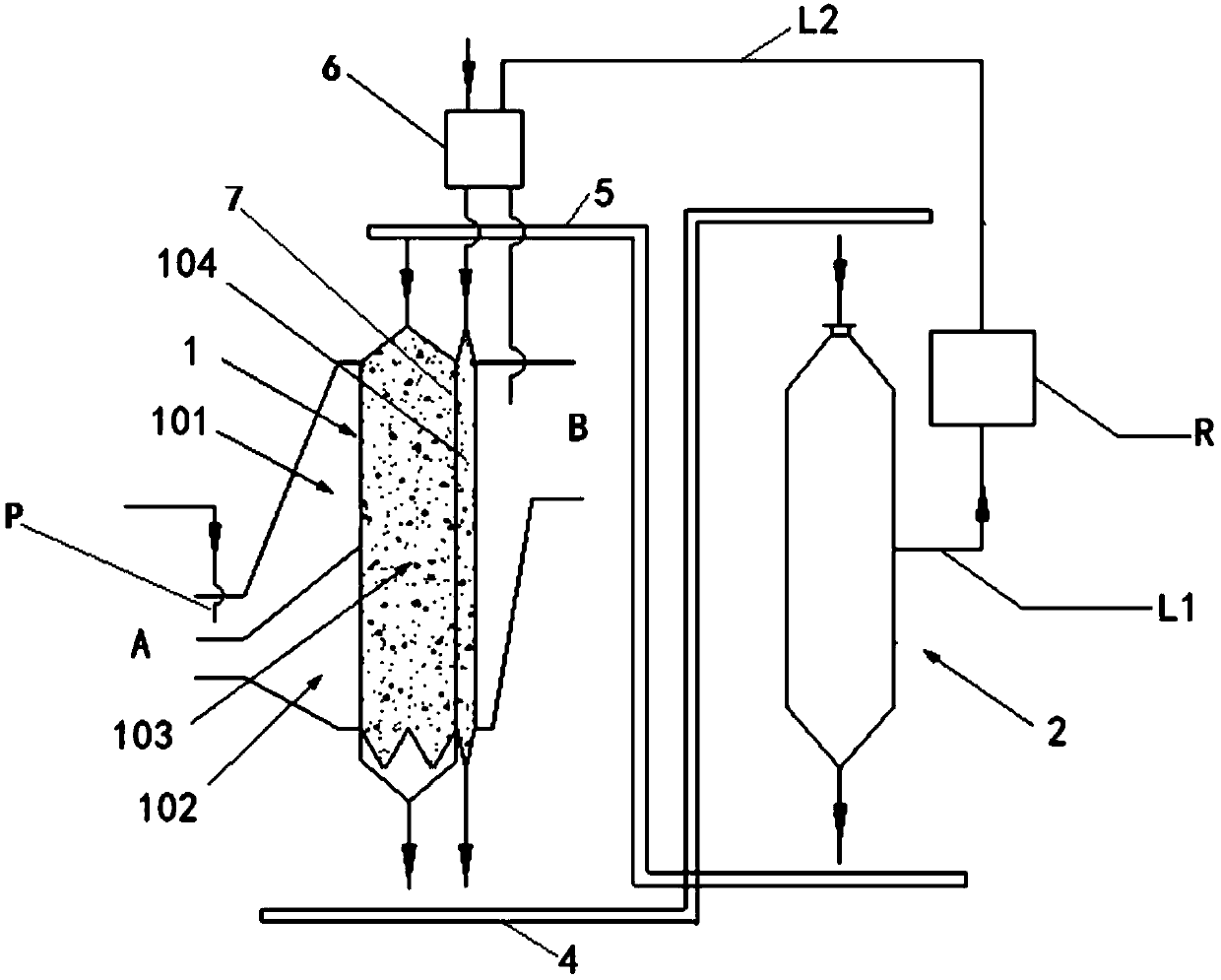

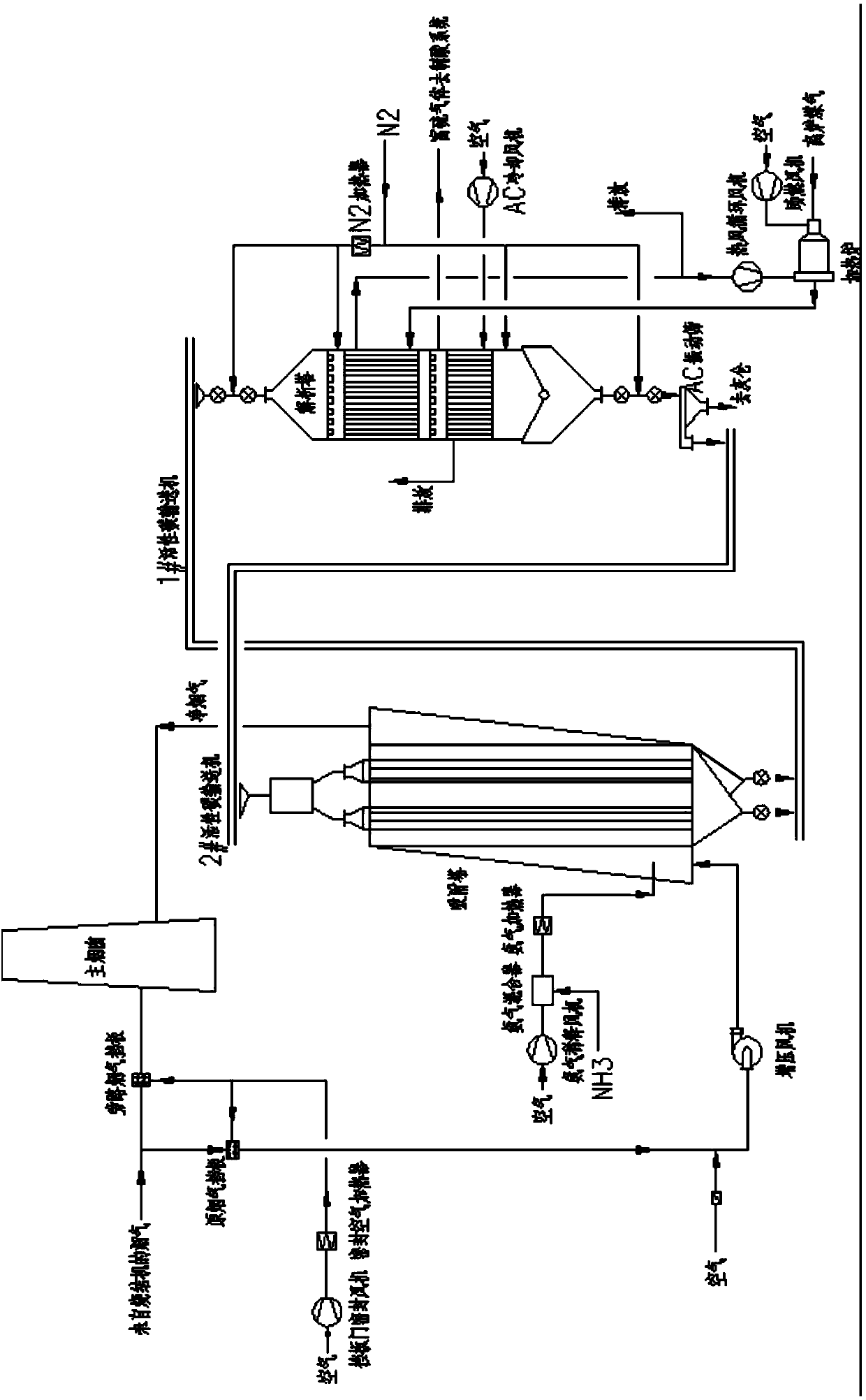

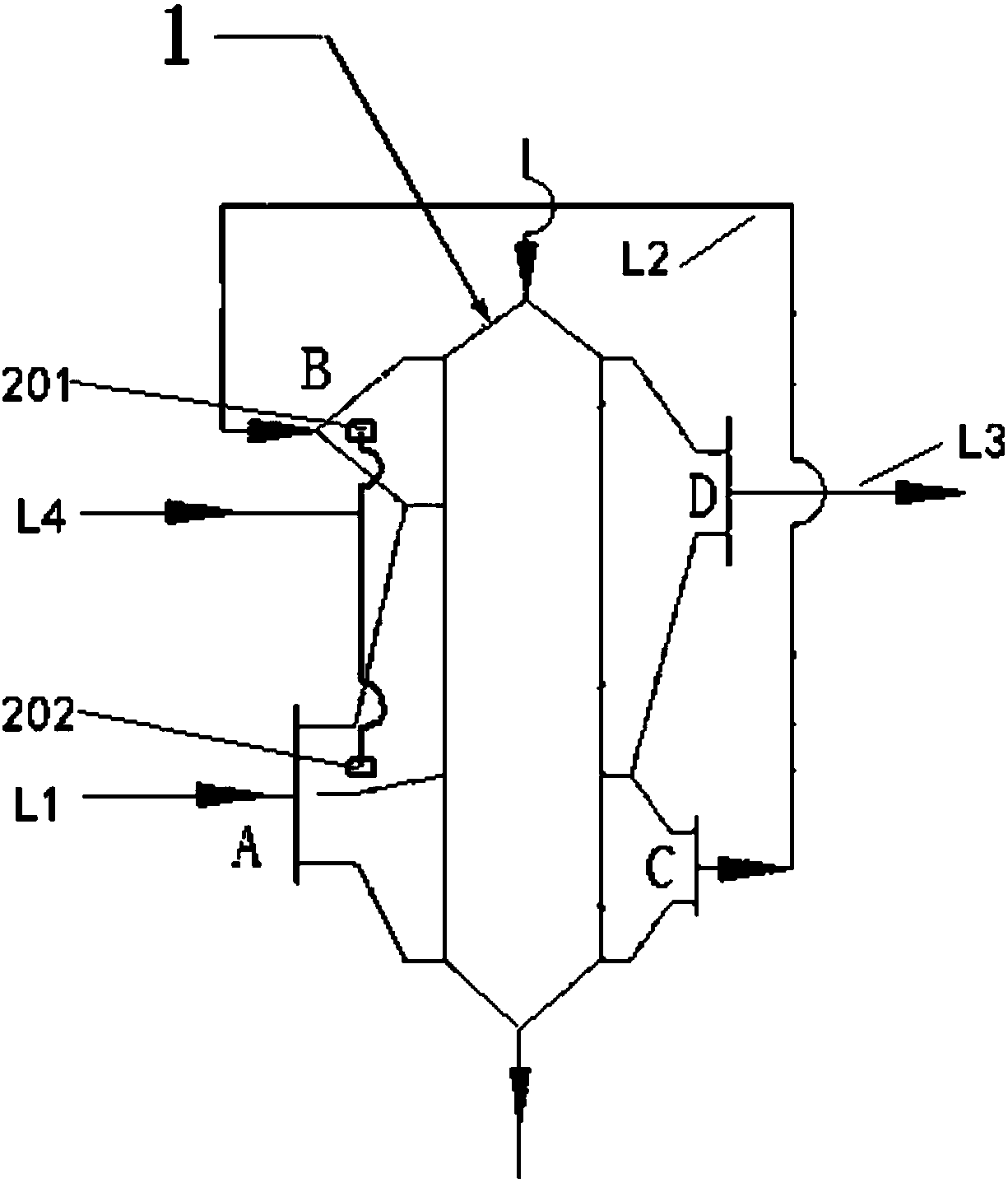

Desulfurization and denitration ammonia-removing system

ActiveCN108479344ACapturePrevent escapeGas treatmentDispersed particle separationActivated carbonDesorption

The invention discloses a desulfurization and denitration ammonia-removing system. The system comprises an adsorption tower, a desorption tower, a distributor, a first activated carbon conveyer and asecond activated carbon conveyer. One side of the adsorption tower is provided with a smoke inlet A, and the other side of the adsorption tower is provided with a smoke outlet B, the interior of the adsorption tower is provided with an adsorption cavity and an ammonia-removing cavity, the adsorption cavity is installed at one side adjacent to the smoke inlet A, the ammonia-removing cavity is installed at one side adjacent to the smoke outlet B, the first activated carbon conveyer is connected with a discharging port of the adsorption tower and a feeding port of the distributor, the second activated carbon conveyer is connected with a discharging port of the desorption tower and a feeding port of the adsorption cavity, a discharging port of the distributor is respectively connected with a feeding port of the ammonia-removing cavity and a feeding port of the desorption tower. The system adopts a mode that the adsorption tower is divided to two functional areas. The adsorption reaction cavity is capable of achieving the functions of desulfurization, denitration, dust removal and the like. The ammonia-removing cavity is filled with fresh activated carbon or acidic activated carbon, andis capable of gathering ammonia in smoke passing through an adsorption reaction layer, and effectively preventing the ammonia at the outlet from escaping.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

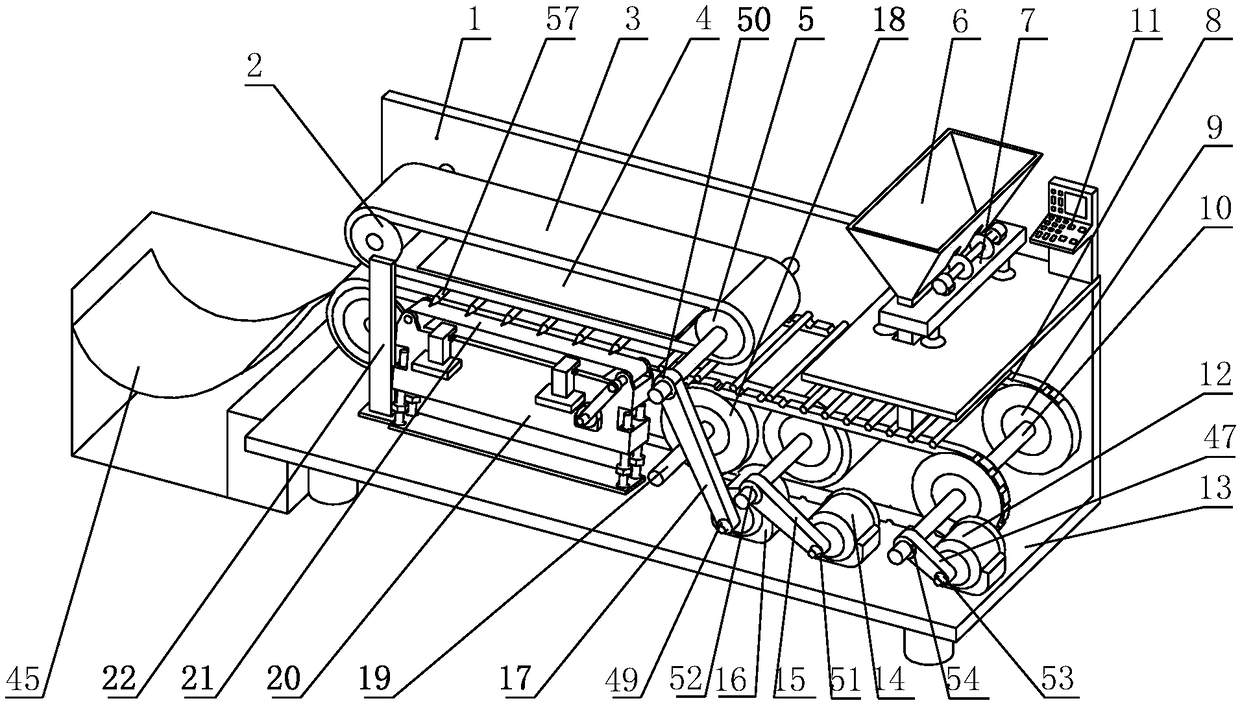

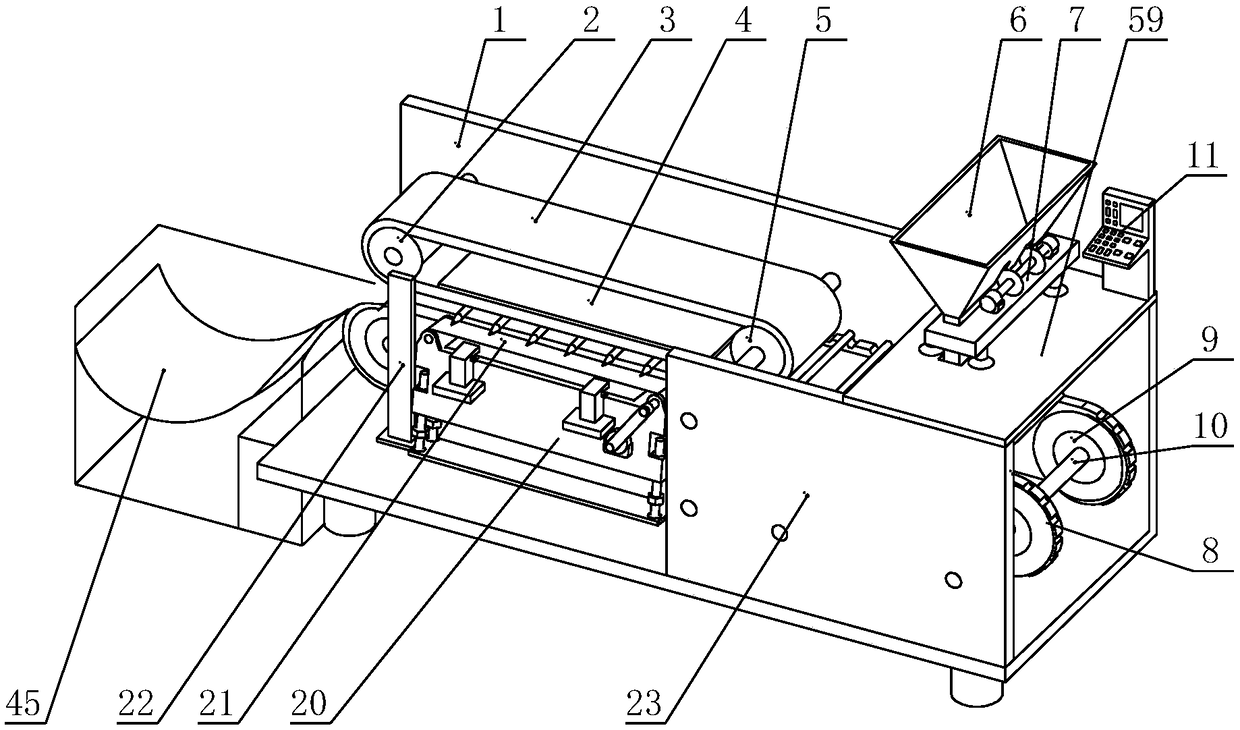

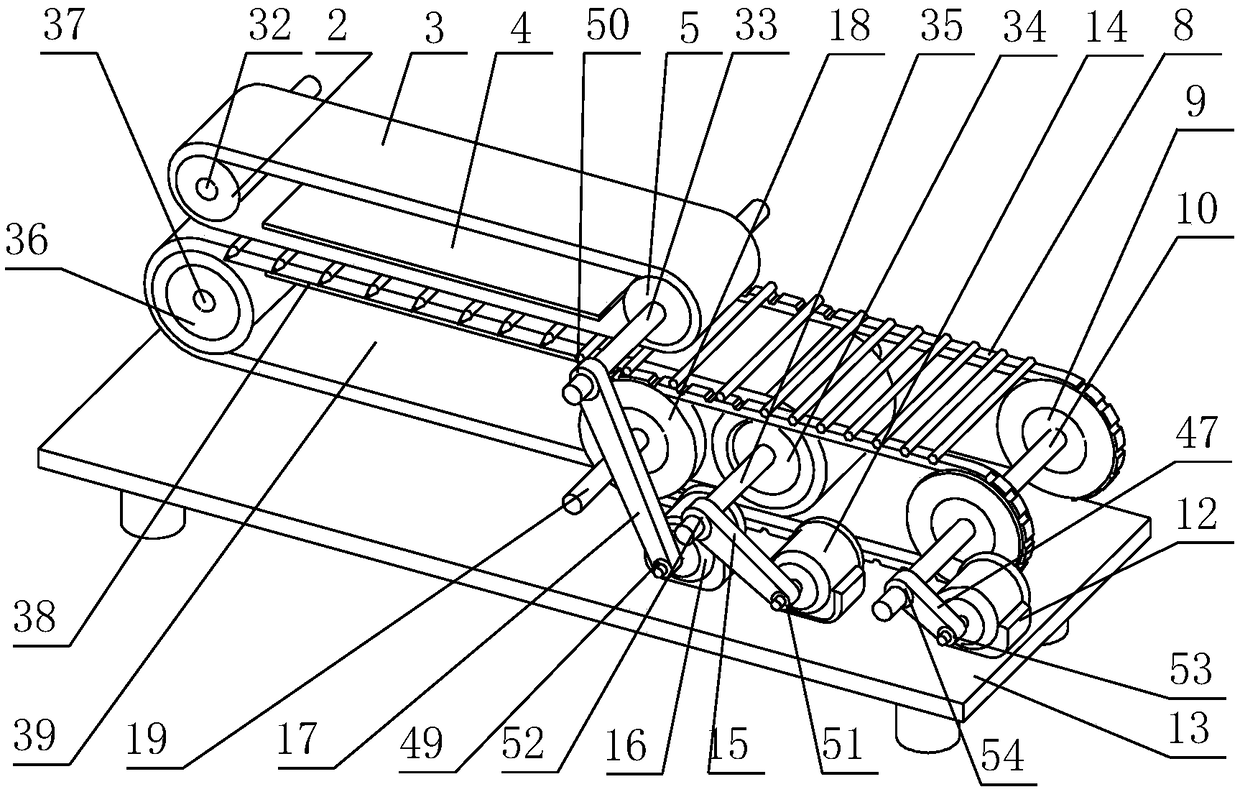

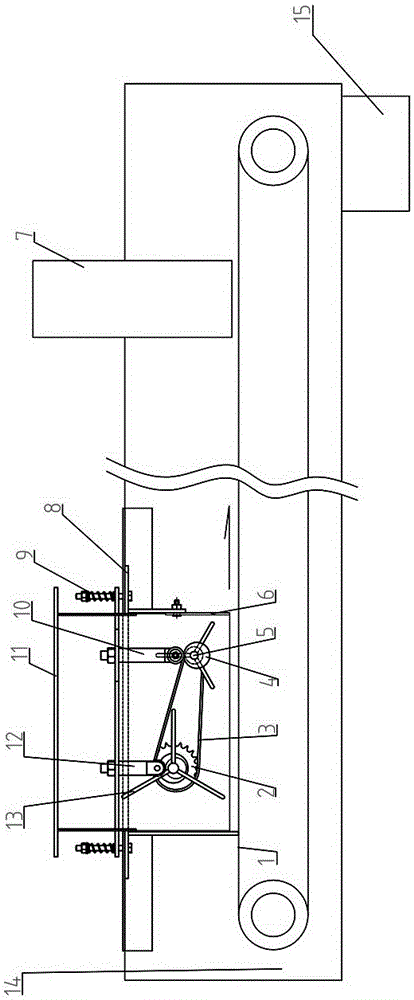

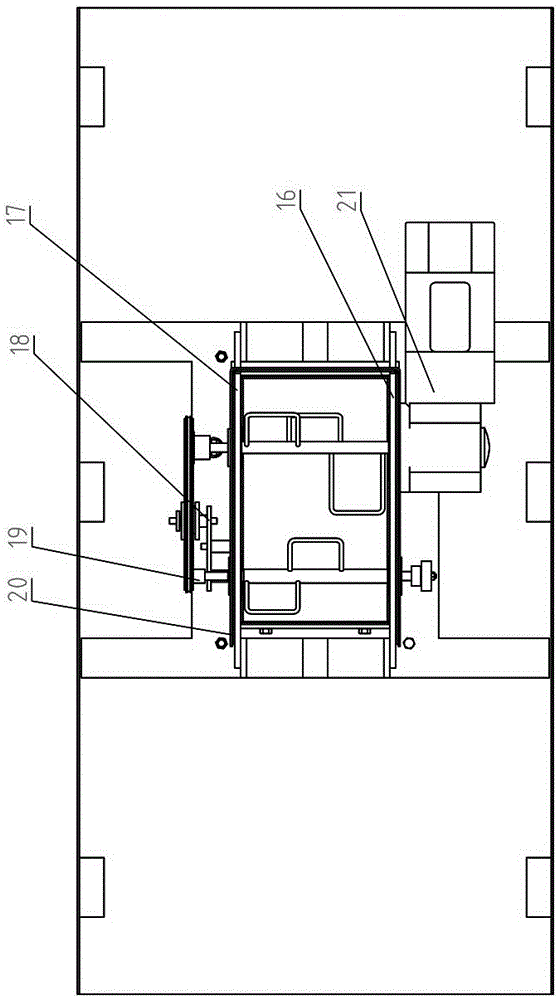

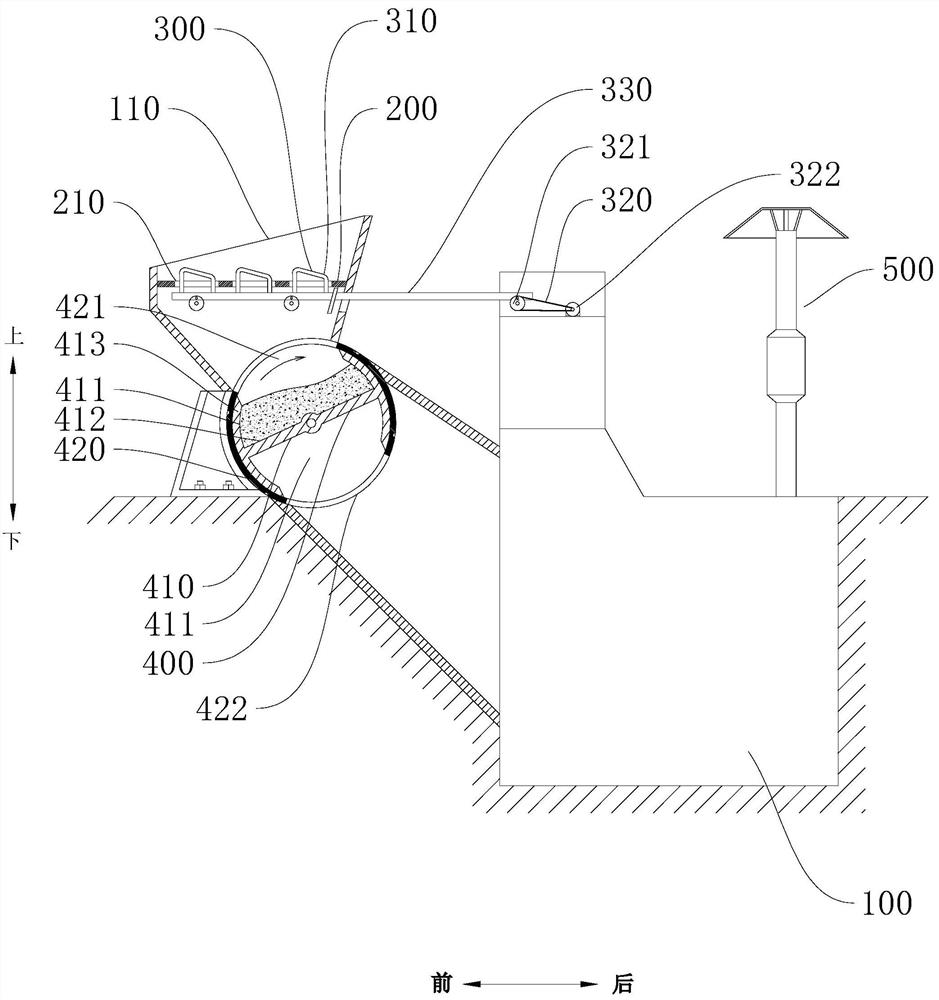

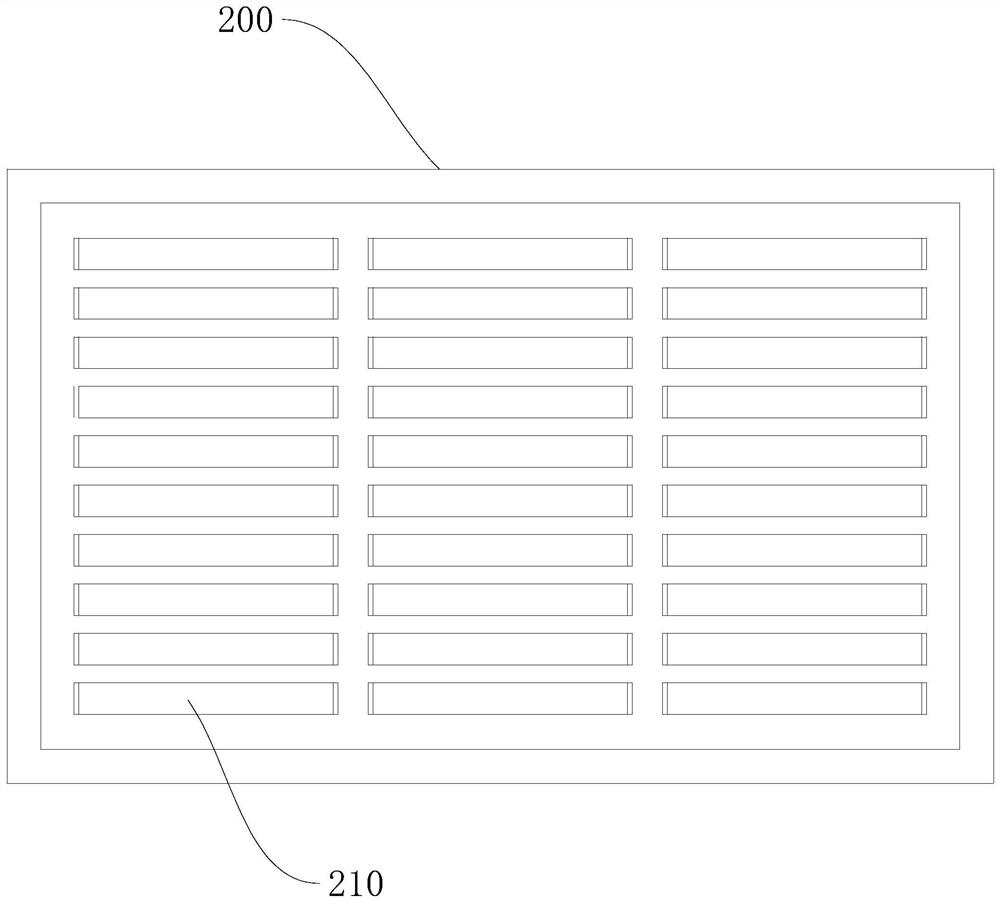

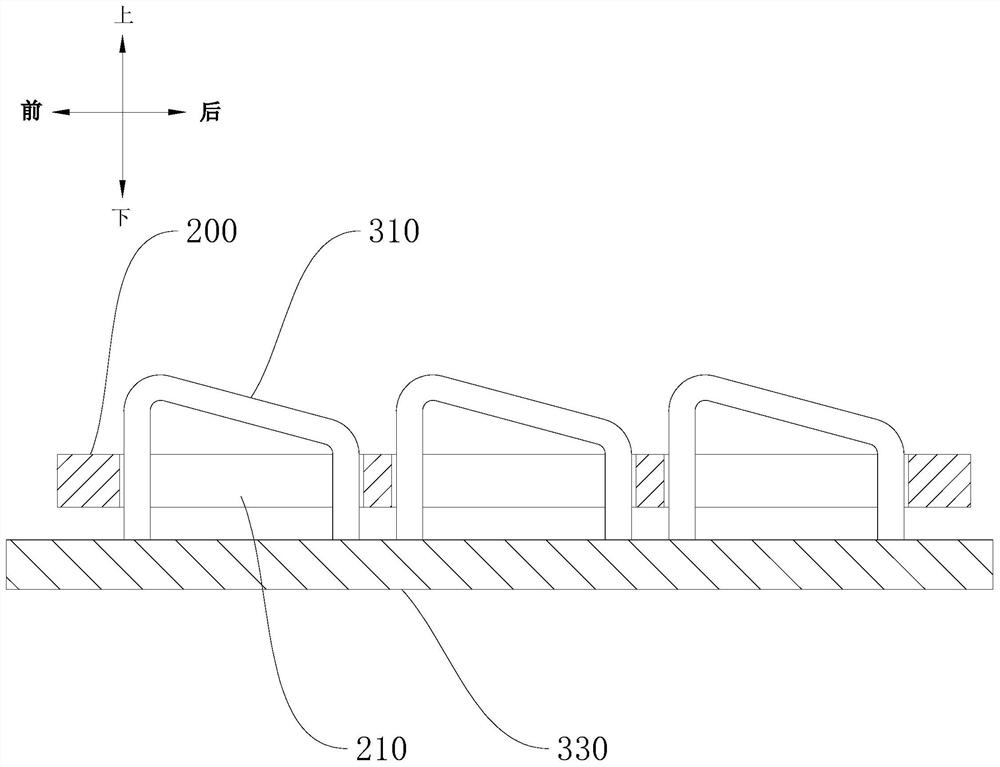

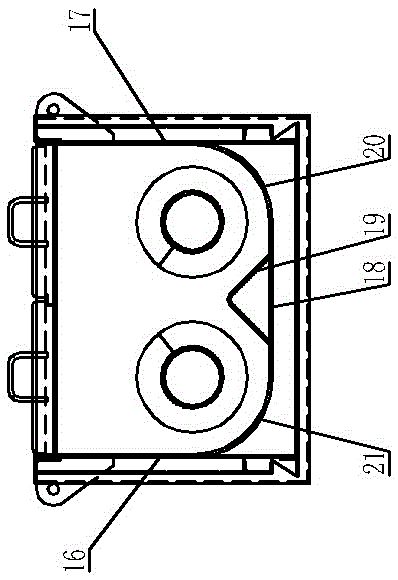

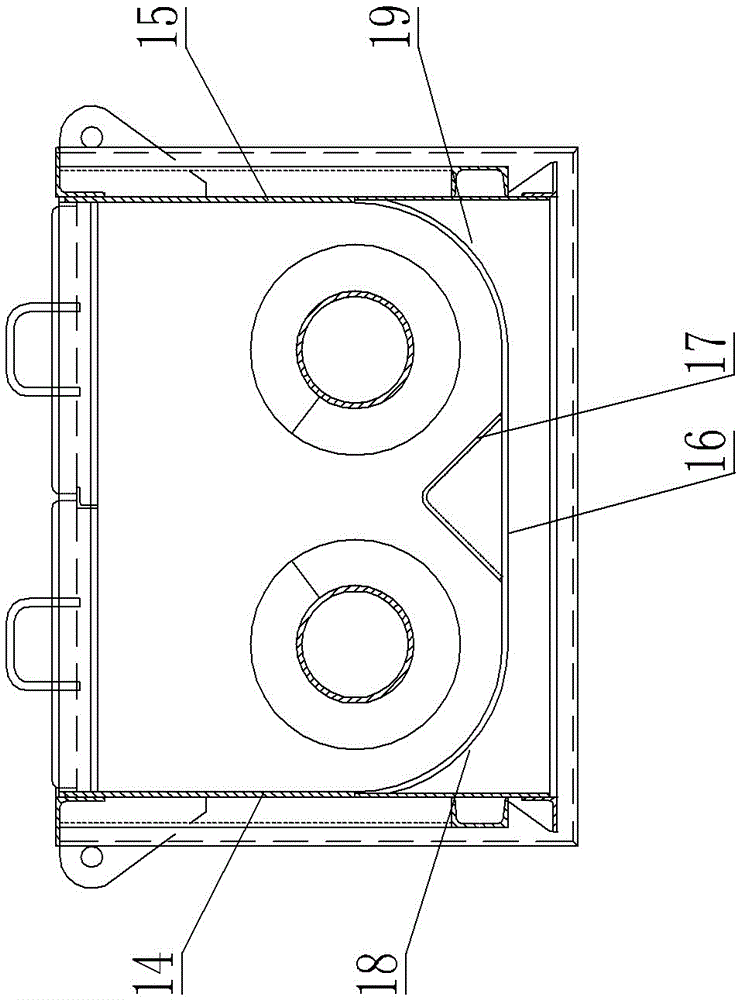

Pencil sharpening machine

ActiveCN108790520ARealize continuous automatic feed cuttingImprove cutting efficiencySharpenersEngineeringSharpening

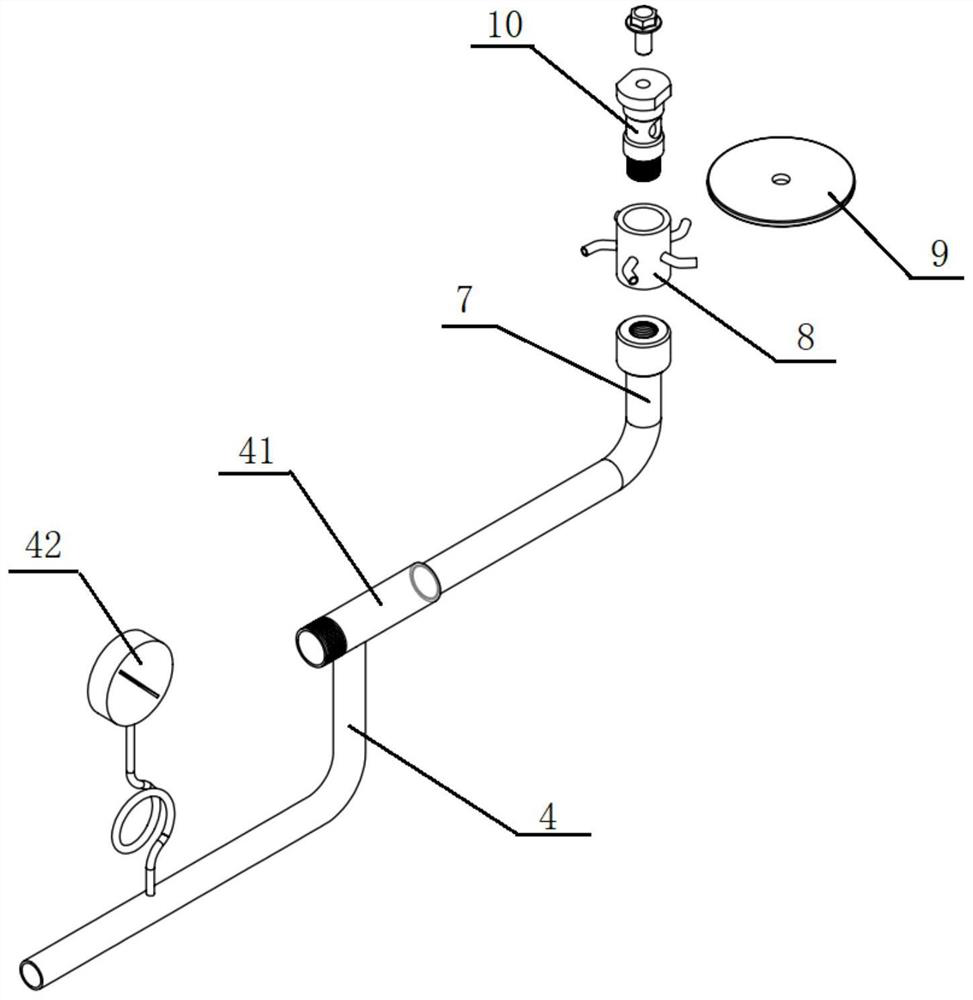

The invention belongs to the technical field of pencil sharpening, and relates to a pencil sharpening machine. The problem that production efficiency of an existing pencil sharpening device is low dueto the fact that the existing pencil sharpening device usually adopts a method that clamping is performed on each pencil is solved, pencils can be continuously fed and sharpened, and pencil sharpening efficiency is improved. The pencil sharpening machine comprises a supporting part, a pencil feeding part, a rolling feeding part, a sharpening part and a collection part. The sharpening part is installed on the front side of the rolling feeding part, the collection part is installed on the left side of the rolling feeding part, the pencil feeding part is installed on the right side of the rolling feeding part, an anti-bridging device of the pencil feeding part is installed on the right side of a pencil feeding funnel, the rolling feeding part enables the pencils to rotate and also roll fromright to left, and continuous sharpening is realized.

Owner:李冠余

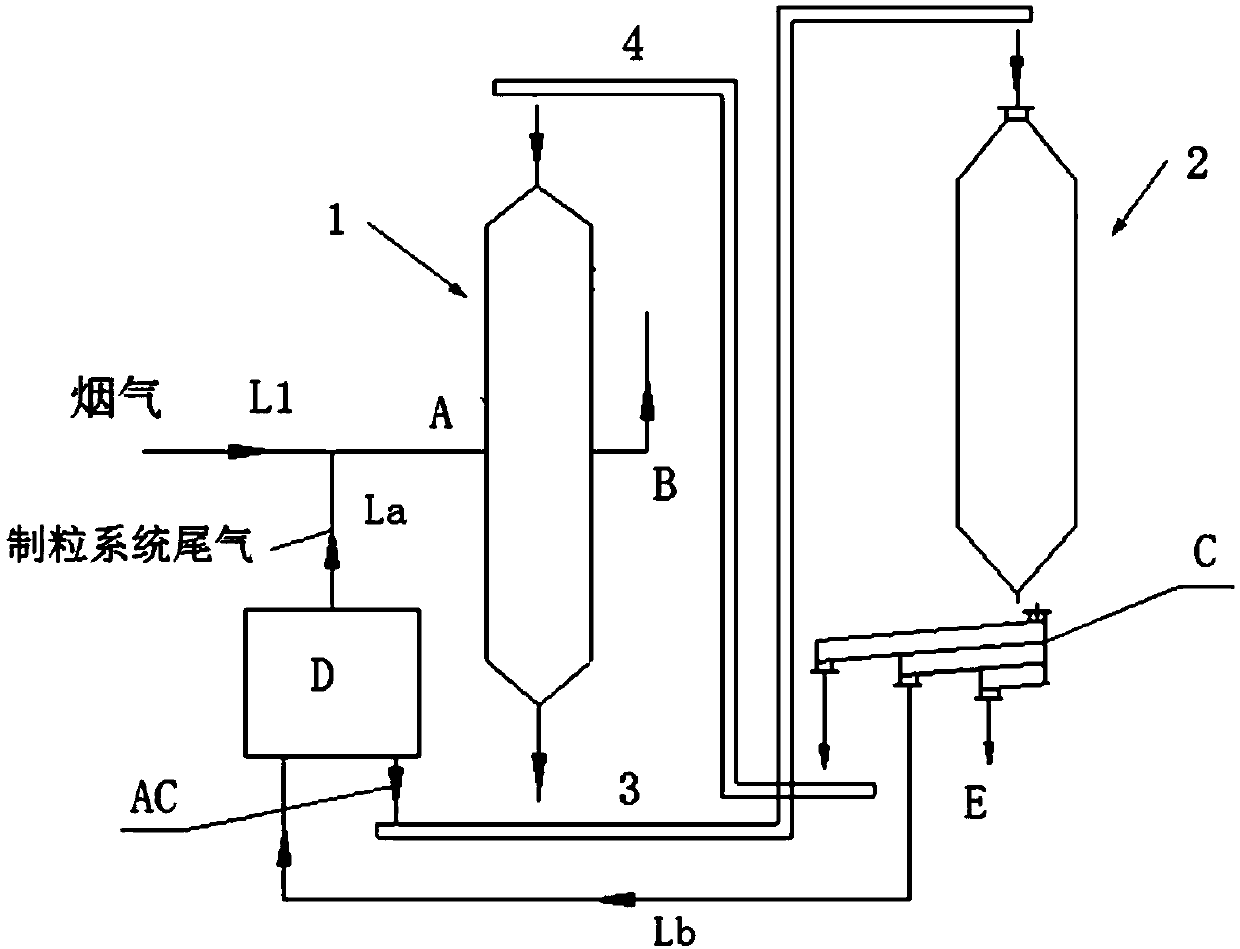

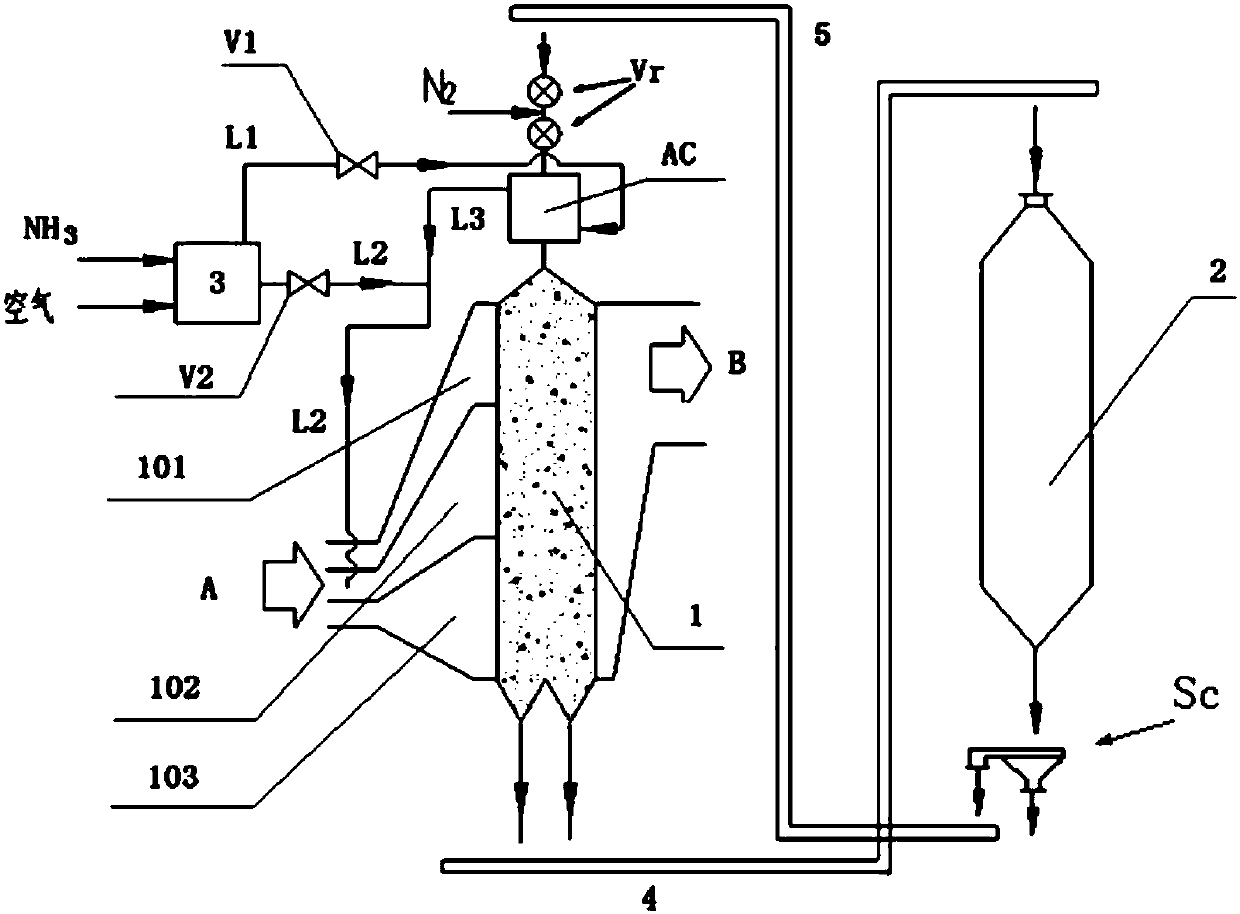

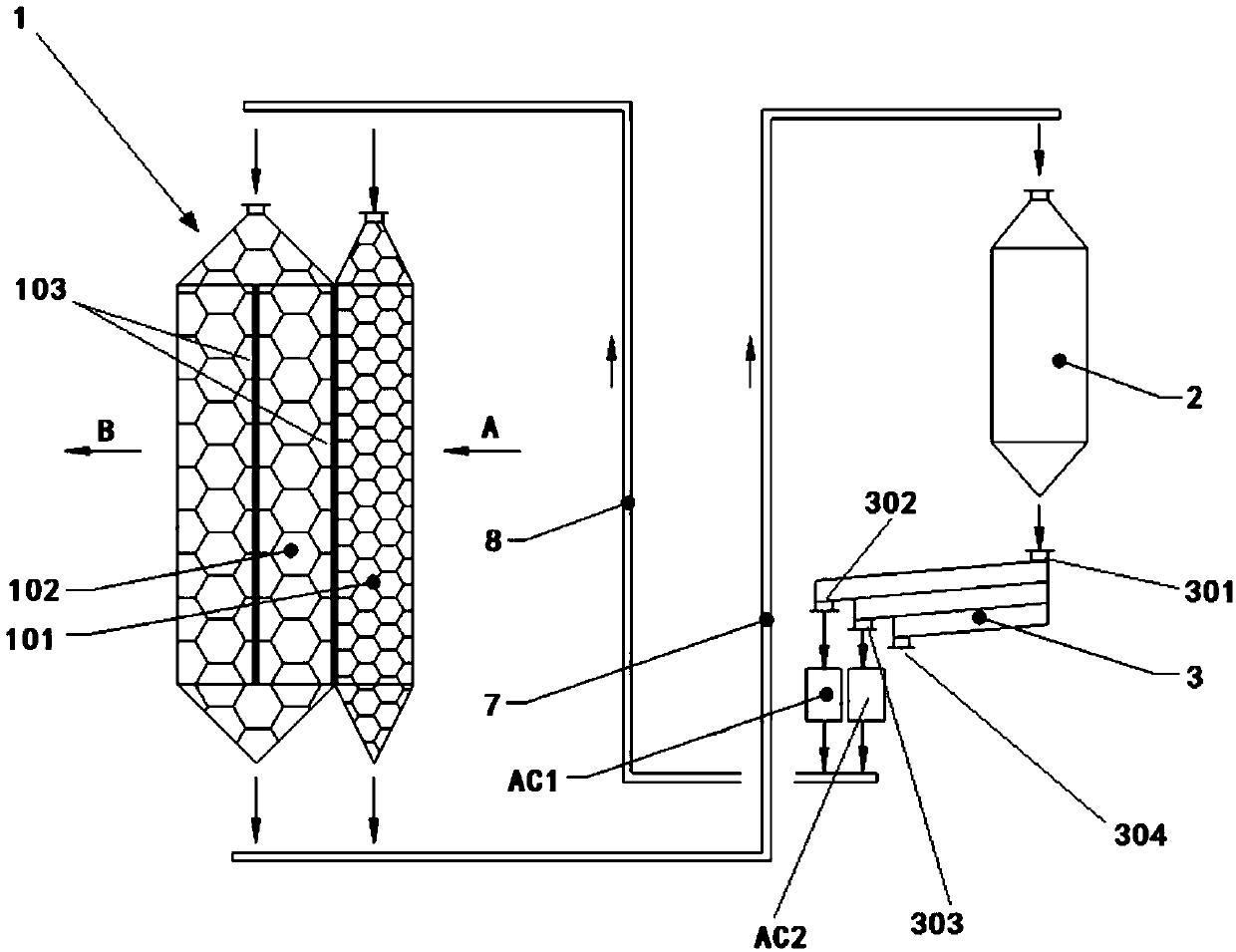

Desulfurization and denitration device for efficient denitration

ActiveCN108371872AImprove denitrification performanceReduce escapeGas treatmentDispersed particle separationActivated carbonDesorption

The invention relates to a desulfurization and denitration device for efficient denitration. The device comprises an adsorption tower (1), a desorption tower (2), a gas mixer (3), a first activated carbon conveyor (4), a second activated carbon conveyor (5) and an activated carbon material bin (AC) arranged above the adsorption tower (1), wherein a smoke inlet (A) is formed in one side of the adsorption tower (1), a smoke outlet (B) is formed in the other side of the adsorption tower (1), a first gas pipeline (L1) led out from the gas outlet of the gas mixer (3) is connected with the gas inletof the activated carbon material bin (AC), a second gas pipeline (L2) led out from the gas outlet of the gas mixer (3) is connected with the smoke inlet (A), and a third gas pipeline (L3) led out from the gas outlet of the activated carbon material bin (AC) converges with the second gas pipeline (L2). The desulfurization and denitration device provided by the invention adopts activated carbon foradsorbing partial ammonia in advance; meanwhile, partial ammonia is sprayed into the middle part of the adsorption tower again for enhancing a denitration effect.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

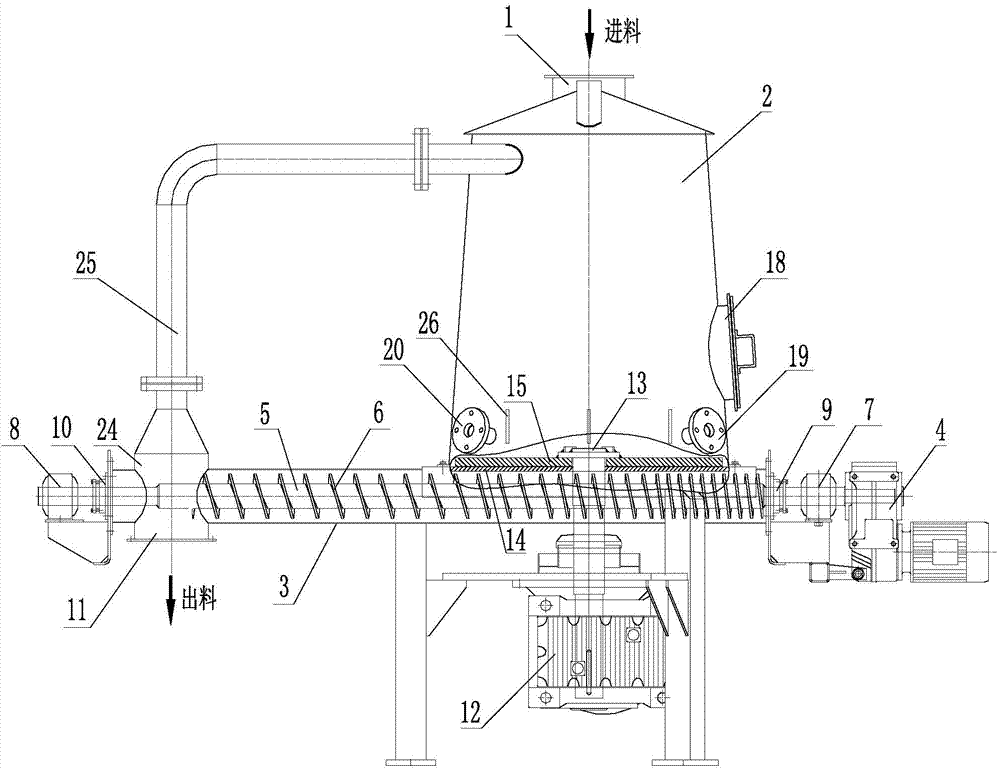

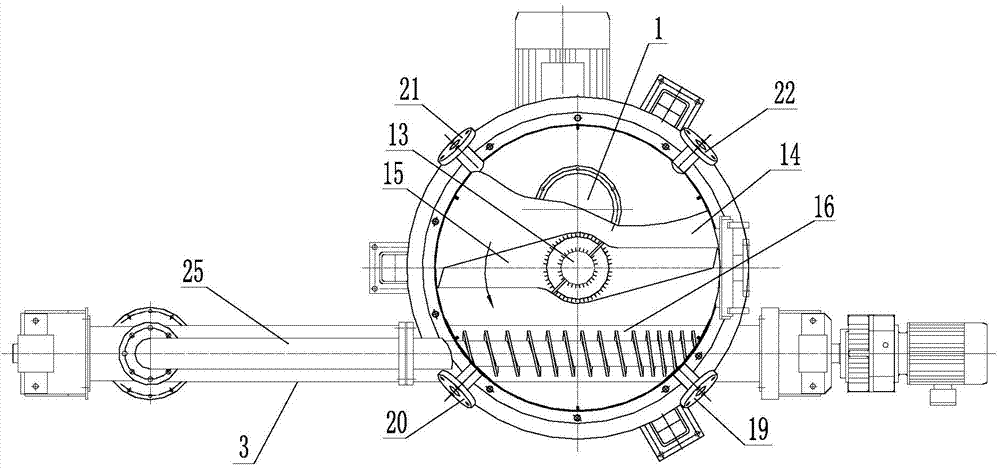

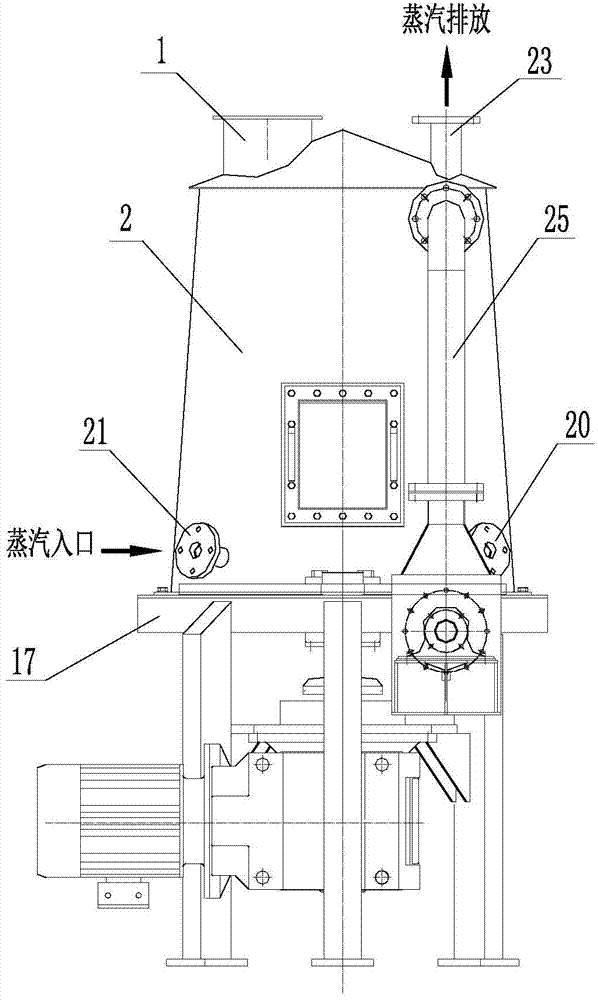

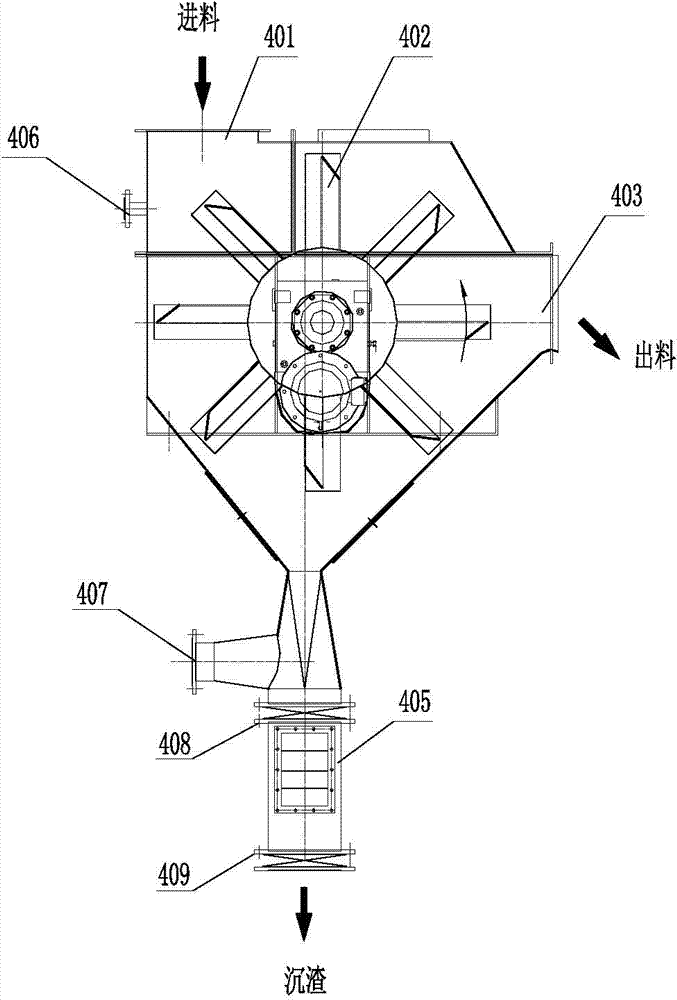

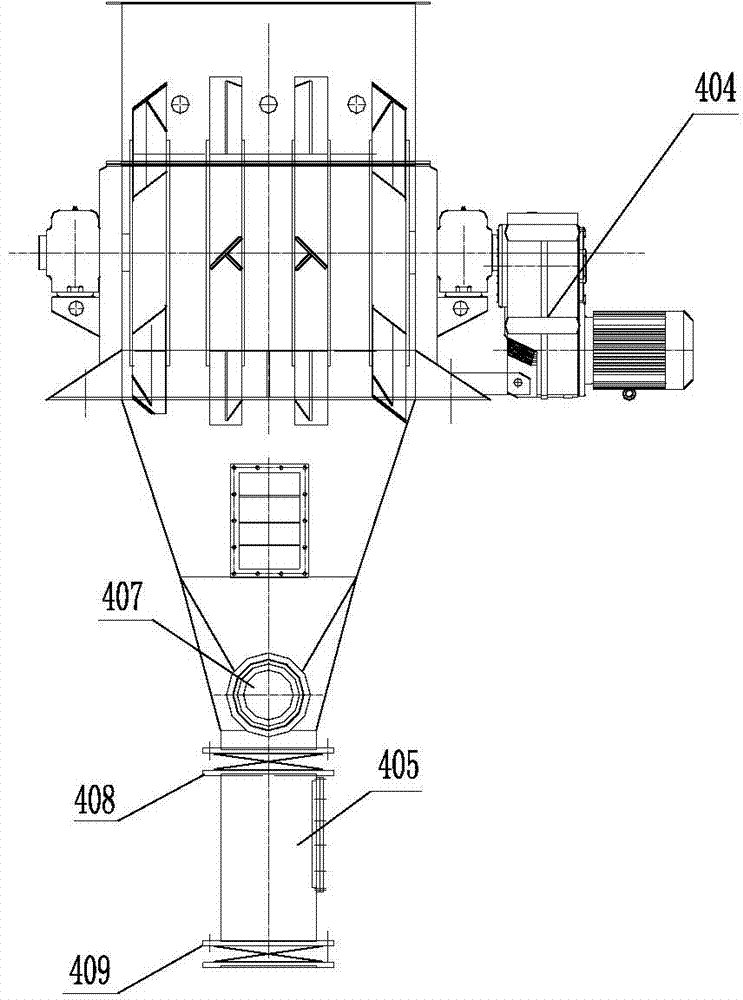

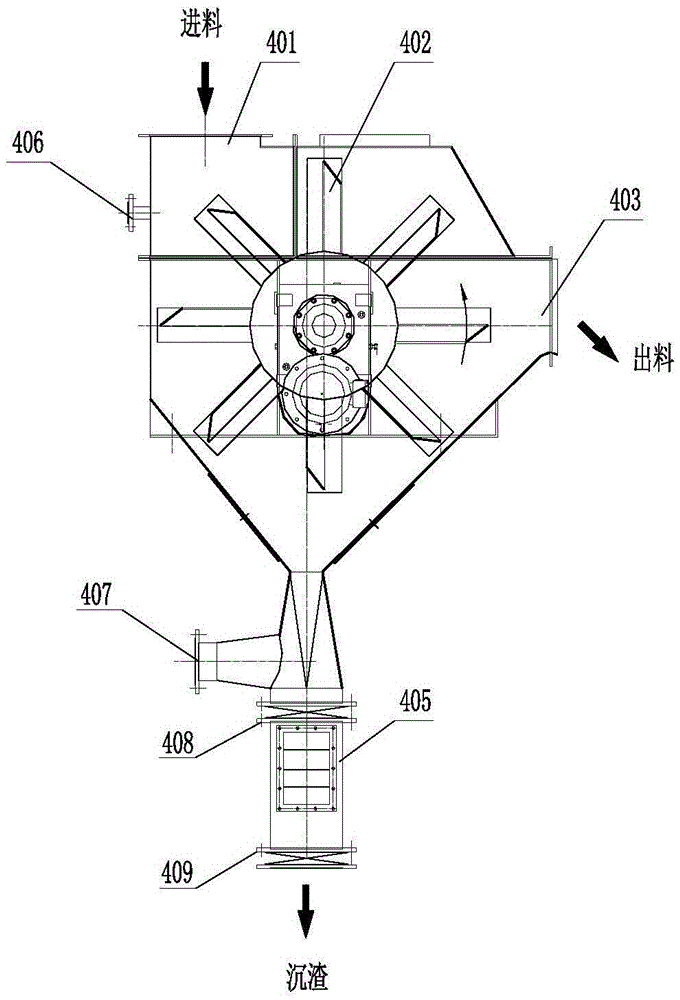

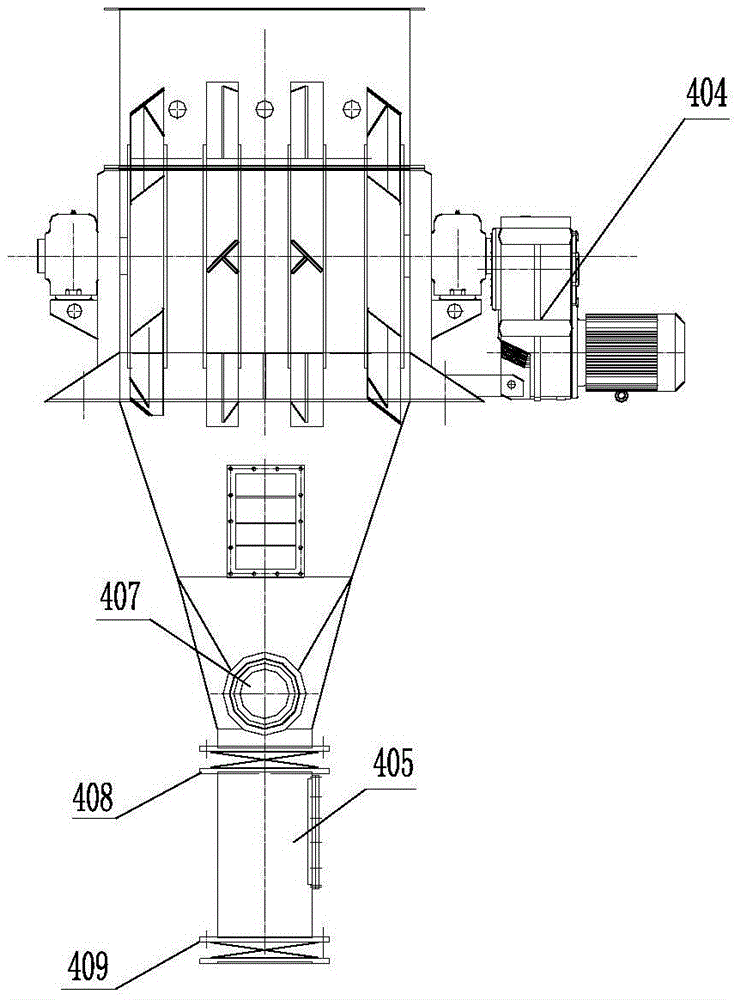

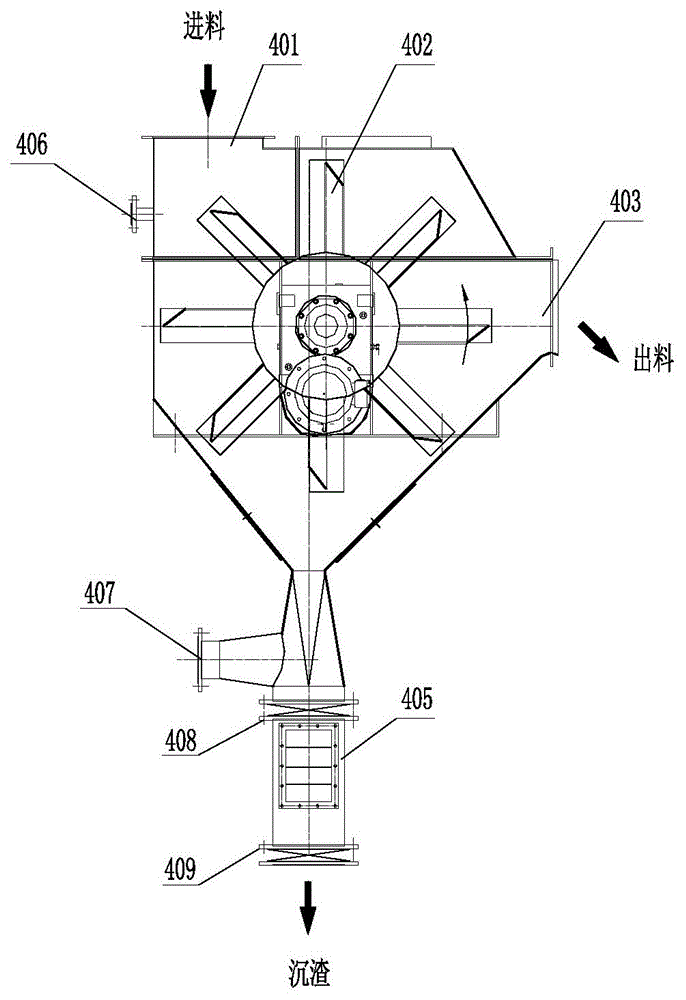

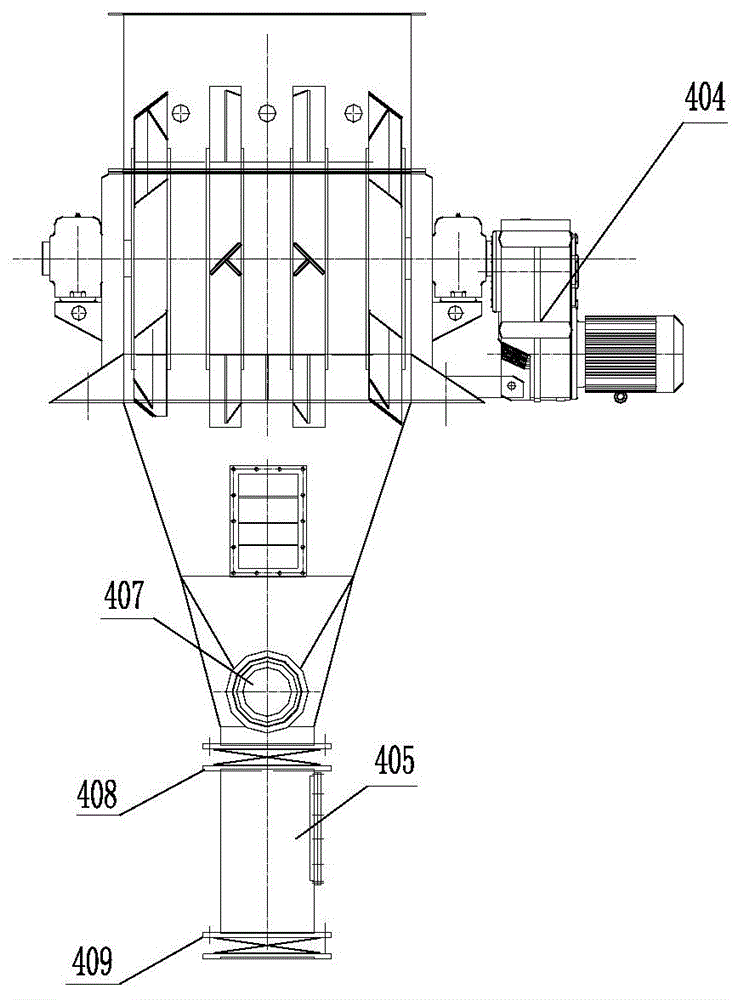

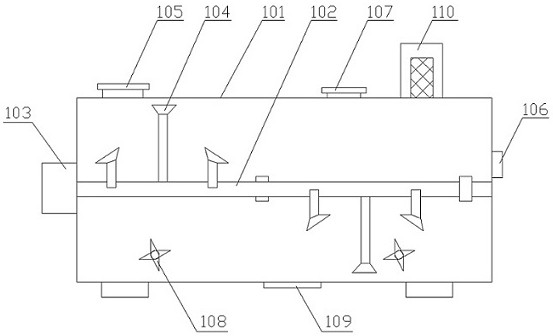

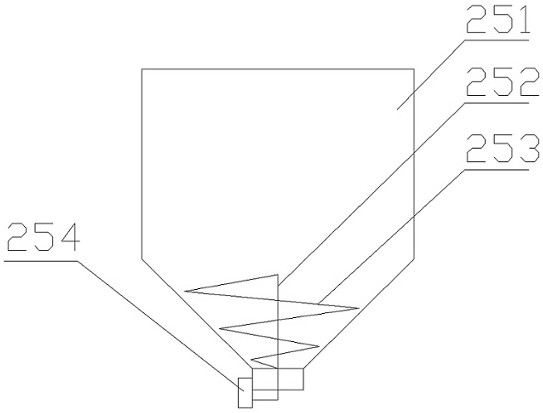

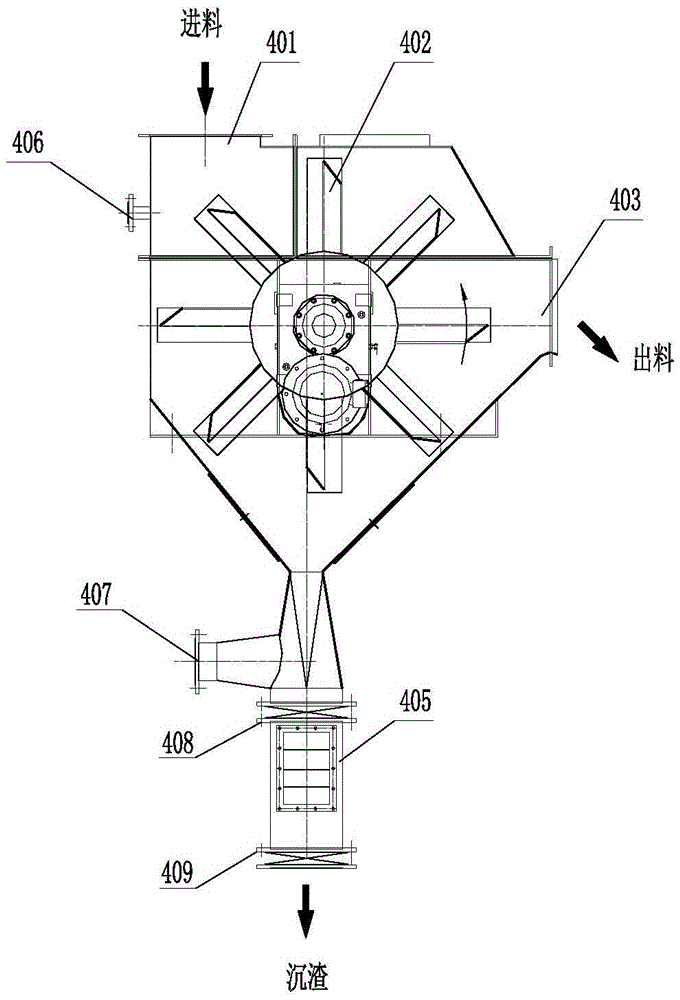

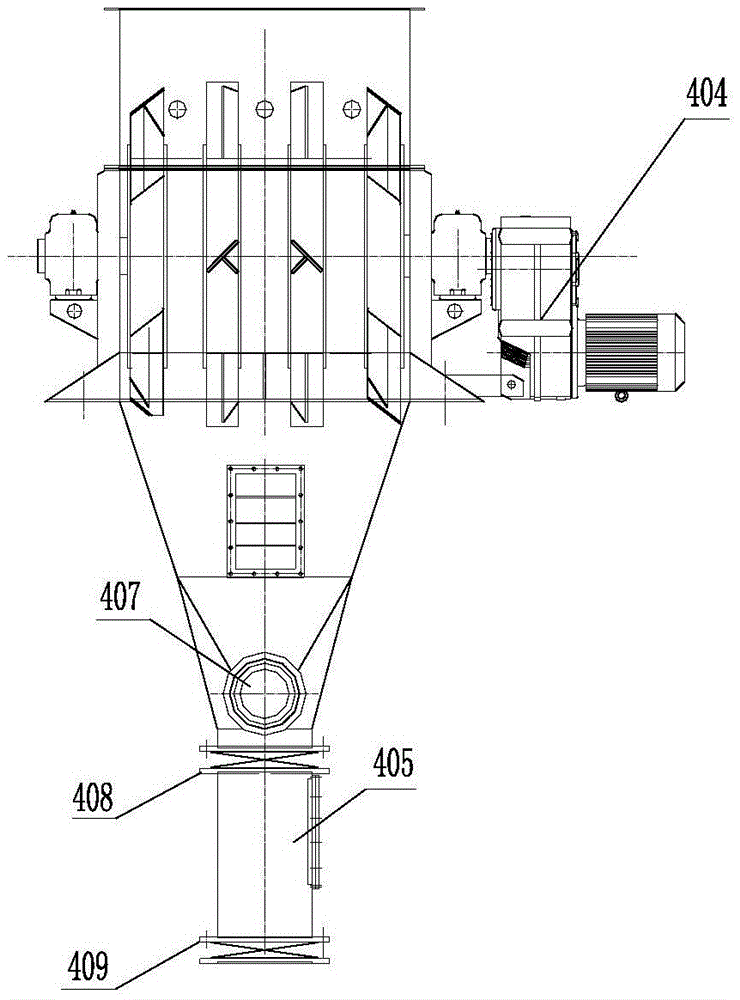

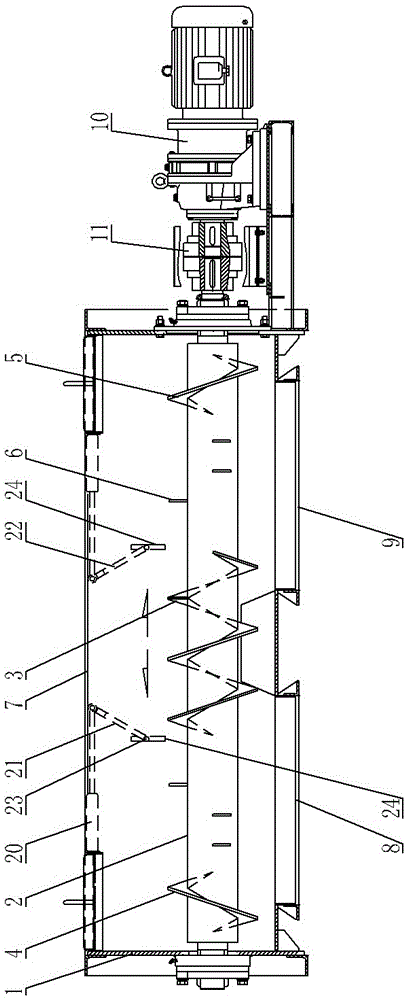

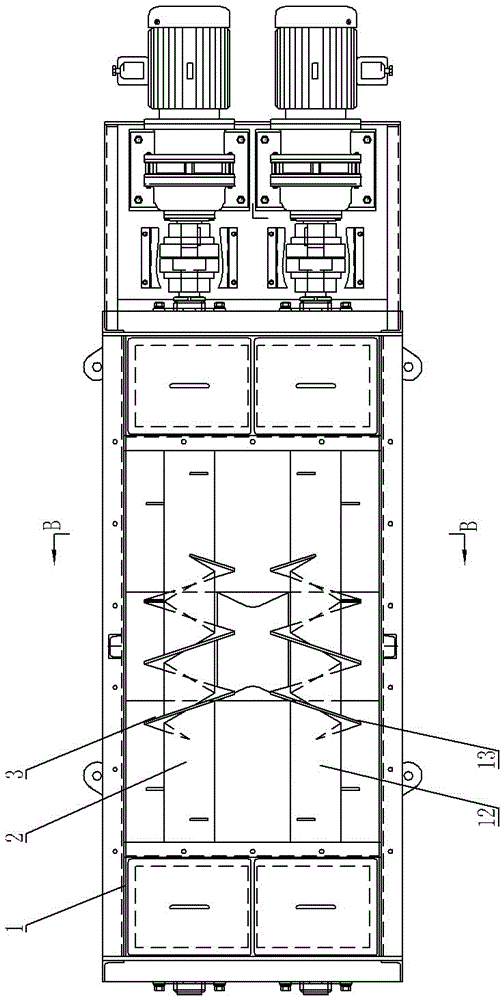

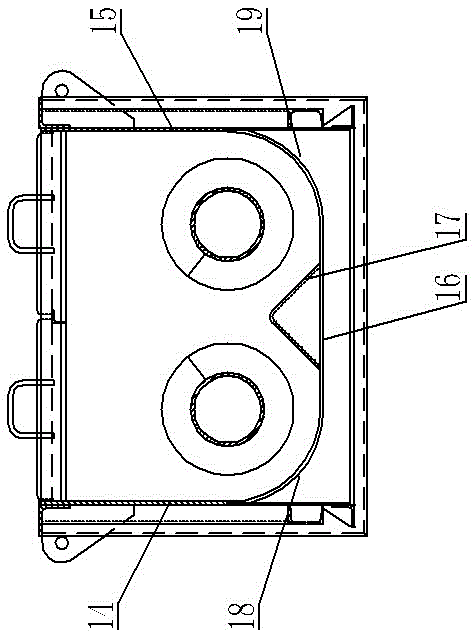

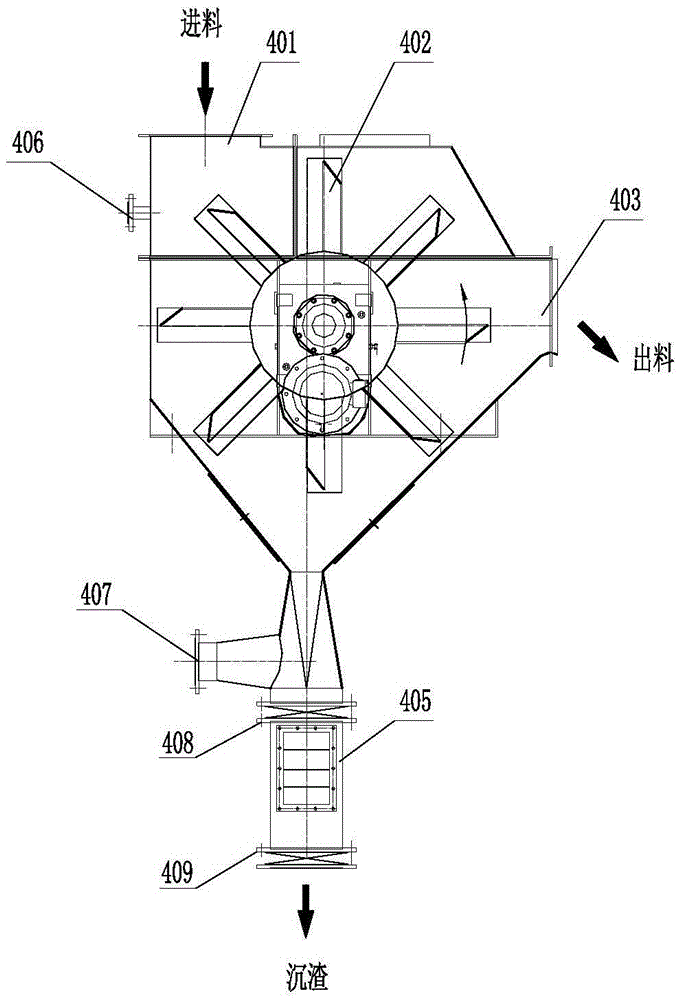

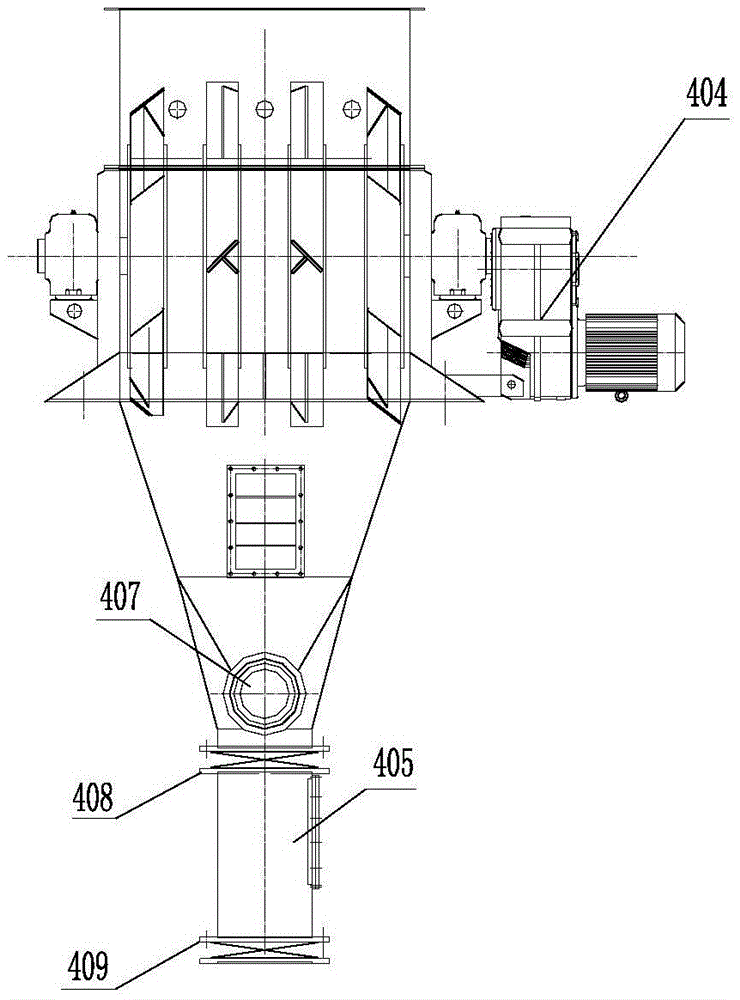

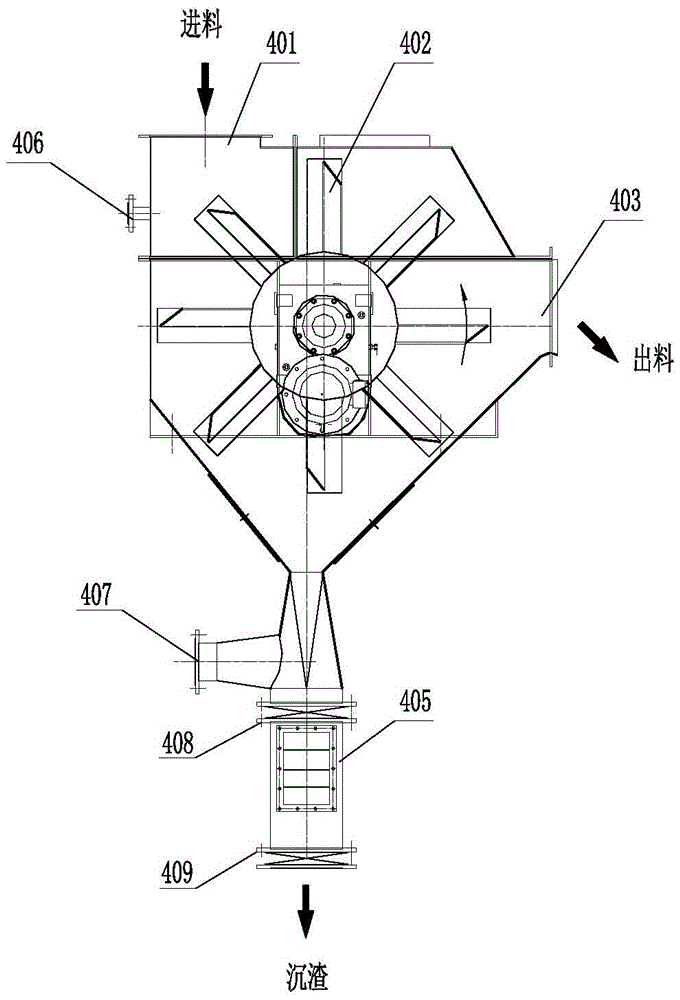

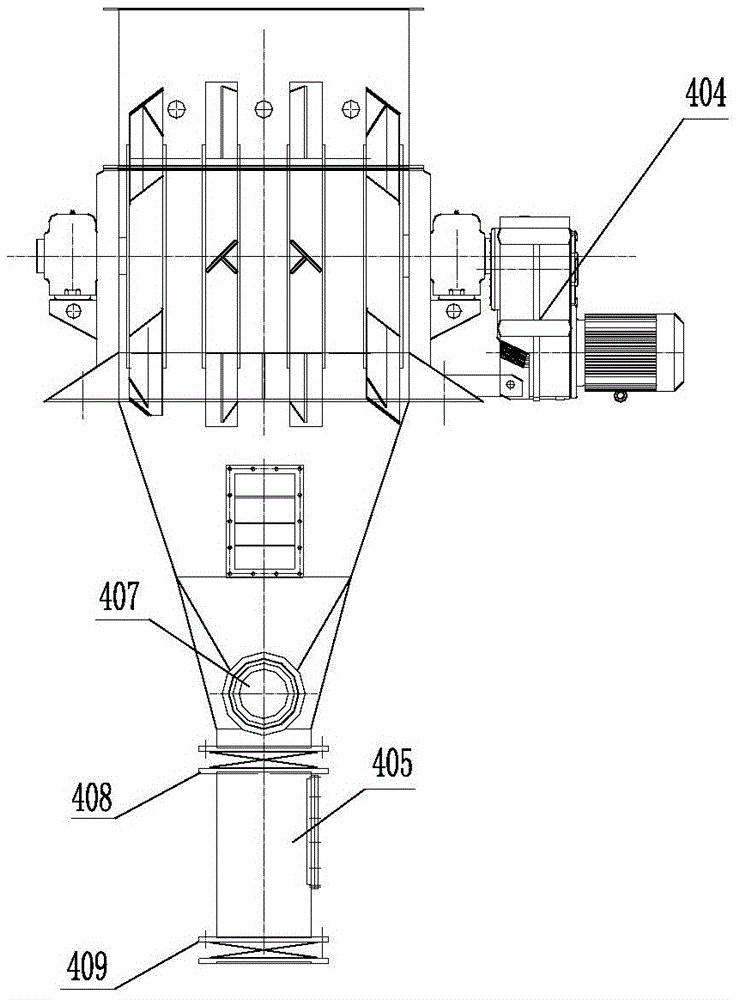

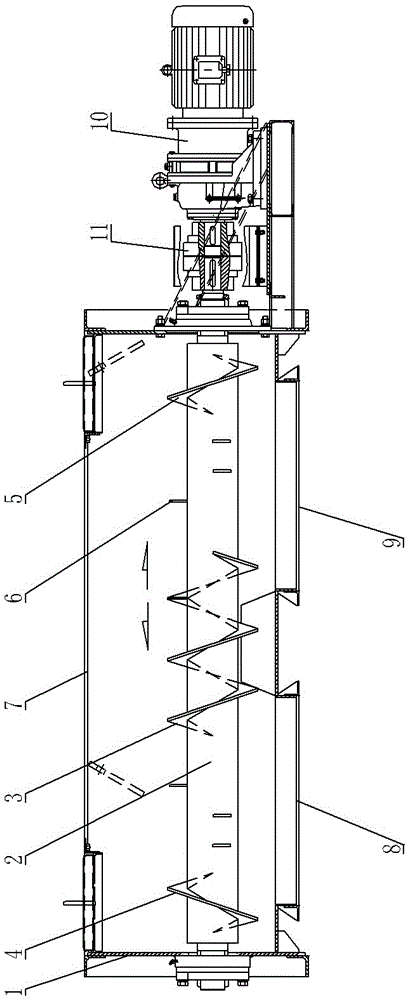

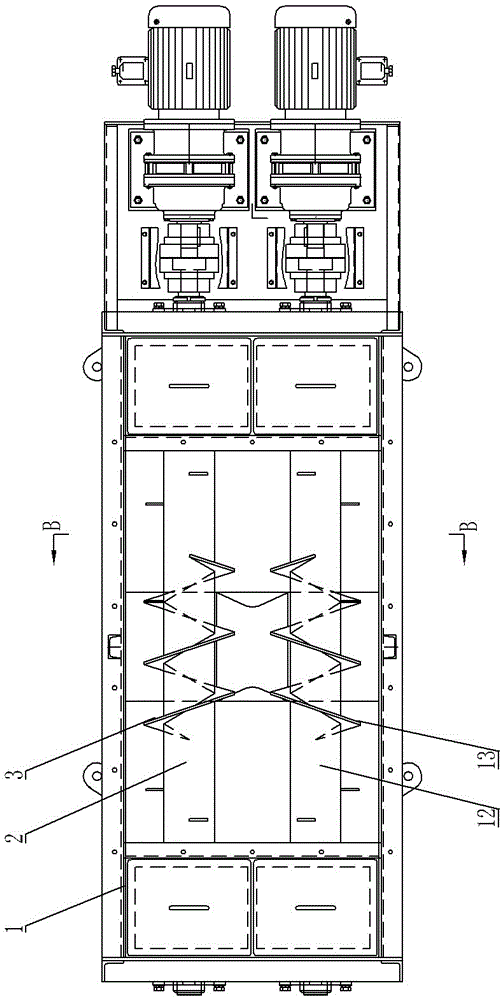

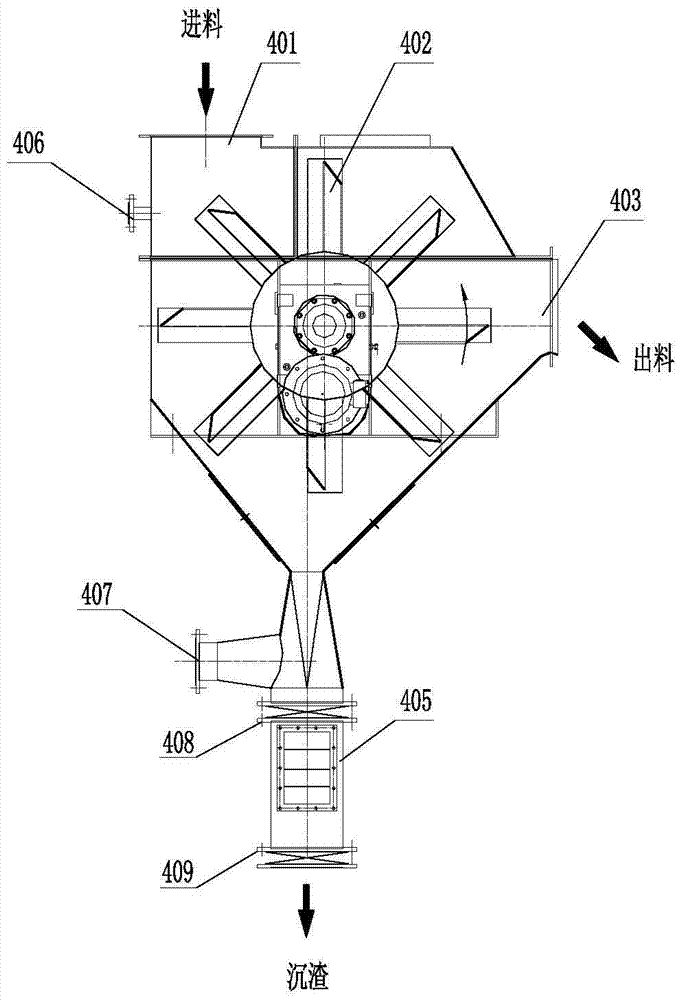

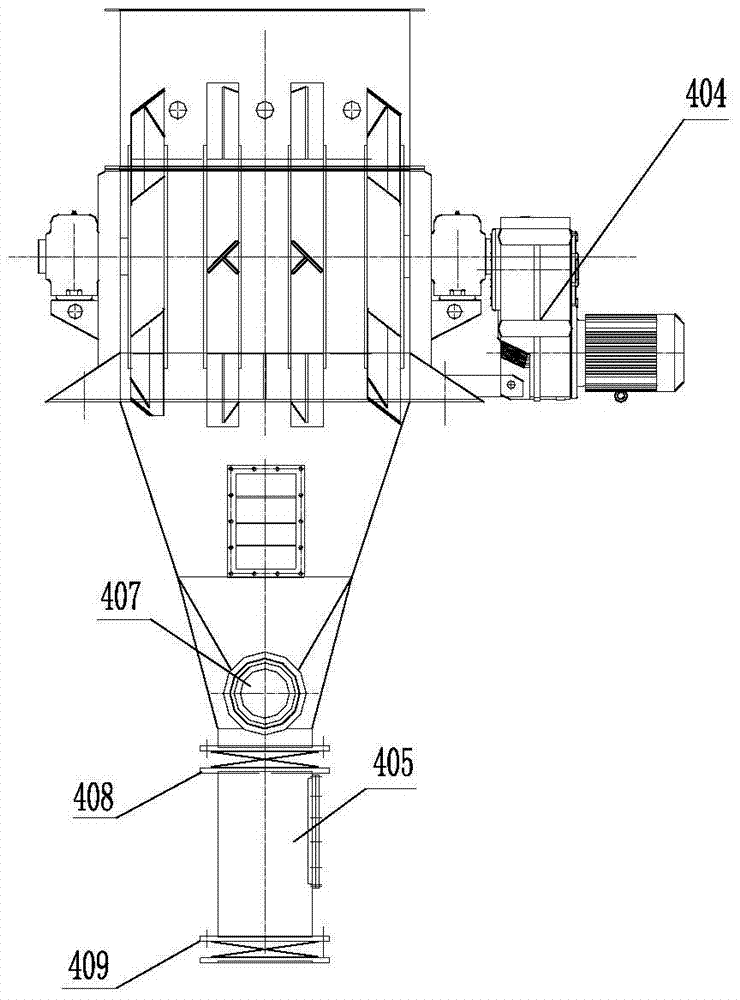

Rotary material-shifting type steaming warehouse

InactiveCN104120614AGuaranteed steaming effectEliminate bridgingPretreatment with water/steamElectric machineryEngineering

The invention discloses a rotary material-shifting type steaming warehouse. The rotary material-shifting type steaming warehouse comprises a warehouse body, a discharging device and a rotary material-shifting device, wherein the rotary material-shifting device comprises a material shifting disk arranged at the bottom of the warehouse body, the material shifting disk comprises a chassis and a material shifting plate capable of rotating on the chassis; the discharging device comprises a shell and a discharging motor; a discharging helix is arranged in the shell; a helix shaft of the discharging helix is connected with a discharging motor which is arranged on one side of the shell in a transmission mode; a discharging port is formed in the lower part of the other side of the shell; the discharging device is positioned below the material shifting disc; a blanking opening is formed in an abut-jointed part of the chassis of the material shifting disc and the discharging device shell. According to the rotary material-shifting type steaming warehouse, raw materials are continuously layered by rotating the material shifting device and shifted into the discharging device through the blanking opening, and the materials are prevented from sliding and rotating by virtue of an anti-slipping strip, so that the bridging phenomenon caused by volume expansion due to the heating of the materials is avoided, the utilization rate of the volume of the warehouse is improved, the materials are fully steamed and softened, the subsequent chemical extrusion steeping effect and the removal rate of soluble colored and resin substances are effectively improved, and the consumption of chemical products is reduced.

Owner:JIANGSU JINWO MACHINERY

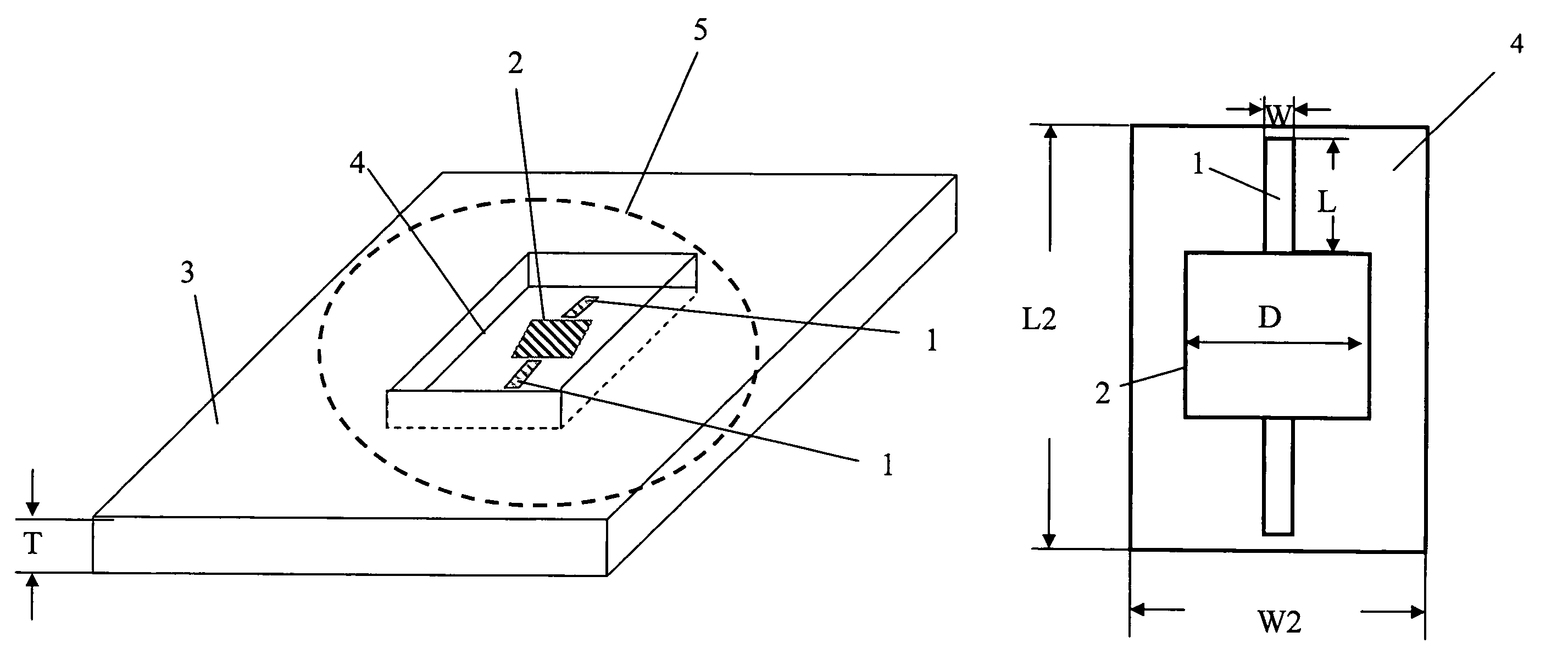

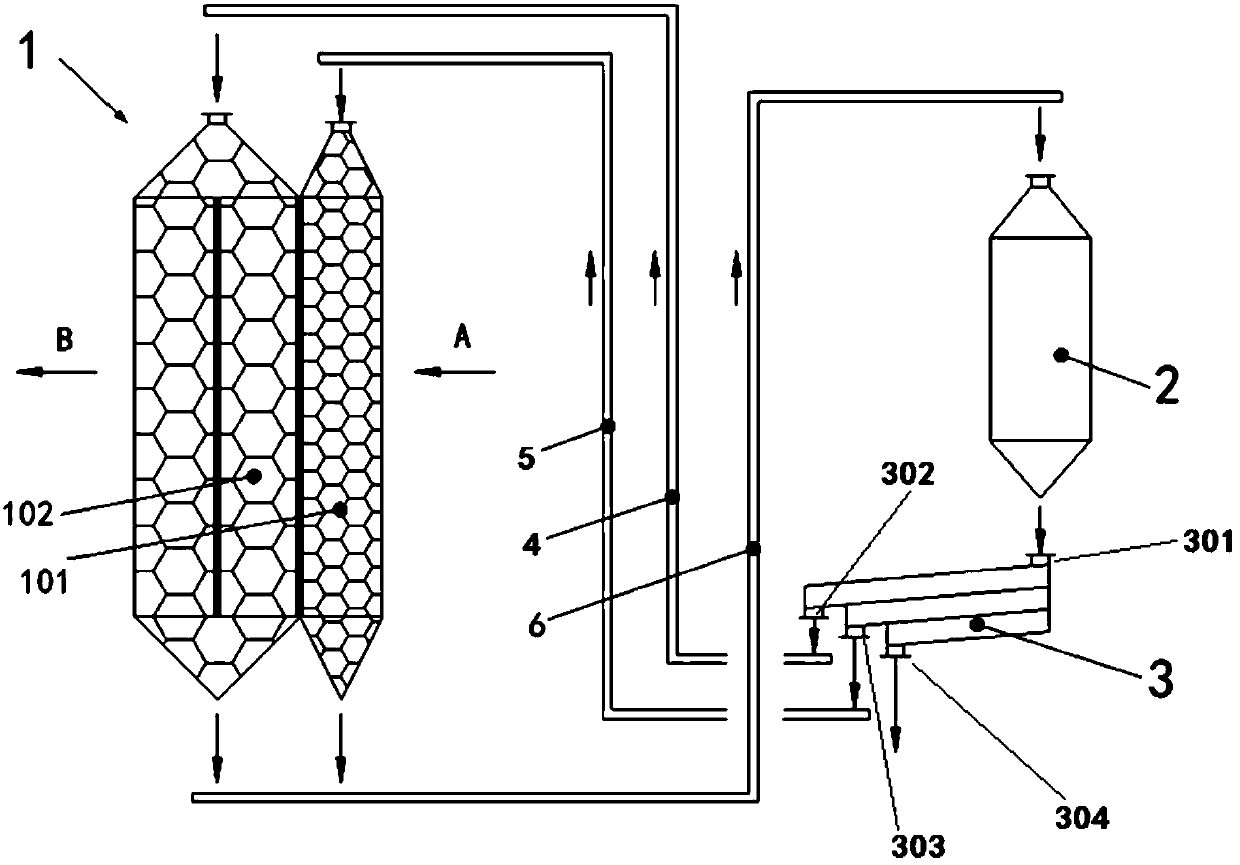

Stencil mask design method and under bump metallurgy for C4 solder bump

ActiveUS7135355B2Eliminate separationReduce spacingSemiconductor/solid-state device detailsSolid-state devicesStencil printingMetallurgy

A method for the fine-pitch stencil mask design for stencil printing bumping technology for eutectic Sn / Pb and lead-free solder material is described. In the method, a reflowing enhancement layer is introduced to improve the solder quality and reduce the pitch of solder bumps. The method of forming the layer is described as well as the forming method of matching under-bump metallurgy layer. The method of stencil mask design can match various sizes and pitch of the solder bumps. The designed mask is fixed on the stencil printer to deposit the solder materials with the required patterns. This method can increase the solder paste volume to increase the height of solder bumps after the reflowing process.

Owner:THE HONG KONG UNIV OF SCI & TECH

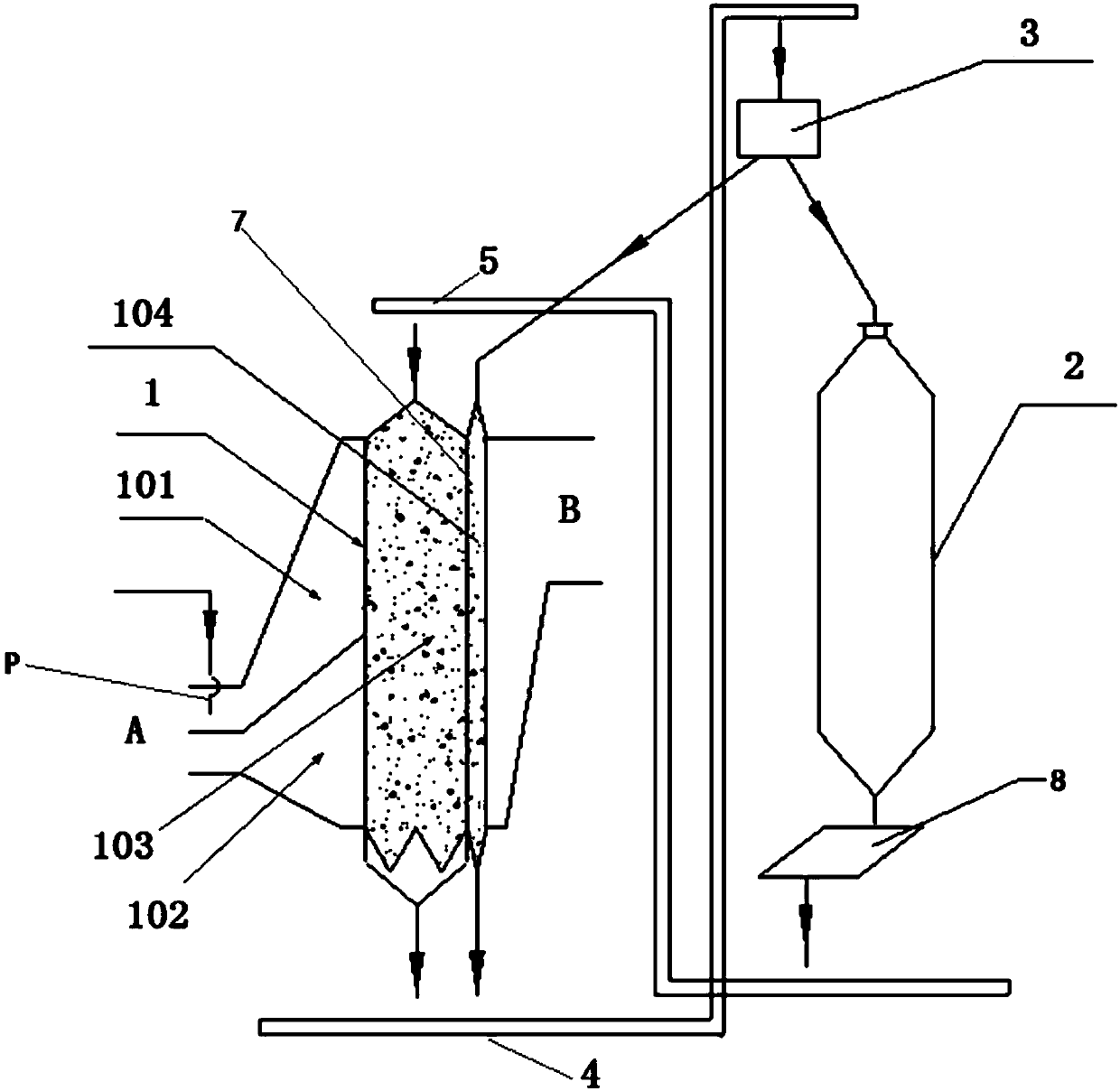

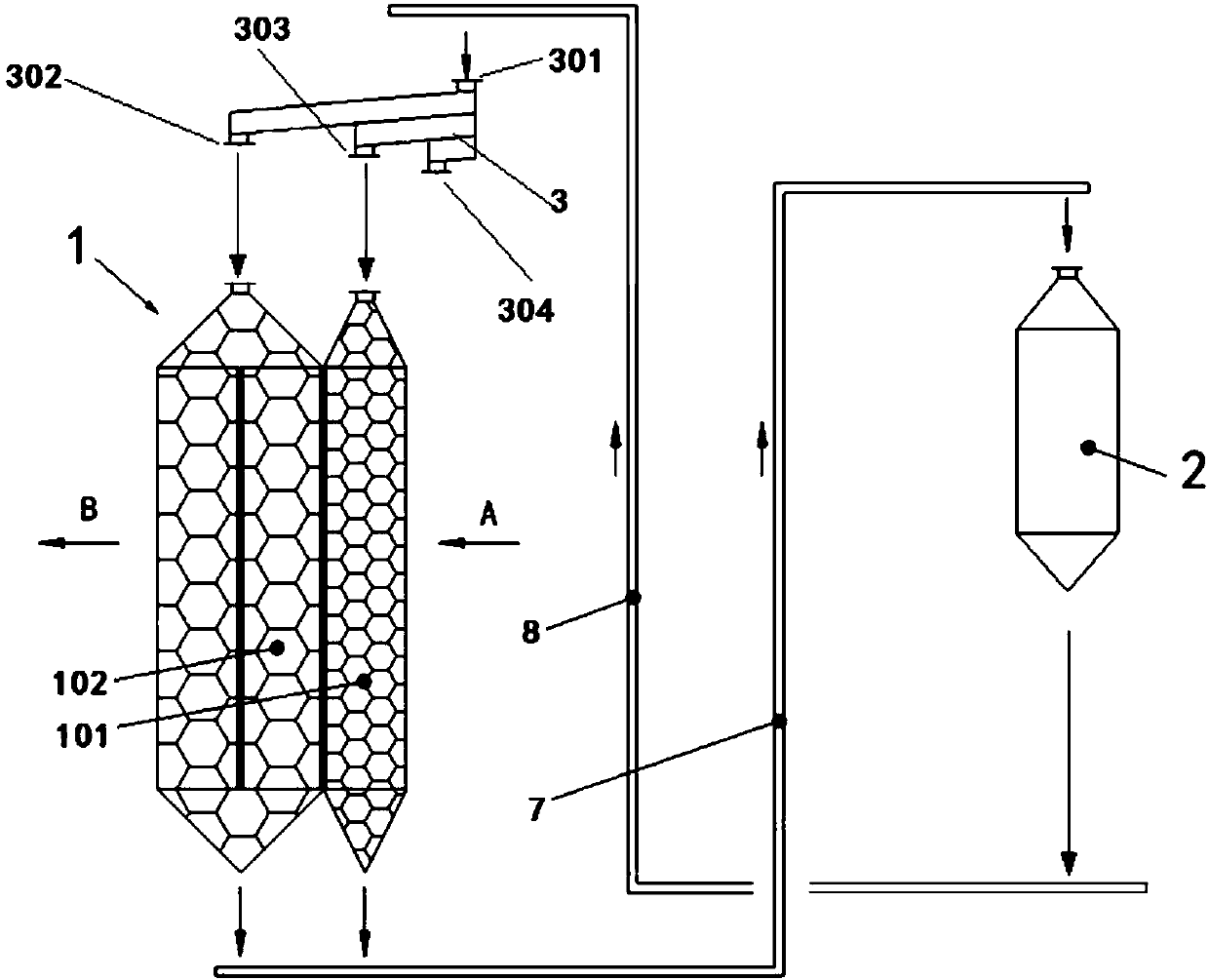

Desulfurization and denitrification system

ActiveCN108371873AEffective entrainmentEasy dischargeGas treatmentDispersed particle separationActivated carbonDesorption

The invention relates to a desulfurization and denitrification system. The system comprises an adsorption tower, a desorption tower, a graded sieving machine, a first activated carbon conveying machine, a second activated carbon conveying machine and a third activated carbon conveying machine, wherein a smoke inlet is formed in one side of the desorption tower; a smoke outlet is formed in the other side of the desorption tower; an adsorption layer front cavity and an adsorption layer rear cavity are formed in the adsorption tower; the first activated carbon conveying machine is connected witha first discharging hole of the graded sieving machine and a feeding hole of the adsorption layer rear cavity; the second activated carbon conveying machine is connected with a second discharging holeof the graded sieving machine and a feeding hole of the adsorption layer front cavity; and the third activated carbon conveying machine is connected with a discharging hole of the adsorption tower and a feeding hole of the desorption tower; and a discharging hole of the desorption tower is connected with a feeding hole of the graded sieving machine. According to the desulfurization and denitrification system, large-particle activated carbon is placed at the rear part of an activated carbon bed layer in the adsorption tower, and small-particle activated carbon is placed at the front part of the activated carbon bed layer in the adsorption tower, so that the situation that activated carbon powder is blown out of the bed layer by smoke can be prevented, and the aim that the smoke dust at theoutlet is reduced can be realized.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

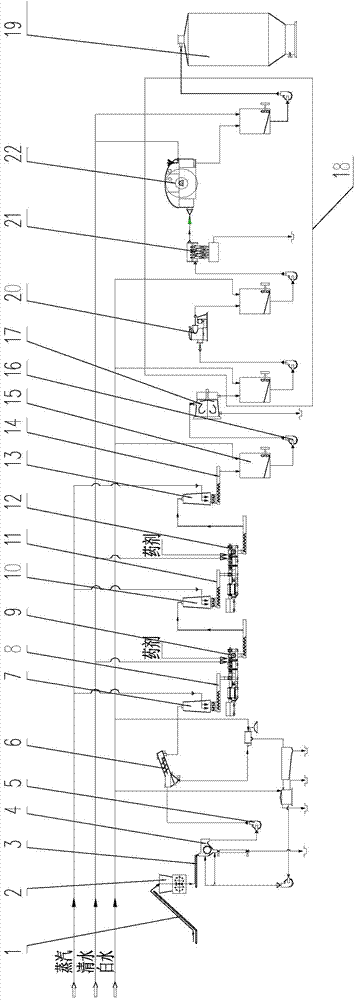

Wet-strength waste paper recycling chemical mechanical pulping system

ActiveCN104120613AReduce consumptionImprove chemical reaction efficiencyPaper recyclingWaste paper working-upChemical treatmentFiber

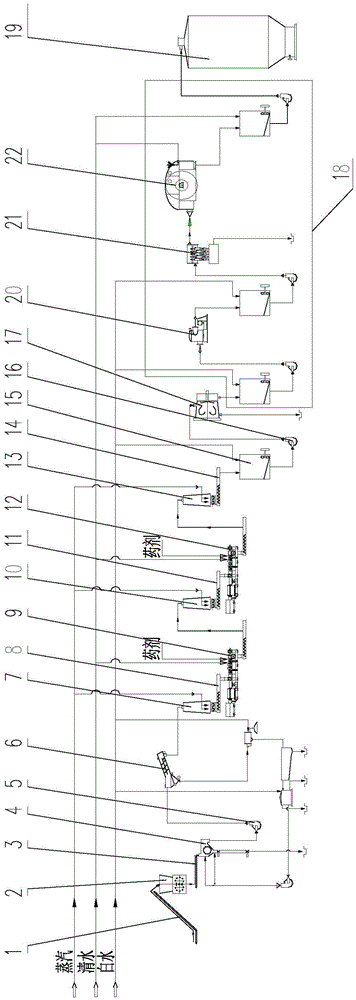

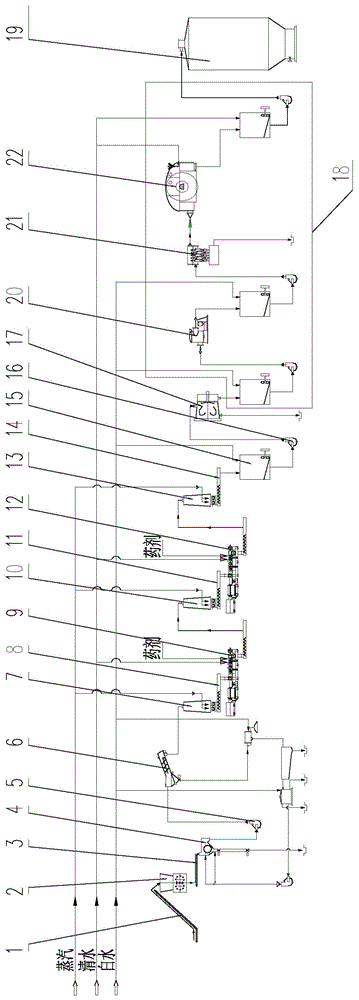

The invention discloses a wet-strength waste paper recycling chemical mechanical pulping system. In the material process running direction, the system comprises first conveying equipment, a crusher, second conveying equipment, a tumbler-type washing machine, an oblique spiral dehydrator, a steaming bin, a third spiral conveyer, a first double-screw impregnator, a first reaction bin, a fourth spiral conveyer, a second double-screw impregnator, a second reaction bin, a fifth spiral conveyer, a latency chest, a pulp pump, a fiber separator, a purification, filtration and concentration device and a pulp storage device. The uniform-discharging-type reaction bins are used for achieving uniform discharging so as to reduce the load fluctuation amplitude; the rotary material-poking-type steaming bin is used for eliminating the bridging phenomenon, sufficiently steaming materials so as to soften the materials and reducing chemical consumption; the double-screw impregnators are used for dissociating wet-strength waste paper gradually, achieving high-concentration mixing and homogeneous immersion of chemical agents and pulp and improving the chemical reaction efficiency. The problems that when the wet-strength waste paper is recycled for pulping, the dissociation rate is low and the strength is greatly reduced are solved through the effects of mechanical strength and chemical treatment.

Owner:JIANGSU JINWO MACHINERY

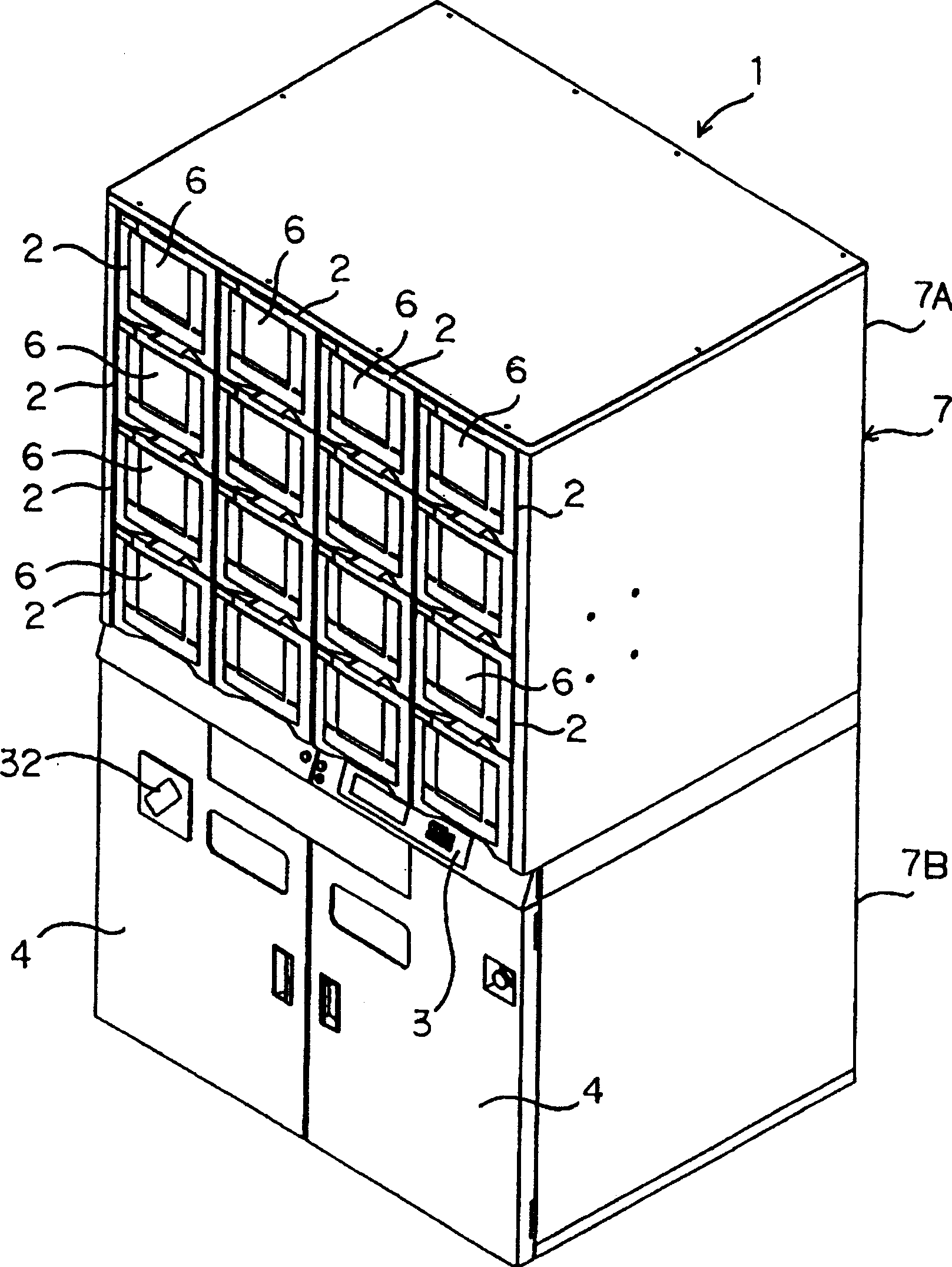

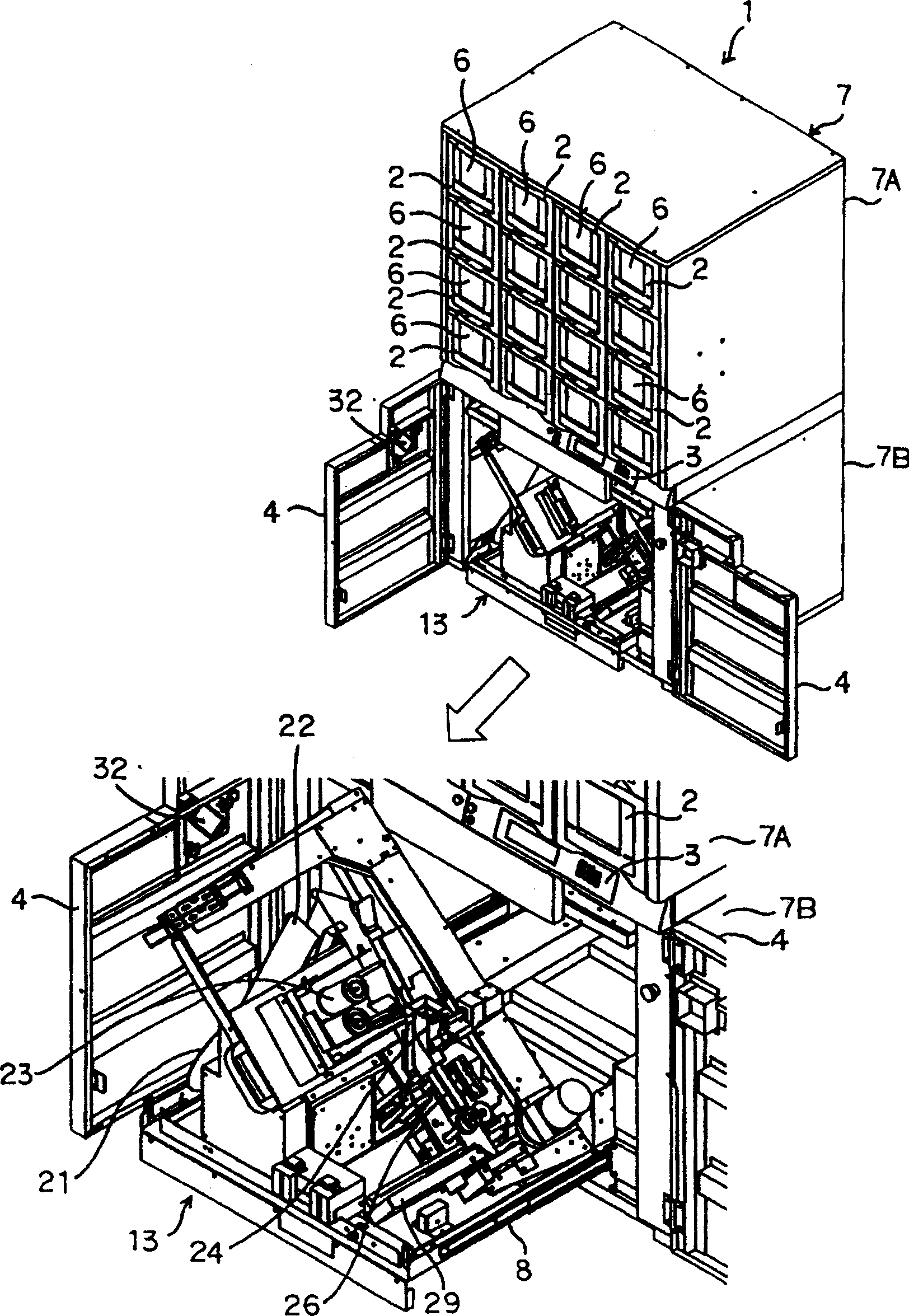

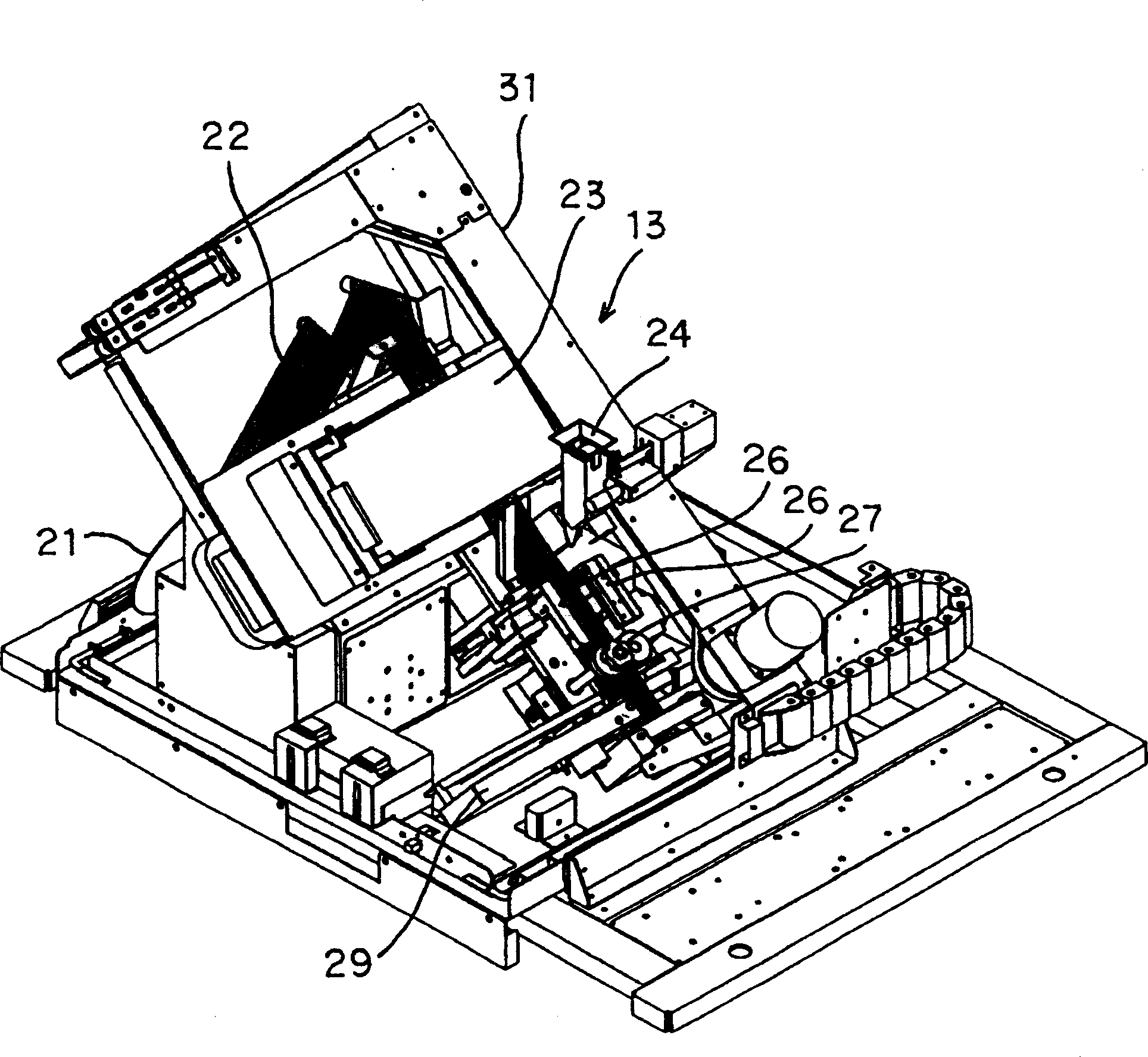

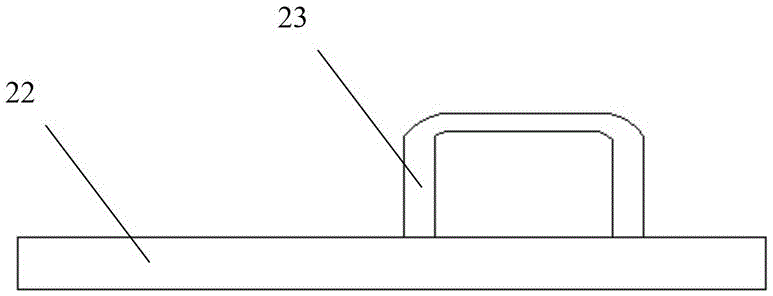

Medicine supplying apparatus

InactiveCN1724310AFalling smoothlyUnblockCoin-freed apparatus detailsPharmaceutical product form changeMechanical engineering

The invention provides a pill supply device, used to supply the drugs released from the pill boxes, comprising a canister opening (24), a flashboard (37) and a roller (9), wherein the canister opening (24) is used to let out the pills from the pill box and arrange the pills; the flashboard (37) is arranged freely rotary in the canister opening (24) and opens and closes the downward passway (34) in the canister opening (24); and the roller (9) faces the downward passway (34) in the canister opening (24) and is freely rotary. The roller (9) is arranged at the height position corresponding to the flashboard (37), and automatically rotates along with the on-off of the flashboard (37). The pill supply device is capable of effectively eliminating the plugging of the drugs in the canister opening as the pills are released into the wrapping paper,etc.

Owner:SANYO ELECTRIC CO LTD +1

Material flow shaping device

ActiveCN106044296AAdjustable thicknessContinuous uniform shapeLoading/unloadingConveyor partsConveyor beltMaterial flow

The invention discloses a material flow shaping device. The material flow shaping device is mounted above a conveyor belt and comprises a feeding bucket and a levelling baffle plate; a material fed into the feeding bucket falls onto the conveyor belt from the lower part of the feeding bucket; the levelling baffle plate is fixed above the conveyor belt through a connector and is in contact fitting with the material so as to perform shaping. The material flow shaping device has the advantages of being simple and compact in structure, simple and convenient to operate, high in adaptability, and capable of improving the material flow shaping effect.

Owner:HUNAN SUNDY SCI & TECH DEV

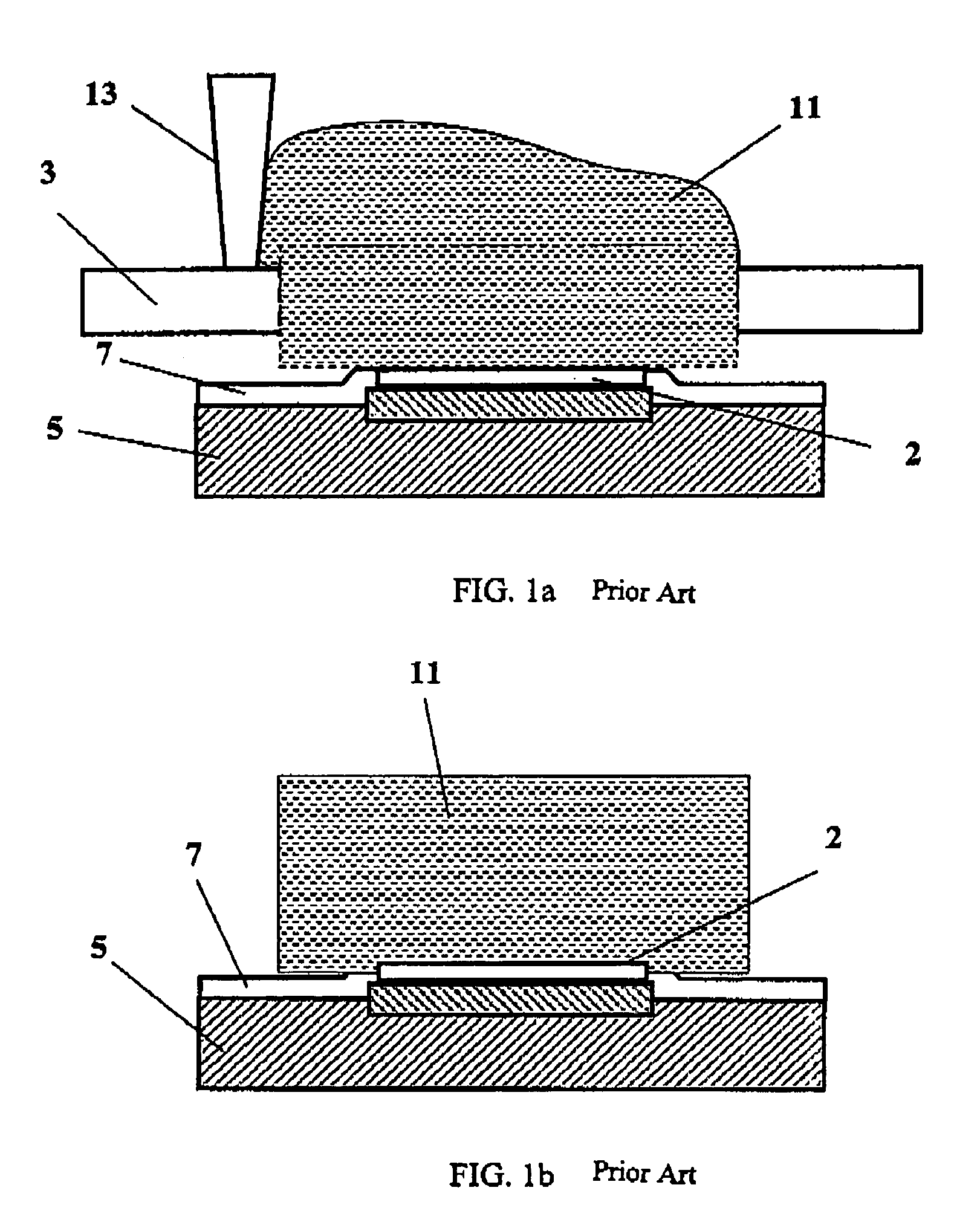

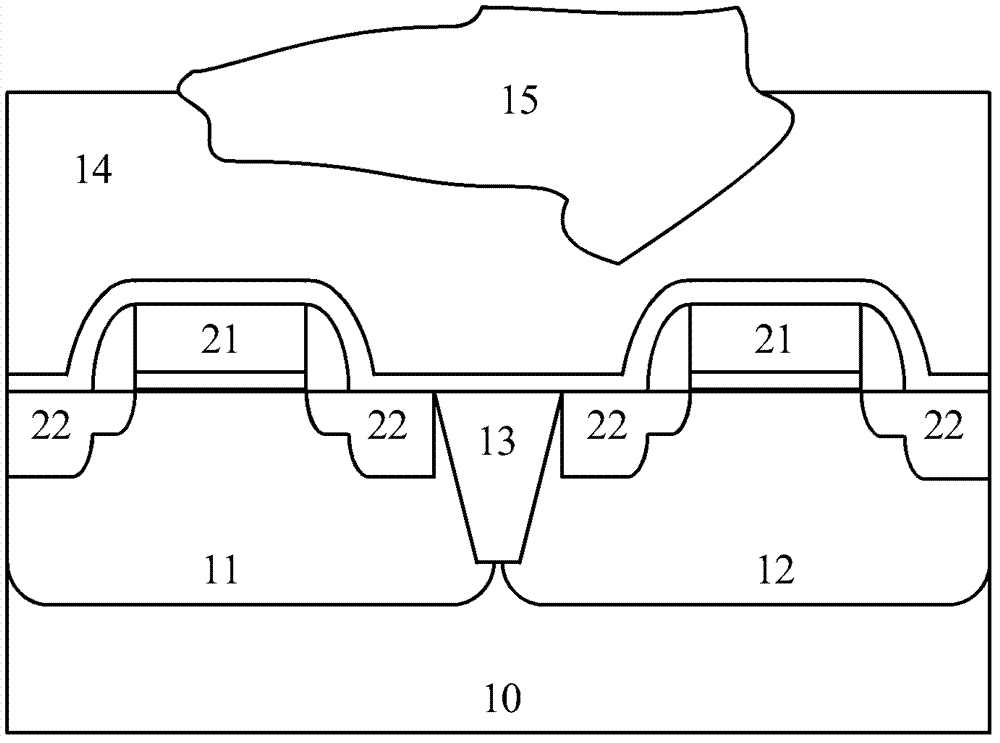

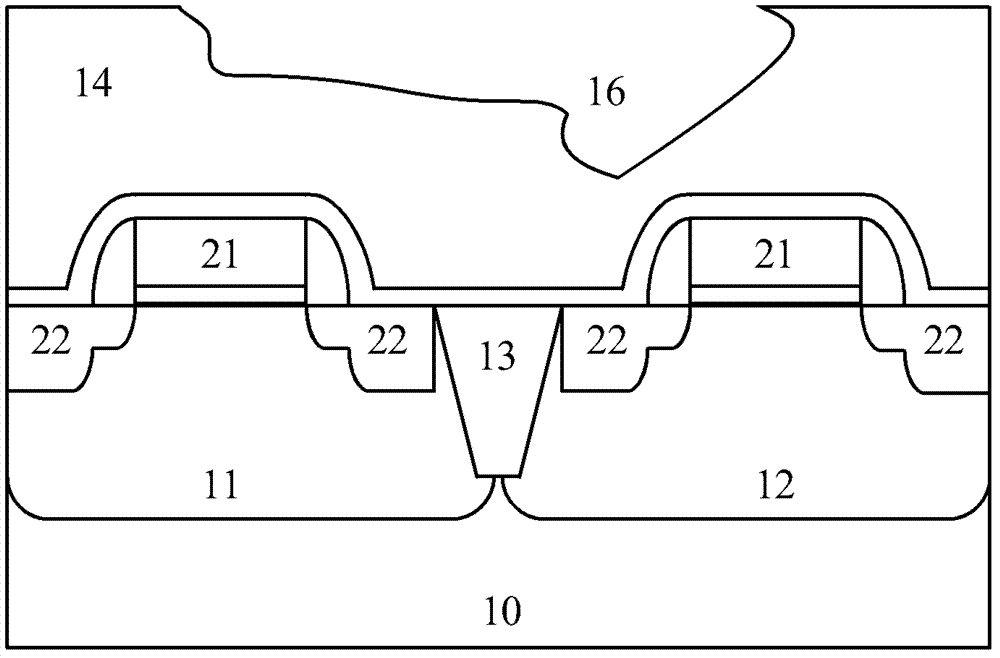

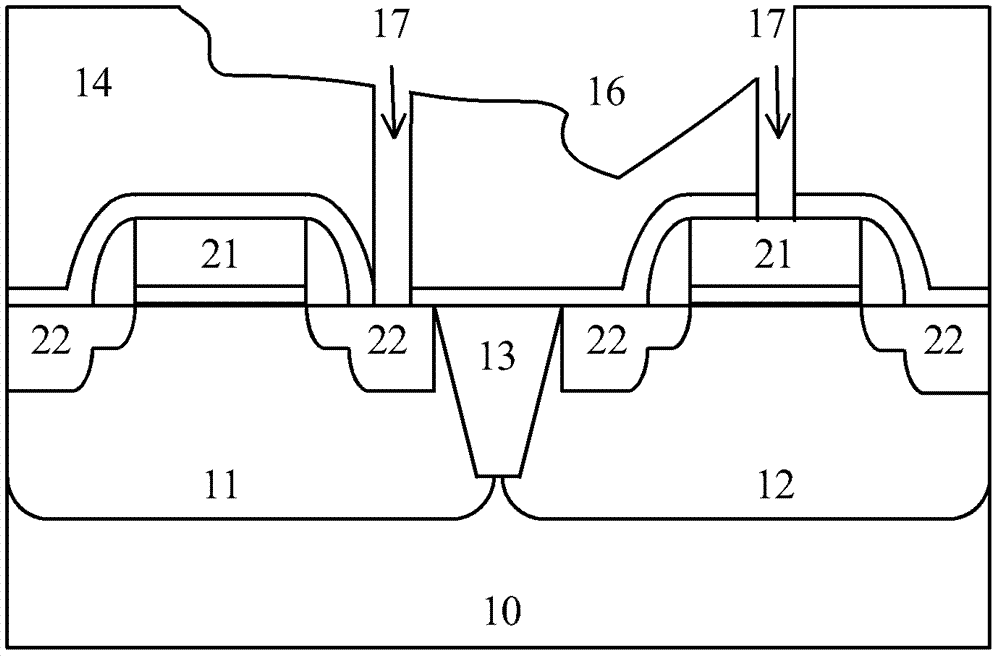

Method for eliminating bridging in contact hole technique

ActiveCN102903613AImprove adhesionImprove compactnessSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHigh densityChemical vapor deposition

The invention relates to a method for eliminating bridging in a contact hole technique, which provides a cleaning menu comprising a plurality of adaptive protective film deposition technical steps. A laminated adaptive protective film is formed on the side wall of the chamber of HDP CVD (high-density plasma chemical vapor deposition) equipment; and the laminated adaptive protective film with favorable adhesiveness, compactness and uniformity can protect the side wall of the chamber of the HDP CVD equipment from damage of plasma, avoids the generation of defective granules, enhances the yield of the HDP CVD technique, and eliminates the phenomenon of bridging in the contact hole technique.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Pulping system for recycling wet-strength recycled paper

ActiveCN105648817AReduce consumptionImprove chemical reaction efficiencyPaper recyclingWaste paper working-upChemical treatmentHigh concentration

The invention discloses a chemical mechanical pulping system for recycling wet-strength recycled paper. The system comprises first conveying equipment, a crusher, second conveying equipment, a drum washing machine, an oblique spiral dehydrator, a steaming bin, a third screw conveyer, a first double-screw impregnator, a first reaction bin, a fourth screw conveyer, a second double-screw impregnator, a second reaction bin, a fifth screw conveyor, a latency chest, a stock pump, a fiber separator, a purifying, screening and concentrating device and a pulp storage device in the running direction of the material procedure. The even feeding type reaction bins are utilized for achieving even feeding and reducing the load fluctuation range; the rotary stirring type steaming bin is utilized for eliminating a bridging phenomenon, materials are fully steamed and softened, and chemical consumption is reduced. The double-screw impregnators are utilized for gradually dissociating the wet-strength recycled paper, high-concentration mixing and homogenizing impregnation of a chemical additive and pulp are achieved, and the chemical reaction efficiency is improved. By means of the function of mechanical strong force and chemical treatment, the problems that during wet-strength recycled paper recycling, pulping and dissociating rate is low, and the strength is greatly reduced are solved.

Owner:JIANGSU JINWO MACHINERY

Chemical mechanical pulping method for recycling of wet strength waste paper

ActiveCN104099795AReduce consumptionImprove chemical reaction efficiencyPretreatment with water/steamPretreatment with alkaline reacting compoundsChemical treatmentProcess engineering

The invention discloses a chemical mechanical pulping method for recycling of wet strength waste paper. The method comprises a material preparation section, a steaming section, a first squeezing dipping chemical mechanical treatment section, a second squeezing dipping chemical mechanical treatment section, a latency and re-defibering section and a purification, screening and concentration section. According to the method, wet strength waste paper fiber dissociation and re-pulping are realized while the original pulp strength is not reduced under the action of mechanical strength and chemical treatment; furthermore, at the two squeezing dipping chemical mechanical treatment sections in series connection, a wet strength agent in the waste paper can be oxidized under the acidic condition firstly, and then hydrolysis is further promoted under the alkaline condition, so that the chemical bonding among molecules of the wet strength agent and between the wet strength agent and pulp fibers are destroyed more effectively, and the fiber dissociation rate and the re-pulping yield are effectively increased. The problems that the wet strength waste paper recycling, pulping and dissociation rate is low and the strength is substantially reduced are solved, and continuous, large-scale, low-water-consumption, low-energy-consumption, pollution-free and environment-friendly pulping can be realized.

Owner:JIANGSU JINWO MACHINERY

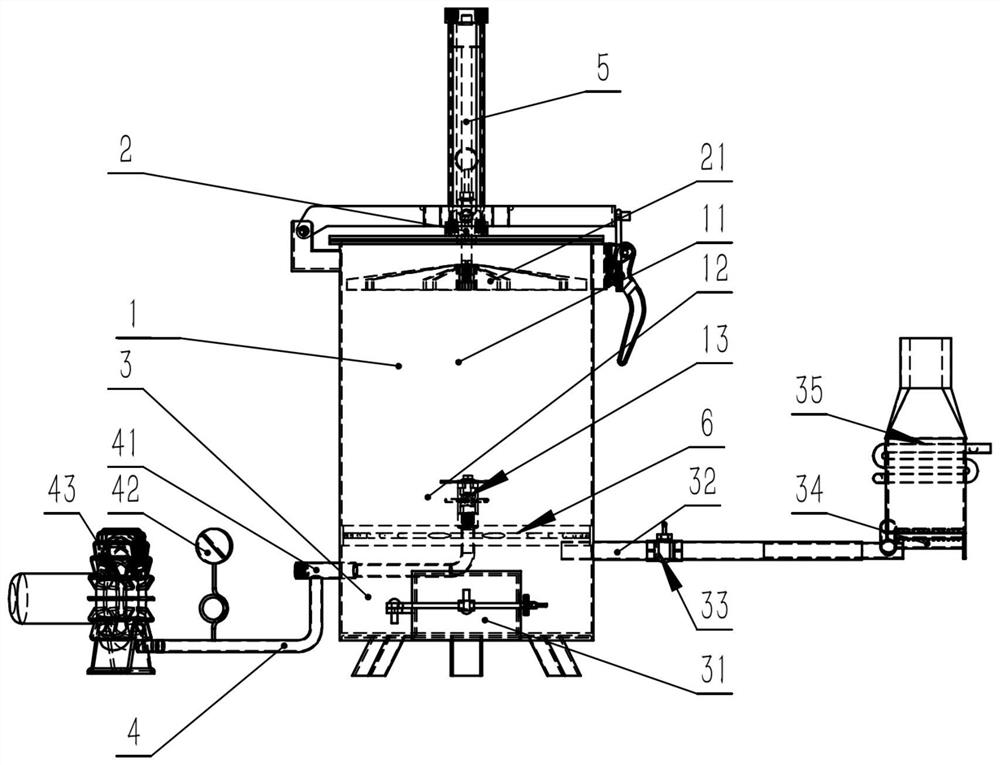

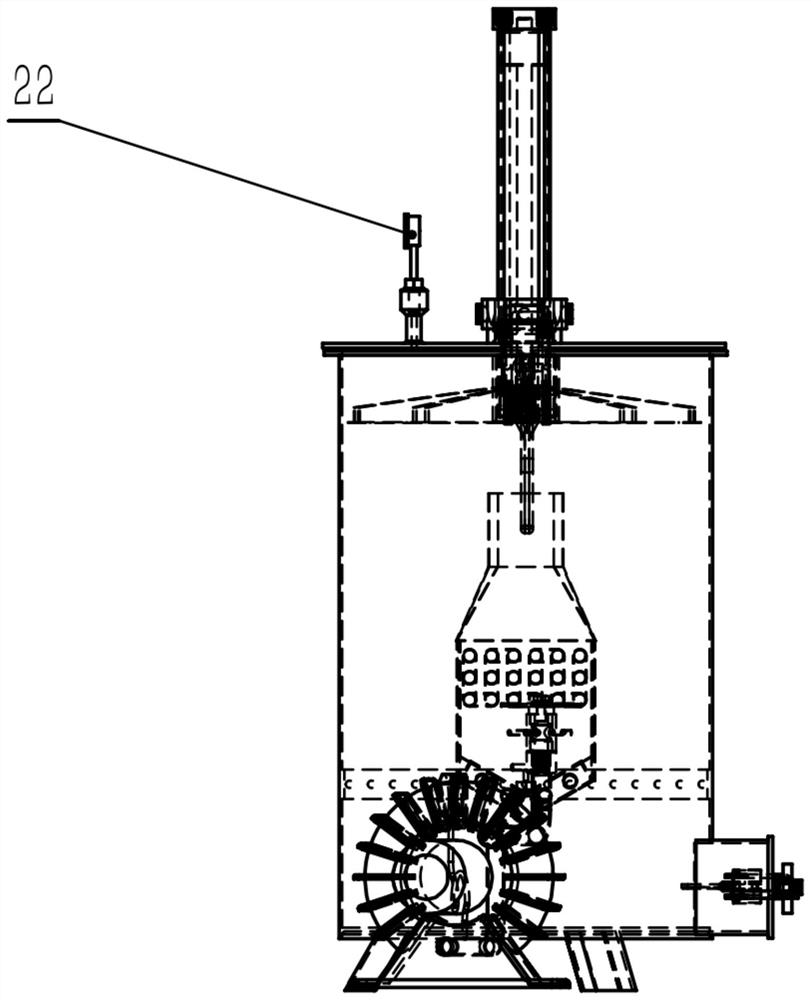

Constant-density biomass gasifier

ActiveCN112980513AEliminate bridgingImprove compactnessGasification processes detailsCombustible gas productionProcess engineeringBiomass gasifier

The invention provides a constant-density biomass gasifier which comprises a gasifier body, a movable gasifier cover and a self-rotating nozzle, a material pressing mechanism is arranged on the movable gasifier cover and comprises a driving device and a material pressing disc, and the material pressing disc is used for providing downward constant pressure for biomass fuel in the gasifier body under the driving of the driving device; therefore, through the material pressing mechanism arranged on the movable furnace cover, a continuous pressure from top to bottom or an intermittent impact striking effect is exerted on the biomass fuel in the material storage area in the furnace, so that a fuel layer stably descends, the compactness of the material layer is improved, and the bridging phenomenon of the material layer is eliminated; meanwhile, by means of the self-rotating nozzle, a gasifying agent evenly enters the reaction area from the center direction, an oxidation layer and a reduction layer are stable and balanced, and the burn-through phenomenon is eliminated; besides, except for filling the biomass raw materials and discharging the biochar, other operation processes are easy to realize automatic control, so that the operation cost is greatly reduced, and the economic applicability is better.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

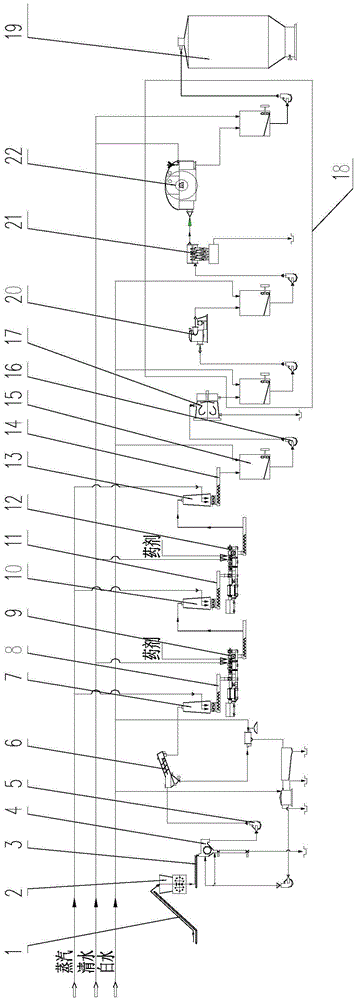

Continuous production line and continuous production method for emulsified ammonium nitrate fuel oil explosive

InactiveCN111892464AEnsure personal safetyIncrease productivityMixing methodsTransportation and packagingProduction lineExplosive Agents

The invention relates to a continuous production line and a continuous production method for an emulsified ammonium nitrate fuel oil explosive. The production line comprises a latex matrix continuouspreparation system, an ammonium nitrate fuel oil explosive continuous preparation system, continuous mixing equipment and an automatic filling system, material outlets of the latex matrix continuous preparation system and the ammonium nitrate fuel oil explosive continuous preparation system are connected with a material inlet of the continuous mixing equipment, wherein a continuous material outletof the continuous mixing equipment is connected with a material inlet of the automatic filling system, and the production method comprises the following steps of: simultaneously and continuously conveying the ammonium nitrate fuel oil explosive and the cooled latex matrix into the continuous mixing equipment for mixing, adding wood flour into the mixture, and continuously performing mixing to prepare the emulsified ammonium nitrate fuel oil explosive. Continuous production of the emulsified ammonium nitrate fuel oil explosive can be achieved, the production efficiency is high, the productivity is large, the automation level is high, no fixed operation post exists on the whole line, the number of operators is small, the production safety level is high, and due to the adoption of the continuous production mode, the product consistency is high, and the quality is stable and reliable.

Owner:北京京煤化工有限公司

Method for improving flaw detection qualification rate of Q345C steel plate with specification of 14-30 mm

ActiveCN113005353AReduce segregationQuality improvementManufacturing convertersChemical compositionManganese

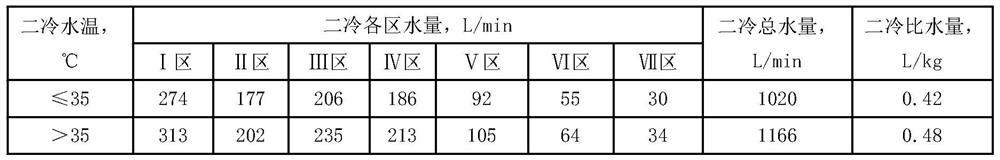

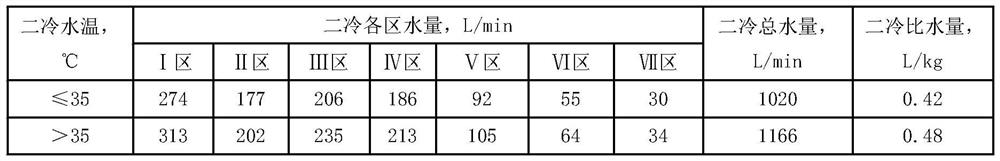

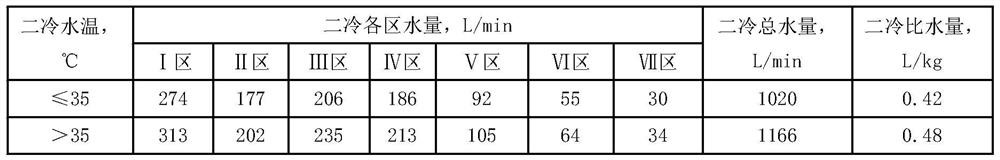

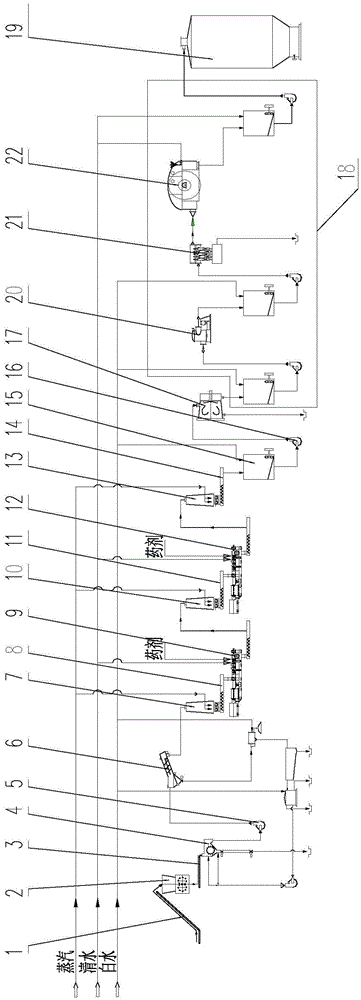

The invention provides a method for improving the flaw detection qualification rate of a Q345C steel plate with the specification of 14-30 mm, belongs to the technical field of medium-thickness steel plate production, and comprises a Q345C steel plate and a production method of the Q345C steel plate. The Q345C steel plate comprises the following chemical components of (unit, wt%) 0.15wt% to 0.18wt% of C, 0.20wt% to 0.40wt% of Si, 1.25wt% to 1.35wt% of Mn, P less than or equal to 0.025wt%, S less than or equal to 0.005wt%, 0.015wt% to 0.025wt% of Ti, 0.015wt% to 0.030wt% of Als and the balance Fe and residual elements. According to the method, in the production, the Q345C process technology is strictly controlled, the sulfur content and the manganese content of a finished product are strictly controlled; on the premise that the surface temperature of a casting blank is higher than the third brittleness temperature interval of steel by 900 DEG C or above when the casting blank is straightened, when the secondary cooling water temperature is lower than or equal to 35 DEG C, the secondary cooling specific water flow is controlled to be 0.42 L / kg, and when the secondary cooling water temperature is higher than 35 DEG C, the secondary cooling specific water flow is controlled to be 0.48 L / kg; and the casting blank is rolled after being cut and slowly cooled. Through the implementation of the method, the flaw detection qualification rate of the rolled Q345C steel plate with the specification of 14-30 mm is increased to 99.80% from 98.40%, and the qualification rate is increased.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Wet-strength wastepaper recycling double-pH-value chemical and mechanical pulping method

ActiveCN105568726AReduce consumptionImprove chemical reaction efficiencyPretreatment with water/steamPretreatment with alkaline reacting compoundsChemical treatmentFiber

The invention discloses a wet-strength wastepaper recycling double-pH-value chemical and mechanical pulping method. The method includes a material preparation section, a steaming section, a first extrusion and impregnation chemical and mechanical treatment section, a second extrusion and impregnation chemical and mechanical treatment section, a latency and re-defibering section and a purification, screening and concentration section. Wet-strength wastepaper fiber dissociation re-pulping is achieved while original pulp strength is not reduced through the mechanical strong force effect and the chemical treatment effect. Furthermore, on the two extrusion and impregnation chemical and mechanical treatment sections connected in series, a wet strength agent in wastepaper is oxidized under the acid condition firstly, hydrolysis is further promoted under the alkaline condition, chemical bonding between molecules of the wet strength agent and between the wet strength agent and pulp fibers is more effectively damaged, and the fiber dissociation rate and the re-pulping yield are effectively increased. The problems that the wet-strength wastepaper recycling pulping dissociation rate is low and strength is greatly decreased are solved, and continuous, large-scale, low-water-consumption and low-energy-consumption pollution-free and environment-friendly pulping can be achieved.

Owner:JIANGSU JINWO MACHINERY

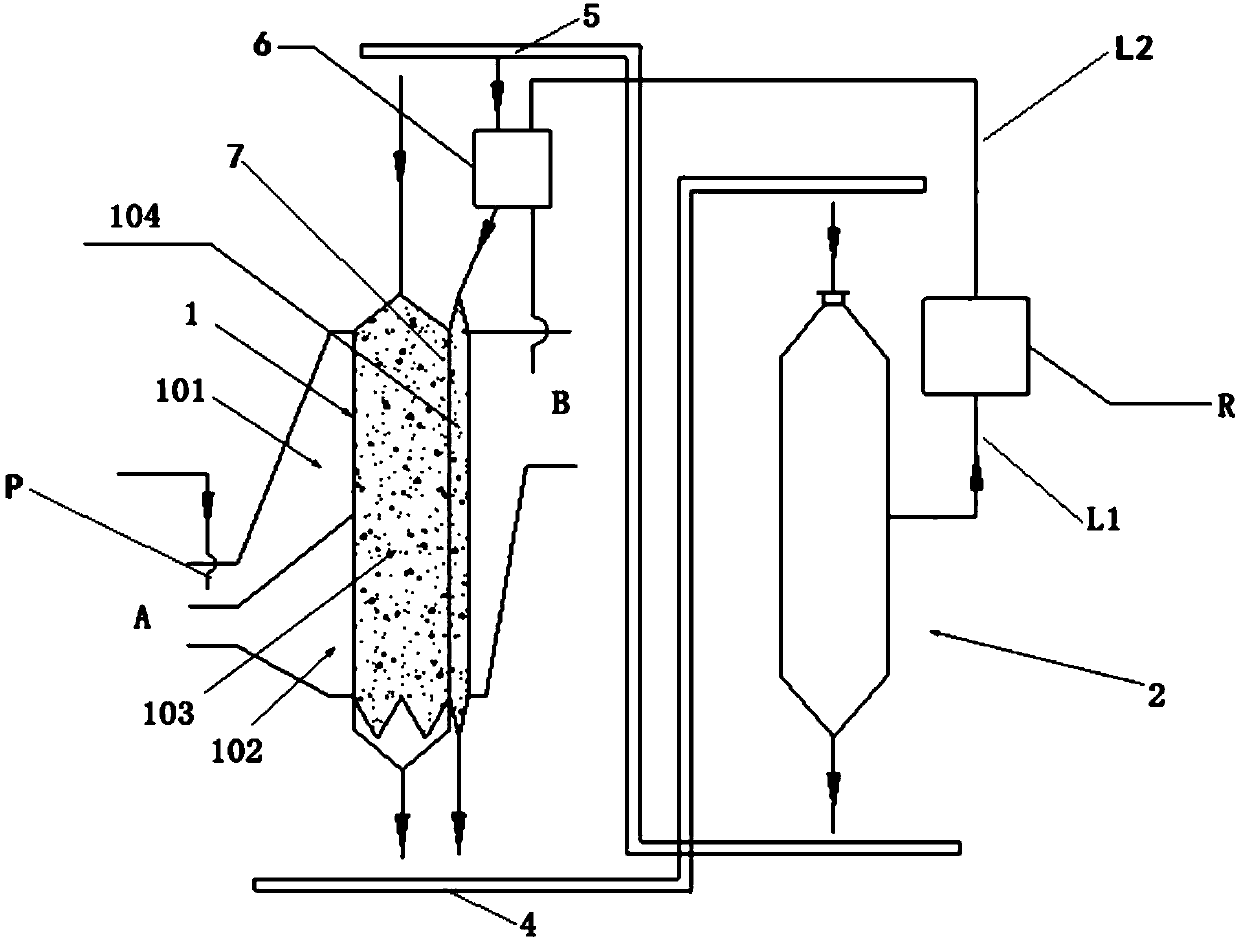

Activated carbon adsorption tower system and desulfurization and denitration system

ActiveCN108543403AImprove purification effectEnsure normal dischargeGas treatmentDispersed particle separationActivated carbonFlue gas

An activated carbon adsorption tower system is disclosed. One side of an activated carbon adsorption tower is provided with a first flue gas inlet and a second flue gas inlet. The other side of the adsorption tower is provided with a first flue gas outlet and a second flue gas outlet. The first flue gas inlet is disposed below the second flue gas inlet. The first flue gas outlet is disposed belowthe second flue gas outlet. The first flue gas inlet is connected to an original flue gas conveying pipe. The first flue gas outlet is connected to the second flue gas inlet through a first delivery pipe. The second flue gas outlet is connected to a clean flue gas pipe. Both a first ammonia injection device and a second ammonia injection device are connected to a mixed gas delivery pipe. The activated carbon adsorption tower system adsorbs original flue gas into different parts of the adsorption tower through a pipeline or a separator, and is beneficial to the full utilization of activated carbon, and the denitration rate of the system is improved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Dustproof safe feeding device for power battery black powder acid leaching feeding

PendingCN113387194APrevent fallingAvoid cloggingLarge containersProcess efficiency improvementPower batteryElectrical battery

The invention discloses a dustproof safe feeding device for power battery black powder acid leaching feeding. The dustproof safe feeding device comprises a leaching tank, a discharging grid and a material shaking assembly, and the leaching tank comprises a feeding port; and the discharging grid is installed in the feeding port and provided with a discharging hole. The material shaking assembly comprises a material shaking part and a driving device, the material shaking part is movably arranged in the discharging hole, the driving device is connected with the material shaking part, and the driving device drives the material shaking part to move in the discharging hole. The feeding port is provided with the discharging grid, so that operators are prevented from falling into the feeding port; and the material shaking part and the driving device are installed, so that the bridging phenomenon of battery powder is eliminated, and the battery powder is prevented from blocking the feeding port.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

Straw distributing equipment

The invention provides straw distributing equipment which can solve the technical problems that in the prior art, during straw stokehold distributing and supplying, the supply continuity is poor, and the bridging phenomenon is prone to occurrence. The straw distributing equipment comprises a shell, rotating shafts and a driving device for driving the rotating shafts to rotate, a feeding opening is formed in the top of the shell, and two discharging openings are formed in the bottom of the shell; the straw distributing equipment is characterized in that the two rotating shafts are supported to the left side wall and the right side wall of the shell in parallel, the parts, located below the feeding opening, of the rotating shafts are provided with middle spiral blades, the parts, located above the discharging openings, of the rotating shafts are provided with stirring rods, and the middle spiral blades of the two rotating shafts are arranged in the reversed directions; material guide plates are symmetrically arranged below the feeding opening, the portions on the upper sides of the material guide plates are hinged to a piston rod of an air cylinder, and the rotating shafts are arranged at the positions on the lower sides of the material guide plates; the air cylinder and the shell are fixedly connected, the two ends of each rotating shaft are inserted into guide grooves in the front side inner wall and the back side inner wall of the shell, and springs are arranged at the portions, located in slot bodies of the two sides of the rotating shafts, of the guide grooves.

Owner:WUXI XIDONG ENERGY TECH

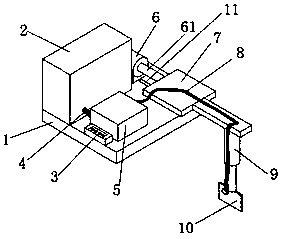

Automatic material feeding and material scraping device for grinding wheel production

The invention discloses an automatic material feeding and material scraping device for grinding wheel production. The device comprises a platform, a material box, a controller, a material conveying pipe, a material conveying machine, a discharging pipe, a first pushing rod motor, a sliding block, a second pushing rod motor and a material scraping plate; the material box, the controller, the material conveying machine and the first pushing rod motor are installed on the platform, the first pushing rod motor is located on the right side of the material box, and the controller is located on the left side of the material conveying machine; the material box is connected to the material conveying machine through the material conveying pipe, the discharging pipe is installed on the material conveying machine, and the tail end of a pushing rod of the first pushing rod motor is fixedly connected to the tail end of the sliding block; and the second pushing rod motor is fixedly installed on the lower surface of the top end of the sliding block, the tail end of a pushing rod of the second pushing rod motor is fixedly connected to the material scraping plate, and the tail end of the dischargingpipe is fixedly installed on the side surface of the material scraping plate. According to the device, the defects in the prior art are overcome, material feeding and material scraping are carried out at the same time, forming material is uniformly distributed in a mold, so that a bridge phenomenon in the material scraping process is eliminated, and manufactured grinding wheels are uniform in hardness and stable in quality.

Owner:安徽佑开科技有限公司

Wet-strength waste paper recycling chemi-mechanical pulping system

ActiveCN105544264AReduce consumptionImprove chemical reaction efficiencyPaper recyclingWaste paper working-upChemical treatmentHigh concentration

Owner:JIANGSU JINWO MACHINERY

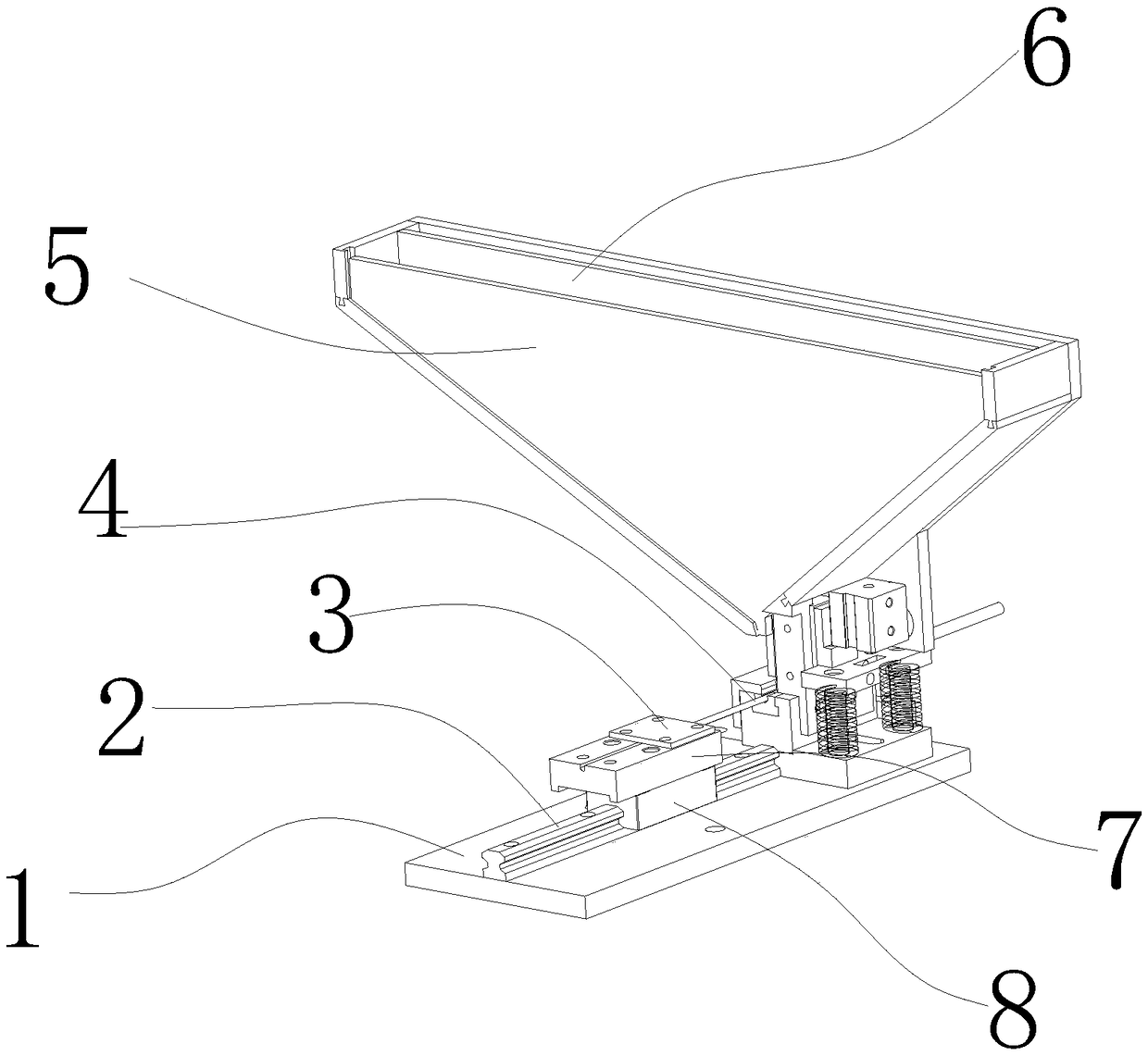

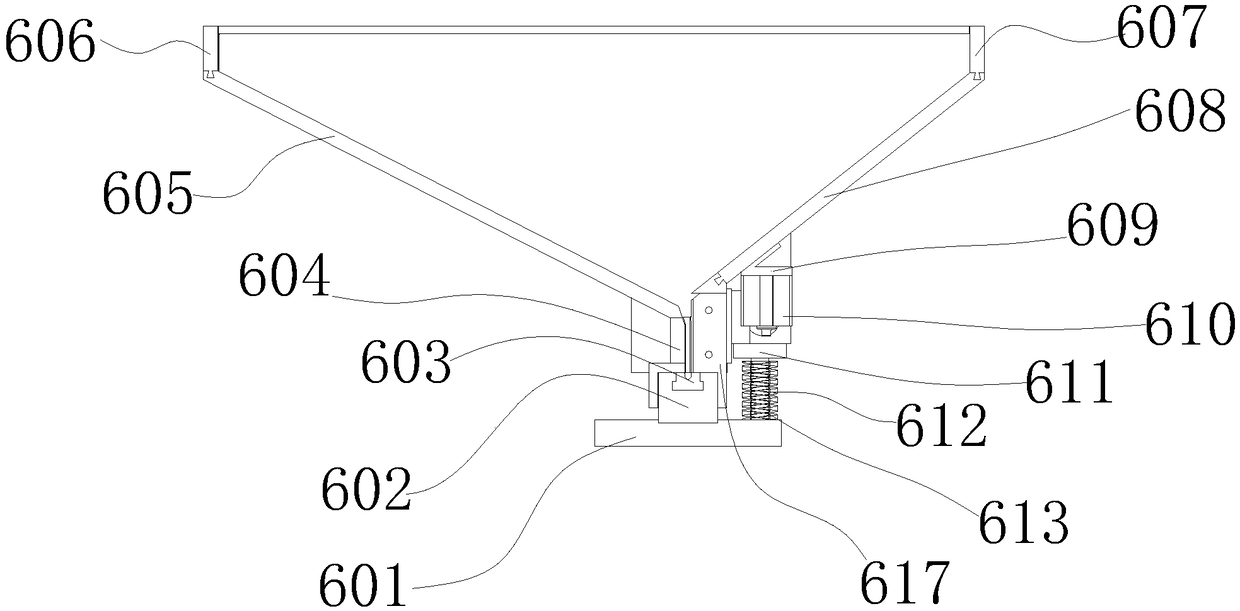

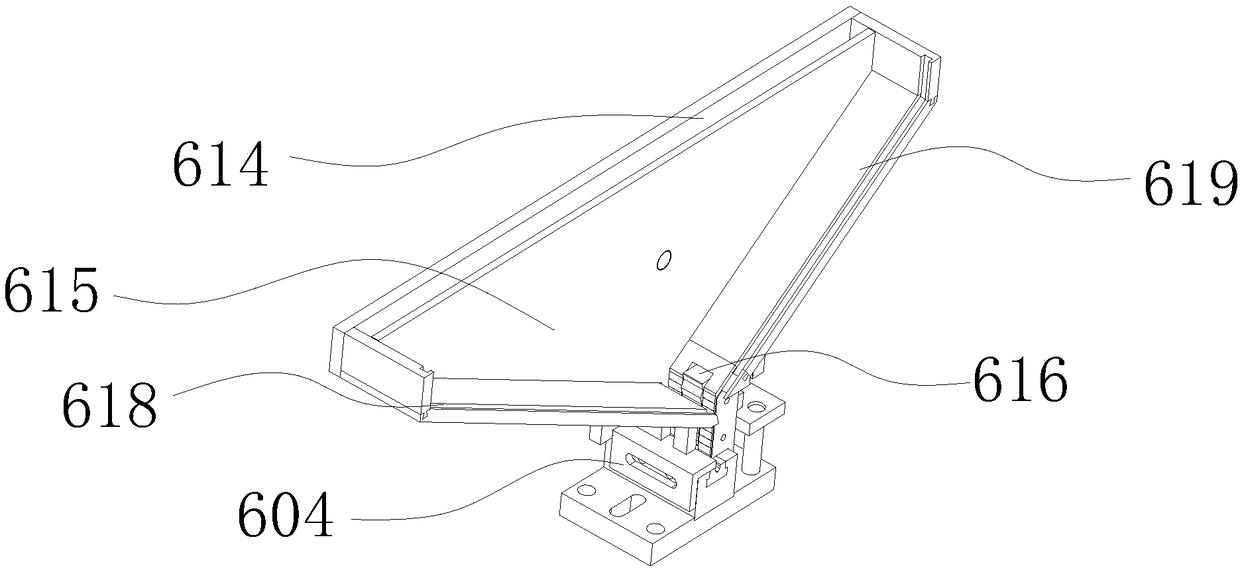

Automatic feeding mechanism for minisized round bars and installation method of automatic feeding mechanism for minisized round bars

PendingCN108941618AReduce the probability of tiltSmooth feedingRevolution surface grinding machinesMetal working apparatusEngineeringPower component

The invention discloses an automatic feeding mechanism for minisized round bars. The automatic feeding mechanism for the minisized round bars comprises a base, a linear guide rail, an ejector rod pressing plate, an ejector rod, a hopper front baffle, a hopper discharging mechanism, an ejector rod fixing block and a sliding block, wherein the linear guide rail is fixedly installed on the base through screws and is in sliding fit with the sliding block; the ejector rod fixing block is fixedly installed on the sliding block and provided with the ejector rod; the ejector rod pressing plate is arranged on the ejector rod and fixedly installed on the ejector rod fixing block through screws; the hopper discharging mechanism is fixedly installed at one end of the base; and the hopper front baffleis inserted at one end of the hopper discharging mechanism. The invention further discloses an installation method of the automatic feeding mechanism for the minisized round bars. The installation method comprises the steps of base assembly, hopper support assembly, hopper base assembly, hopper assembly, power component assembly, testing and trial operation. According to the automatic feeding mechanism for the minisized round bars and the installation method of the automatic feeding mechanism for the minisized round bars, feeding is stable, the probability of blocking is low, efficiency is high, operation and adjustment are convenient, and the labor and time are saved.

Owner:六安市新突破机械设备有限公司

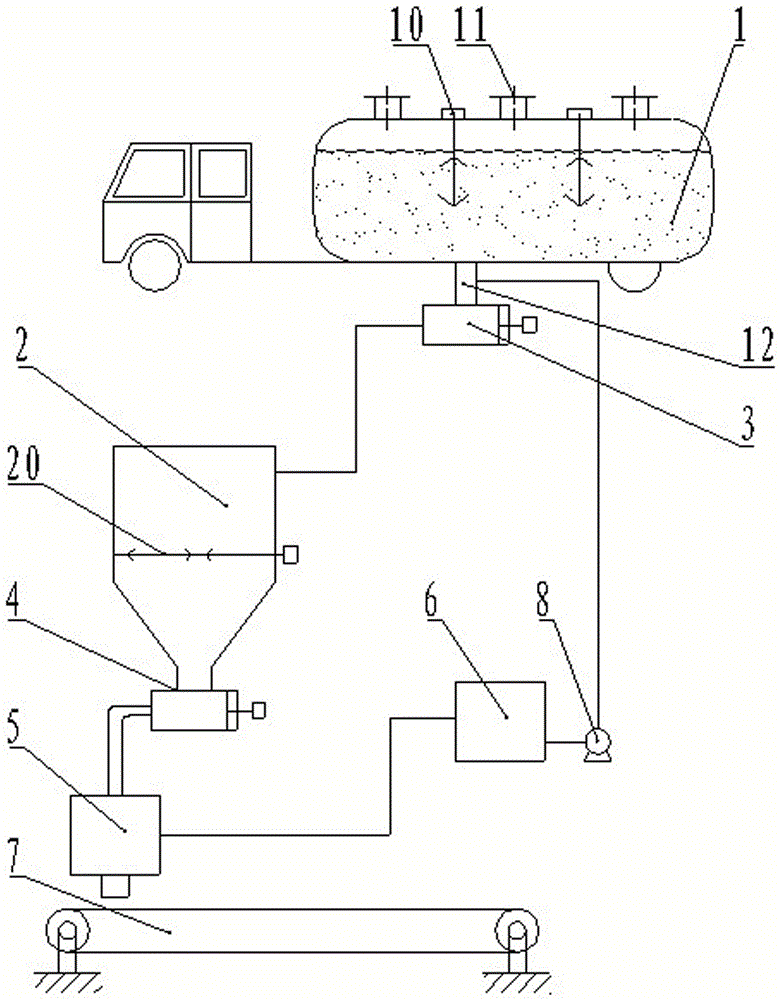

Brine-circulation industrial waste salt discharge device and use method thereof

InactiveCN106115303ANo pollution in the processNo secondary pollutionLarge containersBulk conveyorsTank truckCirculating pump

The invention provides a brine-circulation industrial waste salt discharge device capable of carrying out automatic discharge on industrial waste salt conveyed by a tank truck, the operation is completely carried out in a closed pipeline, and the discharge is thorough and free from secondary pollution. The brine-circulation industrial waste salt discharge device comprises the tank truck bearing a storage tank, and an unloading tank, wherein a plunger pump A is connected to a bottom pipeline of the storage tank, and the plunger pump A is connected with the unloading tank through a pipeline; the bottom of the unloading tank is connected with a centrifugal machine via a plunger pump B, a brine pond and a conveying device are further comprised, a solid-phase outlet of the centrifugal machine and the conveying device are arranged in a matching manner, and a liquid-phase outlet of the centrifugal machine is connected with the brine pond through a pipeline; and the brine pond is connected with the plunger pump A through a pipeline via a circulation pump. At least one group of vibration devices is arranged in the storage tank. A stirring device is arranged in the unloading tank.

Owner:安徽今朝环保科技有限公司

Double-pH-value wet-strength waste paper recycling pulping method

ActiveCN105648818AReduce consumptionImprove chemical reaction efficiencyPaper recyclingWaste paper working-upMaterials preparationPollution

The invention discloses a double-pH-value wet-strength waste paper recycling pulping method. The method includes a material preparation work section, a steaming work section, a first extrusion and dipping chemical-mechanical treatment section, a second extrusion and dipping chemical-mechanical treatment section, a latency and re-defibering section and a purification, screening and concentration section. According to the method, fiber dissociation and re-pulping of wet-strength waste paper are achieved under the effects of strong mechanical force and chemical treatment without reducing the strength of raw paper pulp; furthermore, in the two serial extrusion and dipping chemical-mechanical treatment sections, a wet-strength agent in the waste paper is oxidized under the acidic condition, and then hydrolysis is further promoted under the alkaline condition, so that chemical bonding between molecules of the wet-strength agent and chemical bonding between the wet-strength agent and pulp fibers are effectively damaged, and the fiber dissociation rate and the re-pulping yield are effectively increased. The problems that in wet-strength waste paper recycling pulping, the dissociation rate is low and strength is substantially reduced are solved, and continuous, large-scale, pollution-free and environment-friendly pulping with low water consumption and energy consumption can be achieved.

Owner:JIANGSU JINWO MACHINERY

Device for straw distribution

The invention provides a device for straw distribution. According to the device, technical problems that in the prior art, stokehole distribution feeding is poor in feeding continuity and a bridging phenomenon occurs easily can be solved. The device comprises a casing, rotating shafts and a driving device for driving the rotating shafts to rotate. The top of the casing is provided with a feeding port, and the bottom of the casing is provided with two discharging ports. The device for straw distribution is characterized in that the rotating shafts comprise first rotating shafts and second rotating shafts, the number of the first rotating shafts is two, the first rotating shafts are supported on the left side wall and the right side wall of the casing side by side; parts of the first rotating shafts located below the feeding port are provided with middle helical blades, parts of the first rotating shafts located above the discharging ports are polished shafts, and the middle helical blades of the two first rotating shafts are arranged in reverse directions. The number of the second rotating shafts is two, the two second rotating shafts are arranged at the positions of the two discharging ports respectively, and the second rotating shafts are provided with stirring rods.

Owner:WUXI XIDONG ENERGY TECH

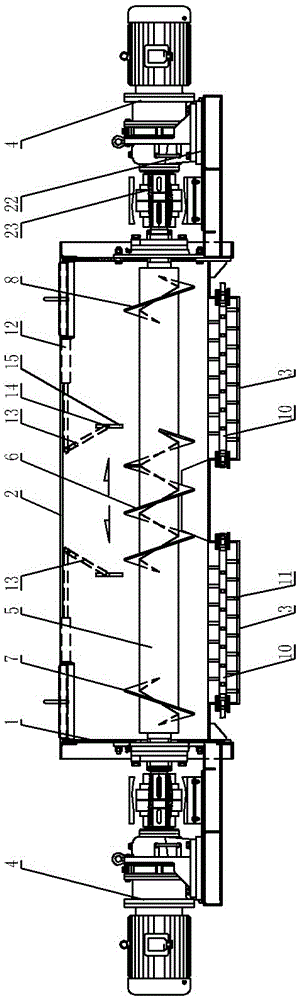

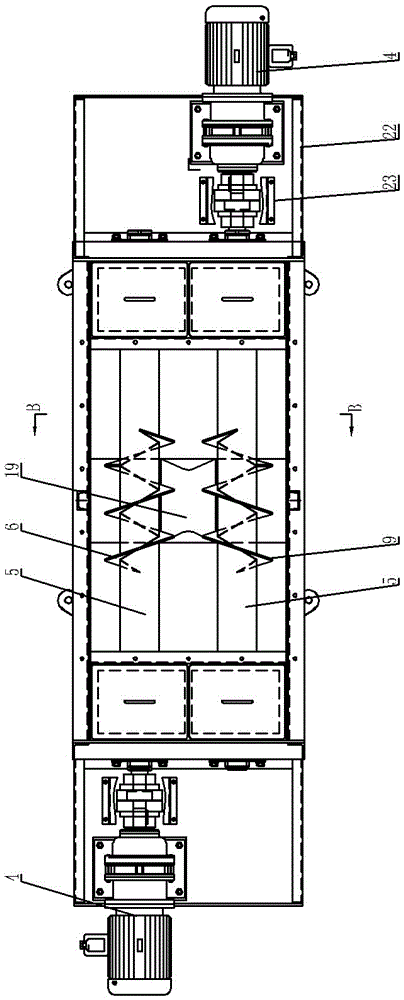

Straw distributing device

InactiveCN106742834AImprove continuityEliminate bridgingLarge containersAgricultural engineeringSpiral blade

The invention provides a straw distributing device. The device can solve the technical problems that according to straw distributing supply in front of a furnace in the prior art, the supply continuity is poor, and the phenomenon of bridging is likely to happen. The straw distributing device comprises a shell and is characterized by further comprises rotating shafts, and a driving device driving the rotating shafts to rotate; a feeding port is formed in the top of the shell, two discharging ports are formed in the bottom of the shell, and the two rotating shafts are supported in the shell in parallel in the horizontal direction; and a middle spiral blade is arranged at the portion, located below the feeding port, of each rotating shaft, a stirring rod is arranged at the portion, located above the corresponding discharging port, on each rotating shaft, and the middle spiral blades of the two rotating shafts are arranged in different directions.

Owner:WUXI XIDONG ENERGY TECH

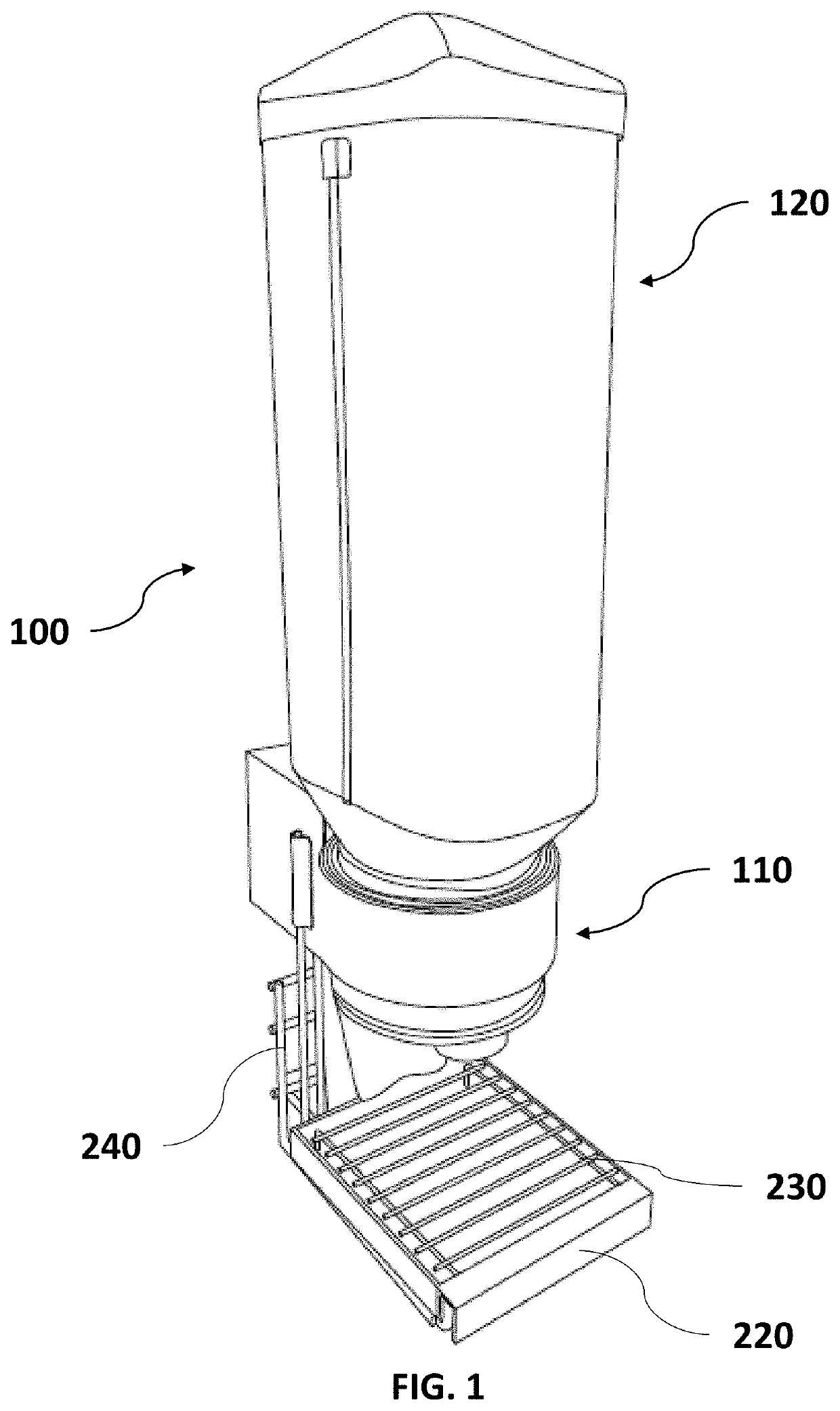

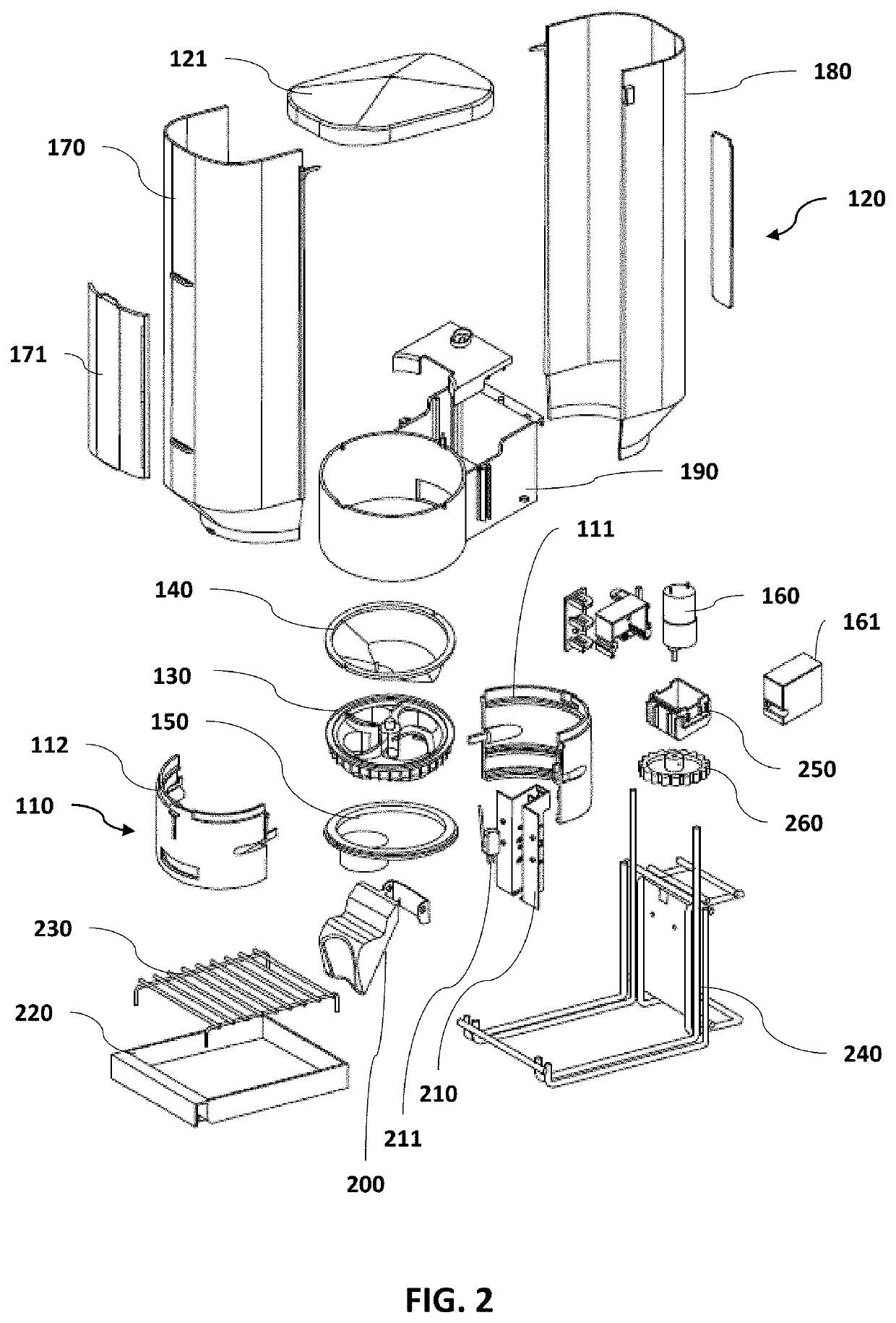

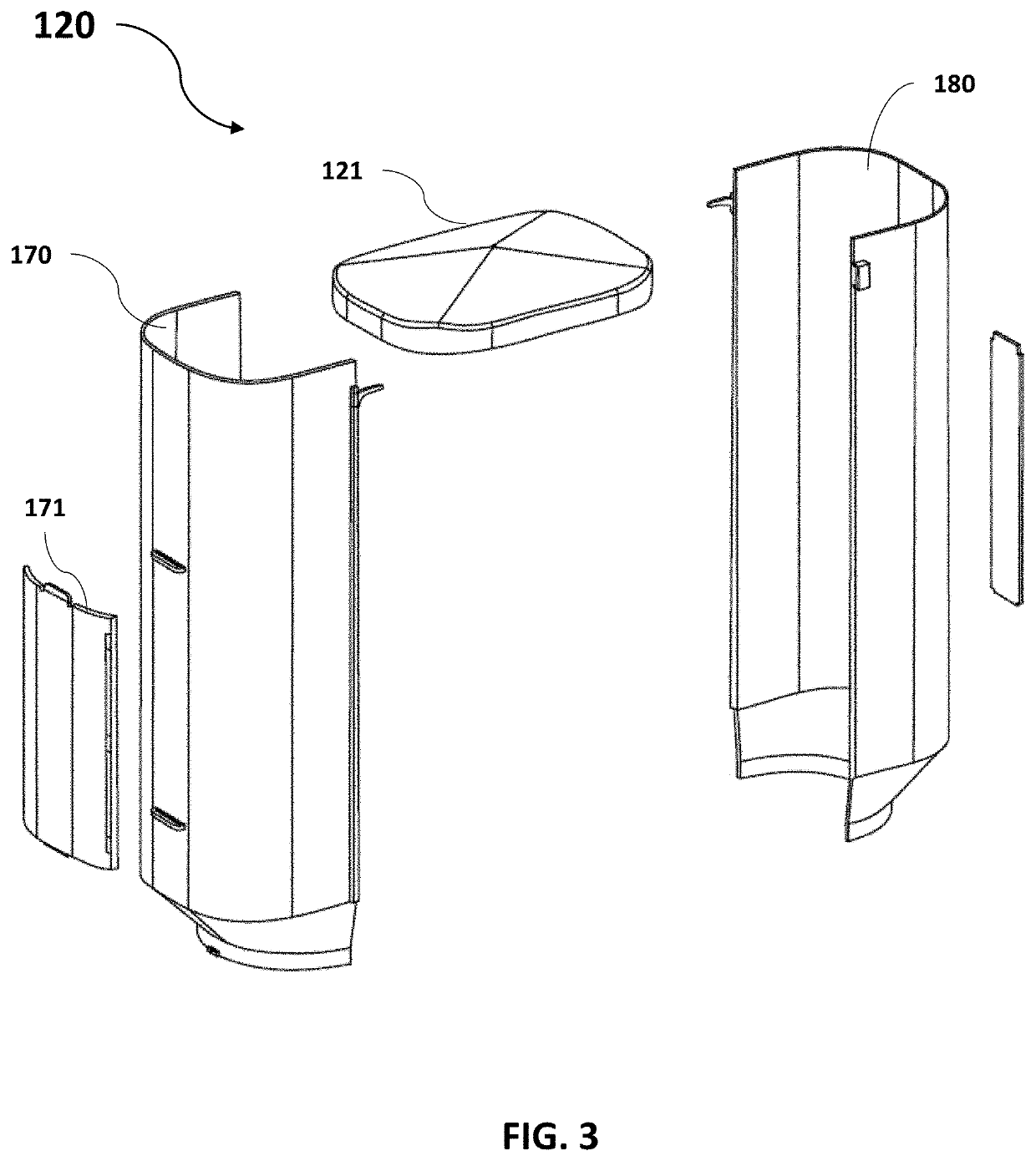

Motorized dry food dispensing apparatus

ActiveUS20210347583A1Preventing user fatigueEliminate bridgingConveyorsTable equipmentsHome useAgricultural science

The present invention provides a new motorized bulk, dry foods dispensing apparatus and system for commercial, retail and home use designed to dispense a predetermined volume of dry bulk food into a bowl or other receptacle without crushing or breaking the food. The bulk food dispenser includes a hopper, a feed house including two or more openings, and a feed wheel located within the feed house, where the feed wheel further includes a plurality of protrusions for directing a solid material out of the hopper when the feed wheel is rotated mechanically via a motor, where at least one of the two or more openings receive the solid material directed by a baffle, and where at least one of the two or more openings dispense the solid material out of the feed house.

Owner:CHICAGO SHOW INC

A wet-strength waste paper recovery and reuse pulping system

ActiveCN105648817BReduce consumptionImprove chemical reaction efficiencyPaper recyclingWaste paper working-upChemical treatmentHigh concentration

The invention discloses a chemical mechanical pulping system for recycling wet-strength recycled paper. The system comprises first conveying equipment, a crusher, second conveying equipment, a drum washing machine, an oblique spiral dehydrator, a steaming bin, a third screw conveyer, a first double-screw impregnator, a first reaction bin, a fourth screw conveyer, a second double-screw impregnator, a second reaction bin, a fifth screw conveyor, a latency chest, a stock pump, a fiber separator, a purifying, screening and concentrating device and a pulp storage device in the running direction of the material procedure. The even feeding type reaction bins are utilized for achieving even feeding and reducing the load fluctuation range; the rotary stirring type steaming bin is utilized for eliminating a bridging phenomenon, materials are fully steamed and softened, and chemical consumption is reduced. The double-screw impregnators are utilized for gradually dissociating the wet-strength recycled paper, high-concentration mixing and homogenizing impregnation of a chemical additive and pulp are achieved, and the chemical reaction efficiency is improved. By means of the function of mechanical strong force and chemical treatment, the problems that during wet-strength recycled paper recycling, pulping and dissociating rate is low, and the strength is greatly reduced are solved.

Owner:JIANGSU JINWO MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com